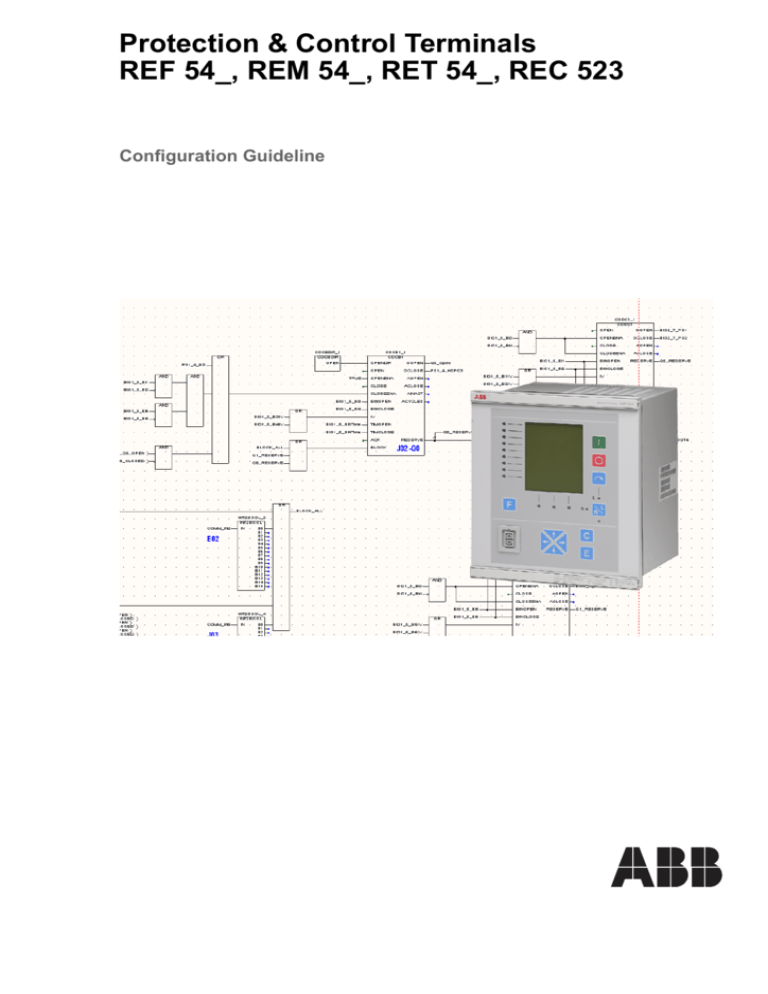

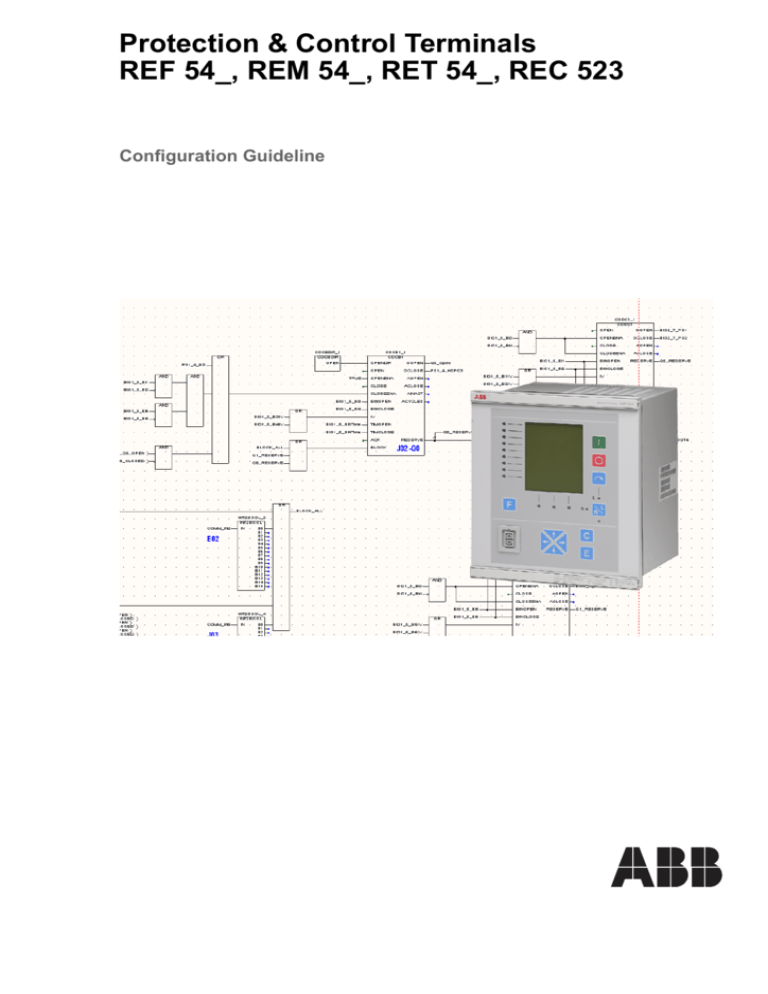

Protection & Control Terminals

REF 54_, REM 54_, RET 54_, REC 523

Configuration Guideline

1MRS750745-MUM

Issued:

Version:

20.10.1998

L/08.07.2005

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

Contents

1. About this manual .....................................................................7

1.1.

1.2.

1.3.

1.4.

1.5.

1.6.

1.7.

1.8.

1.9.

Copyrights .....................................................................................7

Trademarks ...................................................................................7

General .........................................................................................7

Use of symbols ..............................................................................8

Document conventions ..................................................................9

Abbreviations ................................................................................9

Terminology ..................................................................................9

Related documents .....................................................................10

Document revisions .....................................................................11

2. Safety information ...................................................................13

3. Relay Configuration Tool .......................................................15

4. Specification for relay configuration .....................................17

5. Editing the relay configurations ............................................19

5.1. Getting started .............................................................................19

5.1.1. Libraries ...........................................................................19

5.1.2. Program organisation unit ................................................21

5.1.3. Logical POUs ...................................................................23

5.1.4. Physical hardware ............................................................25

5.1.4.1. Configuration ......................................................26

5.1.4.2. Resource for REF 54_, REM 54_

and REC 523 ......................................................27

5.1.4.3. Resource for REF 54_ Release 2.5 or later,

REC 523 revision F and RET 54_

37

5.1.4.4. Tasks ..................................................................47

5.2. Declaring variables ......................................................................49

5.2.1. Global variables ...............................................................52

5.2.2. Local variables .................................................................52

5.3. Compiling project ........................................................................57

5.4. Add-on protocol ...........................................................................57

5.5. Downloading the configuration ....................................................57

5.5.1. REF 54_ Release 2.5, RET 54_ and

REC 523 revision F additions ..........................................59

6. Main configuration rules ........................................................63

6.1.

6.2.

6.3.

6.4.

6.5.

