Ostwald viscometers

advertisement

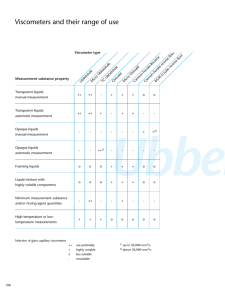

Capillary-Viscometers Contents Page Capillary viscometry 2 3 – 10 Ubbelohde viscometers, normal form 11 – 12 Ubbelohde viscometers, with additional tube and threads 13 Ubbelohde viscometers, with TC sensors 14 Micro-Ubbelohde viscometers 15 Viscometers for dilution series 15 Cannon-Fenske viscometers 16 – 17 Ostwald viscometers 18 Accessories 19 – 25 Capillary viscometry Capillary viscometry is the most precise method used to determine the kinematic viscosity of liquids with Newtonian flow behavior. For this reason, many procedures use the options of this method, unsurpassed in precision, at international, national, and plant operating levels. To fully exploit these options, the instruments being used must meet high quality requirements. Which viscometers are available ? The capillary viscometers most frequently used are the three-armed viscometers according to Ubbelohde and their variants. With this viscometer type, the sample volume must not be precisely calibrated. The liquid volume reaching the measuring point including the resulting average pressure head is automatically regulated by means of the suspended bulb level which forms at the lower end of the capillaries. Ubbelohde viscometers are available for all practical applications: Technical characteristics of glass viscometers Precision capillaries for viscometers made of borosilicate glass or other highquality glass guarantee constant quality at the highest level of international standards. The capillaries are manufactured according to methods that guarantee a consistent inner diameter. The outlet of the capillaries is adapted in its geometric form to the theoretical Hagenbach correction factor in accordance with DIN standards. The interaction of these technical glass properties ensure uniform flow-through times which then form the basis for precise results. d for absolute and relative measurements d for manual and automatic detection of meniscus passage d for normal and opaque samples d for manual and automatic rinsing d in macro and micro sizes. The two-legged viscometers, e.g. the Ostwald viscometers, continue to be used in classic methods although the level of automation with applications of these types of viscometers is limited. In addition, there are a number of viscometer types that are only of specific importance in the field of routine and research work in each instance. Each calibrated viscometer has a consecutive series number which is only awarded once by Schott. Accordingly, individual viscometers can be clearly identified even after many years. 3 Which evaluation options are available in capillary viscometry ? Viscosity is a "classic" characteristic quantity for liquids. The result provided during application of capillary viscometry is the kinematic viscosity which is measured in the unit of mm2/s (formerly centistokes, cSt). Since viscosity is temperature-dependent, the measurement temperature must be correctly adhered to and mentioned in the test results. The absolute kinematic viscosity is calculated by means of simple multiplication of the measured flow-through time in seconds with the constant K valid for the viscometer. At the same time, it is important to note that the constants for manual and for automatic measurements are basically different. The ring marks and the constant K refer to manual measurements; for measurements with Schott measuring stands, a correction factor must be taken into account. The flow-through time must be reduced by the Hagenbach correction factor. The Hagenbach correction factor, however, only achieves an amount worth mentioning with shorter flow-through times and/or smaller constants. 4 The Micro-Ubbelohde viscometers which are being used more frequently in recent times have a particularly small Hagenbach correction factor which also complies with the theoretical calculation in accordance with DIN standards even for flow-through times of 10 s. From the absolute viscosity, classic data, such as the SUS (Saybolt Universal Viscosity), SF (Saybolt Furol Viscosity) and E (Engler Degree), for instance, can be calculated directly with an equation or with the help of a calculation chart. The relative kinematic viscosity is the quotient of the viscosities of a solution and the pure solvent. This viscosity is extremely important in the food industry and especially for the evaluation of polymers. From the time when Staudinger discovered the relationships between the average chain length and the viscosity, polymers have been evaluated to an increasing extent with the help of viscosity determination. From the relative viscosity, other characteristic quantities are derived mathematically, such as the specific viscosity and the inherent viscosity as well as the viscosity number J and the K value. Influence quantities in viscometry and how can they be influenced ? The constant K for the determination