Benefits of Using a Scanning Matrix for Multi

advertisement

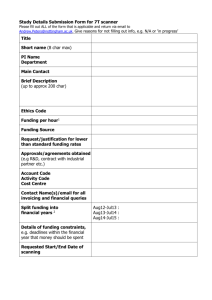

Instruments for Electrical Safety Testing . . . Since 1936 Benefits of Using a Scanning Matrix for Multi-point Testing Associated Research, Inc Introduction Recent advances in electrical safety testing technology have made complying with safety agency standards far easier and more efficient for electrical product manufacturers. From microprocessor controlled instruments to all-in-one testing equipment, safety testing instruments with intuitive features help increase efficiency, reduce operator error, and improve safety around the production environment. While the majority of production line managers and test operators have upgraded their old transformer-in-a-box testers to new models, some are either unaware of the benefits of incorporating new multi-point testing technology into their testing procedure, or are not yet convinced that this technology can improve performance on the production line. In this article we will discuss some of the benefits that multi-point testing technology can provide, and how manufacturers can ultimately improve throughput, efficiency, and accuracy during production line electrical safety compliance testing. Introducing the Scanning Matrix From appliances to medical devices, most electrically powered products must comply with safety agency standards that specify some combination of hipot, ground bond, insulation resistance, and line leakage tests. More advanced applications not only require these tests, but also specify that they be performed at multiple points on a product’s chassis. The nature of multi-point testing can drastically increase setup time, contribute to operator error, and reduce production efficiency. Until recently, test operators were forced to painstakingly change connections and re-wire test leads in between each test, but all the negative aspects of multi-point testing can be eliminated by using a scanning matrix. Scanning matrices are instruments that act as high voltage and/or high current relay switch boxes. These types of devices take the output of a piece of test instrument (hipot 13860 W Laurel Drive, Lake Forest, IL 60045 U.S.A. • Phone: (847) 367-4077 Fax: (847) 367-4080 • E-mail: info@asresearch.com • http://www.asresearch.com 1 Instruments for Electrical Safety Testing . . . Since 1936 tester, ground bond tester, etc.) and apply it to different points on the DUT without the need for additional connections or rewiring. By providing all of the necessary relays inside the instrument, test operators no longer need to manually change test connections in between test steps. Scanning matrices can help to increase throughput on the production line because the test operator need only configure the test instrument and scanner once prior to testing. This saves time as the test routine does not need to stop in order for the test operator to manually change test connections from one test to another. Scanning matrices also increase operator safety and minimize damage to the DUT. Since test operators are no longer required to change test leads during testing or in between test steps, the chance of incorrectly wiring the test leads (the leading cause of injury or DUT damage) is eliminated. Scanning Matrix Options Scanning matrices can be located internal or external to the safety tester. Internal scanning matrices are usually included as an option on certain types of testers, while external scanners are sold separately in stand-alone chasses. Automation capability is also another means of classify scanning matrices, as some are controlled directly from the front panel of the testing instrument while others can be controlled by a PC. Internal, external and automation-ready scanning matrixes have advantages that depend on the application for which the instrument is being used. Internal Scanner Matrices Some safety testing equipment, such as the Associated Research model 7650 (see Figure 1), includes a built-in scanning matrix for easy multi-point hipot and insulation resistance testing. This kind of instrument is perfect for cable harness and motor manufacturers that must subject multiple test points to high AC or DC voltages. 13860 W Laurel Drive, Lake Forest, IL 60045 U.S.A. • Phone: (847) 367-4077 Fax: (847) 367-4080 • E-mail: info@asresearch.com • http://www.asresearch.com 2 Instruments for Electrical Safety Testing . . . Since 1936 Figure 1: AR Model 7650 w/ 8-Channel Internal Scanning Matrix The 8-high voltage channels can be configured from the front panel of the instrument (or through software which we will discuss later), and allow test operators to apply high voltage between multiple points quickly and easily without the need to purchase any additional equipment. An electrical safety testing instrument with an internal scanning matrix is a cost-effective solution for manufacturers with multi-point testing applications that wish to increase productivity and improve safety. External Scanning Matrices Some electrical safety testing equipment may not include an internal scanner, but can be configured to operate one. The Associated Research model 8106 (see Figure 2) can be combined with a model SC6540 (see Figure 4) external scanning matrix to perform hipot, ground bond, insulation resistance, and line leakage tests on products with multiple test points from a single instrument. The SC6540 scanning matrix can be configured from the front panel of the test instrument or through software. Figure 3 shows how to connect the SC6540 to an OMNIA 8106. When used together, the test instrument and external scanning matrix make test setup quick and easy and reduce the chances for operator error or injury. An electrical safety testing instrument and external scanning matrix is an ideal 13860 W Laurel Drive, Lake Forest, IL 60045 U.S.A. • Phone: (847) 367-4077 Fax: (847) 367-4080 • E-mail: info@asresearch.com • http://www.asresearch.com 3 Instruments for Electrical Safety Testing . . . Since 1936 solution for appliance or medical device manufacturers that must perform multiple safety tests at different points on each product. Figure 2: AR Model OMNIA 8106 Figure 3: OMNIA 8106 w/ 8 HV –8 HC Channel SC6540 Modular Scanning Matrix Automation and Modularity 13860 W Laurel Drive, Lake Forest, IL 60045 U.S.A. • Phone: (847) 367-4077 Fax: (847) 367-4080 • E-mail: info@asresearch.com • http://www.asresearch.com 4 Instruments for Electrical Safety Testing . . . Since 1936 For manufacturers with complex test routines, the benefits of a scanning matrix don’t end with direct front-panel control. Indeed, automated test routines that utilize both an electrical safety testing instrument and accompanying scanning matrix are an economical solution that increases production efficiency, reduces the risk of operator error or DUT damage, and can improve performance exponentially. Most safety testing equipment providers realize that manufacturers’workplace requirements and skill sets vary. That is why models like the AR model SC6540 can be configured to work with a PC and any number of automation interfaces, including GPIB, RS-232, Ethernet, and USB. Figure 4: AR SC6540 Modular Scanning Matrix Available software packages such as AR’s Autoware program make controlling the instrument and accompanying scanning matrix quick and easy. Autoware allows the test operator to configure multiple test routines, execute them, and store the test results on the PC or a local network. Another unique benefit of the scanning matrices like the SC6540 is their modular design. Modular scanning matrices allow manufacturers to increase the number of scanner channels to fit a particular application. With multiple channel configurations to choose from, including 16 HV channels, 16 HC channels, and 8 HV and 8 HC channels, choosing the right modular scanning matrix for any application is easy. This is especially important when testing needs change and manufactures must upgrade their electrical safety testing routine to include additional scanner channels. 13860 W Laurel Drive, Lake Forest, IL 60045 U.S.A. • Phone: (847) 367-4077 Fax: (847) 367-4080 • E-mail: info@asresearch.com • http://www.asresearch.com 5 Instruments for Electrical Safety Testing . . . Since 1936 Conclusion Scanning matrices are an ideal solution for multi-point testing applications. With a multitude of optional topologies available, it has never been easier for a manufacturer to select the ideal instrument-scanning matrix combination for the job. Whether it is internal or external, locally-controlled or automated, incorporating a scanning matrix into your electrical safety testing routine will provide big benefits in productivity and safety. 13860 W Laurel Drive, Lake Forest, IL 60045 U.S.A. • Phone: (847) 367-4077 Fax: (847) 367-4080 • E-mail: info@asresearch.com • http://www.asresearch.com 6