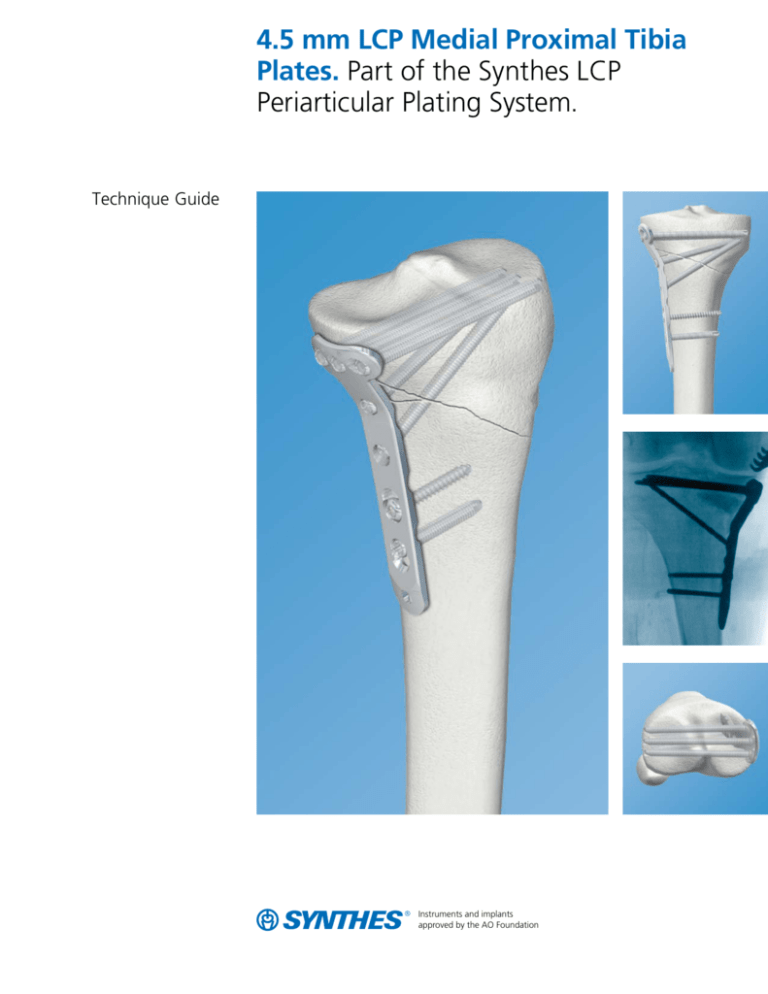

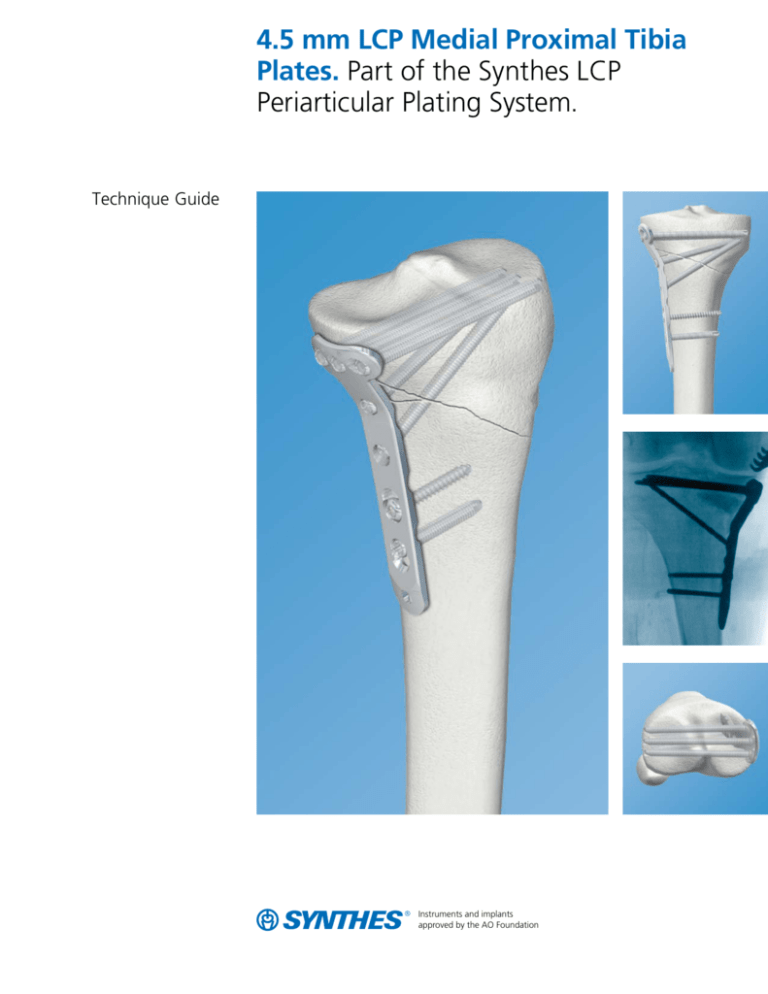

4.5 mm LCP Medial Proximal Tibia

Plates. Part of the Synthes LCP Periarticular Plating System.

Technique Guide

Instruments and implants

approved by the AO Foundation

Table of Contents

Introduction

4.5 mm LCP Medial Proximal Tibia Plates

2

AO Principles

4

Indications5

Surgical Technique

Product Information

Preparation and Planning

6

Reduce Articular Surface

7

Position Plate

8

Insert Proximal Screws

10

Reduce Plate to Plateau

12

Insert Screws in Plate Shaft

15

Screws20

Set Lists

22

Image intensifier control

Synthes

4.5 mm LCP Medial Proximal Tibia Plates

The Synthes 4.5 mm LCP Medial Proximal Tibia Plate is part

of the LCP Periarticular Plating System, which merges locking

screw technology with conventional plating techniques.

The 4.5 mm LCP medial proximal tibia plate is available in

stainless steel and has a limited-contact shaft profile. The

head and neck portions of the plate accept 5.0 mm cannulated locking and 5.0 mm cannulated conical screws. The

screw hole pattern allows a raft of subchondral locking screws

to buttress and maintain reduction of the articular surface.

This provides fixed-angle support to the tibial plateau.

The locking compression plate (LCP) has Combi holes in the

plate shaft that combine a dynamic compression unit (DCU)

hole with a locking screw hole. The Combi hole provides

the flexibility of axial compression and locking capability

throughout the length of the plate shaft.

Note: For information on fixation principles using conventional and locked plating techniques, please refer to the

Synthes Large Fragment Locking Compression Plate (LCP)

Technique Guide.

2

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Available in left and right plates, in

implant quality 316L stainless steel.

Plate head

