50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference<br>17th

4 - 7 May 2009, Palm Springs, California

AIAA 2009-2251

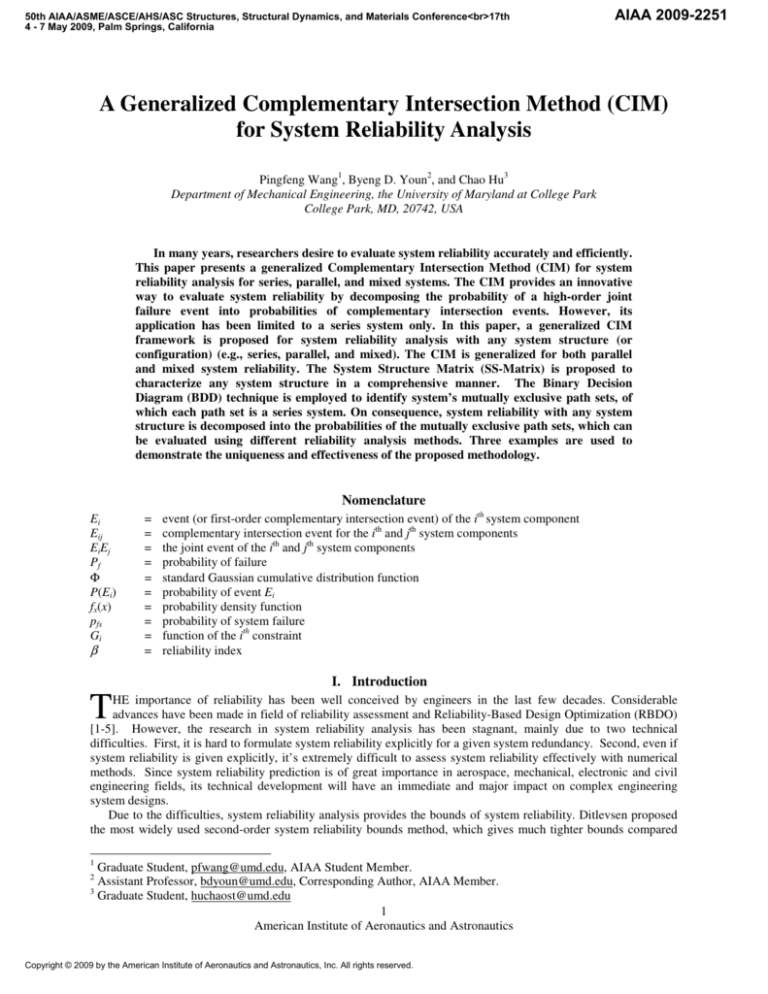

A Generalized Complementary Intersection Method (CIM)

for System Reliability Analysis

Pingfeng Wang1, Byeng D. Youn2, and Chao Hu3

Department of Mechanical Engineering, the University of Maryland at College Park

College Park, MD, 20742, USA

In many years, researchers desire to evaluate system reliability accurately and efficiently.

This paper presents a generalized Complementary Intersection Method (CIM) for system

reliability analysis for series, parallel, and mixed systems. The CIM provides an innovative

way to evaluate system reliability by decomposing the probability of a high-order joint

failure event into probabilities of complementary intersection events. However, its

application has been limited to a series system only. In this paper, a generalized CIM

framework is proposed for system reliability analysis with any system structure (or

configuration) (e.g., series, parallel, and mixed). The CIM is generalized for both parallel

and mixed system reliability. The System Structure Matrix (SS-Matrix) is proposed to

characterize any system structure in a comprehensive manner. The Binary Decision

Diagram (BDD) technique is employed to identify system’s mutually exclusive path sets, of

which each path set is a series system. On consequence, system reliability with any system

structure is decomposed into the probabilities of the mutually exclusive path sets, which can

be evaluated using different reliability analysis methods. Three examples are used to

demonstrate the uniqueness and effectiveness of the proposed methodology.

Nomenclature

Ei

Eij

EiEj

Pf

Φ

P(Ei)

fx(x)

pfs

Gi

β

=

=

=

=

=

=

=

=

=

=

event (or first-order complementary intersection event) of the ith system component

complementary intersection event for the ith and jth system components

the joint event of the ith and jth system components

probability of failure

standard Gaussian cumulative distribution function

probability of event Ei

probability density function

probability of system failure

function of the ith constraint

reliability index

I. Introduction

T

HE importance of reliability has been well conceived by engineers in the last few decades. Considerable

advances have been made in field of reliability assessment and Reliability-Based Design Optimization (RBDO)

[1-5]. However, the research in system reliability analysis has been stagnant, mainly due to two technical

difficulties. First, it is hard to formulate system reliability explicitly for a given system redundancy. Second, even if

system reliability is given explicitly, it’s extremely difficult to assess system reliability effectively with numerical

methods. Since system reliability prediction is of great importance in aerospace, mechanical, electronic and civil

engineering fields, its technical development will have an immediate and major impact on complex engineering

system designs.

Due to the difficulties, system reliability analysis provides the bounds of system reliability. Ditlevsen proposed

the most widely used second-order system reliability bounds method, which gives much tighter bounds compared

1

Graduate Student, pfwang@umd.edu, AIAA Student Member.

Assistant Professor, bdyoun@umd.edu, Corresponding Author, AIAA Member.