of the absolute kinematic viscosity is determined with extreme care by means of comparative measurements with normal viscometers whose constants were determined at the Federal German PhysicalTechnical Institute (PTB). Accordingly, for Ubbelohde viscometers of Type 501.. to constant K = 10 mm2/s2 from the normal production, a maximum measuring uncertainty of 0.60 % related to national standards is ensured. The measuring uncertainty can be reduced further by means of a second calibration. This renewed measurement can be confirmed for Ubbelohde viscometers with a quality test certificate in accordance with DIN 55 350 Part 18. The confidence level (probability level) for this data is 95 %. – In practice, the repeating accuracy is the most important criterion in most cases. As repeating accuracy, values of < 0.1 % can be achieved, provided that the influence quantities described below are taken into account. – The constancy of temperature of the thermostatic bath being used is, in addition to the correctness of the constant, the most important influence quantity in the field of viscometry. As a rule-ofthumb, a deviation of mT = 0.1 K results in a measured value variation of 0.2...1%. Thermostats made by Schott of the type series CT 1650/. provide a constancy of temperature of mT = 0.02 ... 0.05 K, depending on the temperature range and fluctuations of ambient conditions. The required thermometers must be capable of providing readings of ± 0.01 K and must be officially calibrated. – Following the sample filling procedure, the tempering time must amount to at least 15 minutes for manual measurements. For measurements with automatic viscosity measuring instruments, shorter times can be selected because the instruments ensure thorough mixing due to constant pumping during the tempering period. The outlier test for automatic measurements makes it easier to recognise whether or not the first measured value of a series was already determined under correct temperature conditions. – The actual time measurement is performed with a stopwatch or with an automatic viscosity measuring instrument. Normally, the time measurement includes a very small degree of measuring uncertainty. Regular inspection of the time measuring instruments, however, is absolutely required. 5 Viscometers and their range of use Ubbelohde viscometers (DIN) for transparent liquids, viscosity range from 0.35 to 60,000 mm2/s, viscometers with the smallest degree of measuring uncertainty, for precision measurements, easy to fill up. Ubbelohde viscometers (ASTM) for untransparent liquids, viscosity range from 0.3 to 60,000 mm2/s, for precision measurements, easy to fill up. Dilution viscometers for transparent liquids, viscosity range from 0.3 to 100 mm2/s, for dilution series, only for automatic measurements, only for polymer applications. Micro-Ubbelohde viscometers for transparent liquids, minimum sample quantity, viscosity range from 0.3 to 800 mm2/s, measuring time ≥ 30 s, easy to fill up. TC viscometers specially designed for untransparent oils, viscosity range from 0.5 to 30,000 mm2/s, only for automatic measurements that possess one or several of the following properties: untransparent, black, electrical conductive, aqueous. 6 Ostwald viscometers viscosity range from 0.3 to 10 mm2/s, only for manual measurements, defined filling volume (formerly used for the determination of molecular weight). Micro-Ostwald viscometers for transparent liquids, for foaming liquids, viscosity range from 0.4 to 800 mm2/s, minimum sample quantity, short measuring time, defined filling volume. Cannon-Fenske routine viscometers for transparent liquids, viscosity range from 0.4 to 20,000 mm2/s. Cannon-Fenske reverse flow viscometers specially designed for untransparent liquids, viscosity range from 0.4 to 20,000 mm2/s, only for manual measurements, defined filling volume. BS/IP U-tube reverse flow viscometers specially designed for transparent or untransparent liquids, viscosity range from 6,000 to 300,000 mm2/s, only for manual measurements, defined filling volume. w ald Ca nn Fe onns ke -R ou Ca tin nn e re onve F rs en e s flo ke BS w /IP re -U ve tu rs b e e flo w icr oO st ++ ++ – + + + u u Transparent liquids automatic measurement ++ ++ + – + + – – Opaque liquids manual measurement – – – – – – + +2) Opaque liquids automatic measurement – – + +1) – – – – – Foaming liquids u u u + + + u u Liquid mixture with highly volatile components u u u + + + u u Minimum measurement substance and/or rinsing agent quantities – ++ – – + – – – High-temperature or lowtemperature measurements + + + u u u u u M O st w ald be lo TC -U b Ub M icr o hd e hd e be lo e hd be lo Ub Transparent liquids manual measurement Viscometer type Measurement substance property Selection of glass capillary viscometers ++ + u – use preferably highly suitable less suitable unsuitable 1) to 30,000 mm2/s 2) above 30,000 mm2/s 7 Overview table for estimation