– Anatomically contoured to approximate the anteromedial proximal tibia.

– Three convergent threaded screw

holes accept 5.0 mm cannulated

locking screws or 5.0 mm

cannulated conical screws.

– Two 2.0 mm holes for preliminary

fixation with K-wires, or meniscal

repair with sutures.

Plate shaft

– The two angled locking holes distal

to the plate head accept a 5.0 mm

cannulated locking screw or 5.0 mm

cannulated conical screw to secure

the plate position. The hole angles

allow the locking screws to converge

with two of the three screws in the

plate head.

– Combi holes, distal to the angled

locking holes, combine a DCU hole

with a threaded locking hole. The

Combi holes accept 4.0 mm or

5.0 mm locking screws in the threaded portion of the hole and

4.5 mm cortex screws or 4.5 mm

shaft screws in the DCU portion of

the hole.

– Available with 4, 6, 8, 10, 12, 14, or

16 Combi holes in the plate shaft.

– Limited-contact profile.

Two 2.0 mm holes for

K-wires and sutures

Three locking screw holes

accept 5.0 mm cannulated

locking or 5.0 mm cannulated

conical screws

Angled locking holes accept

5.0 mm cannulated locking

screws or 5.0 mm cannulated

conical screws and support

the proximal screws

Combi holes combine a

DCU hole with a threaded

locking hole

For articulated

tension device

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes3

AO Principles

In 1958, the AO formulated four basic principles, which

have become the guidelines for internal fixation.1 They are:

Anatomic reduction

Fracture reduction and fixation to restore anatomical

relationships.

Stable fixation

Stability by fixation or splintage, as the personality of

the fracture and the injury requires.

Preservation of blood supply

Preservation of the blood supply to soft tissue and bone

by careful handling.

Early, active mobilization

Early, active mobilization of the part and patient.