3

Graduate Student, huchaost@umd.edu

1

American Institute of Aeronautics and Astronautics

2

Copyright © 2009 by the American Institute of Aeronautics and Astronautics, Inc. All rights reserved.

with the first-order bounds for both series and parallel systems [6]. Other equivalent forms of Ditlevsen’s bounds

are given by Thoft-Christensen and Murotsu [7], Karamchandani [8], Xiao and Mahadevan [9] and K.

Ramachandran [10]. Recently, Song and Der Kiureghian formulated system reliability to a Linear Programming

(LP) problem, referred to as the LP bounds method [11]. The LP bounds method is able to calculate the optimal

bounds for system reliability based on available information. However, it is extremely sensitive to accuracy of the

given information, which is the probabilities for the first-, second-, or higher-order joint safety events. To assure

high accuracy of the LP bounds method for system reliability prediction, the probabilities must be given very

accurately.

Besides the system reliability bound methods, one of the most popular approaches is the multimodal adaptive

importance sampling (AIS) method, which is found satisfactory for the system reliability analysis of large structures

[12, 13]. The integration of surrogate model techniques with MCS-based methods can be an alternative approach to

system reliability prediction as well [14]. This approach can construct the surrogate model for multiple limit-state

functions to represent the joint failure region. This approach is quite practical but accuracy of the method depends

on fidelity of the surrogate model. It is normally expensive to build an accurate surrogate model with high

confidence.

Most recently, Youn and Wang [15] introduced an innovative concept of complementary intersection event and

proposed the Complementary Intersection Method (CIM) for system reliability analysis with any system structure

(e.g., series, parallel, and mixed). The CIM method provides not only a unique formula for system reliability but

also an effective numerical method to evaluate the system reliability with high efficiency and accuracy. The CIM

decomposes the probabilities of high-order joint failure events into probabilities of complementary intersection

events. For large scale systems, a CI-matrix was proposed to store the probabilities of component safety and

complementary intersection events. Then, series system reliability can be evaluated efficiently by any reliability

method, such as First-Order Reliability Method (FORM), Second-Order Reliability Method (SORM), Eigenvector

Dimension Reduction (EDR) method, or Monte Carlo Simulation (MCS). The accuracy and efficiency of these

reliability methods used for the evaluation of the CI-matrix were also compared. However, the application of the

CIM has been limited to a series system only.

The work presented in this paper is the continuous investigation of the CIM for system reliability analysis. In this

work, the CIM is advanced for parallel systems and mixed systems, and a generalized CIM framework is proposed

for system reliability analysis with any system structures. The CIM is generalized for both parallel and mixed

system reliability. The System Structure Matrix (SS-Matrix) is proposed to characterize any system structure in a

comprehensive manner. The Binary Decision Diagram (BDD) technique is employed to identify system’s mutually

exclusive path sets, of which each path set is a series system. On consequence, system reliability with any system

structure is decomposed into the probabilities of the mutually exclusive path sets, which can be evaluated using

different reliability analysis methods. Three examples are used to demonstrate the uniqueness and effectiveness of

the proposed methodology.

Section II reviews the complementary interaction method (CIM) and CI-matrix. Section III presents system

reliability analysis for series, parallel, and mixed system, and the proposed unified system reliability analysis

framework will be introduced in Section IV. The proposed method is demonstrated with three examples in Section

V.

II. Complementary Intersection Method (CIM)

This section reviews the Complementary Intersection Method (CIM). First, the complementary intersection (CI)

event is defined and the probability decomposition theorem is reviewed. Then, the probability of the second-order

joint failure event is defined in terms of the probability of component safety events and complementary intersection

events. Second, the CI-matrix is defined to facilitate the system reliability analysis for large-scale problems, which

is composed of the probabilities of the component safety and complementary intersection events.

A. CI event and probability decomposition theorem

This subsection reviews the definition of CI event. This event enables the decomposition of the probability of

any second or higher-order events into the probabilities of the CI events.

Definition: Complementary Intersection (CI) Event

Let an Nth-order CI event denote E12…N ≡ {X | G1⋅ G2 ⋅ …⋅ GN ≤ 0}, where the component safety (or 1st-order CI)

event is defined as Ei = {X | Gi ≤ 0, i = 1, 2, …, N}.

2

American Institute of Aeronautics and Astronautics

The defined Nth-order CI event is actually composed of N distinct intersections of component events Ei and their

complements Ēj in total where i = 1,…, N, j =1,..., N, i ≠ j. For example, for the second order CI event Eij, it is

composed of two distinct intersection events, Ē1E2 and E1Ē2. These two events are the intersections of E1 (or E2) and

the complementary event of E2 (or E1). Thus, we refer to the defined event as the Complementary Intersection (CI)

Event.

Theorem: Decomposition of the Probability of an Nth-Order Joint Safety Event

With the definition of the CI event, the probability of an Nth-order joint safety event can be decomposed into the

probabilities of the CI events as

N

N

N

N

N

1

m −1

N −1

P ∩ Ei = N −1 ∑ P ( Ei ) − ∑ P ( Eij ) + ∑ P ( Eijk ) + + ( −1)

P

E

+

+

−

1

P

E

(

)

(

)

∑

ijl

12 N

i =1;

i =1;

i =1;

i =1 2 i =1

m

j = 2;

j = 2;

j = 2;

i< j

k =3

i< j<k

l =m

i < j << l

(1)

The detailed derivation of Eq. (1) can be found in Ref. [15]. It is noted that each CI event has its own limit state

function, which enables the use of any reliability analysis methods. In general, higher-order CI events are expected

to be highly nonlinear. Considering the tradeoff between computational efficiency and accuracy, this paper uses the

probabilities of the first and second-order CI events in Eq. (1) for system reliability analysis. However, more terms

in Eq. (1) can be employed as advanced reliability analysis methods are developed in future.