General .......................................................................................63

Digital inputs and outputs ............................................................63

Explicit feedback path .................................................................64

Analog inputs ..............................................................................65

Error outputs of application function blocks ................................66

©Copyright 2005 ABB Oy, Distribution Automation, Vaasa, FINLAND

3

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

6.6. Warnings ..................................................................................... 67

6.7. Execution order ........................................................................... 67

6.8. F-key ........................................................................................... 68

7. Engineering tips ..................................................................... 71

7.1. Horizontal communication .......................................................... 71

7.1.1. Guideline for using LON NV-variables in PLC logic ......... 71

7.1.1.1. COMM_IN .......................................................... 71

7.1.1.2. COMM_OUT ...................................................... 72

7.1.1.3. Cyclic sending generation .................................. 73

7.1.1.4. Cyclic communication check .............................. 74

7.1.1.5. Blocking ............................................................. 74

7.1.1.6. Control of objects ............................................... 75

7.1.1.7. Bypass mode ..................................................... 76

7.2. Events from the measurement function blocks ........................... 76

8. APPENDIX A: Relay configuration procedure ..................... 77

9. APPENDIX B: Specification for REF 54_ feeder

terminal configuration

79

9.1. General data ............................................................................... 79

9.2. Electrotechnical data .................................................................. 80

9.2.1. Analog inputs ................................................................... 80

9.2.2. System frequency ............................................................ 82

9.2.3. Digital inputs .................................................................... 82

9.2.4. Digital outputs .................................................................. 84

9.2.5. RTD module .................................................................... 88

9.2.5.1. RTD/analog inputs ............................................. 88

9.2.5.2. RTD outputs ....................................................... 89

9.3. Functionality ................................................................................ 89

9.3.1. Order number .................................................................. 89

9.3.2. Application function blocks used ..................................... 90

9.3.3. Communication ................................................................ 91

9.4. Relay MIMIC configuration ......................................................... 93

9.4.1. Illustration of the system, MIMIC diagram ....................... 93

9.4.2. Alarm LEDs ..................................................................... 94

9.5. Functionality logic ....................................................................... 95

9.6. Feeder terminal settings ............................................................. 96

10.APPENDIX C: Specification for REM 54_ machine

terminal configuration

97

10.1.General data .............................................................................. 97

10.2.Electrotechnical data .................................................................. 97

10.2.1.Analog inputs ................................................................... 97

4

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

10.2.1.1.Hardware versions with 5 current

and 4 voltage transformers

97

10.2.1.2.Hardware versions with 6 current

and 3 voltage transformers

98

10.2.1.3.Hardware versions with 7 current

and 2 voltage transformers

99

10.2.1.4.Hardware versions with 8 current

and 1 voltage transformer

101

10.2.1.5.Sensor inputs ...................................................102

10.2.2.System frequency ..........................................................102

10.2.3.Digital inputs ..................................................................103

10.2.4.Digital outputs ................................................................105

10.2.5.RTD module ...................................................................108

10.2.5.1.RTD/analog inputs ...........................................108

10.2.5.2.RTD outputs .....................................................109

10.3.Functionality .............................................................................109

10.3.1.Order number .................................................................109

10.3.2.Application function blocks used ................................110

10.3.3.Communication ..............................................................111

10.4.Relay MIMIC configuration .......................................................112

10.4.1.Illustration of the system, MIMIC diagram ......................112

10.4.2.Alarm LEDs ....................................................................113

10.5.Functionality logic .....................................................................114

10.6.Machine terminal settings .........................................................115

11.APPENDIX D: Specification for RET 54_

transformer terminal configuration .....................................117

11.1.General data .............................................................................117

11.2.Electrotechnical data ................................................................118

11.2.1.Analog inputs .................................................................118

11.2.1.1.Hardware versions with 6 current

and 3 voltage transformers

118

11.2.1.2.Hardware versions with 7 current

and 2 voltage transformers

119

11.2.1.3.Hardware versions with 8 current

and 1 voltage transformer

120

11.2.2.System frequency ..........................................................120

11.2.3.Digital inputs ..................................................................121

11.2.4.Digital outputs ................................................................123

11.2.5.RTD module ...................................................................126

11.2.5.1.RTD/analog inputs ...........................................126

11.2.5.2.RTD outputs .....................................................127

11.3.Functionality .............................................................................127

11.3.1.Order number .................................................................127

5

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

11.3.2.Application function blocks used ................................... 128

11.3.3.Communication .............................................................. 129

11.4.Relay MIMIC configuration ....................................................... 130

11.4.1.Illustration of the system, MIMIC diagram ..................... 130

11.4.2.Alarm LEDs ................................................................... 131

11.5.Functionality logic ..................................................................... 132

11.6.Transformer terminal settings .................................................. 133

12.APPENDIX E: Specification for REC 523 Remote

Monitoring and Control Unit configuration

135

12.1.General data ............................................................................ 135

12.2.Electrotechnical data ................................................................ 136

12.2.1.Analog inputs ................................................................. 136

12.2.2.System frequency .......................................................... 140

12.2.3.Digital inputs .................................................................. 141

12.2.4.Digital outputs ................................................................ 142

12.3.Functionality ............................................................................. 143

12.3.1.Order number ................................................................ 143

12.3.2.Application function blocks used ................................... 143

12.3.3.Communication .............................................................. 144

12.4.Virtual channels ........................................................................ 144

12.4.1.LED configuration .......................................................... 144

12.5.Remote monitoring and control unit settings ............................ 146

13.APPENDIX F: Power quality application

guide for harmonics

147

13.1.Power quality and harmonics ................................................... 147

13.2.Background for harmonics ....................................................... 147

13.3.Harmonic sources .................................................................... 149

13.3.1.Single-phase power supplies ......................................... 149

13.3.2.Three-phase power converters ...................................... 150

13.3.3.Other harmonic sources ................................................ 151

13.4.System response characteristics ............................................. 152

13.5.Effects of harmonics ................................................................. 154

13.6.Applications for harmonic measurements ................................ 155

13.6.1.Power quality and harmonics ......................................... 155

13.6.2.Harmonic monitoring with individual loads and devices 156

13.6.3.Locating sources of harmonics ...................................... 157

13.6.4.Harmonic filter performance monitoring ......................... 157

14.Index ..................................................................................... 159

6

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

1.

About this manual

1.1.

Copyrights

The information in this document is subject to change without notice and should not

be construed as a commitment by ABB Oy. ABB Oy assumes no responsibility for

any errors that may appear in this document.

In no event shall ABB Oy be liable for direct, indirect, special, incidental or

consequential damages of any nature or kind arising from the use of this document,

nor shall ABB Oy be liable for incidental or consequential damages arising from use

of any software or hardware described in this document.

This document and parts thereof must not be reproduced or copied without written

permission from ABB Oy, and the contents thereof must not be imparted to a third

party nor used for any unauthorized purpose.

The software or hardware described in this document is furnished under a license and

may be used, copied, or disclosed only in accordance with the terms of such license.

Copyright © 2005 ABB Oy

All rights reserved.

1.2.

Trademarks

Brand and product names mentioned in this document are trademarks or registered

trademarks of their respective companies.

1.3.

General

This guideline describes in general the procedures for configuring REF 54_ feeder

terminals, REM 54_ machine terminals, RET 54_ transformer terminals and

REC 523 remote monitoring and control units correctly with the Relay

Configuration Tool. In this document, the term “device” is used when referring to

all the above mentioned products.

Chapter 5. Editing the relay configurations describes step-by-step the engineering

actions required to create a relay configuration for a single device.

Chapter 6. Main configuration rules defines a set of programming rules that should

be followed while creating the configuration. These rules should be carefully

checked when finalizing the configuration.

Chapter 7. Engineering tips provides some engineering tips for doing the

configuration.

For instructions on operating the tool itself, refer to the operator’s manual for

CAP 505 (see Section 1.8. Related documents). This version of the Configuration

Guideline complies with products of Release 3.01. For information about the

changes and additions compared to earlier revisions, refer to the technical reference

manual of the appropriate product (see Section 1.8. Related documents).

