• COLUMNS: BUCKLING (DIFFERENT ENDS) Buckling of Long

advertisement

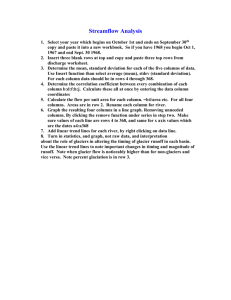

• COLUMNS: BUCKLING (DIFFERENT ENDS) Slide No. 1 Buckling of Long Straight Columns Example 4 A simple pin-connected truss is loaded and supported as shown in Fig. 12. All members of the truss are WT102 × 43 sections made of structural steel with a modulus of elasticity of 200 GPa and a yield strength of 250 MPa. Determine (a) the factor of safety with respect to failure by slip, and (b) the factor of safety with respect to failure by buckling. 1 Slide No. 2 Buckling of Long Straight Columns Example 4 (cont’d) Figure 12 D E 3m A C B 4m 15 kN 4m 30 kN Slide No. 3 Buckling of Long Straight Columns Example 4 (cont’d) Free-body diagram: D E 3m A B θ 4m 15 kN θ C RE RCy RCx 4m 30 kN 2 Slide No. 4 Buckling of Long Straight Columns Example 4 (cont’d) Find the reactions RE and RC: ∑M + ∑M +↑ ∑F + C = 15(8) + 30(4) − RE (3) = 0; ⇒ RE =80 kN E = 15(8) + 30(4 ) + RCx (3) = 0; ⇒ RCx = − 80 kN y = 0; RCy − 30 − 15 = 0; ⇒ RCy = 45 kN Note that, FDE = RE = 80 kN (T) θ = tan −1 3 = 36.87 0 4 Slide No. 5 Buckling of Long Straight Columns Example 4 (cont’d) FDC At pin C: FBC 45 36.87 + ↑ ∑ Fy = 0; FDC sin 36.87 + 45 = 0 C 80 FDC = −75 kN = 75 kN (C) + → ∑ Fx = 0; − FBC − 80 − FDC cos 36.87 = 0 ⇒ − FBC − 80 − (− 75)(0.8) = 0 ⇒ FBC = −20 kN = 20 kN (C) 3 Slide No. 6 Buckling of Long Straight Columns FDB Example 4 (cont’d) At joint B: B FAB FDB = 30 kN FAB = −20 kN = 20 kN (C) 20 30 At Joint A: FAD + ↑ ∑ Fy = 0; A − 15 + FAD sin 36.87 = 0 ∴ FAD = 25 kN (T) 36.87 20 15 Slide No. 7 Buckling of Long Straight Columns Example 4 (cont’d) – Thus, the forces in the truss are as follows: D 3m A kN 25 ( T) 20 kN (C) 80 kN (T) 75 30 kN (T) B 4m 15 kN kN E (C ) C 20 kN (C) 4m 30 kN 4 Slide No. 8 Buckling of Long Straight Columns Example 4 (cont’d) (a) Factor of safety with respect to slip: • For WT102 × 43, A = 5515 mm2 (Appendix B) • For member DE, the critical member that gives the largest force: ( ) Pmax = σ yield A = 250 ×10 6 5515 × 10 −6 = 1379 × 103 N = 1379 kN ∴ FS = Pmax 1379 = = 17.24 FDE 80 Slide No. 9 Buckling of Long Straight Columns Example 4 (cont’d) (b) Factor of safety with respect to failure by buckling: • For WT102 × 43, rmin = 26.2 mm (Appendix B) • For member DC, the critical member that gives the largest compressive force: L 5,000 = = 190.84 (slender) rmin 26.2 Pcr = π 2 EA (L / rmin )2 ∴ FS = = π 2 (200 ×109 )(5515 ×10 −6 ) (190.84)2 = 298.9 kN 298.9 Pcr = = 3.99 ≅ 4 75 FDC 5 Slide No. 10 Effects of Different Idealized End Conditions General Notes On Column Buckling 1. Boundary conditions other than simplysupported will result in different critical loads and mode shapes. 2. The buckling mode shape is valid only for small deflections, where the material is still within its elastic limit. 3. The critical load will cause buckling for slender, long columns. In contrast, failure will occur in short columns when the strength of material is exceeded. Between the long and short column Slide No. 11 Effects of Different Idealized End Conditions General Notes On Column Buckling limits, there is a region where buckling occurs after the stress exceeds the proportional limit but is still below the ultimate strength. These columns are classified as intermediate and their failure is called inelastic buckling. 4. Whether a column is short, intermediate, or long depends on its geometry as well as the stiffness and strength of its material. This concept is addressed in the columns introduction page. 6 Slide No. 12 Effects of Different Idealized End Conditions The Concept of Effective Length – The Euler buckling formula, namely Eqs. 9 or 12 was derived for a column with pivoted ends. – The Euler equation changes for columns with different end conditions, such as the four common ones found in Figs.13 and 14. – While it is possible to set up the differential equation with appropriate boundary Slide No. 13 Effects of Different Idealized End Conditions Figure 13 7 Slide No. 14 Effects of Different Idealized End Conditions Figure 14 (Beer and Johnston 1992) Slide No. 15 Effects of Different Idealized End Conditions ENES 220 ©Assakkaf The Effective Length Concept – Conditions to determine the Euler buckling formula for each case, a more common approach makes use of the concept of an “effective length”. – The pivoted ended column, by definition, has zero bending moments at each end. – The length L in the Euler equation, therefore, is the distance between 8 Slide No. 16 Effects of Different Idealized End Conditions The Effective Length Concept – Successive points of zero bending moment. – All that is needed to modify the Euler column formula for use with other end conditions is to replace L by L.