Based on the definition of the CI event, the second-order CI event can be denoted as Eij ≡ {X | Gi ⋅ Gj ≤ 0}. The

CI event can be further expressed as Eij = Ēi Ej ∪ Ei Ēj where the component failure events are defined as Ēi = {X |

Gi > 0} , Ēj = {X | Gj > 0}. The event Eij is composed of two events: Ei Ēj = {X | Gi ≤ 0 ∩ Gj > 0} and Ēi Ej = {X | Gi

> 0 ∩ Gj ≤ 0}. Since the events, Ēi Ej and Ei Ēj, are disjoint, the probability of the CI event Eij can be expressed as

P( Eij ) ≡ P( X | Gi ⋅ G j ≤ 0)

= P( X | Gi > 0 ∩ G j ≤ 0) + P( X | Gi ≤ 0 ∩ G j > 0)

(2)

= P( Ei E j ) + P( Ei E j )

Based on the probability theory, the probability of the second-order joint safety event Ei ∩ Ej can be expressed

as

P( Ei E j ) = P( Ei ) − P( Ei E j )

(3)

= P( E j ) − P( Ei E j )

From Eqs. (2) and (3), the probabilities of the second-order joint safety and failure events can be decomposed as

1

P ( Ei E j ) = P ( Ei ) + P ( E j ) − P ( Eij )

(4)

2

1

P( E i E j ) = 1 − P( Ei ) + P( E j ) + P ( Eij )

(5)

2

B. CI-matrix

For large-scale systems, the CI events can be conveniently written in the CI-matrix. For instance, if the system

includes m components in total, the CI-matrix is defined as

P ( E1 ) P ( E12 ) P ( E13 ) P ( E1m )

P ( E2 ) P ( E23 ) P ( E2 m )

(6)

CI = P ( E3 ) P ( E3m )

P

(

E

)

m

In the upper triangular CI-matrix, the diagonal elements correspond to the component reliabilities (or

probabilities of the first-order CI events) and the element on ith row and jth column corresponds to the probability of

the second-order CI event Eij if j < i. The probabilities of the second-order joint safety and failure events in Eqs. (4)

and (5) can be evaluated with the probabilities of all component safety and complementary intersection events found

from the CI-matrix. The CI-matrix facilitates to evaluate system reliability. The probability of the complementary

3

American Institute of Aeronautics and Astronautics

intersection events can be computed using any reliability analysis method, such as MCS, FORM, SORM, EDR

method and Stochastic Expansion (SE) methods and so on.

III. Generalized CIM for System Reliability Analysis

This section will generalize the CIM for system reliability analysis for series, parallel, and mixed systems.

Section A will briefly review the CIM for series system reliability analysis from Ref. [15]. The proposed CIM for

parallel and mixed system reliability analysis are developed in Sections B and C, respectively. Section D provides a

generalized CIM framework for system reliability analysis.

A. Series system reliability analysis

Although the second-order system reliability bounds method or the LP bounds method can generally give fairly

narrow system reliability bounds, system reliability is not unique with an explicit formula. This section introduces

an explicit formula for system reliability assessment, which is developed based a mathematical inequality equation.

In addition to the second-order reliability bounds method and LP bounds method, this explicit formula can provide

an alternative way for system reliability assessment.

Considering a structural serial system with m components, the probability of system failure can be expressed as

m

Pfs = P ∪ Ei

i =1

(7)

th

where pfs represents the probability of system failure and Ēi denotes the failure event of the i component. Based on

the well known Boolean bounds in Eq. (8), the first-order system reliability bound is given in Eq. (9), suggested by

Ang and Amin [10] and Cornell [11].

m

m

max( P( Ei )) ≤ P(∪ Ei ) ≤ ∑ P ( Ei )

i =1

i

(8)

i =1

m

max P Ei ≤ Pfs ≤ min ∑ P Ei , 1

i =1

( )

( )

(9)

However, these methods provide wide bounds of system reliability. Thus, the second-order bounds method proposed

by Ditlevsen [14] in Eq. (10) is widely used because it gives quite narrow bounds of system reliability.

m

i −1

m

m

P E1 + ∑ max P Ei − ∑ P Ei E j , 0 ≤ Pfs ≤ min ∑ P Ei − ∑ max P Ei E j , 1

j <i

i =2

j =1

i=2

i =1

( )

( )

(

)

( )

(

)

(10)

where E1 is the event having the largest probability of failure.

Since the probabilities of all events are non-negative, the following inequalities must be satisfied as

2

m

max( P( Ei )) ≤

i

m

P( Ei ) ≤ ∑ P( Ei )

∑

i =1

i =1

(11)

Based on Eqs.(10) and (11), the probability of system failure (Pfs) of a serial system failure can be simplified to a

unique explicit formula as

m

Pfs ≅ P E1 + ∑ P Ei −

( )

i=2

i −1

( ) ∑ P ( E E )

i

2

(12)

j

j =1

It is proven in Ref.[15] that this approximate probability lies in the second-order bounds in Eq. (10).