1. Except REC 523 with revision D or later, and REM 54_ with Release 2.5

7

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

For information on what RE_ 5__ products support which add-on protocols, refer to

the product manuals (Section 1.8. Related documents).

Note that in this manual, the examples and dialog box pictures of the Relay

Configuration Tool refer to REF 54_ feeder terminals (except Fig. 5.5.-1). The

corresponding cases and dialog boxes can be slightly different for REM 54_, RET

54_ and REC 523.

1.4.

Use of symbols

This publication includes warning, caution, and information icons that point out

safety-related conditions or other important information. It also includes tip icons to

point out useful information to the reader. The corresponding icons should be

interpreted as follows:

The electrical warning icon indicates the presence of a hazard which

could result in electrical shock.

The warning icon indicates the presence of a hazard which could

result in personal injury.

The caution icon indicates important information or warning related

to the concept discussed in the text. It might indicate the presence of

a hazard which could result in corruption of software or damage to

equipment or property.

The information icon alerts the reader to relevant facts and

conditions.

The tip icon indicates advice on, for example, how to design your

project or how to use a certain function.

Although warning hazards are related to personal injury, and caution hazards are

associated with equipment or property damage, it should be understood that

operation of damaged equipment could, under certain operational conditions, result

in degraded process performance leading to personal injury or death. Therefore,

comply fully with all warning and caution notices.

8

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

1.5.

Document conventions

The following conventions are used for the presentation of material:

• The words in names of screen elements (for example, the title in the title bar of a

dialog box, the label for a field of a dialog box) are initially capitalized.

• The names of push and toggle buttons are boldfaced. For example, click OK.

• The names of menus and menu items are boldfaced. For example, the File menu.

• The following convention is used for menu operations: Menu Name > Menu

Item > Cascaded Menu Item. For example: select File > Open > New

Project.

1.6.

Abbreviations

ASD

CPU

CSI

FBD

HMI

I/O

LCD

LED

LON

NV

PLC

POU

PWM

RCT

RMS

RS

RTD

VD

1.7.

Adjustable speed drive

Central processing unit

Current source inverter

Function block diagram

Human-machine interface

Input/output

Liquid chrystal display

Light-emitting diode

Locally operating network

Network variable

Programmable logic controller

Program organisation unit

Pulse width modulation

Relay Configuration Tool

Root mean square

Rogowski sensor

Resistance temperature device

Voltage Divider

Terminology

device

DNP 3.0

IEC 60870-5-101

IEC 60870-5-103

MIMIC

Modbus

RCT project file

SPA

In this document refers to REF 54_ feeder terminal, REM 54_

machine terminal, RET 54_ transformer terminal and REC 523

remote monitoring and control unit

Distributed Network Protocol, a communication protocol controlled

by the DNP Users Group

Communication protocol standardized by International

Electrotechnical Commission

Communication protocol standardized by International

Electrotechnical Commission

Graphic configuration picture on the relay’s LCD

Communication protocol introduced by Modicon Inc.

Relay Configuration Tool project, a zipped project file

Communication protocol developed by ABB

9

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

1.8.

Related documents

Document

ID

Manuals for REF 54_, REM 54_, RET 54_ and REC 523

Installation Manual RE_ 5_ _a

1MRS750526-MUM

Operator’s Manual RE_ 54_a

Feeder Terminal REF 54_

Technical Reference Manual, Generala

1MRS750500-MUM

Technical Reference Manual REM 54_a

Transformer Terminal RET 54_

Technical Reference Manual, General

Remote Monitoring and Control Unit REC 523

Technical Reference Manuala

REM 54_ Machine Terminal Technical Reference Manual, General

Technical Descriptions of Functions (CD-ROM)

REF 54_ and RET 54_ Modbus Communication Protocol

Technical Description

Modbus Remote Communication Protocol for REM 54_

Technical Description

REM 543 Modbus Configurations (CD-ROM)

Modbus Remote Communication Protocol for REC 523

Technical Description

REF 54_, RET 54_ and REX 521 DNP 3.0 Communication Protocol

Technical Description

DNP 3.0 Remote Communication Protocol for REC 523

Technical Description

IEC 60870-5-101 Remote Communication Protocol for REC 523,

Technical Description

1MRS750915-MUM

1MRS750527-MUM

1MRS755225

1MRS750881-MUM

1MRS750915-MUM

1MRS750889-MCD

1MRS755238

1MRS750781-MUM

1MRS151023-MUM

1MRS752015-MUM

1MRS755260

1MRS750958-MUM

1MRS750956-MUM

Tool-specific manuals

CAP 505 Installation and Commissioning Manualb

1MRS751273-MEN

CAP 505 Operator’s Manualb

1MRS751709-MUM

CAP 505 Protocol Mapping Tool Operator’s Manualb

CAP 501 Installation and Commissioning

CAP 501 Operator’s

Manualc

1MRS751270-MEN

1MRS751271-MUM

Manualc

Relay Configuration Tool, Quick Start

1MRS755277

Referenceb

1MRS751275-MEN

Relay Configuration Tool, Tutorialb

1MRS751272-MEN

Relay Mimic Editor, Configuration Manualb

LIB, CAP and SMS, Tools for Relays and Terminals, User’s Guide

1MRS751274-MEN

1MRS752008-MUM

a. Included on the CD-ROM Technical Descriptions of Functions, 1MRS750889-MCD

b. Included on the CD-ROM Relay Product Engineering Tools

c. Included on the CD-ROM Relay Setting Tools

10

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

1.9.

Document revisions

Version

Date

G

H

K

L

02.04.2004

20.01.2005

01.03.2005

08.07.2005

History

Manual updated

RET 54_ added to manual

Updates according to REC 523 revision F

Updates according to REF 54_, Release 3.5

11

12

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

2.

Safety information

!

Dangerous voltages can occur on the connectors, even though the

auxiliary voltage has been disconnected.

National and local electrical safety regulations must always be

followed.

The device contains components which are sensitive to electrostatic

discharge. Unnecessary touching of electronic components must

therefore be avoided.

The frame of the device has to be carefully earthed.

Only a competent electrician is allowed to carry out the electrical

installation.

Non-observance can result in death, personal injury or substantial

property damage.

Breaking the sealing tape on the rear panel of the device will result in

loss of warranty and proper operation will no longer be guaranteed.

When a plug-in unit has been detached from the case, do not touch the

inside of the case. The relay case internals may contain high voltage

potential and touching these may cause personal injury.

13

14

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

3.

Relay Configuration Tool

The Relay Configuration Tool is a standard programming system for RED 500

devices. It is used for configuring the protection, control, condition monitoring,

measurement and logic functions of the feeder terminal. The tool is based on the

IEC 61131-3 standard, which defines the programming language for relay terminals,

and includes a wide range of IEC features. The programmable logic controller (PLC)

logics are programmed with Boolean functions, timers, counters, comparators and

flip-flops. The programming language described in this manual is a function block

diagram (FBD) language.

15

16

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

4.

Specification for relay configuration

Prior to starting the configuration of a product, the specification for relay

configuration is to be filled out. Separate specifications for REF 54_, REM 54_,

RET 54_ and REC 523 can be found in appendices B, C, D and E in the end of this

manual.

The purpose of the specification is to provide the technical information required for

the proper configuration of the products.

17

18

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

5.

Editing the relay configurations

5.1.

Getting started

1. Start up the CAP 505 tool by double clicking the tool icon.

2. Add a new object as an empty configuration to the CAP 505 environment. For

instructions, refer to the operator’s manual for CAP 505 (see Section 1.8.

Related documents). The program opens an empty project template (see

Fig. 5.1.-1) with a toolbar at the top.

