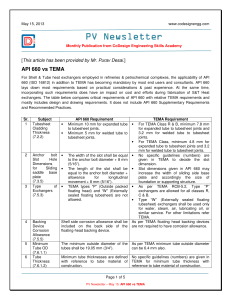

TEMA/ASME Exchanger

advertisement

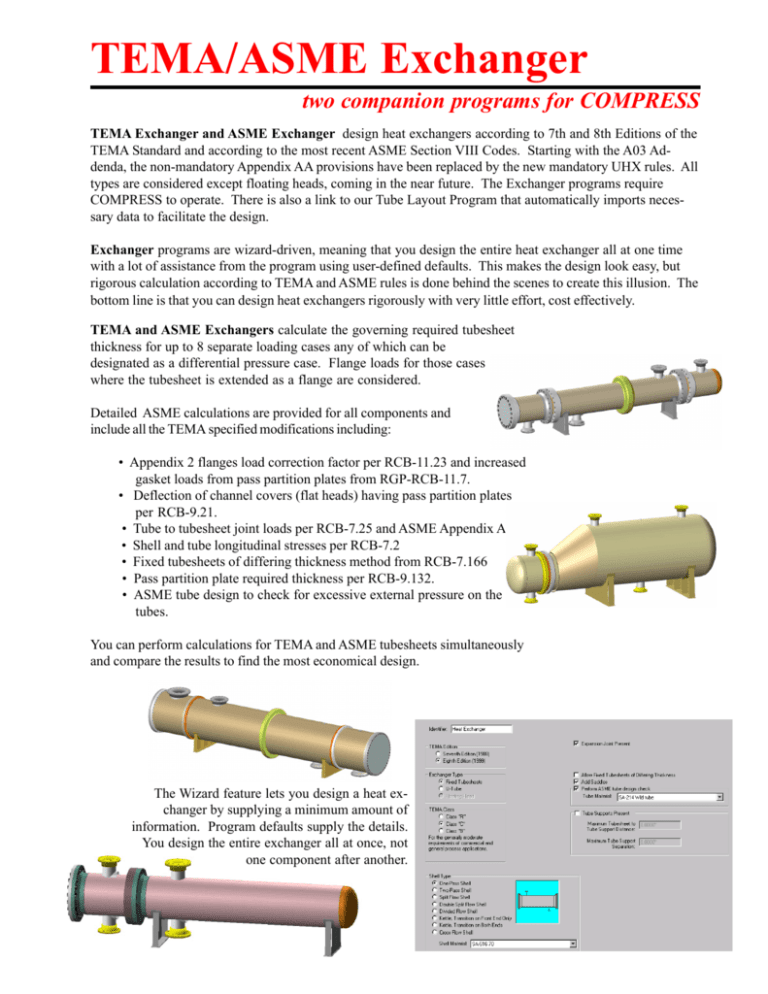

TEMA/ASME Exchanger two companion programs for COMPRESS TEMA Exchanger and ASME Exchanger design heat exchangers according to 7th and 8th Editions of the TEMA Standard and according to the most recent ASME Section VIII Codes. Starting with the A03 Addenda, the non-mandatory Appendix AA provisions have been replaced by the new mandatory UHX rules. All types are considered except floating heads, coming in the near future. The Exchanger programs require COMPRESS to operate. There is also a link to our Tube Layout Program that automatically imports necessary data to facilitate the design. Exchanger programs are wizard-driven, meaning that you design the entire heat exchanger all at one time with a lot of assistance from the program using user-defined defaults. This makes the design look easy, but rigorous calculation according to TEMA and ASME rules is done behind the scenes to create this illusion. The bottom line is that you can design heat exchangers rigorously with very little effort, cost effectively. TEMA and ASME Exchangers calculate the governing required tubesheet thickness for up to 8 separate loading cases any of which can be designated as a differential pressure case. Flange loads for those cases where the tubesheet is extended as a flange are considered. Detailed ASME calculations are provided for all components and include all the TEMA specified modifications including: • Appendix 2 flanges load correction factor per RCB-11.23 and increased gasket loads from pass partition plates from RGP-RCB-11.7. • Deflection of channel covers (flat heads) having pass partition plates per RCB-9.21. • Tube to tubesheet joint loads per RCB-7.25 and ASME Appendix A-2. • Shell and tube longitudinal stresses per RCB-7.2 • Fixed tubesheets of differing thickness method from RCB-7.166 • Pass partition plate required thickness per RCB-9.132. • ASME tube design to check for excessive external pressure on the tubes. You can perform calculations for TEMA and ASME tubesheets simultaneously and compare the results to find the most economical design. The Wizard feature lets you design a heat exchanger by supplying a minimum amount of information. Program defaults supply the details. You design the entire exchanger all at once, not one component after another. The same degree of printing control is provided as in COMPRESS: you can print a full or partial report directly or save to file as a self-expanding set of HTML files or, if you have Adobe Acrobat, as a pdf document. The output report is presented in a novel format which shows the calculation method and equations used, with results, but excludes non-limiting calculations in order to reduce report size. For example: Flanged and flued expansion joints are analyzed in depth. Expansion joint spring rate calculation per RCB-8.3 through RCB-8.6 is included as is the stress analysis of RCB-8.81 and RCB-8.82. Stresses are classified as primary or secondary. Stresses exceeding allowable limits are reported. User specified (purchased) expansion joints can also be specified. An optional ASME Appendix CC cycle life calculation is provided. Both TEMA and ASME material properties sources are provided, including coefficient of thermal expansion, elastic modulus allowable stress etc. User defined inputs also are permitted. Optional Tube Layout Program is now available! Discount given if purchased together with Exchanger. So how do I run the demo? Install the COMPRESS demo. Then choose File/New Heat Exchanger. 11221 Richmond Ave Ste C-103 Houston, Texas 77082 Ph 281-497-5705, FAX 281-497-5839 sales@codeware.com www.codeware.com