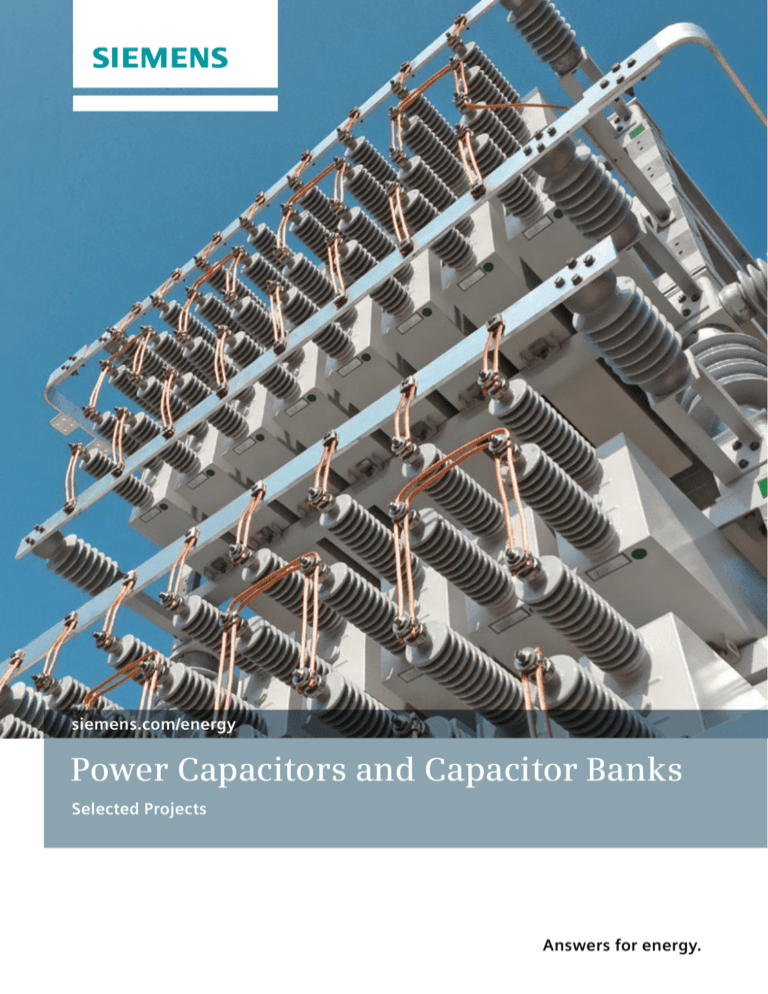

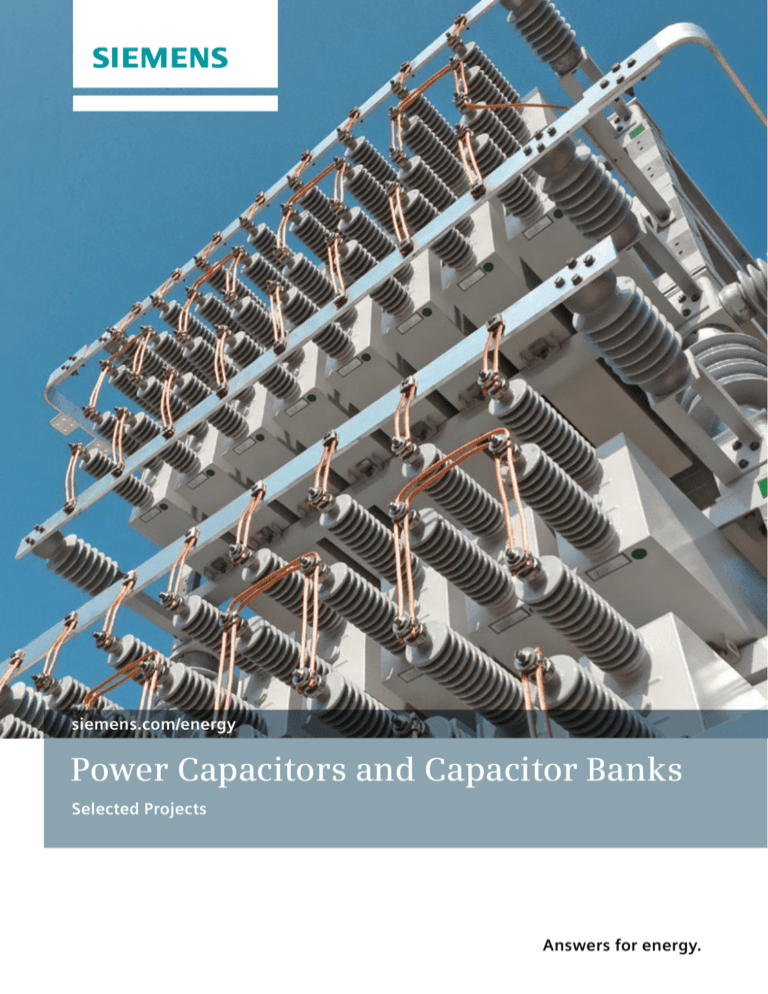

siemens.com/energy

Power Capacitors and Capacitor Banks

Selected Projects

Answers for energy.

Capacitors for the World

In 2009, Siemens extended its product portfolio and since then delivers

High Voltage Power Capacitors and Capacitor Banks to renowned customers

worldwide. These products and systems fulfill the highest electrical and

mechanical requirements; they are used for the most diversified applications

and can be operated under the most stringent environmental conditions.

Siemens High Voltage Power Capacitors do not only enhance the transmission

capacity or the network stability, but also contribute to economical growth and

enable a significant reduction of carbon dioxide emissions.

02

04

06

05

01

03

2

Siemens

Power Capacitor Factory

Siemens Power Capacitor

factory is located in the

industrial complex in

­Jundiaí, Brazil, the largest

production complex of

­Siemens in Latin America.

High Voltage Power Capacitor Factory

Selected Projects

Page

01

HVDC AdaniIndia

5

02

HVDC Estlink 2

6

03

FSC Tucuruí-ManausBrazil

7

04

MSCDN Lincs Wind FarmUK

8

05

HVDC HudsonUSA

9

06

HVDC Black SeaGeorgia

10

07

Other selected projects

11

Finland & Estonia

History – 50 Years of Experience

1959 Laelc starts operations, manufacturing Power Capacitors for several

projects, including Itaipú HVDC, the first 600 kV HVDC of the world in

the 80’s.

1979 Laelc buys the technology to manufacture internally fused capacitors

2007 Siemens acquires from Laelc the technology to manufacture

power capacitors and capacitor banks

2009 Siemens High Voltage Power Capacitors factory starts commercial

operation and was awarded its first large HVDC order for India

2013 Siemens High Voltage Power Capacitors are globally present

in several countries around the world with a product portfolio

for all types of application

Other selected projects

3

Power Capacitors –

Technical Data

Siemens entered the Power Capacitor market with a