3. Build the project tree structure by inserting libraries, program organisation units

(POUs) and target-specific items to the project tree.

The project tree editor is a window in which the whole project is represented as a

tree. The project tree is illustrated with several icons. Most of the icons represent a

file of the project, and different looking icons represent different types of files. The

tree always contains 4 subtrees: Libraries, Data Types, Logical POUs and Physical

Hardware.

ProjectTree

Fig. 5.1.-1 Project tree and the four subtrees

The project tree is the main tool for editing the project structure. Editing the project

structure means inserting POUs or worksheets to the project structure, or deleting

existing ones. The editors for editing the code-body data and the variable declaration

can be opened by double-clicking the corresponding object icons.

If you edit an old project, note that saving the changes made with the

Save as command does not work as in other Windows programs. If

you want to keep the old project unchanged, save the project with a

new name before making any changes.

5.1.1.

Libraries

Before editing any worksheets of POUs, the whole project tree structure must be

build. The function block library (protection, control, measurement, condition

monitoring and standard functions) needed in the relay configuration needs to be

inserted to the Libraries subtree. For instructions on announcing libraries, refer to

the tutorial manual for the Relay Configuration Tool, see Section 1.8. Related

documents.

Before inserting a library to the project, close all open worksheets in

order to avoid confusing the I/O description of the function blocks.

19

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

The programs, function blocks (for example NOC3Low, the low-set stage of nondirectional three-phase overcurrent protection) and functions of the library can be

reused in the new project, which is edited.

The library, for example REFLIB01 for REF 54_ (see Fig. 5.1.1.-1), includes the full

set of function blocks, but only those ordered by the customer can be used in the

configuration.

If a configuration is transferred to a newer version of the product, the

library in the project must also be updated.

ref/rem/ret/reclib01

Fig. 5.1.1.-1

Libraries for REF 54_, REM 54_, RET 54_ and REC 523

The library version to be selected depends on the software revision of the product as

listed in the table below. The directory path to the libraries is

<installation drive>\CAP505\Common\IECLibs\Fi.

Table 5.1.1-1

Product

Software

revision

REF 541

A

REF 541 (RTD1)

REF 543

REF 543 (RTD1)

20

Product software revisions and libraries

B

C

D and E

K

A

B and C

K

C and D

E

F

G and H

K

A

B and C

K

Library file name

COMMU_01, CONDM_01, CONTR_01,

MEASU_01, PROTE_01, STAND_01

REFLIB01

REFLIB02

REFLIB03

REFLIB04

REFLIB02

REFLIB03

REFLIB04

COMMU_01, CONDM_01, CONTR_01,

MEASU_01, PROTE_01, STAND_01

REFLIB01

REFLIB02

REFLIB03

REFLIB04

REFLIB02

REFLIB03

REFLIB04

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

Table 5.1.1-1

Product software revisions and libraries (Continued)

Product

Software

revision

REF 545

A

REM 543

REM 543 (RTD1)

REM 545

REM 545 (RTD1)

RET 541

RET 541 (RTD1)

RET 543

RET 543(RTD1)

RET 545

REC 523

5.1.2.

B

C

D and E

K

A

B

C

A

B

A

B

A

B

A

A

A

A

A

A

B

C

D

E

F

Library file name

COMMU_01, CONDM_01, CONTR_01,

MEASU_01, PROTE_01, STAND_01

REFLIB01

REFLIB02

REFLIB03

REFLIB04

REMLIB01

REMLIB02

REMLIB03

REMLIB02

REMLIB03

REMLIB02

REMLIB03

REMLIB02

REMLIB03

RETLIB01

RETLIB01

RETLIB01

RETLIB01

RETLIB01

RECLIB01

RECLIB01

RECLIB02

RECLIB03

RECLIB03

RECLIB04

Program organisation unit

Each Program Organisation Unit (POU) consists of several worksheets:

• Description worksheet for comments

• Variable worksheet for variable declarations

• Code body worksheet for the configuration.

The name of each worksheet is indicated beside the corresponding icon. The

“*” symbol after the name of a worksheet indicates that the worksheet has not been

compiled yet.

POU_unit

Fig. 5.1.2.-1

Program organisation unit with three worksheets

21

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

The description worksheet (for example ProtectT) illustrated below is for describing

the POU or the configuration element. The worksheet is automatically named by

adding a “T” to the name of the POU.

text

Fig. 5.1.2.-2

Description worksheet

The variable worksheet (for example ProtectV) is for the variable declaration. The

worksheet is automatically named by adding a “V” to the name of the POU. The

variable worksheet is not edited manually but is created by the tool.

variables

Fig. 5.1.2.-3

Variable declaration worksheet

A code body worksheet (for example Protect) is for a code body declaration in the

form of an function block diagram (FBD). All configurations for the devices of the

RED 500 platform are made in the graphical FBD language.

A code body programmed in the FBD language is composed of functions and

function blocks that are connected to each other using variables, connection lines or

connectors. An output of a function block can be combined with the output of

another function block for example via an OR gate (refer to Section 6.1. General).

Connectors are objects that can be used instead of connection lines, for example

where the distance between two objects on the worksheet is long. The connectors

can only be used within one worksheet, and they are resolved by textual names.

22

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

Connectors should be used with care since the tool may not warn if a

match to a connector cannot be found (for example, the comparison

of connectors is case sensitive).

Note that visually the connectors are distinguished from variables by embedding

them with “larger than” signs, “> >”.

Connectors

Fig. 5.1.2.-4

Code body declaration in FBD language

Even though the tool permits adding several code body worksheets under one POU,

only one worksheet is recommended to be used per POU. If more space is needed

for a configuration, the worksheet size can be increased or the functionality can be

divided into several POUs.

Avoid creating very large configurations per POU since the RED 500 PLC

environment has an inherent limit for the number of input/output points per POU.

The limit is 511 I/O points and is consumed by called function block instances only.

Note that the limit is checked during the configuration downloading. If the

downloading fails for this reason, the user has to divide the POU into smaller units.

For example, the function block NOC3Low in Fig. 5.1.2.-4 includes 14 I/O points.

The I/O points are consumed regardless of whether they are connected or not.

5.1.3.

Logical POUs

In the project tree editor and in the library editor, the Logical POUs subtree

represents a directory for all the POUs related to the project. The maximum of 20

POUs can be inserted to the subtree. Fig. 5.1.3.-1 shows a Logical POUs subtree

23

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

with 4 POUs; “CondMon” represents a function block, “Confirm” represents a

function, and “Measure” and “Control” are programs. The associated icon

represents the POU type.

LogicalPOUs

Fig. 5.1.3.-1

Logical POUs subtree with 4 POUs

Each POU type has specific characteristics from the programming point of view.

• A function yields exactly one data element which is evaluated from its input

parameters. In other words, a function cannot contain any internal state

information. Furthermore, a function can call other functions but not function

blocks.

• A function block (FB) can return 0,1,2.. output values and can have internal

variables. Function blocks can call any other function or function block except

itself. Multiple copies of function blocks are called instances and each instance is

given an identifier.

• Programs are specialized function blocks that can only be called by tasks.

Note that recursion is not allowed for any POU type.

The POU category is selected when a POU is inserted to the project tree. Fig. 5.1.3.2 below shows the dialog box for inserting POUs. The programming language

(FBD) for the POU and the return data type for functions are also selected here. The

PLC type and Processor type selections should be left to their default values.