From Eq. (12), serial system reliability can be assessed as (1 − the probability of system failure) and formulated

as

m

Rs = P( E1E2 Em −1Em ) ≅ P ( E1 ) − ∑ P Ei −

i=2

i −1

( ) ∑ P ( E E )

i

j =1

j

2

A,

where A ≡

0,

if A > 0

if A ≤ 0

(13)

Note that the terms inside the bracket, ⟨ ⟩, should be ignored if it is less than zero and Rs should be set to zero if

the approximated one given by Eq. (13) is less than zero. Equation (13) provides an explicit and unique formula for

system reliability assessment based on the second-order reliability bounds shown in Eqn.(10) and an inequality

equation (11). To the application of large system with multiple failure events, The CI-matrix facilitates to evaluate

system reliability. The probability of the CI events can be computed using any reliability analysis method, such as

MCS, First-Order Reliability Method (FORM), Second-Order Reliability Method (SORM), Eigenvector Dimension

Reduction (EDR) Method or Stochastic Expansion (SE) methods.

B. Parallel system reliability analysis

4

American Institute of Aeronautics and Astronautics

A parallel system reliability formula can be obtained based on the formula of series system reliability by using

the De Morgan’s law. According to the De Morgan’s law, the probability of parallel system failure can be expressed

as

m

m

m

P ∩ Ei = 1 − P ∩ Ei = 1 − P ∪ Ei

i =1

i =1

i =1

(14)

___

where Ei is the ith component failure event.

Eq. (14) relates the probability of failure of a parallel system with the probability of series system safety

(reliability). If we treat Ei as the ith component failure event in a series system, the right side of Eq. (14) is then the

series system reliability. Based on this relationship, the probability of parallel system failure can be obtained from

Eq. (13) by treating safe events in the series system as failure events in the parallel system as

A, if A > 0

A ≡

(15)

i=2

j =1

0, if A ≤ 0

Finally, parallel system reliability can be obtained from Eq. (15) by one minus the probability of system failure as

i −1

m

P(failure of a parallel system) ≅ P( E1 ) − ∑ P( Ei ) −

m

Rs _ parallel ≅ P( E1 ) + ∑ P( Ei ) −

i=2

∑ P ( E E )

i

i −1

∑ P ( E E )

i

j

2

,

j =1

2

j

,

A,

A ≡

0,

if A > 0

if A ≤ 0

(16)

C. Mixed system reliability analysis

A mixed system may have various system structures (or configurations). There is no unique system reliability

formula available for a mixed system. This study develops a systematic procedure for mixed system reliability

analysis using the CIM. The developed procedure is introduced below with a mixed system example. Considering a

mixed system with N components, the following procedure can be proceeded to carry out system reliability analysis.

Step I: Constructing a System Structure Matrix (SS-Matrix)

A 3-by-M SS-Matrix can be used to model the system structure in a systematic manner. The first row of the

matrix contains a component number, while the second and third rows correspond to the starting and end nodes of

the component. Generally, the total number of columns of a SS-Matrix, M, is equal to the total number of system

components, N. In the case of complicated system structures, one component may repeatedly appear in between

different sets of nodes and, consequently, M could be larger than N, for example a 2-out-of-3 system.

E6

①

⑤

③

E1

E2

②

E3

E4

⑥

E5

④

E7

Figure 1 A mixed-system block diagrams

Let us consider a mixed system with 7 components, as shown in Fig. 1. The system structure matrix is a 3×7

matrix. The first column of the system structure matrix, [1, 1, 2]T, indicates that the 1st component connects nodes 1

and 2. The SS-Matrix for the system in Fig. 1 can be constructed as

1 2 3 4 5 6 7

SS- Matrix = 1 2 3 4 5 2 3

2 3 4 5 6 4 5

Step II: Finding system path sets based on the SS-Matrix

Based on the SS-Matrix, the Binary Decision Diagram (BDD) technique can be employed to find the mutually

exclusive system path sets, of which each path set is a series system. More information on the BDD can be found in

references [16] and [17].

5

American Institute of Aeronautics and Astronautics

For the mixed system shown in Fig. 2, the mutually exclusive path sets can be found by using the BDD as

{

Pathset = E1 E2 E3 E4 E5 , E1 E2 E6 E4 E5 , E1 E2 E3 E7 E5 , E1 E2 E6 E4 E3 E7 E5

}

Step III: Calculating system reliability for all mutually exclusive path sets and the overall system

Due to the mutual exclusiveness, the mixed system reliability, RM, is the sum of the probabilities of all paths as

Np

Np

Rs _ mixed = Pr ∪ Path i = ∑ Pr ( Path i )

(17)

i =1

i =1

where Pathi is the ith mutually exclusive path set obtained by the BDD and Np is the total number of mutually

exclusive path sets. For the system in Fig. 2, the system reliability can be calculated as

4

4

Rs _ mixed = Pr ∪ Path i = ∑ Pr ( Path i )

(18)

i =1

i =1

= Pr( E1 E2 E3 E4 E5 ) + Pr( E1 E2 E6 E4 E5 ) + Pr( E1 E2 E3 E7 E5 ) + Pr( E1 E2 E6 E4 E3 E7 E5 )

where the probability of each individual path set can be calculated using the series system reliability formula in

Eq.(13).