of the measuring uncertainty for measurements of absolute viscosity using Ubbelohde viscometers Possible influence of viscosity determination (data in percent) Influence quantity for a flow-through time of 100 s Specified measuring uncertainty of a PTB-tested normal oil (to 10 000 mm2/s) – 0.3 … 0.5 0.6 … 0.75 0.6 … 0.75 0.45 0.45 0.03 … 0.1 0.3 … 1 0.03 … 0.1 0.3 … 1 Stopwatch, standard stopwatch error, individual 0.02 0.2 0.01 0.1 Hagenbach correction for K = 0.01 Absolute error residual error following correction ≤ 1.2 0.2 ≤ 0.2 0.03 Inclination error (inclined slope) 1° 3° 0.02 0.14 0.02 0.14 0.1 … 0.2 0.1 … 0.2 Thermal expansion of glass ∆ T = 80 K 0.03 0.03 Acceleration of fall, change from 40° to 50° latitude north 1000 m change in altitude 0.1 0.02 0.1 0.02 Radiation heat (insolation) ≥2 ≥2 0…5 0…5 Soiling, particles ≥1 ≥1 Alkaline cleaning agents ≥2 ≥2 Measuring uncertainty of Ubbelohde viscometer constants from running production (K < 10 mm2/s2) Measuring uncertainty of Ubbelohde viscometer constants with manufacturer’s inspection certificate (K < 10 mm2/s2) Temperature variation ∆ T = 0.01 K ∆ T = 0.1 K Surface tension > 30 mN/m Repairs * confidence level of data = 95% 8 for a flow-through time of 200 s Viscometers within quality assurance systems Recommendations for companies that have introduced a quality assurance system in accordance with the standards DIN EN ISO 9000 ff. In this quality assurance system, an inspection of the measuring equipment is planned. The intervals and required accuracy can be defined by each company according to its own requirements. The standard DIN/ISO 100 12, Part 1 serves as a guideline in this matter. We recommend regular inspection of the viscometers in defined intervals. The constants of the viscometers to be inspected are then calculated according to the equation (see below). Within the quality assurance system in accordance with DIN EN ISO 9000 ff., retraceability of the measuring equipment to national measuring standards is demanded. This form of retraceability can be achieved by inspecting the comparative viscometers (reference measuring standards) at regular intervals at the PTB. The time intervals are defined according to the specifications made in the quality assurance system of the user. Inspection of viscometer constants 1. Calibration using comparative measurements with reference measuring standards Comparative measurements must be performed with a viscometer (reference measuring standard) which was tested at the PTB (Federal German Physical-Technical Institute) and provided with a constant. During this comparative measurement, the viscometer to be inspected and the PTBtested viscometer were placed simultaneously in the same thermostatic bath. The test liquid tested, the viscosity of which must not be known exactly, is filled into both viscometers, tempered and the flowthrough time then measured. K K PTB K PTB · t PTB K = ———————— t t PTB t 2. Calibration of the capillary viscometer with normal oils of the PTB During this calibration, a normal oil from the PTB with known viscosity is used as a reference measuring standard. The measurement is performed by means of flowthrough measurement of the PTB normal oil in the viscometer to be inspected in a temperature bath, the temperature of which must correspond precisely to the test temperature of the PTB. In this case, it is extremely important to make sure that the temperature is absolutely correct. In case of temperature variation, this will always result in a constant for the viscometer that deviates from the constant applied. A temperature variation of 0.01 K, for instance, will result in a measuring error of up to 0.01%. = constant of the inspected viscometer = constant of the viscometer inspected at the PTB = flow-through time of the viscometer inspected at the PTB (adjusted by the Hagenbachcorrection factor) = flow-through time of the inspected viscometer (adjusted by the Hagenbach correction factor) 9 3. Inspection by Schott-Geräte with quality certificates in accordance with DIN 55 350 (Part 18, 4.2.2) The inspection at Schott-Geräte is carried out by means of comparative measurements using viscometers as reference measuring standards that were tested at the PTB (corresponds to Item 1). Information on the stability of viscometer constants Each inspection (even with a certificate) can guarantee the technical measuring direction only for a limited period of time. The constants of viscometers made of the borosilicate glass DURAN®, however, can remain unchanged for long periods of time if the viscometers are kept away from altered influences. Especially extreme changes can be expected, for instance, during the use of liquids that attack glass or during glass-blowing repairs (even for apparently insignificant repairs). Liquids whose components adhere to the glass wall also cause errors. In such cases, regular cleaning is required whereby the corrosive