WHO API GMP Inspections

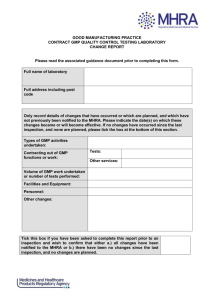

advertisement

WHO Prequalification Programme: Priority Essential Medicines WHO API GMP Inspections Presented by Mr. Ian Thrussell Head of Inspections WHO thrusselli@who.int In this presentation: • • • • WHO-PQ: Inspection activities WHO-PQ: Norms and standards WHO-GMP for APIs and ICH Q7 WHO-PQ API inspections: Observed trends and deficiencies • Conclusions Inspection of API manufacturing sites: put in perspective. • Chris Joneckis, Ph.D., senior adviser for chemistry, manufacturing and controls (CMC) issues: USFDA, noted that: – "quality, safety and effectiveness must be designed and built into the product. Quality cannot be inspected or tested into the finished product." • http://www.entrepreneur.com/tradejournals/article/154459079.html • Ensuring the quality of the API greatly contributes to achieving the objective of building the quality, safety and efficacy into the product. – Inspection of API manufacturing sites is to assess compliance with Good Manufacturing Practices, and to verify data submitted in product dossiers and APIMFs. 3 http://www.who.int/medicines/areas/quality_safety/en/ WHO Prequalification: Inspection activities *Stringent Regulatory Authority APIs, FPPs BE/CROs Prequalification: Inspection Processes By a team of qualified and experienced inspectors WHO representative (Qualified inspector small team of 6 with almost a hundred years of GMP inspection experience – all have had senior regulatory experience 2/3 with so called SRAs) Inspector from well-established inspectorate (e.g. EEA, Pharmaceutical Inspection Cooperation Scheme countries – PIC/S) National inspector/s invited to be part and/or observe the inspection Observer from recipient/developing countries (nominated by DRA of the country) Scope: Compliance with guidelines: GMP (FPP and API (ICHQ7)), GCP, GLP Î Data verification – ÎIn accordance with dossier submitted ÎData manipulation, falsification, (validation, stability, clinical, bioanalytical) Quality control (QC, BAL, National QCL, IQCL) Normally announced but some are NOT 9 9 9 9 Prequalification Programme: Use of Inspection reports from other NMRAs • • • An inspection by the PQP may be omitted when other acceptable evidence of GMP compliance (Report + CAPAs) is provided by the FPP or API manufacturer. An inspection by another acceptable organization, such as a PIC/S member country, or US FDA or EU, may be considered in lieu of a PQP inspection when: – The inspection was conducted within the last 2 years, and Î The scope of the inspection covered the specific API in question, and Î The FPP or API manufacturer submits a copy of the last inspection report for review by the PQP. (During the review, the inspectors will determine whether the inspection was comprehensive, covered the relevant areas appropriate to the product in question and that the inspection report supports the final outcome in accordance with WHO GMP). – Irrespective of the above, the PQP reserves the right to inspect any API manufacturer if considered necessary (specific product issues). Whether inspected by the PQP or GMP compliance is based on an inspection by another acceptable organization, on-going GMP compliance will be confirmed by WHO (also using update information from other NMRAs). Extensive collaboration with regulators • • • Not duplicating work done by stringent regulatory authorities • Recognition of inspections by other parties • Joint inspections with PIC/S members • SRA approval of new and generic products – abridged procedure • US FDA tentative approvals – based on confidentiality agreement including in the PQ products list • European Medicines Agency (EMA) – Art 58 … and beyond • Collaboration with EDQM, in particular in the area of APIs (confidentiality agreement to be signed) Active participation and involvement of National Regulatory Authorities • SRA experts • Regulatory authority experts from less resourced settings Joint Inspections • In February WHO joined Programme to rationalise international GMP inspections of active pharmaceutical ingredients/active substances manufacturers • http://www.ema.europa.eu/docs/en_GB/document_library/Other/2012/02/WC500 123489.pdfFebruary 2012 • 8 Number of inspections performed by WHO Pre‐ qualification Programme 60 50 40 FPP API CRO QCL total 30 20 10 0 2005 2006 2007 2008 2009 2010 WHO GMP and Inspection of API manufacturers 35 • Most API inspections were