D. Generalized CIM framework for system reliability analysis

As a series system or a parallel system can be viewed as special case of a mixed system, the proposed CIM with

the SS-Matrix and BDD can perform system reliability analysis with any system structures (or configurations) (e.g.,

series, parallel, and mixed). Figure 2 shows a generalized CIM framework for system reliability.

Figure 2 A generalized CIM framework for system reliability analysis

IV. Case Studies

This section presents three case studies for a series system, a parallel system and a mixed system, respectively, to

demonstrate the efficiency and accuracy of the proposed generalized CIM for system reliability. For each case study,

the generalized CIM framework is demonstrated in a wide range of system reliability levels and compared with

Monte Carlo Simulation (MCS). For series and parallel systems, the results of the generalized CIM framework are

also compared with First-Order Bound (FOB) and Second-Order Bound (SOB) methods. The main objective of the

examples is to demonstrate the accuracy of the proposed generalized CIM framework for system reliability analysis.

So in three examples we focus on a mathematical error produced by a system reliability formulae rather than a

numerical error by a numerical method. In order to eliminate the numerical error in system reliability analysis, the

Monte Carlo Simulation (MCS) with 1,000,000 sample points is used to obtain the CI matrix.

A. Series system example: an internal combustion engine system

The following internal combustion engine case study demonstrates the application of the generalized CIM for

series system reliability analysis. Five random variables are considered in this example: the cylinder bore b,

compression ratio cr, exhaust valve diameter dE, intake valve diameter dI, and the revolutions per minute (rpm) at

peak power, ω. All the random variables are assumed to follow normal distribution with statistical information

shown in Table 1. More detail information of this example can be found in Ref. [19].

6

American Institute of Aeronautics and Astronautics

Table 1 Statistical information of input random variables for combustion engine

Random Variable

b (mm)

cr (mm)

dE (mm)

dI

ω, (×10-3)

Mean

-----------

Standard Deviation

0.40

0.15

0.15

0.05

0.25

Distribution Type

Normal

Normal

Normal

Normal

Normal

From a thermodynamic viewpoint, nine component safety events are defined as follows:

E1 = {1.2 N c b − 400 ≤ 0}

{

( min. bore wall thickness )

0.5

}

E2 = 8V / ( 200π N c ) − b ≤ 0

( max. engine height )

E3 = {d I + d E − 0.82b ≤ 0}

( valve geometry and structure )

E4 = {0.83d I − d E ≤ 0}

( min. value diameter ratio )

E5 = {d E − 0.89d I ≤ 0}

( max. value diameter ratio )

−5

E6 = 9.428 × 10 4V / (π N c ) (ω /d I 2 ) − 0.6Cs ≤ 0 ( max. Mech/Index )

E7 = {0.045b + cr − 13.2 ≤ 0}

( knock-limit compression ratio )

E8 = {ω − 6.5 ≤ 0}

( max. torque converter rpm )

E9 = {230.5Qηtw − 3.6 × 106 ≤ 0} ( max. fuel economy )

{

(19)

}

where

ηtw = 0.85951(1 − cr−0.33 ) − Sv , V = 1.859 × 106 mm3

Q = 43,958 kJ/kg, Cs = 0.44, and N c = 4

In this study, system reliability analyses are performed at the eight different design points as listed in Table 2.

These design points are the reliability-based optimum designs using FORM with eight different target component

reliability levels from 80% to 99.9%. The results of system reliability analysis at these design points are summarized

in Table 3 and also graphically shown in Fig. 3. From the results, it is found that the first-order bounds method gives

too wide bounds to be of practical use. Whereas, the second-order bounds method gives tighter bounds. The

generalized CIM method provides more accurate results at all reliability levels and its high accuracy is maintained at

high reliability levels, which are often encountered in engineering practices. The error in the CIM comes from the

probabilities of the third- or higher-order joint failure events. As the reliability level decreases, the effects of the

third- or higher-order joint failure events increase. That is why the error increases as the system reliability decreases.

Table 2 Eight different design points for system reliability analysis

designs points

1

2

3

4

5

6

7

8

b

82.1025

82.3987

82.5511

82.6770

82.8234

82.8750

82.9204

82.9977

Mean values for random variables

cr

dE

dI

35.8039

30.3274

9.3397

36.1754

30.4835

9.3684

36.3630

30.5676

9.3811

36.5187

30.6334

9.3920

36.7006

30.7121

9.4049

36.7655

30.7407

9.4096

36.8222

30.7657

9.4137

36.9197

30.8084

9.4204

7

American Institute of Aeronautics and Astronautics

ω

5.2827

5.5983

5.7550

5.8901

5.9498

5.9754

5.9772

5.9795

Table 3 Results of System Reliability Analysis with MCS, FOB using MCS, SOB using MCS, and Generalized

CIM using MCS (N=1,000,000)

Analysis Method

FOB

SOB

1

2

System Reliability Level at Each Design

3

4

5

6

7

8

Upper

0.9989

0.9899

0.9745

0.9495

0.8984

0.8742

0.8490

0.7988

Lower

0.9949

0.9506

0.8744

0.7432

0.5367

0.4318

0.3410

0.1513

Upper

0.9949

0.9520

0.8822

0.7741

0.6224

0.5554

0.4987

0.3967

Lower

0.9949

0.9517

0.8798

0.7653

0.5929

0.5190

0.4418

0.3049

CIM

0.9949

0.9518

0.8805

0.7674

0.6026

0.5312

0.4612

0.3371

MCS

0.9949

0.9520

0.8820

0.7731

0.6179

0.5476

0.4871

0.3748

Figure 3 Results of system reliability analysis at eight different reliability levels

B. Parallel System Example: A Ten Brittle Bar System

The following ten-bar system example demonstrates the application of the generalized CIM framework for

parallel systems. As shown in Fig. 4, ten brittle bars are connected in parallel to sustain a load applied at one end.