action cleaning agent on the glass must be eliminated. For this reason, we recommend that the user should write up a special processing instructions for all important measurements and include them in his quality assurance manual in accordance with DIN EN ISO 9000 ff. In all cases the user is responsible for the correctness of his measuring and testing equipment and is not released from his responsibility for quality (cp. DIN 55 350, Part 18). Relative uncertainty of the numerical value for the specified constant based on a confidence level (probability level) of 95% 10 Viscometer type Viscometers from running production available on request with manufacturer’s certificate in accordance with DIN 55 350, Part 18 Viscometers with manufacturer’s inspection in accordance with DIN 55 350, Part 18 501.. Reference constant: K ≤ 10 mm2/s2: 0.65 % K > 10 mm2/s2: 0.8 % 0.45 % 0.60 % 525.. 532.. Reference constant: K ≤ 10 mm2/s2: 0.65 % K > 10 mm2/s2: 0.8 % 0.5 % 0.65 % 516.. 517.. 536.. 537.. all sizes: 0.8 % 0.65 % 541.. 542.. 543.. 544.. 545.. 547.. 548.. 549.. all sizes: 1.2 % 0.9 % 511.. 513.. 520.. all sizes: 1.2 % – Ubbelohde viscometers, normal form Viscometers with suspended ball level for determination of absolute and relative kinematic viscosity of liquids with Newtonian flow behaviour. The calibrated viscometers are delivered with manufacturer’s certificate in accordance with DIN 55 350, Part 18. All viscometers are provided with ring marks. This ensures that viscometers for automatic measurements can also be checked by means of manual measurements. The recommended minimum flowthrough time is 200 s. Ubbelohde viscometers (DIN) – in accordance with DIN 51 562, Part 1, ISO/DIS 3105 (BS-IP-SL) – filling quantity: 15 ... 20 ml – overall length: approx. 290 mm calibrated, with constant for manual measurements calibrated with constant, for manual measurements, automatic measurement with stand AVS/SK-HV Type No. Type No. 501 00 501 03 501 01 501 10 501 13 501 11 501 20 501 23 501 21 501 30 501 33 501 31 501 40 – – – – – – – – – – – – – – – Capillary No. acc. DIN not calibrated, without constant, for determination of relative viscosity 502 43 502 41 502 50 calibrated, with constant for automatic measurements Type No. Type No. – 530 03 530 01 530 10 530 13 – 530 20 530 23 – 530 30 530 33 – 530 40 532 00 532 03 532 01 532 10 532 13 532 11 532 20 532 23 532 21 532 30 532 33 532 31 532 40 n = kinematic viscosity in mm2/s K = constant [mm2/s2] t = flow-through time in s n =K·t K =n t t =n 0 0c 0a I Ic Ia II IIc IIa III IIIc IIIa IV IVc IVa – acc. ISO – – – I Ia – II IIa – III IIIa – IV IVa – V n =K·t K =n t t =n K 0 0c 0a I Ic Ia II IIc IIa III IIIc IIIa IV Constant K (approx.) Measuring range [mm2/s] (approx.) 0.36 0.47 0.53 0.63 0.84 0.95 1.13 1.50 1.69 2.01 2.65 3.00 3.60 4.70 5.34 6.30 0.001 0.003 0.005 0.01 0.03 0.05 0.1 0.3 0.5 1 3 5 10 30 50 100 0.3 … 1 0.5 … 3 0.8 … 5 1.2 … 10 3 … 30 5 … 50 10 … 100 30 … 300 50 … 500 100 … 1000 300 … 3000 500 … 5000 1000 … 10000 3000 … 30000 6000 … 30000 über 10000 n = kinematic viscosity in mm2/s K = constant [mm2/s2] t = flow-through time in s Capillary No. acc. DIN Capillary ø i W 0,01 [mm] acc. ISO – – – I Ia – II IIa – III IIIa – IV Capillary ø i W 0,01 [mm] Constant K (approx.) 0.36 0.47 0.53 0.63 0.84 0.95 1.13 1.50 1.69 2.01 2.65 3.00 3.60 0.001 0.003 0.005 0.01 0.03 0.05 0.1 0.3 0.5 1 3 5 10 Measuring range [mm2/s] (approx.) 0.3 … 1 0.5 … 3 0.8 … 5 1.2 … 10 3 … 30 5 … 50 10 … 100 30 … 300 50 … 500 100 … 1000 300 … 3000 500 … 5000 1000 … 10000 11 Ubbelohde viscometers (ASTM) – in accordance with ISO/DIS 3105, ASTM D 2515, ASTM D 446 calibrated, with constant for manual measurements 12 – filling quantity: 15 ... 20 ml – overall length: approx. 285 mm not calibrated, without constant, for determination of relative viscosity Type No. Type No. Capillary No. Capillary øi [mm] Constant K (approx.) Measuring range [mm2/s] (approx.) 525 00 525 03 525 01 525 10 525 13 525 20 525 23 525 30 525 33 525 40 525 43 526 00 526 03 526 01 526 10 526 13 526 20 526 23 526 30 526 33 526 40 526 43 0 0c 0b I Ic II IIc III IIIc IV IVc 0.24 0.36 0.46 0.58 0.78 1.03 1.36 1.83 2.43 3.27 4.32 0.001 0.003 0.005 0.01 0.03 0.1 0.3 1 3 10 30 0.35… 1 0.6 … 3 1 ,… 5 2 ,… 10 6 ,… 30 20 , … 100 60 , … 300 200 , … 1000 600 , … 3000 2000 , … 10000 6000 , … 30000 Ubbelohde viscometers, with additional tube and threads Viscometers with suspended ball level for determination of absolute or relative kinematic viscosity. These viscometers are preferably used for automatic measurements when an AVS 24 or AVS 26 automatic viscometer cleaner is used simultaneously. The additional filling and cleaning tube and the glass thread ensure safe ope- rational use. The calibrated viscometers are delivered with manufacturer’s certificate in accordance with DIN 55 350, Part 18. The ring marks that are also present serve as auxiliary marks in case the viscometers must be checked by means of manual measurements. Ubbelohde viscometers (DIN) – filling quantity: 18 ... 