product for the most diversified applications. Long-term

reliable technology and intensive R&D investments lead

to a state-of-the-art product, compliant with the most

stringent technical and environmental requirements,

including extremely low temperatures (like -50 °C in

northern Canada), extremely high temperatures (like

+50 °C in India), high humidity (like in the rainforests

of northern Brazil) and the most extreme seismic zones

(like in New Zealand).

Capacitor Banks – Applications

Flexible AC

Transmission

Systems

(FACTS)

Parallel

Compensation

Static Var Compensator (SVC)

Mechanically Switched Capacitor with Damping Network (MSCDN)

Mechanically Switched Capacitors (MSC)

Series

Compensation

Thyristor Controlled Series Compensation (TCSC)

Thyristor Protected Series Compensation (TPSC)

Fixed Series Compensation (FSC)

AC Harmonic Filters

AC PLC Filters

Long Distance and Back-to-Back HVDC – AC & DC Filters

AC & DC Surge Capacitors

Capacitor Unit Design

4

Technology

Internally fused, externally fused, fuseless,

and unfused

Rated voltage

With internal fuses: 15 kV

Without internal fuses: 24 kV

Frequency

50 Hz/60 Hz

Rated power

Up to 1000 kvar (50 Hz)

Up to 1200 kvar (60 Hz)

Current

Max. 180 A

BIL

95 kV, 125 kV, 150 kV, 170 kV, 200 kV

Dielectric

Polypropylene film and oil

Impregnant

Biodegradable PCB-free oil

Discharge resistor

75 V/10 min or 50 V/5 min

Losses

With internal fuses: < 0.20 W/kvar

Without internal fuses: < 0.12 W/kvar

Temperature range

-50/+55 ºC

Standards

IEC, IEEE, ABNT, CSA, and others

Quality certificates

ISO 9001; ISO 14001; OHSAS 18001

Final figures to be confirmed during project

For other standards please consult the factory

HVDC Adani –

India

The HVDC system operated by Adani Power Ltd. has a

transmission capacity of 2500 MW and provides low-loss

energy transmission over a distance of approximately

960 km, from the port of Mundra located on the west

coast to the industrial regions in the Haryana state.