This case study is modified from the example employed in Ref. [20] by increasing the total number of bars from 2 to

10. Ten bars are all brittle with different fracture strains εf, and the strain level for the maximum allowable load

should be one of the ten fracture strain levels. At the ith fracture strain level εfi, components with fracture strains

below εfi fail, and the overall allowable load is simply the strength summation of components with fracture strains

above εfi. Thus, as the maximum allowable load, the system strength RT can be formulated as at ten fracture strain

levels εf1,…, εf10, as shown in Eq. (20).

8

American Institute of Aeronautics and Astronautics

10

10

RT = max ∑ R j (ε ) = max ∑ R j (ε fi )

ε

j =1

1≤i ≤10 j =i

(20)

R1 (ε f 1 ) + R2 (ε f 1 ) + R3 (ε f 1 ) + R4 (ε f 1 ) + R5 (ε f 1 ) + R6 (ε f 1 ) + R7 (ε f 1 )

+ R8 (ε f 1 ) + R9 (ε f 1 ) + R10 (ε f 1 ),

R2 (ε f 2 ) + R3 (ε f 2 ) + R4 (ε f 2 ) + R5 (ε f 2 ) + R6 (ε f 2 ) + R7 (ε f 2 )

= max

+ R8 (ε f 2 ) + R9 (ε f 2 ) + R10 (ε f 2 ),

......

R10 (ε f 10 )

1

2

……

10

F

(a)

(b)

Figure 4 Ten brittle bar parallel system: (a) system structure model; (b) brittle material behavior in parallel

system

For example, at fracture strain εf2, the 1st brittle bar fails due to fracture and thus does not contribute to the

overall system strength, which becomes the strength summation of the surviving nine brittle bars. This scenario can

be treated as a component corresponding to fracture strain εf2. There are totally ten components corresponding to ten

strain levels, respectively, as shown in Eq.(20). The brittle bar system fails to sustain the load F only if all the ten

components fail. This is a parallel system with ten components. The component safety events can be expressed in

terms of several random variables.

10

10

j =i

j =i

Gi = F − ∑ R j (ε fi ) = F − ∑ ( E j Aj ) ⋅ ε fi ,

1 ≤ i ≤ 10

(21)

where, Rj represents the allowable load that can be sustained by the jth brittle bar; Aj the cross section area of the jth

brittle bar; Ej Young’s modulus of the jth brittle bar.

Random variables and their random properties are summarized in Table 4. Ten different system reliability levels

are used for comparison with ten different loading conditions (F). These loading points are used to validate the

generalized CIM method at different reliability levels. Table 5 summarizes the results of system reliability analysis

which are graphically summarized in Fig. 5. It can be seen that the first-order bounds are too wide to be of practical

use. Whereas, the second-order bounds method gives tighter system reliability bounds compared with the first order

bounds method. The generalized CIM method provides more accurate results at all reliability levels and its high

accuracy is maintained at high reliability levels, which are often encountered in engineering practices. The error in

the CIM comes from the probabilities of the third- or higher-order joint failure events. For a parallel system, as the

reliability level decreases, the effects of the third- or higher-order joint failure events also decrease. That is why the

error decreases as the system reliability decreases.

9

American Institute of Aeronautics and Astronautics

Table 4 Statistical information of input random variables for the ten bar system

Random Variable

E1-E10 (GPa)

A1 (mm2)

A2 (mm2)

A3 (mm2)

A4 (mm2)

A5 (mm2)

A6 (mm2)

A7 (mm2)

A8 (mm2)

A9 (mm2)

A10 (mm2)

εf1

εf2

εf3

εf4

εf5

εf6

εf7

εf8

εf9

εf10

F (kN)

Mean

200.0

100.0

120.0

140.0

140.0

140.0

150.0

150.0

150.0

200.0

300.0

0.0010

0.0012

0.0018

0.0025

0.0027

0.0030

0.0033

0.0036

0.0040

0.0050

---

Standard Deviation

10.0

5.0

5.0

5.0

10.0

10.0

10.0

15.0

15.0

15.0

25.0

0.0002

0.0003

0.0004

0.0005

0.0006

0.0007

0.0008

0.0009

0.0010

0.0011

30.0

Distribution Type

Gumbel

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Lognormal

Uniform

Uniform

Uniform

Uniform

Uniform

Uniform

Uniform

Uniform

Uniform

Uniform

Normal

Table 5 Results of System Reliability Analysis with MCS, FOB using MCS, SOB using MCS, and Generalized

CIM using MCS (N=1,000,000)