24

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

InsertNewPOU

Fig. 5.1.3.-2

Inserting a new program POU called “Demo” which is

programmed by using the function block diagram language

At first, a POU framework is created, that is, empty POUs are inserted to the project

according to the Specification for Relay Configuration filled out prior to starting the

configuration procedure. The physical hardware must be defined before creating the

actual contents for the POUs, otherwise the predefined target-specific POUs are not

available for the programmer.

The task execution intervals recommended for function blocks must be considered

already when defining the POU framework. In general, each POU forms a functional

unit for example for protection function blocks. Some function blocks, however,

require a different task than most of the same category, and must therefore be

assigned a separate POU. For example, the task execution interval of most

protection function blocks is 10 ms but Freq1St_ requires the task of 5 ms, which is

why it usually needs a separate POU. However, if all the protection function blocks

used are associated with the task of 5 ms, no separate POU is required for Freq1St_.

5.1.4.

Physical hardware

In the project tree editor, the physical hardware is represented as a subtree (see

Fig. 5.1.4.-1) after the hardware of the device, that is, Configuration, Resource and

Tasks, has been defined.

25

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

PhysicalHardware

Fig. 5.1.4.-1

Example of a subtree for the physical hardware

The configuration elements available in the Physical Hardware subtree may differ

from configuration to configuration. Each terminal of the RED 500 platform can be

configured separately.

5.1.4.1.

Configuration

In the Relay Configuration Tool, the name of the configuration and the appropriate

product family, programmable logic controller (PLC) type, are first defined:

1. Select a Physical Hardware tree element and select Edit > Insert.

2. Define Name and PLC type, and click OK.

configuration_b

Fig. 5.1.4.1.-1 Defining the configuration type

26

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

5.1.4.2.

Resource for REF 54_, REM 54_ and REC 523

For REF 54_ Release 2.5 and later, RET 54_, and REC 523

revision F, refer to Section 5.1.4.3. Resource for REF 54_ Release

2.5 or later, REC 523 revision F and RET 54_.

The PLC type selected in the Configuration dialog box above determines which

processor types are available. To select the processor type and name the resource:

1. Select an object under the Physical Hardware tree and select Edit>Insert.

2. In the opening dialog box, click the option button Resource, select the correct

processor type and name the resource.

For example, the processor type REF543R refers to a REF 543 feeder terminal

equipped with an resistance temperature device (RTD) module.

resource

Fig. 5.1.4.2.-1 Defining the processor type

Hardware version

After selecting the processor type, click the Settings button in the dialog box (see

Fig. 5.1.4.2.-1 above) to define the correct hardware version (see Fig. 5.1.4.2.-2).

Do not click OK after selecting the correct hardware version (see

Fig. 5.1.4.2.-2), but wait until the next dialog box opens and click

the option button Analog Channels (see Fig. 5.1.4.2.-3).

The hardware version number is included in the order number of the product. The

order number is labelled on the marking strip on the front panel of the product.

Example:

Order No: REF543FC127AAAA

Note that for REC 523, the selectable relay variants are given as

order numbers, for example REC523C 033AAA. Refer to the

technical reference manual of REC 523, see Section 1.8. Related

documents)

27

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

hw_variant

Fig. 5.1.4.2.-2 Defining hardware version

select_analog_channels

Fig. 5.1.4.2.-3 Selecting the dialog box for analog settings

Analog channels

In the dialog box for defining analog channels (Fig. 5.1.4.2.-4), click the option

button for each channel in turn, and select the measuring device and signal type for

the channels in use from the drop-down list. Select the option Not in use for other

channels.

28

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

analog_channels

Fig. 5.1.4.2.-4 Defining the analog channel settings

Furthermore, define the technical data and measurements for the selected channels

before the configuration is used in a real application.

29

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

Technical data

rated_values

Fig. 5.1.4.2.-5 Defining the rated values for the selected measuring device

Measurements

For information about the special measurements required for each

function block, refer to the Technical Descriptions of Functions (see

Section 1.8. Related documents).

True RMS measurement and 2nd harmonic restraint measurements

If the signal type selected for an analog channel is going to be measured by any

measurement function block (MECU3A etc.), select the option True RMS mode in

the Special Measurements dialog box.

If the Inrush3 function block (3-phase transformer inrush and motor start-up current

detector) is to be used, select the option 2nd Harmonic Restraint for the analog

channels (IL1, IL2, IL3) used.

30

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

SpecMeasIL1

Fig. 5.1.4.2.-6 Selecting the required special measurement modes for phase

current measurement

Neutral current

When the DEF2_ function block (directional earth-fault protection) is going to be

used, select the option Intermittent earth-fault protection in the Special

Measurements dialog box for the channel via which the current I0 is measured.

The intermittent earth-fault protection can be enabled for the maximum of two

physical channels at a time. Note that the intermittent earth-fault protection requires

the residual voltage for directional operation. Therefore, the channel for the residual

voltage U0 must be defined before the selection can be made. Unless intermittent

earth-fault protection has been chosen, the following configuration error indication

appears on the display of REF 54_, REM 54_ or RET 54_ ( “#” denotes the number

of the analog channel in question):

System: SUPERV

Ch # error

SpecMeasIo

Fig. 5.1.4.2.-7 Selecting the required special measurement modes for neutral

current measurement

31

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

Frequency

When, for example, the function block MEFR1 (system frequency measurement) is

in use, frequency measurement must be selected for the channel via which the

voltage is measured for frequency measurement. For example Channel 10 (Voltage

Transformer 4, Signal type U3), click the Measurements button in the

Configuration of REF543 dialog box.

The power quality function blocks PQCU3H and PQVO3H require frequency

measurement for the channel that is connected to the FREQ_REF input, that is, the

channel for frequency reference (for more information, refer to the manuals of

PQCU3H and PQVO3H on the CD-ROM Technical Descriptions of Functions, see

Section 1.8. Related documents). Furthermore, frequency protection must be

selected if any of the function blocks SCVCSt_ or Freq1St_ is in use.

SpecMeasUL1

Fig. 5.1.4.2.-8 Selecting the required special measurement modes for frequency

measurement

Virtual channels

In case no measuring devices are applied for measuring residual voltage (U0) and

neutral current (I0), the virtual channels 11 and 12 can be used. If only one virtual

channel is used, the channel is numbered as channel 11 regardless of whether

residual voltage or neutral current is calculated. If both I0 and U0 are calculated,

channel 11 is used for I0S and channel 12 for U0S.

32

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

virtual_channels

Fig. 5.1.4.2.-9 Using virtual channels 11 and 12 in case no measuring devices are

applied for measuring I0 and U0

In case of the virtual channels for calculating I0 and U0, phase currents and voltages

must be associated with current and voltage measuring devices (see Fig. 5.1.4.2.-10

and Fig. 5.1.4.2.-11).

Summed_Ios

Fig. 5.1.4.2.-10 Associating phase currents with current measuring devices

33

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

Summed_Uos

Fig. 5.1.4.2.-11 Associating phase voltages with voltage measuring devices

After a compiled configuration is downloaded to a device, it checks

internally whether the analog channels are correctly configured

regarding the analog inputs of function blocks.

If the connected channels have been configured incorretly, the ERR

output signal of the specific function block activates and the analog

channel configuration error event (E48) is sent. Some function

blocks have special error events that are explained in the

corresponding function block manuals on the CD-ROM Technical

Descriptions of Functions (see Section 1.8. Related documents).

Digital inputs

The filter time is set for each digital input of the device via the resource settings

dialog box Binary Inputs. Inversion of the inputs can also be set. Note, however, that

the inversion of an input cannot be seen from the configuration. For further

information refer to the technical reference manual of REF 54_, REM 54_, RET 54_

or REC 523 (see Section 1.8. Related documents).