1. Müller ME, M Allgöwer, R Schneider, H Willenegger. Manual of Internal Fixation.

3rd Edition. Berlin: Springer-Verlag. 1991.

4

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Indications

The 4.5 mm LCP medial proximal tibia plates are intended

to buttress metaphyseal fractures of the medial tibia plateau,

split-type fractures of the medial tibia plateau, medial split

fractures with associated depressions and split or depression

fractures of the medial tibia plateau. The plates may also be

used for fixation of the proximal quarter (lateral and medial) of

the tibia, as well as segmental fractures of the proximal tibia.

The 4.5 mm version may also be used for fixation of

nonunions and malunions of the medial proximal tibia

and tibia shaft, as well as opening and closing wedge

tibial osteotomies.

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes5

Preparation and Planning

1

Preparation and preoperative planning

Required Set

01.240.201 Periarticular LCP Plating System,

with 5.0 mm Locking Screws

or

01.240.209Periarticular LCP Plating System,

with 4.0 mm Locking Screws

Also Available Sets

01.240.401Periarticular LCP Plating System,

with 5.0 mm Titanium Locking Screws

105.210Periarticular LCP Plating System

Instrument and Screw Set

Complete the preoperative radiographic assessment and

prepare the preoperative plan. Determine plate length and

instruments to be used.

Important: Determine proximal screw placement and screw

lengths to ensure proper screw placement in the metaphysis.

Position the patient supine on a radiolucent operating table.

Visualization of the proximal tibia under fluoroscopy in both

the lateral and AP views is necessary.

6

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Reduce Articular Surface

2

Reduce articular surface

Optional Sets

115.700

Large Distractor Set

115.720Large External Fixator Set with Self-Drilling

Schanz Screws

Instruments

394.35

Large Distractor

or

External Fixator

Technique Tip: Prior to reduction, application of an external

fixator or large distractor may facilitate visualization and

reduction of the joint.

Reduce the fracture fragments and confirm reduction using

image intensification. Fragments may be reduced using

independent Kirschner wires; however, K-wire holes are also

provided on the plate to help achieve provisional reduction,

plate position, or fixation.

The locking screws do not provide interfragment or plateto-bone compression; therefore, any desired compression

must be achieved with traditional lag screws or 5.0 mm

cannulated conical screws. The articular fragments must

be reduced and compression must be obtained prior to

applying the 4.5 mm LCP medial proximal tibia plate with

locking screws.

Technique Tip: To verify that independent lag screws will

not interfere with plate placement, hold the plate to the

bone.

Apply the distractor to assist in the visualization and

reduction of the joint.

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes7

Position Plate

3

Determine plate position

Instruments

292.6522.0 mm Non-Colored Threaded Guide Wire,

230 mm, spade point

324.174

2.5 mm Wire Guide, for 5.0 mm screws

Using anatomic landmarks and fluoroscopy, mount the plate

on the intact or reconstructed plateau without attempting to

reduce the distal portion of the fracture.

8

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Mount the plate

With a 2.5 mm wire guide for 5.0 mm screws attached

to the central hole in the head of the plate, insert a 2.0 mm

threaded wire through a K-wire hole. Readjust the plate

position, if necessary. Place a second wire in the other

K-wire hole to prevent rotation of the plate and to secure

provisional fixation of the plate to the tibial plateau.

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes9

Insert Proximal Screws

4

Insert proximal provisional (conical) screw

Instruments

310.243

2.5 mm Drill Tip Guide Wire

310.6344.3 mm Cannulated Drill Bit, quick coupling,

for 5.0 mm screws

319.701

Cannulated Screw Measuring Device

Insert guide wire

While the plate is placed against the bone, insert the 2.5 mm

drill tip guide wire through the 2.5 mm wire guide in the

central screw hole in the plate head. It is imperative to drill

using fluoroscopy to ensure proper screw trajectory and

screw placement. Advance the guide wire through to the

lateral cortex or to the desired screw tip location.

Determine proper screw trajectory by using clinical

examination and fluoroscopy to confirm:

– Guide wire trajectory in the proximal locking hole is

parallel to the joint and the reduction is maintained;

– That the screw and plate placement will be consistent

with the preoperative plan; and

– Alignment of the plate to the shaft of the tibia is correct

in both the AP and lateral views. Placement of the plate

at this point will determine final flexion/extension.