conducted in India followed by China. • The number of China API sites inspected has increased of recent 30 25 India China South Korea Vietnam 20 15 10 5 0 Countries inspected WHO GMP and Inspection of API manufacturers The early Years (2002 – 2009) Number of inspections per year 12 10 2002 2004 2005 2006 2007 2008 2009 8 6 4 2 0 Inspections • • API inspections have been increasing over time. Most API inspections were conducted in 2005, 2006, 2008 and 2009. Guide to Manufacturer Risk Classification Ref: SOP 401.1: Inspection Frequency and Scheduling RELATIVE RISK CATEGORY PRODUCT TYPE / ACTIVITY CRITICAL Finished Products: Sterile finished products Non-sterile finished products APIs: Sterile APIs Non-sterile APIs where there is a special risk (e.g. isomerism, polymorphism, special risk of harmful impurities, etc) Other non-sterile APIs QC Laboratories CROs HIGH MEDIUM LOW WHO GMP and Inspection of API manufacturers 2012 • In 2012 there are a total of 27 GMP inspections sites located in China programmed out of a total of 79 planned inspections of (this compares to 41 scheduled sites which are in India) • Of these 27 site inspections 22 are of API manufacturers and 5 are FPP. (For India APIs represent 19 API sites and 22 FPP sites). Risk based approach to inspections Inspections are scheduled on a risk basis, taking into account all known factors that could affect quality, safety and efficacy, including but not limited to the following: – results of previous WHO inspections – results of inspections by other National Regulatory Agencies – type of APIs, products and dosage form manufactured or activities performed – recalls or complaints since last inspection – results of product testing – significant changes within the manufacturer, e.g. changes to key personnel, buildings, equipment, products etc. – any other relevant information (e.g. variations) RISK ASSESSMENT FORM FOR ACTIVE PHARMACEUTICAL INGRADIENTS WITHIN THE WHO PREQUALIFICATION PROGRAMME (1 of 2) API Manufacturer Present in Product (Ref. Nos.) Number of Products Parameter Risk = 2 Risk = 1 Y N Low High 3 Synthesis Complex Not complex 4 Solvents High Risk Low risk 5 Impurities High Risk Low risk 6 Sterile Y N 7 Fermentation Y N 1 Polymorphism 2 Solubility in water Risk Score RISK ASSESSMENT FORM FOR ACTIVE PHARMACEUTICAL INGRADIENTS WITHIN THE WHO PREQUALIFICATION PROGRAMME (2 of 2) Parameter 8 Toxicity 9 Activity/potency 10 Particle size Risk = 2 Risk = 1 High Low High Risk Low risk High Risk Low risk Negative Positive Risk Score 11 Other property consideration 12 Site compliance information (WHO/EDQM/USFDA/Other) Total Risk Score General remarks: Last inspection date Outcome High Inspection prioritization Medium Low Compliant Not Compliant Inspection Duration Guide (on-site days) Ref: SOP 401.1: Inspection Frequency and Scheduling RISK Manufacturer Size C H M L C Initial Inspection H M L Re-inspection Large 5 4 3 3 4 3 3 2 Major 4 4 3 3 3 3 2 2 Standard 4 3 3 2 3 2 2 2 Risk-based approach in: definition and classification of deficiencies • Deficiencies are descriptions of non-compliance with GMP requirements. – A distinction is made between deficiencies as a result of: • a defective system or, • failure to comply with the system. • Deficiencies may be classified as: – Critical Observation – potential risk harm to the user – Major Observation – major deviation from GMP – Minor or Other Observation – departure from good practice Further considerations for classification 1. Classification of an observation is based on the assessed risk level and may vary depending on the nature of API manufactured, e.g. in some circumstances an example of an "other" deficiency may be categorized as "major". 2. A deficiency that was reported at a previous inspection and not corrected may be reported in a higher classification. 