22 ml – in accordance with ISO/DIS 3105, DIN 51 562, Part 1, BS 188, NFT 60-100 – overall length: approx. 290 mm calibrated, with constant for automatic measurements Capillary No. acc. DIN acc. ISO Capillary øi [mm] 0c 0a I Ic II IIc III IIIc IV – – I Ia II IIa III IIIa IV 0.47 0.53 0.63 0.84 1.13 1.50 2.01 2.65 3.60 Type No. 541 03 541 01 541 10 541 13 541 20 541 23 541 30 541 33 541 40 Ubbelohde viscometers (ASTM) – the technical measurement characteristics are in accordance with ISO/DIS 3105, ASTM D 2515, ASTM D 446 Constant K (approx.) 0.003 0.005 0.01 0.03 0.1 0.3 1 3 10 Measuring range [mm2/s] (approx.) 0.5 0.8 1.2 3 , 10 , 30 , 100 , 300 , 1000 , … 3 … 5 … 10 … 30 … 100 … 300 … 1000 … 3000 … 6000 – filling quantity: 18 ... 22 ml – overall length: approx. 290 mm calibrated, with constant for automatic measurements Type No. Capillary No. Capillary øi [mm] Constant K (approx.) Measuring range [mm2/s] (approx.) 545 00 545 03 545 01 545 10 545 13 545 20 545 23 545 30 545 33 545 40 545 43 0 0c 0b I Ic II IIc III IIIc IV IVc 0.24 0.36 0.46 0.58 0.78 1.03 1.36 1.83 2.43 3.27 4.32 0.001 0.003 0.005 0.01 0.03 0.1 0.3 1 3 10 30 0.35 … 1 0.6 … 3 1.8 … 5 2.2 … 10 6 , … 30 20 , … 100 60 , … 300 200 , … 1000 600 , … 3000 2000 , …10000 6000 , …30000 13 Ubbelohde viscometers with TC sensors Viscometers with suspended ball level for determination of absolute and relative kinematic viscosity of liquids with Newtonian flow behaviour. The measuring levels are marked by TC sensors. The meniscus passage is detected due to the different conductivity of the liquid phase and the gas phase. A measurement stand of the type series AVS/S is not required. TC viscometers can be used to determine the kinematic viscosity of all liquids with Newtonian flow behaviour. They are especially suitable for liquids that cannot be detected with other systems: untransparent and/or black and/or electric conductive measuring samples. TC viscometers are manufactured from technical glass types with an expansion coefficient of a = approx. 9 • 10–6 . Due to the electric properties of TC sensors, it is important to make that a type is selected that is suitable for the required application temperature. TC viscometers with additional filling and cleaning tube and with glass thread – the technical measurement characteristics are in accordance with DIN 51562, Part 1, ISO/DIS 3105 (BS-IP-SL) – for use in combination with an automatic viscosity measuring instrument and an AVS 24 or AVS 26 automatic viscometer cleaner – filling quantity: 18 ... 22 ml – overall length: approx. 355 mm calibrated, with constant for automatic measurements 14 + 70 … + 150°C Capillary No. Capillary øi [mm] Constant K (approx.) Measuring range [mm2/s] (approx.) – – 544 10 544 13 – 544 20 544 23 – 544 30 544 33 – 544 40 544 43 – 0c 0a I Ic Ia II IIc IIa III IIIc IIIa IV IVc IVa 0.47 0.53 0.64 0.84 0.95 1.15 1.51 1.69 2.05 2.70 3.00 3.70 4.90 5.34 0.003 0.005 0.01 0.03 0.05 0.1 0.3 0.5 1 3 5 10 30 50 0.5 … 3 0.8 … 5 1.2 … 10 3 … 30 5 … 50 10 … 100 30 … 300 50 … 500 100 … 1000 300 … 3000 500 … 5000 1000 … 10000 3000 … 20000 5000 … 30000 Type No. Type No. Type No. + 10 … + 80°C – 40 … + 30°C 542 03 542 10 542 13 542 20 542 23 542 21 542 30 542 33 542 31 542 40 542 43 542 41 – – 543 10 543 13 – 543 20 543 23 – 543 30 543 33 – 543 40 543 43 543 41 Micro-Ubbelohde viscometers Viscometers for dilution series Viscometers with suspended ball level for determination of absolute and relative kinematic viscosity of liquids with Newtonian flow behaviour. Due to their design, these viscometers are especially suitable for measurement of small liquid quantities and for particularly short running times. All viscometers are provided with ring marks. This ensures that viscometers for automatic measurements can also be checked by means of manual measurements. calibrated, with constant for manual measurements calibrated, with constant for automatic measurements Micro-Ubbelohde viscometers (DIN) The calibrated viscometers are delivered with manufacturer’s certificate in accordance with DIN 55 350, Part 18. For measurements with automatic viscosity measuring instruments, another constant is valid. This constant is determined by multiplication of the constant K with the correction factor F. – in accordance with DIN 51 562, Part 2 – filling quantity: 3 ... 4 ml – overall length: approx. 290 mm not calibrated, without constant, for determination of relative viscosity Type No. Type No. Type No. Capillary No. Capillary øi [mm] 536 10 536 13 536 20 536 23 536 30 537 10 537 13 537 20 537 23 537 30 538 10 538 13 538 20 538 23 538 30 MI M Ic M II M IIc M III 0.40 0.53 0.70 0.95 1.26 Constant K (approx.) 0.01 0.03 0.1 0.3 1 Measuring range [mm2/s] (approx.) 