Measure for screw length

Measure for screw length using the cannulated screw

measuring device.

Note: The measuring device must contact the end of the

wire guide for an accurate measurement.

Technique Tip: The self-drilling, self-tapping flutes of the

5.0 mm cannulated conical screws make predrilling and

pretapping unnecessary in most cases. If necessary, in dense

bone, the lateral cortex can be predrilled with the 4.3 mm

cannulated drill bit.

10

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Instruments

314.05

Cannulated Hexagonal Screwdriver

314.23

Cannulated Hexagonal Screwdriver Shaft

511.771

Torque Limiting Attachment, 4 Nm

or

511.774Torque Limiting Attachment, 4 Nm,

for AO Reaming Coupler

Use the 4.0 mm cannulated hexagonal screwdriver to remove

the wire guide. Using the torque limiting attachment (TLA),

insert a 5.0 mm cannulated conical screw in the central

hole in the plate head to pull the plate to the bone and gain

interfragmentary compression through the plate. Insert a

screw that is approximately 5 mm shorter than the measurement from the cannulated screw measuring device.

Warning: If the TLA is unavailable, do not tighten the screws

to the plate using power. Perform final tightening by hand.

Reminder: Locking screws are not lag screws. When

interfragmentary compression is desired, use 5.0 mm

cannulated conical screws.

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes11

Reduce Plate to Plateau

5

Secure the plate to the plateau

Instruments

310.243

2.5 mm Drill Tip Guide Wire

314.05

Cannulated Hexagonal Screwdriver

314.23

Cannulated Hexagonal Screwdriver Shaft

319.701

Cannulated Screw Measuring Device

324.174

2.5 mm Wire Guide, for 5.0 mm screws

511.771

Torque Limiting Attachment, 4 Nm

or

511.774Torque Limiting Attachment, 4 Nm,

for AO Reaming Coupler

Attach 2.5 mm wire guides for 5.0 mm screws to the anterior

and posterior holes in the head of the plate. Insert 2.5 mm

drill tip guide wires through these wire guides to the desired

screw tip location. Use the cannulated screw measuring device

to measure for screw length. Use the 4.0 mm cannulated

hexagonal screwdriver to remove the wire guides.

Remove the 2.0 mm Kirschner wires.

12

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Insert the appropriate length 5.0 mm cannulated locking

screws into the bone with power using the torque limiting

attachment (TLA) and cannulated hexagonal screwdriver

shaft.

Warning: If the torque limiting attachment (TLA) is unavailable, do not tighten the screws to the plate using power.

Perform final tightening by hand.

Technique Tip: The self-drilling, self-tapping flutes of the

5.0 mm cannulated locking screws make predrilling and

pretapping unnecessary in most cases. If necessary, in dense

bone, the lateral cortex can be predrilled with the 4.3 mm

cannulated drill bit.

Once both the anterior and posterior locking screws are

securely locked to the plate, the central 5.0 mm cannulated

conical screw may be removed and replaced with a third

5.0 mm cannulated locking screw using the technique

described above.

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes13

Reduce Plate to Plateau

6

Reduce shaft to the tibial plateau

Instruments

321.12

Articulated Tension Device

398.81

or

398.813

Bone Forceps

Plate Holding Forceps

Reduce the tibial plateau to the shaft of the tibia, using

indirect reduction techniques whenever possible. Using

atraumatic technique, secure the plate to the tibial shaft

with bone forceps.

Confirm rotational alignment of the extremity by clinical

examination.

Once reduction is satisfactory, and if it is appropriate based

on the fracture morphology, the plate should be loaded in

tension using the articulated tension device.

Note: With multifragment fractures, it may not always be

possible or desirable to achieve anatomic reduction of the

fracture. However, in simple fracture patterns, the articulated

tension device may facilitate anatomic reduction. This device

may be used to generate either compression or distraction.

14

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Insert Screws in Plate Shaft

7

Insert screws in plate shaft

1

2

2

1

1

1

2

In addition to having threaded locking holes, the plate

functions similarly to DCP plates which offer the ability to

axially compress fracture fragments. Therefore, a combination of cortex screws and locking screws may be used.

Important: If a combination of cortex (1) and locking screws

(2) is used, a cortex screw should be inserted first to pull the

plate to the bone.

