Diamet Klang Malaysia Sdn. Bhd.

advertisement

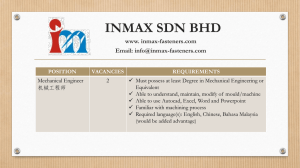

Overview of Powder Metallurgy Activities in Malaysia 30th Oct 2011 Norhamidi Muhamad Dept. of Mechanical Engineering, Universiti Kebangsaan Malaysia APMA Forum 2011 1 Presentation outline Introduction – Malaysian Powder Metallurgy and Particulate Materials Association (MPM2A) Overview of PM Activities - Industries Overview of PM Activities – Research Center and Universities APMA Forum 2011 2 Malaysian Powder Metallurgy and Particulate Materials Association (MPM2A) Registered officially on 1 Jun 2009 1st AGM - 12th August 2009 Objective of MPM2A The general objective: to promote research and development as well as commercialisation in the field of Powder Metallurgy and Particulate Materials in Malaysia. APMA Forum 2011 3 MPM2A : Activities Powder Metallurgy and Particulate Material Symposium 1st – AMREC, SIRIM, Kulim Kedah (2007) 2nd – UITM, Shah Alam (2008) 3rd – UKM, Kuala Lumpur (2009) 4th – AMREC, SIRIM, Pulau Pinang (2010) 5th – UKM, Kuala Lumpur (14th -15 Dec 2011) Talk to industries - cooperation with Malaysian Investment Development Authority (MIDA) Nov 2009 – Seminar and Business Matching Programme: MIM workshop Identify as one of the target area (Pioneer status-tax incentives) APMA Forum 2011 4 MPM2A: Activities.. 3rd Powder Metallurgy and Particulate Material Symposium: 12-13th August 2009. APMA Forum 2011 5 PM Activities – Industries APMA Forum 2011 6 PM Activities - Industries Three major companies producing parts using PM technologies Sumitomo Electric Sintered Components (M) Sdn. Bhd. (1989) Porite (M) Sdn. Bhd. (1991) Diamet Klang Malaysia Sdn. Bhd. (1992) One company producing part using MIM APMA Forum 2011 7 Sumitomo Electric Sintered Components (M) Sdn. Bhd. Product focus Car and m otorcycle parts P arts for Air con and refrigerator com pressor Others(Bicyle,pow er tools electrical parts) Components for automobiles and motorcycles Powder Usage Ton Iron Powder Reduced Atomised 350 3911 Copper 68 Graphite 35 Lubricant 31 Compressor parts for air-conditioners and refrigerator Manpower : 350 workers APMA Forum 2011 8 Sumitomo Electric Sintered Components (M) Sdn. Bhd. Sales Sales Year RM(mil) Ton Forecast 2010 2011 2012 2013 2014 76 78 82 84 85 4007 4140 4584 4680 4884 Issues M anpow er- difficult to get local people to join our com pany for the operator level Tool M aking -Still need to purchase from Japan for com plex tools and lead tim e to deliver the tools about I m onth APMA Forum 2011 9 Porite (M) Sdn. Bhd. Product focus oilless bearing and pinion gear Autom otive parts Electronic/ electrical parts / Hom e appliance Powder Usage Ton Copper/bronze 104 Brass 206 Iron 85 Manpower : 170 workers APMA Forum 2011 10 Porite (M) Sdn. Bhd. Sales: 2010 -RM 24 m illion 2011 – RM 19.2 m illion Issues Dom estic m ark et sales less than 20% , ex port 80% and effected by USD currency ex change. Raw m aterial/ pow der m etal, im port from over sea and Japan. Supply lead tim e longer and cost increasing. APMA Forum 2011 11 Diamet Klang Malaysia Sdn. Bhd. Product focus By Country Ratio By Application Ratio 36.8% Thailand 7.67% Compressor 2 Wheel Vehicle 0.75% Others 44.82% Malaysia 4 Wheel Vehicle 46.76% 7.4% Indonesia Vietnam Unit: 1,000 Malaysian Ringgit Application 4 Wheel Vehicle 2 Wheel Vehicle Compressor Others Total Sales Amount 2,572 2,465 422 41 5,500 39.0% Others 5.1% 11.8% Unit: 1,000 Malaysian Ringgit Ratio Country 46.76% 44.82% 7.67% 0.75% 100% Malaysia Thailand Indonesia Vietnam Others Total Sales Amount Ratio 406 7.4% 2023 36.8% 2143 39.0% 649 11.8% 279 5.1% 5500 100.0% APMA Forum 2011 12 Diamet Klang Malaysia Sdn. Bhd. Diamet Klang Sales Trend ISO:TS16949 Certification South East Asia Economic Crisis 6000 KRM/month ISO:TS16949 Certification 5000 4000 Rocker Arm Sales Start 3000 1stFactory Expansion R/A Others Thailand Malaysia Japan 2000 Unit : KRM/month 1000 0 1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009 2010 Year APMA Forum 2011 13 PM Activities – Research Center and Universities APMA Forum 2011 14 Institutions Involve in PM Research Research Institute: SIRIM – AMREC (PM & MIM ~1996) Unversities: UKM - (PM and MIM (1996)) USM – (PM) UiTM (MIM ~2000) University Petronas (PM & MIM ~2000) UM – (PM) UTM UNIMAP UNITEN UTHM APMA Forum 2011 15 EXAMPLES OF PROJECT: SIRIM - AMREC Areas Project Friction & Hard Materials *Brake Pad for Light Rail Transit (LRT) Application *Coated High Speed Steel & Tungsten Carbide Tool Insert *Cu-C Composite Collector Shoe for LRT *Titanium/Titanium Alloy for Medical Implant Light/Ultralight Materials *Aluminium Foam and Copper Foam for Heat Sink Application Ferrous Materials Magnetic Materials *SS316L Implant using Metal Injection Technique *Structural Steel using Warm Compaction NdFeB Bonded Magnet High Energy NdFeB Sintered Magnet APMA Forum 2011 16 SIRIM – AMREC (MIM) THE DEVELOPMENT OF FRACTURE FIXATION PLATES FOR ORTHOPEDIC APPLICATIONS Comply to International Standards: MPIF standard 35 - Materials Standards for Metal Injection Moulded Parts ISO 5832-1 Composition D ISO 10993- Biological Evaluation of Medical Devices Part 5 - tests for cytotoxicity- in Vitro methods APMA Forum 2011 17 SIRIM – AMREC (MIM) Up-Scaling of Prototype Titanium Alloy Implant for Dental and Craniofacial Application by Powder Injection Moulding Technique using Palm Oil Based Binder System Development of Inconel 718 Parts using Metal Injection Molding Technique for Aerospace Industry Application Placement Implant in Animal Model APMA Forum 2011 18 UKM MIM Binder Development Development of Palm Oil Binder for Metal Injection Molding Process Application of tapioca starch as a binder system Optimisation processes parameters Micro Metal Injection Molding Flow Analysis in Metal Injection Molding Processes – Moldflow and in house software PM Simulation of thermal mechanical properties of Warm Compaction Process APMA Forum 2011 19 Terima Kasih APMA Forum 2011 20