0.4 … 6 1.2 … 18 4 … 60 12 … 180 40 … 800 Viscometers for dilution series Viscometers with suspended ball level designed according to the principle of the Ubbelohde viscometers for determination of the limit viscosity number of polymers. The limit viscosity number is determined automatically in combination with viscosity measuring instruments and piston burette, type AVS 20, made by Schott. – filling quantity: 15 ... 75 ml – overall length: approx. 290 mm not calibrated, for automatic measurements Type No. Capillary No. Capillary øi [mm] Constant K (approx.) Measuring range [mm2/s] (approx.) 531 00 531 03 531 01 531 10 531 13 531 20 0 0c 0a I Ic II 0.36 0.47 0.53 0.64 0.84 1.15 0.001 0.003 0.005 0.01 0.03 0.1 0.35 … 0.6 0.5 … 2 0.8 … 3 1.2 … 6 3 … 20 10 … 60 15 Cannon-Fenske viscometers Cannon-Fenske routine viscometers Comply with standards ISO/DIS 3105, ASTM D 2515, BS 188 with respect to technical measuring specifications. – are suitable for all Newtonian liquids with a viscosity of 0.35 ... 20,000 mm2/s. – the present design has, as a supplement to the standard, a deepening in the lower bend. Accordingly, these viscometers can also be used for automatic measurements. – filling quantity: approx. 7 ... 10 ml – overall length: approx. 245 mm calibrated, with ring mark, with constant for manual mesurement for automatic measurement Type No. Type No. Capillary No. Capillary øi [mm] Constant K (approx.) 513 00 513 03 513 01 513 10 513 13 513 20 513 23 513 21 513 30 513 33 513 40 513 43 520 00 520 03 520 01 520 10 520 13 520 20 520 23 520 21 520 30 520 33 520 40 520 43 25 50 75 100 150 200 300 350 400 450 500 600 0.30 0.44 0.54 0.63 0.78 1.01 1.27 1.52 1.92 2.35 3.20 4.20 0.002 0.004 0.008 0.015 0.035 0.1 0.25 0.5 1.2 2.5 8 20 Cannon-Fenske reverse flow viscometers Comply with standards ISO/DIS 3105, ASTM D 2515, ASTM D 446, Measuring range [mm2/s] (approx.) 0.4 … 1.6 0.8 … 3.2 1.6 … 6.4 3 … 15 7 … 35 20 … 100 50 … 200 100 … 500 240 … 1200 500 … 2500 1600 … 8000 4000 … 20000 NF T 60 - 100 with respect to technical measuring specifications. – filling quantity: approx. 12 ml – overall length: approx. 295 mm calibrated, with 3 ring marks, with 2 constants, only for manual measurement 16 Type No. Capillary No. Capillary øi [mm] Constant K (approx.) 511 00 511 03 511 01 511 10 511 13 511 20 511 23 511 21 511 30 511 33 511 40 511 43 25 50 75 100 150 200 300 350 400 450 500 600 0.31 0.42 0.54 0.63 0.78 1.02 1.26 1.48 1.88 2.20 3.10 4.00 0.002 0.004 0.008 0.015 0.035 0.1 0.25 0.5 1.2 2.5 8 20 Measuring range [mm2/s] (approx.) 0.4 … 1.6 0.8 … 3.2 1.6 … 6.4 3 … 15 7 … 35 20 … 100 50 … 200 100 … 500 240 … 1200 500 … 2500 1600 … 8000 4000 … 20000 Cannon-Fenske routine viscometers Comply with standards ISO/DIS 3105, ASTM D 2515, BS 188 with respect to technical measuring specifications. These viscometers are preferably used for automatic measurements when an AVS 24 or AVS 26 automatic viscometer cleaner is used simultaneously. The additional filling and cleaning tube and the glass thread ensure safe operational use. The calibrated viscometers are delivered with manufacturer’s certificate in accordance with DIN 55 350, Part 18. – are suitable for all Newtonian liquids with a viscosity of 0.35 ... 20,000 mm2/s. – filling quantity: approx. 7 ... 12 ml – overall length: approx. 245 mm calibrated, with ring marks, with constant, for automatic measurement Type No. Capillary No. Capillary øi [mm] Constant K (approx.) Measuring range [mm2/s] (approx.) 546 00 546 03 546 01 546 10 546 13 546 20 546 23 546 21 546 30 546 33 546 40 546 43 25 50 75 100 150 200 300 350 400 450 500 600 0.30 0.44 0.54 0.63 0.78 1.01 1.27 1.52 1.92 2.35 3.20 4.20 0.002 0.004 0.008 0.015 0.035 0.1 0.25 0.5 1.2 2.5 8 20 0.4 … 1.6 0.8 … 3.2 1.6 … 6.4 3 … 15 7 … 35 20 … 100 50 … 200 100 … 500 240 … 1200 500 … 2500 1600 … 8000 4000 … 20000 17 Ostwald viscometers Ostwald viscometers – filling quantity: 3 ml – overall length: approx. 220 mm calibrated, with ring marks, without constant, for manual measurement Type No. Capillary øi [mm] Transit time for water approx. [s] 509 03 509 04 509 05 509 06 509 07 0.3 0.4 0.5 0.6 0.7 250 75 30 15 10 Micro-Ostwald viscometers are suitable for measurements of small liquid quantities even with extreme formation of foam. calibrated, with ring marks, with constant, for manual measurement 18 calibrated, with ring marks, with constant for automatic measurement Constant K (approx.) For use from [mm2/s] (approx.) 0.004 0.01 0.03 0.07 0.1 0.3 1 2.5 5.5 10 – filling quantity: 2 ml – overall length: approx. 290 mm not calibrated, with ring marks, without constant Type No. Type No. Type No. Capillary No. Capillary øi [mm] 516 10 516 13 516 20 516 23 516 30 517 10 517 13 517 20 517 23 517 30 518 10 518 13 518 20 518 23 518 30 I Ic II IIc III 0.43 0.60 0.77 1.00 1.36 Constant K (approx.) 0.01 0.03 0.1 0.3 1 Measuring range [mm2/s] (approx.) 