Note: If locking screws (1) have been used to fix the plate to

a fragment, subsequent insertion of a cortex screw (2) in the

same fragment without loosening and retightening the locking screw is not recommended.­

Correct

2

Incorrect

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes15

Insert Screws in Plate Shaft

Instruments

03.010.150Star/HexDrive Screwdriver, T25, 3.5 mm

Hexagonal

310.31

3.2 mm Drill Bit

319.10

Depth Gauge

323.46

4.5 mm Universal Drill Guide

4.5 mm cortex screws

Insert as many self-tapping 4.5 mm cortex screws as

necessary into the distal portion of the plate.

Important: All of the 4.5 mm cortex screws must be

inserted prior to insertion of 4.0 mm or 5.0 mm

locking screws.

Use the 4.5 mm universal drill guide to predrill for the

4.5 mm cortex screws and drill through both cortices with

the 3.2 mm drill bit.

For the neutral position, press the drill guide down in the

nonthreaded hole. To obtain compression, place the drill

guide at the end of the nonthreaded hole away from the

fracture. Do not apply downward pressure on the drill

guide’s spring-loaded tip.

Measure for screw length using the depth gauge. Select

and insert the appropriate length 4.5 mm cortex screw.

16

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Instruments

03.010.150Star/HexDrive Screwdriver, T25, 3.5 mm

Hexagonal

03.010.151Star/HexDrive Screwdriver Shaft, T25/

3.5 mm Hexagonal

310.4314.3 mm Drill Bit, 180 mm, quick coupling,

for 5.0 mm Locking Screws

312.4494.3 mm Threaded Drill Guide, for 5.0 mm

Locking Screws

5.0 mm locking screws

Attach the 4.3 mm drill guide to the locking hole in the plate

shaft. Drill a hole using the 4.3 mm drill bit.

Note: Use of the drill guide is mandatory for screws to lock

to the plate properly.

Remove the drill guide and measure screw length using the

depth gauge. Insert the appropriate length 5.0 mm locking

screw with the StarDrive screwdriver, or StarDrive screwdriver

shaft. Repeat as necessary to insert additional locking screws.

Examine the limb clinically and radiographically. It is important that the tibial plateau is in proper orientation to the tibial

shaft.

Important: Securely tighten all locking screws again.

Warning: If the TLA is unavailable, do not tighten the screws

to the plate using power. Perform final tightening by hand.

Alternative Instruments

310.313.2 mm Drill Bit

324.1763.2 mm Drill Guide

Alternatively, when using 4.0 mm locking screws, use the

appropriate 3.2 mm drill guide and 3.2 mm drill bit.

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes17

Insert Screws in Plate Shaft

8

Insert 5.0 mm cannulated locking screws in the

angled holes

Instruments

310.243

2.5 mm Drill Tip Guide Wire

314.05

Cannulated Hexagonal Screwdriver

314.23

Cannulated Hexagonal Screwdriver Shaft

319.701

Cannulated Screw Measuring Device

324.174

2.5 mm Wire Guide, for 5.0 mm screws

Note: Use the oblique locking positions to buttress a

medial fragment.

If not already done, thread a 2.5 mm wire guide for 5.0 mm

screws into an angled locking hole.

Insert a 2.5 mm drill tip guide wire through the 2.5 mm

wire guide. Advance the guide wire until it reaches the

desired screw tip location.

Measure for screw length using the cannulated screw measuring device. The correct length measurement will place

the screw tip at the tip of the guide wire. Use the 4.0 mm

cannulated hexagonal screwdriver to remove the wire

guide. Insert the appropriate length 5.0 mm cannulated

locking screw, using the cannulated hexagonal screwdriver.

Note: The measuring device must contact the end of the

wire guide for an accurate measurement.

Warning: If the TLA is unavailable, do not tighten the screws

to the plate using power. Perform final tightening by hand.

Repeat steps for locking screw insertion for the remaining

angled hole.

18

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Screw length considerations

When using the appropriate length screws in the angled

locking holes, the screw tips should meet the proximal

locking screws.

70 mm

65 mm

65 mm

Suggested screw lengths to achieve desired screw convergence.

Note: Securely tighten all locking screws to lock them

to the plate.

