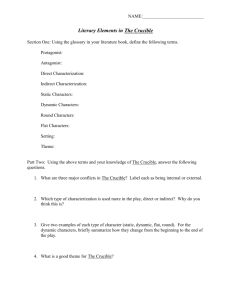

Foundry

advertisement