0.4 … 6 1.2 … 18 4 … 60 12 … 180 40 … 800 Accessories Brackets and stands All brackets and stands are designed to ensure that the viscometers are held vertically. They also protect the viscometers from breakage. The maximum deviation is < 1°. In application in conjunction with Schott and other commercially available see-through thermostats the viscometers can only be used with the appropriate stand or bracket. For DIN Ubbelohde viscometers that are used as reference measuring standard, specifically modified bracket (VZ 5840) must be used. Brackets made of VA steel suitable for use with all Ubbelohde viscometers for manual and automatic measurements Type No. 053 92 053 92 VZ 5840 (accessory for reference measuring standard) suitable for use with Ubbelohde viscometers with TC sensors Type No. 053 93 053 93 suitable for use with all reverse flow viscometers (Cannon-Fenske and BS/IP U-tube viscometers) for manual and automatic measurements (not illustrated) Type No. 053 96 suitable for use with Micro-Ostwald viscometers for manual and automatic measurements Type No. 053 97 053 97 19 Accessories Stands made of PTFE suitable for use with Cannon-Fenske routine viscometers for automatic measurements only (not illustrated) Type no. 065 99 Brackets for reference measuring standard DIN Ubbelohde viscometers which are used as testing standard should be stored in a specially modified viscometer bracket (053 92) according to official inspection / calibration authorities. The extension set for the test standard (VZ 5840) guarantees vertical slope with a maximum deviation of < 1° and the centered positioning of the capillaries. VZ 5840 Type No. VZ 5840 Control thermometers 20 Type No. Measuring range °C Graduation °C VZ 2801 – 5 to + 38 1/10 VZ 2802 + 33 to + 67 1/10 VZ 2803 + 66 to + 102 1/10 VZ 2804 + 95 to + 152 1/10 VZ 2901 + 20 to + 25 1/100 VZ 2907 + 22 to + 27 1/100 VZ 2904 + 35 to + 40 1/100 VZ 2908 + 37 to + 42 1/100 VZ 2905 + 45 to + 50 1/100 VZ 2906 + 97 to + 101 1/100 VZ 2909 + 132 to + 137 1/100 Accessories ViscoPump The ViscoPump VZ 5625 used in manual measurements and semi-automatic measurements to suck and pump up solutions: – filling of viscometers – rinsing with the next sample – sucking up between manual measurements – emptying of viscometers without removing them from the thermostatic bath Since the materials used and the connections of the ViscoPump VZ 5625 are made of PTFE or stainless steel, the pump is suitable for use with aggressive mediums. The range of use for semi-automatic processing of samples, e.g. with a viscosity measuring instrument AVS 360 is possible up to a viscosity of 30,000 mm2/s. For semi-automatic processing work, the PTFE hose combination with stand (see illustration) and the waste bottle, type no. VZ 5624, are used. VZ 5625 Type No. VZ 5625 Polyamide bracket for use with Cannon-Fenske routine viscometers, Cannon-Fenske reverse flow viscometers and all Ostwald viscometers for manual measurements only Type No. 064 99 PTFE bracket for use with Cannon-Fenske routine viscometers, for automatic measurements only (not illustrated) Type No. 065 99 064 99 21 Accessories 2 Temperature stabilization jackets 3 4 1 In the absence of a see-through thermostat the temperature of capillary viscometers can be stabilized in this type of jacket using circulation thermostats in the temperature range 0 to 180°C. The shape of the jacket and the number of holes in the support plate depend upon the type of viscometer being used. The support plate has been designed to facilitate changing the viscometer when required. An additional hole is provided in the support plate so that a control thermometer can be fitted. A quick-action seal simplifies changing viscometers. Temperature stabilization jacket with support plate for Ubbelohde viscometers Type No. Item No. 577 00 Thermometer Complete, without viscometer Component parts 577 01 238 00 225 34 072 34 1 2 3 4 Temperature stabilization jacket, straight Support plate with 4 silicone rings (d = 4, 6, 8 and 10 mm) Silicone O-ring, ND 60 Quick-action seal, ND 60 2 3 4 1 Temperature stabilization jacket with support plate Thermometer for Cannon-Fenske routine viscometers Type No. Item No. 578 00 Complete, without viscometer Component parts 578 01 239 00 225 34 072 34 22 1 2 3 4 Temperature stabilization jacked, angled Support plate with 3 silicone rings (d = 6, 8 and 10 mm) Silicone O-ring, ND 60 Quick-action seal, ND 60 Accessories Temperature stabilization jacket with support plate 2 for Cannon-Fenske reverse flow viscometers and Ostwald viscometers 3 4 Type No. Item No. 579 00 Complete, without viscometer Component parts 1 577 01 239 00 225 34 072 34 1 2 3 4 Temperature stabilization jacket, straight Support plate with 3 silicone rings (d = 6, 8 and 10 mm) Silicone O-ring, ND 60 Quick-action seal, ND 60 Thermometer Silicone rings Type No. d mm D mm h mm 228 11 228 14 228 16 228 17 4 6 8 10 10 16 16 16 5 5 5 5 h KPG auxiliary pipette used for determining the most suitable viscometer capillary number. Type No. 576 99 The KPG auxiliary pipette is filled with the fluid which is then discharged in