34

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

BIN_INPUT

Fig. 5.1.4.2.-12 Defining the digital inputs

Measurements

When the MEPE7 function block (power and energy measurement) is used, the

measuring mode must be selected via the resource settings dialog box

Measurements. True RMS measurement must also be selected for the channels used

by MEPE7.

Note that the measuring modes can only be selected after the analog channels have

been defined (see Fig. 5.1.4.2.-4).

35

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

MEPE7

Fig. 5.1.4.2.-13 Selecting the measuring mode for power and energy measurement

Condition monitoring

Values for the circuit-breaker wear function blocks CMBWEAR 1 and 2 can be set

via the resource settings dialog box Condition Monitoring.

36

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

cbwear

Fig. 5.1.4.2.-14 Setting the values for circuit-breaker wear

5.1.4.3.

Resource for REF 54_ Release 2.5 or later, REC 523 revision F

and RET 54_

The PLC type selected in the Configuration dialog box determines which processor

types are available. To select the processor type and name the resource:

1. Select an object under the Physical Hardware tree and select Edit > Insert.

2. In the opening dialog box, click the option button Resource, select the correct

processor type and name the resource.

For example, the processor type REF543R refers to a REF 543 feeder terminal

equipped with an RTD module.

37

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

processtype2.5

Fig. 5.1.4.3.-1 Defining the processor type

Hardware version

After selecting the processor type, click the Settings button in the dialog box (see

Fig. 5.1.4.3.-1 above) to define the correct hardware version (see Fig. 5.1.4.3.-2).

Do not click OK after selecting the correct hardware version

(Fig. 5.1.4.3.-2), but wait until the next dialog box opens and select

the option Analog Channels (see Fig. 5.1.4.3.-3).

The hardware version number is included in the order number of the product. The

order number is labelled on the marking strip on the front panel of the product.

Example:

Order No: REF543GC127AAAA

hardware2.5

Fig. 5.1.4.3.-2 Defining the hardware version

38

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

analog_settings2.5

Fig. 5.1.4.3.-3 Selecting the dialog box for analog settings

Analog channels

In the dialog box for defining analog channels (see Fig. 5.1.4.3.-4), click the option

button for each channel in turn, and select the measuring device and signal type for

the channels in use from the drop-down list. Select the option Not in use for other

channels.

Furthermore, the technical data and measurements for the selected channels are to

be completed correctly before the configuration is used in a real application.

analog_channels2.5

Fig. 5.1.4.3.-4 Defining the analog channels

39

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

Technical data

rated_values2.5

Fig. 5.1.4.3.-5 Defining the rated values for the selected measuring device

Measurements

For information about the special measurements required for each

function block, refer to the Technical Descriptions of Functions (see

Section 1.8. Related documents).

True RMS and 2nd harmonic restraint measurements

If the signal type selected for an analog channel is going to be measured by any

measurement function block (MECU3A etc.), the true RMS mode must be selected

in the Special Measurements dialog box. Moreover, in case the Inrush3 function

block (3-phase transformer inrush and motor start-up current detector) is to be used,

the 2nd harmonic restraint must be selected for the analog channels (IL1, IL2, IL3)

used.

40

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

phase_measu2.5

Fig. 5.1.4.3.-6 Selecting the required special measurement modes for phase

current measurement

Neutral current

When the DEF2_ function block (directional earth-fault protection) is going to be

used, intermittent earth-fault protection must be selected for the channel via which

the current I0 is measured. The intermittent earth-fault protection can be enabled for

the physical channels I0 and I0b as well as for the virtual channels I0s and I0bs at the

same time.

The intermittent earth-fault protection requires the residual voltage for directional

operation. Therefore, the channel for the residual voltage U0 must be defined before

the selection for I0 measurement channels can be made. The amount of the U0

channels used for the intermittent earth-fault protection is limited to one. The first

available U0 channel should be selected from the list: U0, U0b, U0s and U0bs. Unless

intermittent earth-fault protection has been chosen correctly, a configuration error

indication will appear on the error list of the Relay Download Tool.

neutral_measu2.5

Fig. 5.1.4.3.-7 Selecting the required special measurement modes for neutral

current measurement

41

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

Frequency

When, for example, the function block MEFR1 (system frequency measurement) is

in use, frequency measurement must be selected for the channel via which the

voltage is measured for frequency measurement. For example Channel 10 (Voltage

Transformer 4, Signal type U3), click the Measurements button in the

Configuration of REF543 dialog box.

The power quality function blocks PQCU3H and PQVO3H require frequency

measurement for the channel that is connected to the FREQ_REF input, that is, the

channel for frequency reference (for more information refer to the manuals of

PQCU3H and PQVO3H on the CD-ROM Technical Descriptions of Functions, see

Section 1.8. Related documents). Furthermore, frequency protection must be

selected if any of the function blocks SCVCSt_ or Freq1St_ is in use.

freq_measu2.5

Fig. 5.1.4.3.-8 Selecting the required special measurement modes for frequency

measurement

Virtual channels

The virtual channels can be used if no measuring devices are applied for measuring

phase-to-phase voltages, residual voltage (U0) and neutral current (I0). The virtual

channels selected for use are numbered from the channel number 11. For further

information about the channel numbers of the calculated virtual channels, refer to

the technical reference manual of the terminal in question (see Section 1.8. Related

documents).

An example of when the virtual channels can be used is shown in Fig. 5.1.4.3.-9.

42

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

virtual_channels2.5

Fig. 5.1.4.3.-9 Using virtual channels if phase-to-phase voltages, residual voltage

and neutral current measurement are not available

The virtual channels are selectable according to the selections in the Analog

Channels view. The selection of the virtual channels can be done in Virtual Channels

view (see Fig. 5.1.4.3.-10).

43

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

select_virtual_channels2.5

Fig. 5.1.4.3.-10 The selectable virtual channels when the configuration of the

analog channel is as in Fig. 5.1.4.3.-9

The special measurements are selectable for each used virtual channel (see

Fig. 5.1.4.3.-11 and Fig. 5.1.4.3.-12).

The special measurement view for the virtual channel Ios is shown in Fig. 5.1.4.3.11. The analog channels used for derivation and derivation equation are also shown.

The analog channels are as in Fig. 5.1.4.3.-9.

Ios_measu2.5

Fig. 5.1.4.3.-11 Special measurement view for the virtual channel Ios

Special measurement view for the virtual channel U12s is shown in the Fig. 5.1.4.3.12. The analog channels used for derivation and derivation equation are also shown.

The analog channels are as in Fig. 5.1.4.3.-9.

44

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

Ios_measu_2.5_2

Fig. 5.1.4.3.-12 Special measurement view for the virtual channel U12s.

After a compiled configuration is downloaded to a device, the device

checks internally whether the analog channels are correctly

configured regarding the analog inputs of function blocks.

If the connected channels have been configured incorrectly, the ERR

output signal of the specific function block activates and the analog

channel configuration error indication appears on the error list of the

Relay Download Tool. For more information, refer to Section 5.5.

Downloading the configuration.

Digital inputs

The filter time is set for each digital input of the device via the resource settings

dialog box Binary Inputs field. Inversion of the inputs can be set as well. Note,

however, that the inversion of an input cannot be seen from the configuration. For

further information, refer to the technical reference manual of the terminal in

question (see Section 1.8. Related documents).

digital_inputs2.5

Fig. 5.1.4.3.-13 Defining the digital inputs

45

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

Measurements

When the MEPE7 function block (power and energy measurement) is used, the

measuring mode must be selected by clicking the option button Measurements in the

resource settings dialog box. True RMS measurement must also be selected for the

channels used by MEPE7.