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes19

Screws Used with the 4.5 mm LCP Medial Proximal Tibia Plate

5.0 mm Cannulated Locking Screw

Creates a locked, fixed-angle screw/plate construct

– Threaded conical head

– Fully threaded shaft

– Self-drilling, self-tapping tip

5.0 mm Locking Screw

Creates a locked, fixed-angle screw/plate construct

– Threaded conical head

– Fully threaded shaft

– Self-tapping tip

5.0 mm Cannulated Conical Screw

Compresses the plate to the lateral femoral condyle

and provides interfragmentary compression

– Smooth conical head

– Partially threaded shaft

– Self-drilling, self-tapping tip

4.0 mm Locking Screw

Creates a locked, fixed-angle screw/plate construct

– Threaded conical head

– Fully threaded shaft

– Self-tapping tip

4.5 mm Cortex Screw

(found in the Large Fragment LCP Instrument and

Implant Set, with 4.0 mm and 5.0 mm locking screws)

– May be used in the DCU portion of the Combi holes

in the plate shaft

–Compresses the plate to the bone or creates

axial compression

– Self-tapping tip

5.0 mm Screw Nut

Offers additional fixation and compression options

for complex fractures

– Self-cutting, serrated tip

– Internal threads mate with the 5.0 mm cannulated

conical screws

– Inserted from the lateral aspect of the proximal tibia

Note: See the Synthes 4.5 mm LCP Condylar Plates Technique

Guide for more information on use of the screw nut.

20

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

5.0 mm Cannulated Locking and Cannulated

Conical Screws

The screw design enhances fixation and facilitates

the surgical procedure.

Screw head

The conical head simplifies alignment in the plate hole. This

is of particular importance when using locking screws. The

threaded screw head must align with the plate hole threads

to provide a secure screw/plate construct. To ensure proper

alignment and prevent cross-threading, the appropriate

threaded wire guide or drill guide must always be used.

Large diameter screw core

The large diameter screw core improves bending and

shear strength, and distributes the load over a larger

area in the bone.

Thread profile

The shallow thread profile of the locking screws is necessary

to provide a larger core. This is appropriate since locking

screws do not rely on compression between the plate and

the bone to maintain stability. When required, interfragmentary compression can be achieved with the partially threaded

cannulated conical screws, especially when near the

articular surface.

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes21

4.5 mm LCP Medial Proximal Tibia Plate Implant Sets

Stainless Steel (01.120.432) and Titanium (01.120.434)

Graphic Case

690.3944.5 mm LCP Medial Proximal Tibia Plate Set

Graphic Case

Implants

4.5 mm LCP Medial Proximal Tibia Plates ◊

Stainless Steel Titanium

Holes Length (mm)

239.984 439.9844 106 right

239.985 439.9854 106 left

239.986 439.9866 142 right

239.987 439.9876 142 left

239.988 439.9888 178 right

239.989 439.9898 178 left

239.990 439.990 10214

right

239.991 439.991 10214

left

239.992 439.992 12250

right

239.993 439.993 12250

left

239.994 439.994 14286

right

239.995 439.995 14286

left

239.996 439.996 16322

right

239.997 439.997 16322

left

Required Set

01.240.201Periarticular LCP Plating System,

with 5.0 mm Locking Screws

or

01.240.209Periarticular LCP Plating System,

with 4.0 mm Locking Screws

Also Available Sets

01.223.604Periarticular LCP Plating System Instrument

and Titanium Screw Set

01.240.401Periarticular LCP Plating System,

with 5.0 mm Titanium Locking Screws

01.240.409Periarticular LCP Plating System,

with 4.0 mm Titanium Locking Screws

105.210Periarticular LCP Plating System Instrument

and Screw Set

Recommended Additional Sets

105.909

Periarticular Reduction Forceps Set

115.400Large Fragment LCP Instrument and

Implant Set

115.700 Large Distractor Set

115.720 Large External Fixator Set with Self-Drilling

Schanz Screws

146.400 Large Fragment LCP Instrument and Titanium

Implant Set, with 4.0 mm and 5.0 mm

Locking Screws

146.405 Large Fragment LCP Instrument and Titanium

Implant Set, with 4.0 mm and 5.0 mm

Locking Screws

For detailed cleaning and sterilization instructions, please refer to:

www.synthes.com/cleaning-sterilization

In Canada, the cleaning and sterilization instructions will be provided with

the Loaner shipments.