3. One-off minor lapses or less significant issues are usually not formally reported, but are brought to the attention of the manufacturer during the inspection. Risk-based approach in: Conclusion following an inspection • • • When there are "other" observations only: – considered to be operating at an acceptable level of compliance with WHO GMP/ICHQ7. – The manufacturer is expected to provide CAPAs. – CAPAs are evaluation and followed up during the next routine inspection. When the are "other" and a few "major" observations: – compliance with WHO GMP/ICHQ7 is made after the CAPAs have been assessed. – CAPAs for majors to include documented evidence of completion. – CAPAs paper evaluated ± an on-site follow up inspection. When there are "critical" or several "major" observations: – considered to be operating at an unacceptable level of compliance with WHO GMP/ICHQ7 guidelines. – Another inspection will be required Transparency: Information put in public domain - WHOPIRs and NOCs • These are published in response to the WHA Resolution WHA57.14 of 22 May 2004, which requested WHO, among other actions: – "3. (4) to ensure that the prequalification review process and the results of inspection and assessment reports of the listed products, aside from proprietary and confidential information, are made publicly available;" • A WHO Public Inspection Report (WHOPIR) reflects a positive outcome after an inspection • A Notice of Concern (NOC) is a letter reflecting areas of concern where the non-compliances require urgent attention and corrective action by the manufacturer or research organization. – A NOC may be issued to a company but never published on the WHO Internet Pages because the company resolves the issues promptly and in a manner that satisfies us within the normal inspection process Publication of WHOPIR Publication of WHOPIR Appeals against an NOC • Manufacturers may appeal against notice of concern decision by WHO-PQP • The appeal must be based upon science and risk • Appeal could be sent to the Head of Inspections • Appeal could be sent to the Programme Manager • Investigation of an appeal • Response to appellant 24 Quality of Pharmaceutical Ingredients 29 June 2012 Shanghai Out of 126 API sites participating in PQ activities, 49 were accepted based on approval by PICS inspectorates and/or ICH countries while 31 were inspected. INSPECTION STATUS OF API SITES USED IN PRODUCTS UNDER WHO PREQUALIFICATION 140 120 No of sites 100 80 60 40 20 0 HA, MA, TB Total 0 0 46 0 0 49 0 0 0 6 2 1 1 25 HA TB MA RH IN D HA, IN Not yet Inspected 20 15 8 3 0 0 0 0 Innovators/PICS 33 3 8 5 0 0 0 0 Sites inspected - NC 1 4 1 0 0 0 0 Sites inspected - C 10 5 4 0 0 0 2 Type of API HA, TB HA, MA Prequalification Programme: International norms, standards and guidelines used in inspection activities to ensure wide applicability • • • Quality Assurance of pharmaceuticals. A compendium of guidelines and related materials. Vol.2, GMP and inspection. WHO, Geneva, 2007. http://www.who.int/medicines/areas/quality_safety/quality_a ssurance/production/en/index.html WHO GMP for APIs: Annex 2, WHO TRS957, 2010: http://whqlibdoc.who.int/trs/WHO_TRS_957_eng.pdf#page= 144 WHO GMP: water for pharmaceutical use. 39th Report. Geneva, WHO, 2005 (WHO TRS, No. 929), Annex 3. http://whqlibdoc.who.int/trs/WHO_TRS_929_eng.pdf Prequalification Programme: norms, standards and guidelines used… • WHO guidelines for sampling of pharmaceutical products and related materials. 39th Report. Geneva, WHO, 2005 (WHO TRS, No. 929), Annex 4. http://whqlibdoc.who.int/trs/WHO_TRS_929_eng.pdf • Supplementary GMP guidelines for HVAC systems. 40th Report. Geneva, WHO, 2006 (WHO TRS, No. 937), Annex 2. http://whqlibdoc.who.int/trs/WHO_TRS_937_eng.pdf • Supplementary GMP guidelines: validation. 40th Report. Geneva, WHO, 2006 (WHO TRS, No. 937), Annex 4. http://whqlibdoc.who.int/trs/WHO_TRS_937_eng.pdf • Good Practices for National Pharmaceutical Control Laboratories. 36th Report. Geneva, WHO, 2002 (WHO TRS, No. 902), Annex 3. http://whqlibdoc.who.int/trs/WHO_TRS_902.pdf#page=37 USP BP Ph. Eur. Ph. Int. Other guidelines e.g. ICH, ISO WHO GMP for APIs / ICH Q7 Key definitions: – API starting material (API SM): a raw material, intermediate or an API used in the production of an API and incorporated as a significant structural fragment into the structure of the API. API SM can be an article of commerce, a material purchased from one or more suppliers under contract or commercial agreement, or produced in-house. API SM are normally of defined chemical properties and structure. – Intermediate: A material produced during steps of the processing of an API that undergoes further molecular change or purification before it becomes an API. ICH Q7 : Introduction zFrom what point does ICHQ7 start to be applied ? – “ICH Q7A applies from the point at which production of the API begins”. – Some indications are provided in Table 1 of ICH Q7. • For synthetic process, this corresponds to the introduction of the API starting material into the process; • For other processes, on a case