Analysis

Method

System Reliability Level at Each Design

1

2

3

4

5

6

7

8

9

10

Upper

0.4133

0.5639

0.7331

0.9216

1.0000

1.0000

1.0000

1.0000

1.0000

1.0000

Lower

0.1594

0.2054

0.2507

0.2974

0.3444

0.4395

0.4865

0.5334

0.5803

0.9705

Upper

0.3537

0.467

0.5854

0.7065

0.8293

1.0000

1.0000

1.0000

1.0000

1.0000

Lower

0.3192

0.4062

0.4849

0.5507

0.6068

0.6917

0.7161

0.7459

0.7897

0.9943

CIM

0.3417

0.4456

0.5490

0.6482

0.7388

0.8714

0.9017

0.9069

0.9051

0.9943

MCS

0.3301

0.4272

0.5226

0.6131

0.6961

0.8314

0.8813

0.9192

0.9476

0.9998

FOB

SOB

10

American Institute of Aeronautics and Astronautics

Figure 6 Results of system reliability analysis at ten different reliability levels

C. Mixed System Example: A Cantilever Beam-Bar Mixed System

The following cantilever beam-bar system [18] is employed in this study to demonstrate the effectiveness of the

generalized CIM framework for mixed system reliability analysis. The system is considered as an ideally elasticplastic cantilever beam supported by an ideally rigid-brittle bar, with a load applied at the midpoint of the beam, as

shown in Fig. 6. There are three failure modes and five independent failure events E1 ~ E5. These three failure

modes are formed by different combinations of failure events as:

• 1st Failure Mode: The fracture of the brittle bar (event E1) occurs, and subsequently the formation of a hinge at

the fixed point of the beam (event E2).

• 2nd Failure Mode: The formation of a hinge at the fixed point of the beam (event E3) followed by the formation

of another hinge at the midpoint of the beam (event E4).

• 3rd Failure Mode: The formation of a hinge at the fixed point of the beam (event E3) followed by the fracture of

the brittle bar (event E5).

The five safety events can be expressed as:

E1 = { X , T | 5 X /16 − T ≤ 0} ,

E2 = { X , L, M | LX − M ≤ 0} ,

E3 = { X , L, M | 3LX / 8 − M ≤ 0} ,

E4 = { X , L, M | LX / 3 − M ≤ 0} ,

E5 = { X , L, M , T | LX − M − 2 LT ≤ 0}

Considering these three failure modes, the system success event can be obtained as:

ES = ( E1 ∪ E2 ) ∩ { E3 ∪ ( E4 ∩ E5 )}

(22)

(23)

The statistical information of the random input variables is given in Table 6. Ten different system reliability levels

are used for comparison with ten different loading conditions (X). Figure 7 shows the system block diagram.

Figure 6 A Cantilever beam-bar system

11

American Institute of Aeronautics and Astronautics

Table 6 Statistical information of input random variables

Random Variable

L

T

M

X

Mean

5.0

1000

150

---

①

Standard Deviation

0.05

300

30

20

②

Distribution Type

Normal

Normal

Normal

Normal

④

③

Figure 7 System block diagram for mixed system example

From the system block diagram shown in Fig. 7, the SS-Matrix for this mixed system can be obtained by its

definition as:

1 2 3 4 5

SS-Matrix = 1 1 2 2 3

2 2 4 3 4

With this SS-Matrix, the BDD can be constructed as shown below in Fig. 8

Figure 8 BDD diagram for mixed system example

The BDD shown in Fig. 8 indicates the following mutually exclusive system path sets as

Pathset = {E1 E3 , E1 E2 E3 , E1 E3 E4 E5 , E1 E2 E3 E4 E5 }

The system reliability analysis is carried out with ten different loading conditions (X) using the generalized

CIM. The MCS is used for a benchmark solution. Table 7 summarizes the results. It can be found that the CIM gives

very accurate mixed system reliability results at all reliability levels.

In recent literature, the LP bound method was developed [18] and is able to calculate the optimal bounds for

mixed system reliability based on available information. Results regarding this example using the LP bound method

can be found in Ref. [18]. Compared with the LP bound method, the generalized CIM not only gives a unique

estimate of mixed system reliability, but also provides numerical schemes for system reliability. It is known that the

LP bound method can suffer when an approximate LP algorithm is used for over constrained problems. Besides, it is

extremely sensitive to the accuracy of the given input information, which are the probabilities for the first-, second-,

and high-order joint safety events.

12

American Institute of Aeronautics and Astronautics

Table 7 Results of different system reliability analysis methods:

(1) MCS, (2) Complementary Interaction Method (CIM) using MCS (N=1,000,000)

System Reliability at Each Point

Analysis

Method

1

2

3

4

5

6

7

8

9

10

CIM

0.3546

0.4251

0.4981

0.5724

0.6444

0.7110

0.7708

0.8666

0.9308

0.9681

MCS

0.3548

0.4252

0.4982

0.5725

0.6445

0.7111

0.7708

0.8667

0.9309

0.9681

V. Conclusion

This paper presented a generalized Complementary Intersection Method (CIM) for system reliability analysis

for series, parallel, and mixed systems. The CIM decomposes the probability of a high-order joint failure event into

probabilities of complementary intersection events, and provides an innovative way to evaluate system reliability.