◊ Available nonsterile or sterile-packed. Add ‘S’ to catalog number to order

sterile product.

Stainless steel screws and screw nut are made of implant quality 316L stainless steel.

22

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Periarticular LCP Plating System, with 5.0 mm Locking Screws (01.240.201)

Graphic Case, Screw Racks, Tray

60.240.201Locking Periarticular Plating System

Graphic Case

60.240.203 Screw Rack for 4.5 mm Cortex Screws

60.240.204Screw Rack for 5.0 mm Locking Screws

with T25 StarDrive Recess

60.240.205Screw Rack for 5.0 mm and 7.3 mm

Cannulated Locking Screws and 7.3 mm

Conical Screws

60.240.206Screw Rack for 5.0 mm Cannulated

Conical Screws

60.240.208Locking Periarticular Plating System

Instrument Tray

Implants

4.5 mm Cortex Screws, self-tapping, 4 ea.

Length (mm)

Length (mm)

214.82020

214.81414

214.82222

214.81616

214.82424

214.81818

4.5 mm Cortex Screws, self-tapping, 6 ea.

Length (mm)

Length (mm)

214.83636

214.82626

214.83838

214.82828

214.84040

214.83030

214.84242

214.83232

214.83434

4.5 mm Cortex Screws, self-tapping, 4 ea.

Length (mm)

214.84444

4.5 mm Cortex Screws, self-tapping, 2 ea.

Length (mm)

Length (mm)

214.86060

214.84646

214.86262

214.84848

214.86464

214.85050

214.86666

214.85252

214.86868

214.85454

214.87070

214.85656

214.85858

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes23

Periarticular LCP Plating System, with 5.0 mm Locking Screws (01.240.201)

Implants

5.0 mm Periprosthetic Locking Screws, self-tapping,

with T25 StarDrive recess, 2 ea.

Length (mm)

02.221.5088

02.221.51010

02.221.51212

5.0 mm Locking Screws, self-tapping, with T25 StarDrive

recess, 4 ea.

Length (mm)

Length (mm)

212.20420

212.20114

212.20522

212.20216

212.20624

212.203

18

5.0 mm Locking Screws, self-tapping, with T25 StarDrive

recess, 6 ea.

Length (mm)

Length (mm)

212.21236

212.20726

212.21338

212.20828

212.21440

212.20930

212.21542

212.21032

212.21134

5.0 mm Locking Screws, self-tapping, with T25 StarDrive

recess, 2 ea.

Length (mm)

Length (mm)

212.22265

212.21644

212.22370

212.21746

212.22475

212.21848

212.22580

212.21950

212.22685

212.22055

212.22790

212.22160

5.0 mm Cannulated Locking Screws, 2 ea.

Length (mm)

Length (mm)

02.205.04040

02.205.02525

02.205.04545

02.205.03030

02.205.05050

02.205.03535

24

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

5.0 mm Cannulated Locking Screws, 4 ea.

Length (mm)

Length (mm)

02.205.05555

02.205.07575

02.205.06060

02.205.08080

02.205.06565

02.205.08585

02.205.07070

5.0 mm Cannulated Locking Screws, 2 ea.

Length (mm)

Length (mm)

02.205.120120

02.205.09090

02.205.125125

02.205.09595

02.205.130130

02.205.100100

02.205.135135

02.205.105105

02.205.140140

02.205.110110

02.205.145145

02.205.115115

5.0 mm Cannulated Conical Screws, 2 ea.

Length (mm)

Length (mm)

02.205.27070

02.205.24040

02.205.27575

02.205.24545

02.205.28080

02.205.25050

02.205.28585

02.205.25555

02.205.29090

02.205.26060

02.205.29595

02.205.26565

7.3 mm Cannulated Locking Screws, 2 ea.

Length (mm)

Length (mm)

02.207.02020

02.207.08585

02.207.02525

02.207.09090

02.207.03030

02.207.09595

02.207.03535

02.207.100100

02.207.04040

02.207.105105

02.207.04545

02.207.110110

02.207.05050

02.207.115115

02.207.05555

02.207.120120

02.207.06060

02.207.125125

02.207.06565

02.207.130130

02.207.07070

02.207.135135

02.207.07575

02.207.140140

02.207.08080

02.207.145145

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes25

Periarticular LCP Plating System, with 5.0 mm Locking Screws (01.240.201)

Implants

7.3 mm Cannulated Conical Screws

Length (mm)

Length (mm)

02.207.25050

02.207.27575

02.207.25555

02.207.28080

02.207.26060

02.207.28585

02.207.26565

02.207.29090

02.207.27070

02.207.29595

7.3 mm Cannulated Conical Screws, partially threaded

Length (mm)

Length (mm)

02.207.45050

02.207.47575

02.207.45555

02.207.48080

02.207.46060

02.207.48585

02.207.46565

02.207.49090

02.207.47070

02.207.49595

222.578

5.0 mm Screw Nut, 2 ea.