The measuring modes can only be selected after the analog channels

have been defined (see Fig. 5.1.4.3.-4).

power&energy_measu2.5

Fig. 5.1.4.3.-14 Selecting the measuring mode for power and energy measurement

Condition monitoring

Values for the circuit-breaker wear function blocks CMBWEAR 1 and 2 can be set

via the resource settings dialog box by clicking the option button Condition

Monitoring.

46

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

wear2rle

Fig. 5.1.4.3.-15 Setting the values for circuit-breaker wear

5.1.4.4.

Tasks

Programs and tasks

Programs are associated with tasks via the dialog boxes Properties/Task and

Properties/Program. To define task properties in the Relay Configuration Tool:

1. Select an object in the project tree.

2. Select Edit > Insert and define task name and type.

One task may include several programs. Cyclic tasks are activated within a specific

time interval and the program is executed periodically. As many as 10 POUs can be

associated to a task.

To define program properties in the Relay Configuration Tool:

1. Select a task in the project tree.

2. Select Edit > Insert and define program instance and type.

The two dialog boxes below illustrate the association of a program type (Prot_Me)

with a task (Task1) (see also Fig. 5.1.4.-1).

47

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

TASK1

Fig. 5.1.4.4.-1 Naming a cyclic task

PROT_ME

Fig. 5.1.4.4.-2 Associating the selected task with the desired program type

Task interval

Generally, operation accuracy is increased when task speed is increased, but at the

same time, the load of the microprocessors is increased as well. Although the task

speed can be freely chosen with the tool, it is necessary to define a maximum task

execution interval for each function block. If not defined, the operation accuracy and

operate times for protection functions cannot be guaranteed.

The maximum task execution interval is based on test results and it has been used in

the type testing of the function blocks. The recommended task execution interval

quaranteed by the manufacturer can be found in technical data section in the

technical description of each function block. Furthermore, certain function blocks,

for example MEDREC16, must be tied to the task given by the manufacturer in order

to enable the operation of these function blocks. For more information about the task

execution intervals of function blocks, refer to the introduction chapter in the

Technical Descriptions of Functions CD-ROM, see Section 1.8. Related documents.

For microprocessor loads, refer to Section 5.5. Downloading the configuration.

According to the standard, the Relay Configuration Tool offers a possibility to

define the tasks on two different levels:

1. Each program organisation unit (POU) can be tied to a separate task.

2. Separate function block inside a POU can be tied to any task.

48

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

However, the second alternative is not supported in the RED 500 environment; if a

separate function block inside a POU is given a separate task definition, it is ignored

when transferred to the device. This means that when the function blocks are being

placed in different POUs, not only the category of the function (protection, control,

and so on) but also the maximum task execution interval should be considered, since

all function blocks inside a POU run at the same speed.

Define the task execution interval for each task by selecting a task and by selecting

Edit > Insert; click the Settings button in the opening dialog. For example, the task

execution interval for Task1 in the figure below is defined as 10 ms, which means

that the program Prot_Me is run 100 times per one second. The maximum number

of tasks with different intervals is 4.

The tool automatically modifies the task setting if the set network

frequency is other than 50 Hz (see the Network Frequency text box

in Fig. 5.1.4.2.-4). For example at 60 Hz, 10 ms becomes 8.333 ms.

interval

Fig. 5.1.4.4.-3 Setting the task execution interval for a program

If there is a need for several different tasks that control the same output relay, it is

recommended that the output relay is controlled directly in the fastest task and other

control commands are brought to that task via global variables.

Example:

Some protection function blocks can be run in the 5 ms task, some in the

10 ms task and some even using the 100 ms task. Still, all these function

blocks use the same output relay.

Another way to avoid also the software delays when communicating between the

different tasks is to use a separate output relay for each protection task.

Example:

The trip signal from the 5 ms task is connected to High-Speed Power Output

1 and the trip signal from the 10 ms task to High-Speed-Power-Output 2. The

outputs can then control the same opening coil of the circuit breaker.

5.2.

Declaring variables

The validity range of the declarations that are included in the declaration part should

be “local” to the POU in which the declaration part is contained. However, variables

that are declared to be “global” are only accessible to a POU via a

49

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

VAR_EXTERNAL declaration. The type of a variable declared in a

VAR_EXTERNAL block should agree with the type declared in the

VAR_GLOBAL block of the associated program, configuration or resource.

Program B

FB2

FB_Y

FB1

FB_X

a

y

y

b

Program A

FB2

FB_Y

FB1

FB_X

VAR

y:BOOL;

FB1:FB_X;

FB2:FB_Y;

END_VAR

a

b

VAR

FB1:FB_X;

FB2:FB_Y;

END_VAR

Configuration C

Program A

VAR_EXTERNAL

x:BOOL;

END_VAR

VAR

FB1:FB_X;

END_VAR

Program B

FB1

FB_X

FB2

FB_Y

a

x

VAR_GLOBAL

x:BOOL;

END_VAR

x

b

VAR_EXTERNAL

x:BOOL;

END_VAR

VAR

FB2:FB_Y;

END_VAR

Fig. 5.2.-1 Local and global variables

The figure above illustrates the how variable values can be communicated among

software elements either directly or via global variables.

Variable values within a program can be communicated directly by connecting the

output of one program element to the input of another, or via local variables, such as

the variable “y” illustrated in the upper-left corner of the figure above.

In the same configuration, variable values can be communicated between programs

via global variables, such as the variable “x” illustrated in Configuration C in the

figure above. In such a case, make sure that the global variable is only written from

one location in the project. The global variable can still be read from several

locations.

According to the IEC 61131-3, all the variables that have no explicit initializer are

initialized with a data-type dependent default value. Despite of this, it is always

recommended that the initial value is given explicitly. Naturally, the value to which

each variable should be initialised depends on the logical function of the program .

Table 5.2.-1 Default values according to data types

50

Data type

Default initial value

ANY_REAL

ANY_INT

ANY_BIT

TIME

0.0

0

0 (=FALSE)

T#0s

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

Especially the initial values of global variables are logically significant for the

program. The user cannot choose the order in which tasks are initialised. This means

that if a task reading a global variable is initialized before another task gives the

variable its first value, it is important that an appropriate initial value has been

selected for the global variable.

CASE 1. Variables declaration

VARIABLE WORKSHEET of logical POU

******************************************************************

VAR

TRIPPING :BOOL

:= FALSE;

BLOCK

:BOOL

:= TRUE;

TMP1

:BOOL

:= FALSE;

END_VAR

VAR_EXTERNAL

PS1_4_HSPO1 :BOOL;

(* Double pole high speed power output *)

(* X4.1/10,11,12,13 *)

PS1_4_HSPO2 :BOOL;

(* Double pole high speed power output *)

(* X4.1/15,16,17,18 *)

PS1_4_HSPO3 :BOOL;

(* Double pole high speed power output *)

(* X4.1/6,7,8,9 *)

END_VAR

VAR_EXTERNAL

TCS1_ALARM :BOOL;

END_VAR

******************************************************************

GLOBAL VARIABLE WORKSHEET

******************************************************************

VAR_GLOBAL

PS1_4_HSPO1

PS1_4_HSPO2

PS1_4_HSPO3

END_VAR

VAR_GLOBAL

TCS1_ALARM

END_VAR

AT %QX 1.1.2

:BOOL

:= FALSE;

(* Double pole high speed power output X4.1/10,11,12,13 *)

AT %QX 1.2.2

:BOOL

:= FALSE;

(* Double pole high speed power output X4.1/15,16,17,18 *)

AT %QX 1.3.2

:BOOL

:= FALSE;

(* Double pole high speed power output X4.1/6,7,8,9 *)

:BOOL

:= FALSE;

******************************************************************

51

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

5.2.1.

