Vinyl Makes Life More Affordable

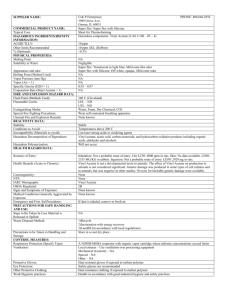

advertisement

Vinyl Makes Life More Affordable Used for more than 60 years, vinyl is the material of choice for a wide range of products. Without vinyl, in North America we would spend $20 billion more to find alternative materials for its many uses — and they almost certainly would not perform as well. An incredibly versatile plastic, vinyl, also known as polyvinyl chloride (PVC), is produced from chlorine and ethylene. With the addition of other additives, vinyl can be flexible, rigid or anything in between; transparent or colorful; thick or thin. This versatility enables vinyl to be made into a variety of products — from pipe, siding, flooring and wallcovering to blood bags, toys, packaging and windows — and also ranks it as the third-largest volume plastic produced in North America. Vinyl makes life more affordable. It brings products that might otherwise be too expensive into reach for many Americans, and brings solutions that save money and resources. Putting Money in Your Pocket is less expensive than many competitive materials because it is one of the world’s most widely produced, highest volume resins and because more than half of the polyvinyl chloride (PVC) molecule (chlorine) is derived from sea water. ■■ Vinyl products have long, useful service lives and, therefore, need to be replaced less often. ■■ Vinyl windows and flexible vinyl roofing dramatically reduce heating and cooling costs. Vinyl has low conductivity, which reduces heat exchange. Reflective vinyl roofing membranes reflect heat, reducing the heat island effect and reducing the need for air conditioning. ■■ Flexible vinyl products help reduce health care costs. For more than 50 years now, vinyl has been prized for its combination of value and wide range of properties specific to medical uses. During World War II, vinyl components were first used in blood transfusion and IV sets on the battlefield. ■■ Vinyl Putting Economical Solutions into Practice pipes help prevent costly water leaks in water distribution systems. (Leaky, mostly cast or ductile iron, water pipes result in water losses of 2.2 trillion gallons per year in the US alone.) ■■ Flexible vinyl booms have been used to help prevent costly damage from offshore oil spills. ■■ Flexible vinyl helps reduce the weight of automobiles, promoting greater fuel efficiency. “Lightweighting” innovations in plastics have given auto manufacturers the opportunity to reduce car weights without compromising safety. ■■ Flexible vinyl helps reduce food spoilage via packaging specially designed to extend the shelflife of food, preserve its nutrient content, and prevent food-borne illnesses. Food waste has at least 10 times the environmental impact of packaging waste. ■■ Flexible vinyl products provide temporary housing following disasters. Such shelter is less expensive than using traditional materials, offers superior strength to weight ratio, improved durability, recyclability, and can often be shipped in modules and assembled with unskilled labor. ■■ Vinyl FOR MORE INFORMATION ON THE DATA PRESENTED HERE PLEASE CONTACT: Barry Eisenberg at beisenberg@plasticsindustry.org Information and Statistics Courtesy of: American Chemistry Council ■■ Abasco LLC ■■ American Chemistry Council ■■ Chemical Fabrics and Film Association/ The Vinyl Roofing Division ■■ European Commission ■■ European Council for Plasticisers and Intermediates ■■ Examiner.com & Clarity Digital Group, LLC ■■ How Products Are Made/Madehow.com (Advameg, Inc.) ■■ LINPAC Packaging Filmco, Inc. ■■ National Center for Policy Analysis ■■ Teknor Apex ■■ SPI: The Plastics Industry Trade Association ■■ Vinyl Institute ■■ Whitfield Associates ■■ SPI: The Plastics Industry Trade Association represents the third largest manufacturing industry in the United States. SPI’s member companies represent the entire plastics industry supply chain, including processors, machinery and equipment manufacturers and raw materials suppliers. The U.S. plastics industry employs 1 million workers, operates 17,348 facilities located in every state, and provides nearly $327 billion in annual shipments. SPI’s Flexible Vinyl Products Division promotes the advancement of the flexible vinyl industry and works for the benefit of all companies within the flexible vinyl industry, regardless of end application. Flexible (plasticized) vinyl includes both plastisols (liquids) and solids (pellets, cubes, powders, etc.) materials. 1667 K St. NW, Suite 1000 Washington, DC 20006-1620 www.plasticsindustry.org