The AC filters for this HVDC system represent the first

large order for the capacitor factory in Jundiaí, which

delivered the first units to India only 6 months after

the official inauguration in December 2009. The total

installed output of the 54 single phase high voltage

AC filters was close to 4000 Mvar and the total number

of units supplied was 4840 (including spare parts).

Technical Data

Locations

Mundra and Mohindergarh S/S

Total rated power

3.7 Gvar

Unit output

815.6 to 852.0 kvar

Bank voltages

280.3 to 294.8 kV

Rated unit voltages

7.8 to 9.7 kV

Quantity of units

4,840

Technology

Internally fused

Supply date

August – 2010

Temperature category -5 /+50 ºC

5

HVDC Estlink 2 –

Finland & Estonia

In December 2010 Fingrid and Elering awarded the

­contract for the Estlink 2 Converter Stations to Siemens,

using a HVDC Transmission System with a transmission

capacity of 650 megawatts at a DC voltage of

± 450 kilovolts.

The Siemens capacitor factory in Brazil supplied a total

of 24 single phase high voltage AC filter banks (C1-type)

using internally fused and fuseless technology and

36 single phase medium voltage AC filter banks

(C2/C3-type unfused technology).

Technical Data

6

Locations

Anttila and Puessi substations

Total rated power

1.17 Gvar

Unit output

113 to 849 kvar

Bank voltages

6.1 to 325.5 kV

Rated unit voltages

3.0 to 19.2 kV

Quantity of units

1,878

Technology

Internally fused, fuseless

and unfused

Supply date

August – 2012

Temperature category

-40/+40 °C

FSC Tucuruí-Manaus –

Brazil

Siemens Ltda. Brazil was awarded the FACTS systems

for the 1800 km long 500 kV HV transmission system

­connecting the Tucuruí Hydro Power Plant with the city

of Manaus in 2010. The scope of supply included a total

of 18 Fixed Series capacitors located at 5 different substations in the Amazon forest.

The Capacitor factory in Jundiaí was responsible for the

supply of all the capacitors of this project, considered to

be the largest FACTS project ever executed worldwide.

Technical Data

Locations

5 substations along the transmission line Tucuruí-Manaus

Total rated power

6.8 Gvar

Unit output

743.8 to 825.4 kvar

Bank voltage

500 kV

Rated unit voltages

6.3 to 7.1 kV

Quantity of units

8,496

Technology

Internally fused

Supply date

2010 – 2012

Temperature category -5/+50 ºC

7

MSCDN Lincs Wind Farm –

UK

The Lincs project, owned by Lincs Wind farm Limited is

located in the Greater Wash wind farm park, England and

will generate capacity of 270 MW. The energy generated

offshore is transferred to the grid via the Walpole onshore

substation located in the Norfolk County. ­Siemens Transmission and Distribution Ltd., UK was awarded with the

construction of the entire onshore ­substation in 2010.

The Siemens High Voltage capacitor plant has provided

a total of 6 single phase Capacitor Banks for the 132 kVMSCDN comprising fuseless C1 and C2-banks with a total

installed rating of 246,3 Mvar, as well as 6 single phase

banks with internally fused capacitors for the 13.9 kV

CMSC with a total output of 145.7 Mvar.

Technical Data

8

Location

Walpole substation, England

Total Rated Power

392 Mvar

Unit output

180 to 867 kvar

Bank voltage

132 and 13.9 kV

Rated unit voltages

4.3 to 11.8 kV

Total units

576

Technology

Internally fused and fuseless

Supply date

April – 2011

Temperature cat.

-25/+40 °C

HVDC Hudson –

USA

In May 2011 Hudson Transmission Partners, LLC awarded

the contract to Siemens to connect the power supply networks of New Jersey and New York, USA using a 660 MW

back-to-back HVDC system will contribute to the stabilization of the connected systems, a key benefit in the event

of grid disturbances or blackouts.