by case basis. Increasing GMP requirements WHO GMP and Inspection of API manufacturers Main issue : How to define the API SM ? RM (solvent, catalyst, reagent, filtration aid, decolorizing agent, chromatography phase, etc.) C, H, O, N SM (Intermediates)n Only flow chart GMPs do not apply Competen t Detailed description API SM GMPs apply Active substance crude Active substance (pure) Industry Authorities Photo : Application of ICHQ7 • Companies should decide at which point ICH Q7A applies for their processes and should have documentation to support it. GMP applies from the declared and approved (API) SM in the registered file. • Stringency of GMP in API manufacturing increases from early steps to final steps • Advanced intermediates and crude APIs outsourced should be manufactured in compliance with GMP – This means that these “late intermediate and crude API” manufacturers should be considered as contract manufacturers (Q7A chapter 16 applicable). • Sterilisation and aseptic processing should be performed according to GMP related to Sterile Pharmaceutical Products. Inspection of API manufacturers observations • • The most frequently found observations were: – Material management – SOPs – Cleaning Others included: – Batch records – Labelling – Cross contamination 10 9 Cross contamination Batch records 8 7 6 SOPs 5 Material Management Cleaning 4 3 2 1 Labeling 0 Major deficiencies • • • Most deficiencies were observed in sites for TB APIs and these were the sites with most of the major observations. Although sites for Malaria APIs had equally high number of observations, most of them were not major. The sites for HIV APIs were generally in a reasonable shape. API GMP Concepts and observations z Quality management (Chapter 2) – Responsibilities of the Quality Unit – Sections 2.22-1 to 2.22-15 – Tools for surveillance, monitoring and continuous improvement: – Internal audits/Self inspection (section 2.4) – Product Quality review (section 2.5) – Complaints, returns and recall (sections 14.5 and 15) – Change control (section 13) Change Management – Raw materials, specifications, analytical methods, facilities, support systems, equipment (including computerized systems), processing steps, labelling and packaging materials – That can impact the quality of the API – Not restricted to the API plant technical process – Expansion and additional shifts ARE changes – Other activities on the site MUST be considered – Proposal drafted, reviewed and approved by the appropriate organisational unit – Change reviewed and approved by QU – Classification and impact assessment – Evaluation and monitoring + Notification Facilities, equipment and utilities system – Facilities designed to prevent mix-ups and contamination – Precautions implemented based on a risk assessment – Equipment cleaning methodology and intervals appropriate to prevent buildup and carry-over of contaminants (degradants) Critical operation with prolonged exposure to the environment Non critical operation with prolonged exposure to the environment Non critical or critical operation in a closed equipment z HVAC systems (section 4.2) – Adequate ventilation, air filtration and exhaust systems should be provided where appropriate (ICH 4.21, 4.22) – Qualification and appropriate monitoring and operating range limits in place (ICH 4.20) z Water (section 4.3) – WHO potable water quality as a minimum (ICH 4.31) – Water for final isolation and purification steps for API for sterile products: test for microbial counts, objectionable counts and endotoxins. Material management and transport z Material management (ICH section 7) – At least, identity testing of each batch on a sample representative of the batch (ICH 7.30) – Reduced testing for approved/validated suppliers (ICH 7.31) • Past quality history • Full analysis at least on three batches before starting reduced-testing • Reliability of the CoA checked at regular intervals • A documented supplier audit is not required but currently performed in the case of critical material by API manufacturers. – Precaution for bulk deliveries in non-dedicated tankers (ICH 7.22) Production – Critical operations should be witnessed or subjected to an equivalent control (ICH 8.12) – Deviations should be documented, explained and/or investigated (ICH8.15) – Process time limits should be respected (ICH8.20) – Conditions and duration of storage of intermediates (ICH 8.21) – In-process sampling and controls (ICH 