However, its application has been limited to a series system only. In this paper, a generalized CIM framework is

proposed for system reliability analysis for a system with any structure or configuration (e.g., series, parallel, and

mixed). Within the generalized framework, (i) the CIM was firstly generalized for parallel system reliability analysis

with a unique explicit formula, (ii) the System Structure Matrix (SS-Matrix) was proposed to characterize any

system structure in a comprehensive manner, and (iii) the Binary Decision Diagram (BDD) technique is employed to

identify system’s mutually exclusive path sets, of which each path set is a series system. On consequence, system

reliability with any system structure is decomposed into the probabilities of the mutually exclusive path sets, which

can be evaluated as series systems using the CIM formula by different reliability analysis methods. The proposed

CIM framework is generally applicable for system reliability analysis for different engineering systems, regardless

the structure or configuration. The proposed methodology was demonstrated to be effective and efficient by three

case studies, one for series systems, one for parallel systems, and one for mixed systems.

Acknowledgments

The work presented in this paper has been partially supported by US National Science Foundation (NSF) under

Grand No. GOALI-07294, U.S. Army TARDEC by the STAS contract (TCN-05122), General Motors under Grant

No. TCS02723.

References

1

Youn, Byeng D., Choi, K. K., and Du, L., “Enriched Performance Measure Approach (PMA+) for ReliabilityBased Design Optimization,” AIAA Journal, Vol. 43, No. 4, pp. 874-884, 2005.

2

Chen, X., Hasselman, T.K., and Neill, D. J., “Reliability-Based Structural Design Optimization for Practical

Applications,” 38th AIAA SDM Conference, AIAA-97-1403, 1997.

3

4

Du, X., and Chen, W., “Sequential Optimization and Reliability Assessment Method for Efficient Probabilistic

Design,” ASME, Journal of Mechanical Design, Vol. 126, No. 2, pp. 225-233, 2004.

Wu, Y-T., Shin, Y., Sues, R. H., and Cesare, M. A., “Safety-Factor Based Approach for Probability-Based Design

Optimization,” AIAA-2001-1522, 42nd AIAA/ASME/ASC /AHS/ASC SDM Conference & Exhibit, Seattle,

Washington, April, 2001.

5

Wang, L, Kodiyalam, S., “An Efficient Method for Probabilistic and Robust Design with Non-normal

Distributions,” 43rd AIAA SDM Conference, Denver, Colorado, April 2002.

6

Ditlevsen, O., and Bjerager, P. “Narrow Reliability Bounds for Structural Systems.” Journal of the Engineering

Mechanics, ASCE, Vol 110, No.5, pp. 671-693, 1984.

7

Thoft-Christensen, P., and Murotsu, Y. Application of Structural Reliability Theory. Springer Verlag, Berlin, 1986.

8

Karamchandani, A. “Structural System Reliability Analysis Methods.” Report No. 83, John A. Blume Earthquake

Engineering Center, Stanford University, Stanford, CA, 1987.

13

American Institute of Aeronautics and Astronautics

9

Xiao Q., and Mahadevan, S. “Second –Order Upper Bounds on Probability of Intersection of Failure Events.”

Journal of Engineering Mechanics, ASCE, Vol. 120, No.3, pp.49-57, 1998.

10

Ramachandran K., "System Reliability Bounds: A New Look with Improvements", Civil Engineering and

Environmental Systems, Vol. 21, No. 4, pp.265-278, December, 2004.

11

Junho Song and Armen Der Kiureghian, 2003, “Bounds on System Reliability by Linear Programming”, ASCE

Journal of Engineering Mechanics.

12

Mahadevan, S., and Raghothamachar, P.,2000, “Adaptive Simulation for System Reliability Analysis of Large

Structures,” Comput. Struct., 77, 725-734

13

Zou T. and Mahadevan, S., 2006, “Versatile Formulation for Multi-objective Reliability-Based Design

Optimization,” Journal of Mechanical Design, ASME, Nov, Vol.128 /1217.

14

Zhou, L., Penmetsa, R.C., and Grandhi, R.V., 2000, “Structural System Reliability Prediction Using Multi-Point

Approximations for Design,” 8th ASCE Specialty Conference on Probabilistic Mechanics and Structural

Reliability, PMC2000-082.

15

Youn, Byeng D., and Wang, P., “Complementary Intersection Method for System Reliability Analysis,” ASME, J.

Mech. Des. Vol. 131, Issue 4, 041004 (15), April, 2009 .

16

Lee CY. Representation of switching circuits by binary-decision programs, Bell Syst Tech J 1959;38:985–99.

17

Akers B. Binary decision diagrams. IEEE Trans Comput 1978; C-27(6):509–16.

18

Song, J., Der Kiureghian, “A. Bounds on Systems Reliability by Linear Programming,” Journal of Engineering

Mechanics, Vol. 129, Issue 6, pp. 627-636 , 2003.

19

Liang, J.H., Mourelatos, Z.P., and Nikolaidis E., “A Single-Loop Approach for System Reliability-Based Design

Optimization, ” ASME, Journal of Mechanical Design, Vol. 126, No. 2, pp. 1215-1224, 2007.

20

Mahadevan, S,, Zhang, R.X., and Smith, N., “Bayesian networks for system reliability reassessment,” Structural

Safety, Vol. 23, No. 3, pp. 231-251, 2001.

14

American Institute of Aeronautics and Astronautics