The capacitor plant in Brazil supplied 18 single phase

High Voltage AC Filter banks (internally fused technology)

and 36 single phase Medium voltage AC Filter banks

(C2/C3 and C4-type, unfused technology) for this HVDC

system, providing unit outputs larger than 1.0 Mvar for

the first time.

Technical Data

Locations

West 49th Street and Bergen

Total Rated Power

1.3 Gvar

Unit output

122 to 1019 kvar

Bank voltages

8.4 to 244.7 kV

Rated unit voltages

7.2 to 17.7 kV

Total units

1,524

Technology

Internally fused and unfused

Supply date

May – 2012

Temperature category

-30/+40 °C

9

HVDC Black Sea –

Georgia

In August 2010 Energotrans Ltd. awarded the contract

to Siemens for 350 MW back-to-back HVDC systems in

Georgia. The HVDC converter station will connect the

networks of Georgia and Turkey via two back-to-back

links.

The capacitor plant in Brazil supplied 27 single phase

High Voltage AC Filter banks (internally fused technology) and 36 single phase Medium voltage AC Filter banks

(C2 and C3-type, unfused technology) for this HVDC

­system located at an altitude of 1,100 meters above

sea level in a seismic region.

Technical Data

10

Location

Akhaltsikhe substation

Total rated power

1.266 Gvar

Unit output

220 to 722 kvar

Bank voltages

60.7 to 354.6 kV

Rated unit voltages

9.3 to 18 kV

Quantity of units

2,237

Technology

Internally fused & unfused

Supply date

August – 2011

Temperature category

-25/+50 °C

Project

HVDC WATL

Customer/

Country/

Year

AltaLink

Canada

2013

Scope

36 x HV single phase AC filter

banks; 60 x MV single phase

AC filter banks; 6 x HV single

phase shunt banks

Technical Data

Total rated power

Unit output

Bank voltage

5.73 to 440.61 kV

Unit voltage

5.73 to 17.06 kV

Quantity of units

MSCDN 400 kV

RTE

France

2013

17 x MSCDN

(Type 150 Mvar – 380 kV)

Total rated power

ATCO Electric

Canada

2013

36 x HV single phase AC filter

banks; 60 x MV single phase

AC filter banks; 12 x HV single

phase shunt banks

Bank voltage

24.39 to 553.91 kV

Unit voltage

7.04 to 10.66kV

Unit output

Transelec

Chile

2013

1 x MSC

(Type 75.64 Mvar – 12.27 kV)

Unit voltage

5.58 to 18.25 kV

Unit output

National Grid

United Kingdom

2013

5 x MSCDN

(Type 225 Mvar – 400 kV)

Unit voltage

6.133 kV

Unit output

RWE

United Kingdom

2012

6 x 132 kV filter banks;

4 x 13.9 MSC banks

Unit voltage

7.925 and 9.403 kV

Unit output

Hydro Quebec

Canada

2013

2 x three-phase single tuned

filter banks; 2 x three-phase

TSC-banks

Unit voltage

6.735 to 12.256 kV

Unit output

Diaco S.A.

Colombia

2012

3 x three-phase filter circuits

Unit voltage

7.1 to 9.1 kV

Unit output

Ande

Paraguay

2011

3 x three-phase single tuned

filter banks; 2 x three-phase

TSC-banks

Unit voltage

4.04 to 12 kV

Unit output

Energinet

Denmark

2011

1 x three-phase HV filter

(282 kV); 2 x three-phase

MV filter banks

17.7 to 21.42 kV

5.57 to 6.18 kV

Unit output

London Array

United Kingdom

2011

4 x MSCDN

(Type 150 kV)

282 kV

20.7 / 17.2 / 19.2 kV

Unit output

Transpower

New Zealand

2011

27 x HV single phase AC filter

banks; 27 x MV single phase

AC filter banks; 3 x HV single

phase shunt banks

ELETRONORTE

Brazil

2010

4 x MSC

(Type 20.52 Mvar – 242 kV)

150 kV

14.2 / 4.16 kV

Total rated power

Unit output

TAESA

Brazil

2010

Filter I and Filter II for SVC

257 to 348 kV

9.1 to 13.7 kV

Unit output

RIEDER & CIA/

CLYFSA

Paraguay

2009

242 kV

11.646 kV

Unit output

1 x MSC

(Type 12 Mvar – 24 kV)