drops through a KPG capillary tube. The time elapsing between each drop (drop rate) indicates the most applicable viscometer constant as shown: 1 second or less with constant 0.01 1 to 5 seconds with constant 0.1 5 to 35 seconds with constant 1 35 seconds or more with constant 10 Drip pan stainless steel This accessory facilitates emptying and drying viscometers Type No. 522 01 23 AVS measuring stands and hose sets AVS measuring stands – Measuring stands of the type series AVS/S can be used to measure the flow-through time in viscometers automatically. – The measuring stands can be connected to all measuring instruments made by SCHOTT for automatic measurement of viscosity and operate with all standard viscometers for repetitive measurements. – Automatic measurements have the following advantages: – the repetitive standard deviation is less than for manual measurements – the measurement is free from subjective factors of influence – the results can be printed out and/or be automatically documented on data memory system – automatic processing of sample series is available. – The use of different materials ensures unproblematic adaptation to existing measurement temperatures and applications. – The measuring stands or brackets can be exchanged at random. This is provided by the precision applied during production. – The distance between the levels of the automatic optoelectronic unloading system is 40.00 mm ± 0.03 mm. When measuring stands are replaced, this results in a standard deviation of VK = 0.05% for Ubbelohde viscometers. – For repetitive measurements with viscosity measuring instruments and Ubbelohde viscometers with measuring stands, the standard deviation VK = 0.03%. – Manually calibrated Ubbelohde viscometers can also be used in AVS measuring stands. If the automatic sensing levels do not correspond to the ring marks, the superimposed meniscus detection system will provide a higher constant. The difference amounts to 0.1% per millimetre of height offset. Required hose/cable combinations Viscometer type 517 .. 520 .. 530 .. 532 .. 537 .. Measuring instrument 1) 2) 3) 24 540 .. 541 .. 545 .. 546 .. 542 .. 543 .. 544 .. 547 .. 548 .. 549 .. 552 .. 553 .. 554 .. 531 .. (3) Hose/cable combinations AVS 300 and AVS 310 VZ 5505(1) or VZ 5501(2) VZ 5621(1) and VZ 5505(1) AVS 350 VZ 5505(1) or VZ 5501(2) VZ 5623(2) AVS 360 and AVS 361 VZ 5104(1) or VZ 5622(2) VZ 5623(2) AVS 400 and AVS 410 VZ 5505(1) or VZ 5501(2) VZ 5621(1) and VZ 5505(1) AVS 440 and AVS 450 VZ 5505(1) or VZ 5501(2) VZ 5621(1) and VZ 5505(1) – – VZ 5857(1) VZ 5606(1) VZ 5505(1) and VZ 6226 VZ 5857(1) VZ 5623(2) VZ 5104(1) or VZ 5622(2) VZ 5104(1) or VZ 5622(2) – VZ 5606(1) – VZ 5857(1) VZ 5505(1) and VZ 6226 VZ 5857(1) Silicon tube PTFE tube (aggressive mediums) The necessary connection tube TZ 1607 (l=1.5 m) is included at the piston burette ViscoDoser AVS 20. AVS measuring stands Measuring stands AVS/S AVS/S-HT AVS/SK AVS/S-CF AVS/SK-V Available viscometers Ubbelohde viscometers in accordance with DIN, ASTM, ISO 3105, Micro-Ubbelohde viscometers, Micro-Ostwald viscometers Cannon-Fenske routine viscometers Ubbelohde dilution viscometers Temperature range –80 to +100°C –80 to +100°C 0 to 60°C other temperature ranges available on request Suitable for use with the measuring units AVS 300, AVS 310, AVS 350, AVS 360, AVS 361, AVS 400, AVS 410, AVS 440, AVS 450, AVS 500 Suitable for use with the thermostatic baths CT 1450/2, CT 1450/3, CT 1450/4, CT 1450/2 HT, CT 1450/4 HT, CT 1450/2 TT, CT 1450/4 TT, CT 1450/2 M, CT 1650/2, CT 1650/4, CT 1650/2 HT, 1650/4 HT, CT 1650/2 TT, CT 1650/4 TT, CT 1650/2 M, CT 050/2, CT 052/2 Suitable brackets (type no.) 05392 05397 Electrical connection Cable VZ 6225 for all measuring stands to all instruments (is included in hose sets VZ 5505, VZ 5622 and VZ 5857), control lamp as function display –80 to +200°C 0 to 60°C no bracket required Distance bet40.00 mm w 0.03 mm at 25°C ween the measuring levels Signal transmission Optically using optical fibres from the measuring level in the stand head, converted into analogue signal from stand to measuring instrument Material Aluminium, TiO2-anodized PVDF, stainless steel Aluminium, TiO2-anodized PVDF, stainless steel Dimensions 90 x 447 x 90 (W x H x D) mm 90 x 496 x 90 90 x 447 x 90 90 x 447 x 90 90 x 447 x 90 Weight (kg) appr. 1.0 1.25 0.8 1.0 0.8 Hose/cable combination VZ 5505 Hose/cable combination VZ 5857, magnetic stirring rods, fastening springs for viscometer Accessories included in scope of delivery Bracket type no. 05392 for Ubbelohde viscometers, hose/cable combination VZ 5505 Note: When TC viscometers are being used, a bracket type no. 05393, with the necessary hose set is required only. A measuring stand is not required. 25 55018 e 42/Makro 0199 pdf SCHOTT Instruments GmbH Postfach 2443 D-55014 Mainz info@schott-instruments.com www.schott-instruments.com Telefon +49(0) 6131/66-5111 Telefax +49(0) 6131/66-5001