8.3) • approved written procedures, avoid risk of cross contamination during sampling, sample integrity Production Blending operations (section 8.4) • Only batches meeting established specifications • Expiry or retest date of the blended batch based on the manufacturing date of the oldest batch included. • Should be controlled and documented – traceability • Validation for homogeneity following blending OOS batches blended with others to meet specifications 1. Blending small batches to ↑se batch size 2. Blending tailings APIs for OSDs/ Suspensions 1. Particle size distribution 2. Bulk density 3. Tap density Reprocessing or reworking for intermediates or APIs which do not conform to standards or specifications z Reprocessing (s. 14.2) – Repeating a step of the established manufacturing process • Crystallization, distillation, filtration, chromatography, milling, etc • Continuation to completes process after IPQC in not reprocessing • Introducing unreacted material into reaction is reprocessing – Included in the standard manufacturing process if reprocessing used for a majority batches z Reworking (section 14.3) – Reason for non conformance determined prior to any reworking – Involves a “treatment” different from the established one • Recrystallization with a different solvent – Reworked batches to be subjected to appropriate evaluation, testing ± stability testing • Concurrent validation • Should have comparable impurity profile Recovery of Materials and solvents – Reactants, intermediates or APIs may be recovered from mother liquor or filtrates. – Must use approved procedures and specifications. – Recovered solvents may be reused in same process or in different process if confirmed to meet appropriate standards. – Fresh and recovered solvents and reagents if confirmed their adequacy 1. No approved procedures 2. Specs – carry over impurities 3. Not adequately tested 4. Use not documented 1. Approved procedures 2. Suitable specs 3. Adequate testing 5. Use documented Validation (section 12) – Applies to • Analytical methods • Process • Cleaning • Computerized systems 1. Prospective validation (≥3 consec batches): • complete before commercial distribution 2. Current validation (≥3 consec batches): • • For API produced infrequently Batches may be released for commercial distribution after monitoring and testing 3. Retrospective Validation (10 - 30 batches): • • • Only in exceptional cases For well established process All batches, including failed ones – Validate operations critical to the quality and purity of the API – Periodic review of validated systems Conclusion – GMP is a “What to do document” – “How to do” is sometimes described – Flexibility – If necessary, when appropriate … – “Should” even if it could be interpreted mostly as “must” – Emphasis on the risks of – Contamination and cross contamination – Mix-ups, build-up and carry-over of degradants – Lack of traceability Summary and Conclusions • • • Inspection of API sites is part of the WHO-PQ procedures International norms and standards are used during WHOPQ inspections Risk management principles are applied when: – scheduling inspections – conducting inspections – closing out inspections • • Inspections of API sites has increased over time. Most of the API sites inspected by WHO-PQ are in India and China Deficiencies have been observed mainly in: – Material management, SOPs, Cleaning, Batch records, Labelling, Cross contamination • Most deficiencies have been observed on sites for TB and Malaria APIs. ధన ా ల 谢谢! WHO-PQP Inspections Benefits to manufacturers: • Inspections by international teams led by WHO. • Standards used are internationally agreed. • Procedures the same as most SRAs. – Enables manufacturers to benchmark themselves against international standards. – Exposure to WHO inspections help manufacturers better understand the expectations of other SRAs. • TGF quality assurance policy requires use of their money to by product prequalified by WHO or approved by a SRA. – Applicants whose products are not yet prequalified or approved by a SRA but are WHO GMP compliant may be recommended for timelimited use based on advice by an Expert Review Panel (ERP) • Reduces inspection burden: – results used by other NMRAs, manufacturers and procurement agents [TGF, UNITAID, UNICEF, UNFPA, GDF, NGOs (ICRC, MSF)]. – Identified by FPP manufacturers as quality sources of APIs. 46 Quality of APIs, Tutorial Hyderabad, 16 September, 2011