82.1 Mvar

570 kvar

Unit voltage

Total rated power

Very high seismic requirements, internally fused and

unfused capacitors

First fuseless application

144

42 + 66 Mvar

786 kvar / 916.3 kvar

Bank voltage

23.16 kV / 21.46 kV

Unit voltage

13.369 kV /12.389 kV

First SVC application,

internally fused

54 / 72

Total rated power

12 Mvar

Unit output

500 kvar

Bank voltage

24 kV

Unit voltage

13.2 kV

Quantity of units

Fuseless capacitors

1,690

Bank voltage

Quantity of units

MSC ANDE

Paraguay

1,165 Mvar

270 to 833 kvar

Unit voltage

Total rated power

Noise reduced with external noise damping hoods,

internally fused and unfused

capacitors

445

Bank voltage

Quantity of units

SVC Bom Jesus

da Lapa II

156.2 Mvar

360.5 / 370.2 kvar

Unit voltage

Quantity of units

MSC S/S Jí Paraná,

S/S Vilhena

157

Bank voltage

Quantity of units

HVDC Cookstraight,

Pole 3

96.7 Mvar

643/435/427 kvar

Unit voltage

Total rated power

Internally fused

350

Bank voltage

Quantity of units

MSC London Array

Windfarm

265 Mvar

727.58 to 783.44 kvar

Unit voltage

Total rated power

Industrial electric arc furnace

application, internally fused

180

Bank voltage

Quantity of units

HVDC Kontek

118.5 Mvar

584.4 to 1091.5 kvar

7 to 20.8 kV

Total rated power

Low temperature -40 °C,

internally fused,

high seismic requirements

1,602

Bank voltage

Quantity of units

SVC Horqueta

1,400 Mvar

922 to 934 kvar

28 to 36.5 kV

Total rated power

Internally fused and fuseless

capacitors

642

Bank voltage

Quantity of units

SVC Gerdau Diaco

495 Mvar

212.6 to 875.5 kvar

6.735 to 98.05 kV

Total rated power

Low temperature -25 °C,

internally fused

1,800

Bank voltage

Quantity of units

SVC Bout de L‘lle

1,459 Mvar

719.8 and 825.1 kvar

244 kV and 31.7 kV

Total rated power

High seismic conditions,

internally fused

84

Bank voltage

Quantity of units

MSCDN

Gwynt Y Mor

75.64 Mvar

900.5 kvar

12.27 kV

Total rated power

Very low temperature -50 °C,

internally fused and unfused

capacitors

3,558

Bank voltage

Quantity of units

Harker, Hutton

and Stella

400 kV MSCDN

2,462 Mvar

126.1 to 963.2 kvar

8.86 to 376 kV

Total rated power

Largest MSCDN project

ever awarded to Siemens,

Internally fused

6,528

Bank voltage

Quantity of units

SVC Diego de

­Almagro

5,665 Mvar

593.2 to 886.2 kvar

Total rated power

Very low temperature -50 °C,

internally fused and unfused

capacitors

3,744

Unit output

Quantity of units

HVDC ATCO

3,045 Mvar

122.9 to 993.5 kvar

Highlight/

Technology

First capacitor bank delivery,

internally fused

24

11

Published by and copyright © 2013:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens AG

Energy Sector

Power Transmission Division

Transmission Solutions

Freyeslebenstrasse 1

91058 Erlangen, Germany

www.energy.siemens.com/hq/en/power-transmission/high-voltage-products/capacitors.htm

For more information, please contact

Siemens Ltda., E T TS TI 3 CA

Av. Eng. João F.G. Molina 1745

13213-080 JundiaÍ – SP – Brazil

Phone:+55 11 4585 2303

+55 11 4585 3150

For more information, please contact

our Customer Support Center.

Phone:+49 180/524 70 00

Fax: +49 180/524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

Power Transmission Division

Order No. E50001-G610-A130-V1-4A00 | Printed in Germany |

Dispo 30003 | c4bs No. 7495 |

TH 150-130701 | WÜ | 473222 | WS | 09131.0

Printed on elementary chlorine-free bleached paper.

All rights reserved.

Trademarks mentioned in this document

are the property of Siemens AG, its affiliates,

or their respective owners.

Subject to change without prior notice.

The information in this document contains general

descriptions of the technical options available, which

may not apply in all cases. The required technical

options should therefore be specified in the contract.