Instruments

03.010.150Star/HexDrive Screwdriver, T25/3.5 mm

Hexagonal, self-retaining

03.010.151Star/HexDrive Screwdriver Shaft, T25/3.5 mm

Hexagonal, self-retaining, 165 mm

292.6522.0 mm Non-Colored Threaded Guide Wire,

spade point, 230 mm, 10 ea.

310.243

2.5 mm Drill Tip Guide Wire, 200 mm, 10 ea.

310.31

3.2 mm Drill Bit, quick coupling, 145 mm

310.4314.3 mm Drill Bit, quick coupling, 180 mm,

for 5.0 mm Locking Screws

310.44

4.5 mm Drill Bit, quick coupling, 145 mm

310.6325.0 mm Cannulated Drill Bit, quick coupling,

200 mm (short flute)

310.6344.3 mm Cannulated Drill Bit, quick coupling,

200 mm (long flute)

310.99

Countersink, for 4.5 mm and 6.5 mm screws

311.44

T-Handle, with quick coupling

311.449Push-Pull Reduction Device, for use with

4.5 mm LCP plates, 2 ea.

311.46

Tap for 4.5 mm Screws

312.4494.3 mm Threaded Drill Guide for 5.0 mm

Locking Screws, 4 ea.

312.48

4.5 mm/3.2 mm Insert Drill Sleeve

26

Synthes 4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

313.93

4.0 mm Solid Hexagonal Screwdriver

314.05

Cannulated 4.0 mm Hexagonal Screwdriver

314.11

Holding Sleeve

314.23Cannulated 4.0 mm Hexagonal Screwdriver Shaft

319.10Depth Gauge, for 4.5 mm and 6.5 mm screws

319.24

2.9 mm Cleaning Brush

319.461

2.5 mm Cleaning Stylet

319.701

Cannulated Screw Measuring Device

321.12

Articulated Tension Device

321.16Combination Wrench, 11 mm width across flats

323.46

4.5 mm Universal Drill Guide

324.174

2.5 mm Wire Guide, for 5.0 mm screws, 5 ea.

324.175

2.5 mm Wire Guide, for 7.3 mm screws, 2 ea.

324.176

3.2 mm Drill Guide, for 4.0 mm screws, 2 ea.

338.49

Large Quick Coupling

397.706

Handle, for AO Reaming Coupler Connection

511.774Torque Limiting Attachment, 4 Nm, for AO

Reaming Coupler

Also Available

60.240.207Screw Rack for 6.5 mm Cancellous Bone Screws

292.20

2.0 mm Kirschner Wire, 150 mm, trocar point

311.66Tap for 6.5 mm Cancellous Bone Screws

312.676.5 mm/3.2 mm Double Drill Sleeve

394.35Large Distractor

397.705Handle, quick coupling, for ComPact

Air Drive Connection

398.81Bone Forceps

398.813Plate Holding Forceps with swivel foot

511.761

Large Quick Coupling

511.771Torque Limiting Attachment, 4 Nm

4.5 mm LCP Medial Proximal Tibia Plates Technique Guide

Synthes27

Synthes (USA)

1302 Wrights Lane East

West Chester, PA 19380

Telephone: (610) 719-5000

To order: (800) 523-0322

Fax: (610) 251-9056

© 2006 Synthes, Inc. or its affiliates. All rights reserved.

Synthes (Canada) Ltd.

2566 Meadowpine Boulevard

Mississauga, Ontario L5N 6P9

Telephone: (905) 567-0440

To order: (800) 668-1119

Fax: (905) 567-3185

Combi, DCP, LCP and Synthes are trademarks of Synthes, Inc. or its affiliates.

www.synthes.com

Printed in U.S.A. 10/12 J6760-C