Global variables

The physical contacts are defined in the Global Variables worksheet (Fig. 5.2.1.-1).

Declarations for the physical contacts are automatically defined when the correct

hardware version of RE_ 54_ is selected. Declarations for the analog channels are

created after the analog channel settings defined in the resource settings dialog box

have been approved.

The textual names of the inputs and outputs, for example BIO2-7_BI10IV (see the

figure below), can be modified. Note, however, that the address (for example

AT %IX 1.29.1 :BOOL := TRUE) following the name may not be changed.

global

Fig. 5.2.1.-1

5.2.2.

Global Variables worksheet

Local variables

At the beginning of each programmable controller POU type declaration there

should be at least one declaration part that specifies the types of the variables used

in the organisation unit. The declaration part should have the textual form of one of

the keywords VAR_INPUT, VAR_OUTPUT, VAR and VAR_EXTERNAL

followed by one or more declarations separated by semicolons and terminated by the

keyword END_VAR. All the comments you write must be edited in parentheses and

asterisks:.

(*******************************)

Variable declaration

(*

*)

of REF 541

(*

*)

(*******************************)

52

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

Caution is required regarding comments and variable declarations. The following

code example would be compiled successfully but because of the non-closed

comment, the END_VAR - VAR_EXTERNAL couple is excluded and thus the

channel numbers become local variables of the POU and they get the initial value

zero:

VAR (*AUTOINSERT*)

NOC3Low_1 :

NOC3Low; (* Erroneous nonclosed comment *

END_VAR

VAR_EXTERNAL (*AUTOINSERT*)

U12

:

SINT;

(* Measuring channel 8 *)

U23

:

SINT;

(* Measuring channel 9 *)

U31

:

SINT;

(* Measuring channel 10 *)

END_VAR

Three examples of creating the textual declaration for different kinds of graphical

programs are given below.

Example 1:

POU type: FBD program

Function block type declaration:

VAR

SIGNAL1

SIGNAL2

SIGNAL3

SIGNAL4

END_VAR

:BOOL :=FALSE;

:BOOL :=FALSE;

:BOOL :=FALSE;

:BOOL :=FALSE;

and_or_gates

Fig. 5.2.2.-1

Function block image

53

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

Example 2:

POU type: NOC3Low, manufacturer-dependent function block

Function block type declaration:

VAR_INPUT

IL1

IL2

IL3

BS1

BS2

TRIGG

GROUP

DOUBLE

BSREG

RESET

END_VAR

VAR_OUTPUT

START

TRIP

CBFP

ERR

END_VAR

:SINT

:SINT

:SINT

:BOOL

:BOOL

:BOOL

:BOOL

:BOOL

:BOOL

:BOOL

:=0;

:=0;

:=0;

:=FALSE;

:=FALSE;

:=FALSE;

:=FALSE;

:=FALSE;

:=FALSE;

:=FALSE;

(* Analog channel *)

(* Analog channel *)

(* Analog channel *)

(* Blocking signal *)

(* Blocking signal *)

(* Triggering *)

(* Grp1/Grp2 select *)

(* Doubling signal *)

(* Blocking registering *)

(* Reset signal *)

:BOOL

:BOOL

:BOOL

:BOOL

:=FALSE;

:=FALSE;

:=FALSE;

:=FALSE;

(* Start signal *)

(* Trip signal *)

(* CBFP signal *)

(* Error signal *)

NOC3Low_b

Fig. 5.2.2.-2

54

Function block image of NOC3Low

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

Example 3:

POU type: Programmer-dependent FBD function block CONDIS

Function block type declaration:

condisv

Fig. 5.2.2.-3

Type declaration of the programmer made function block CONDIS

55

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

condis

Fig. 5.2.2.-4

FBD worksheet contents of the CONDIS function block

condis_control

Fig. 5.2.2.-5

Use of the programmer made function block CONDIS

In the Example 3 above, part of the configuration has been separated to a

programmer-made function block called CONDIS. Such function blocks may not be

given names already belonging to library functions blocks or IEC standard function

blocks. The function block CONDIS has been used like any other function block in

the graphical program. It must also be remembered that a function block with an

instance named by the programmer can only be inserted to the project once.

56

1MRS750745-MUM

Protection & Control Terminals

REF 54_, REM 54_,

RET 54_, REC 523

Configuration Guideline

5.3.

Compiling project

In the Relay Configuration Tool’s Make menu, select the command Build Project

to compile the whole project for the first time after editing. This means compiling

all POUs, global variables, resources and so on.

In the Make menu, use the Make command to compile the worksheets that have

been edited. The changed worksheets are marked with an asterisk, “*”, in the project

tree editor. The Make command is the standard mode for compiling and should

normally be used when you have finished editing.

It is recommended that the Build Project command is given once more

just before downloading the configuration to the product.

In the Relay Configuration Tool you can view the execution order of the different

functions or function blocks in your worksheet. The execution order corresponds to

the intermediate PLC code created while compiling. Note that the execution order

can only be seen if you have already compiled the worksheet by using the menu

command Make > Compile Worksheet.

5.4.

Add-on protocol

If an add-on protocol is used, the protocol mapping must be created by using the

Protocol Mapping Tool (PMT). For more information, refer to the documents in

Section 1.8. Related documents.

Table 5.4.-1

Available add-on protocols

Relay version

REF 54_ Release 2.5

REF 54_ Release 3.0

REF 54_ Release 3.5

REM 54_ Release 2.5

RET 54_ Release 3.0

Modbus

DNP 3.0

IEC 60870-5-103

X

X

X

X

X

X

X

X

X

X

X

REC 523 does not have any add-on protocols, but the device

includes fixed protocols according to the device’s software

configuration. In REC 523 revision F, the protocol interface can be

modified by using the Protocol Mapping Tool. In earlier releases, the

protocol interface can be modified by using the Protocol Editing

Tool. These tools are included in CAP 505. For more information on

the REC 523 protocols, refer to the technical reference manual of

REC 523 (see Section 1.8. Related documents).

5.5.

Downloading the configuration

After the configuration has been built and succesfully compiled in the Relay

Configuration Tool and the MIMIC configuration has been designed, the project can

be downloaded to the device.

57

REF 54_, REM 54_, Protection & Control Terminals

RET 54_, REC 523

1MRS750745-MUM

Configuration Guideline

The parts of the project to be downloaded are selected via a dialog box. The MIMIC

configuration and the Relay Configuration Tool project can be downloaded

separately.

The project can also be downloaded separately as a compressed file.

This enables later uploading of the project from the device. The

compressed file is automatically created if the check box RCT

project has been selected (see Fig. 5.5.-1).

The target device has an inherent limitation over the size of a stored project file. If

this is exceeded, the tool interrupts the downloading and issues a warning.

It is useful to include some information of the project in the file by

giving, for example, the name of the designer, the date and the version

or other description of the configuration. To add project information,

select File > Project Info in the Relay Configuration Tool.

Add-on protocols (for example Modbus and IEC 60870-5-103) of the relay terminal

are activated in the relay according to Add-On protocol selection in object

properties.