′ ′ defined as the effective length of the – Lis column. Slide No. 17 Effects of Different Idealized End Conditions The Effective Length Concept Definition: The effective length L′ (or Le) of a column is defined as the distance between successive inflection points or points of zero moment. 9 Slide No. 18 Effects of Different Idealized End Conditions The Effective Length Concept Based on the effective length concept, the Euler Buckling load formula becomes π 2 EI (16a) Pcr = L2e or Pcr = Le = L′ = effective length π 2 EA (Le / r ) 2 (16b) Slide No. 19 Effects of Different Idealized End Conditions Example 5 What is the least thickness a rectangular wood plank 4 in. wide can have, if it is used for a 20-ft column with one end fixed and one end pivoted, and must support an axial load of 1000 lb? Use a factor of safety (FS) of 5. The modulus of elasticity of wood is 1.5 × 106 psi. 10 Slide No. 20 Effects of Different Idealized End Conditions Example 5 (cont’d) The rectangular cross section is b = 4 in t? I= bt 3 12 For the end conditions specified in the problem, Fig. 13d (or Fig. 14c) gives Le = 0.7 L Slide No. 21 Effects of Different Idealized End Conditions Example 5 (cont’d) Figure 13 11 Slide No. 22 Effects of Different Idealized End Conditions Example 5 (cont’d) Since FS = 5 is required, but Pcr = (FS )P = 5(1000) = 5,000 lb 4t 3 π (1.5 ×10 ) 12 π 2 EI = 5,000 Pcr = = 2 Le [0.7(20 ×12)] From which 2 6 t = 3.06 in Slide No. 23 Effects of Different Idealized End Conditions Example 6 An L102 × 76 × 6.4-mm aluminum alloy (E = 70 GPa) angle is used for fixed-end, pivoted-end column having an actual length of 2.5 m. Determine the maximum safe load for the column if a factor of safety 1.75 with respect to failure by buckling is specified. 12 Slide No. 24 Effects of Different Idealized End Conditions Example 6 (cont’d) For fixed-end, pivoted-end column, Fig. 13d (or Fig. 14c) gives the equivalent length as Le = 0.7 L = 0.7(2.5) = 1.75 m = 1,750 mm For L102 × 76 × 6.4 section (see Fig. 15 or Appendix B of textbook): A = 1090 mm 2 rmin = 16.5 mm Slide No. 25 Effects of Different Idealized End Conditions Figure 15 Example 6 (cont’d) 13 Slide No. 26 Effects of Different Idealized End Conditions Example 6 (cont’d) Therefore, L′ 1750 = = 106.06 (slender) rmin 16.5 π 2 EA Pmax = = 2 Pcr (L′ / rmin ) π 2 EA = = 2 FS FS FS (L′ / rmin ) π 2 (70 × 109 )(1090 ×10 −6 ) 1.75(106.06) 2 = 38,254.54 N = 38.3 kN Slide No. 27 Effects of Different Idealized End Conditions Example 7 Determine the maximum load that a 50mm × 75-mm × 2.5-m long aluminum alloy bar (E = 73 GPa) can support with a factor of safety of 3 with respect to failure by buckling if it is used as a fixed-end, pivoted column. For fixed-end, pivoted column, Fig. 13d (or Fig. 14c) gives effective length, L′ = 0.7 L = 0.7(2.5) = 1.75 m 14 Slide No. 28 Effects of Different Idealized End Conditions Example 7 (cont’d) Computation of the section properties: 75 mm A = 75(50 ) = 3,750 mm 2 ba 3 75(50 ) = = 0.7813 ×106 mm 4 12 12 3 I min = 50 mm rmin 0.7813 × 106 I min = = 14.43 mm 3750 A Slide No. 29 Effects of Different Idealized End Conditions Example 7 (cont’d) Therefore, the slenderness ratio of the column can be obtained: L′ 1.75 ×103 = = 121.28 (slender) rmin 14.43 and Pmax = ( )( ) π 2 EA π 2 73 ×109 3750 ×10 −6 Pcr = = = 61.2 kN 2 FS FS (L′ / rmin ) 3(121.28) 15 Slide No. 30 Effects of Different Idealized End Conditions Example 8 A structural steel (E =29,000 ksi) column 20 ft long must support an axial compressive load of 200 kip. The column can be considered pivoted at one end and fixed at the other end for bending about one axis and fixed at both ends for bending about the other axis. Select the lightest wide-flange or American standard section that can be used for the column. Slide No. 31 Effects of Different Idealized End Conditions Example 8 (cont’d) First case: fixed-end, pivoted column Lex = Lx′ = 0.7(20 ) = 14 ft Pcr = π 2 EI x Lx′2 Pcr Lx′2 200(14 ×12 ) = 19.72 in 2 Ix = 2 = 2 π E π (29,000) 2 16 Slide No. 32 Effects of Different Idealized End Conditions Example 8 (cont’d) Second case: fixed ends column Ley = L′y = 0.5(20 ) = 10 ft 200(10 × 12 ) = 10.06 in 2 Iy = 2 = 2 π E π (29,000 ) Pcr L′y2 2 Use a W254 × 33 section Slide No. 33 Effects of Different Idealized End Conditions Example 9 A 25 mm-diameter tie rod AB and a pipe strut AC with an inside diameter of 100 mm and a wall thickness of 25 mm are used to support a 100-kN load as shown in Fig. 16. Both the tie rod and the pipe strut are made of structural steel with modulus of elasticity of 200 GPa and a yield strength of 250 MPa. Determine 17 Slide No. 34 Effects of Different Idealized End Conditions Example 9 (cont’d) (a) the factor of safety with respect to failure by slip. (b) the factor of safety with respect to failure by buckling Slide No. 35 Effects of Different Idealized End Conditions Example 9 (cont’d) B Figure 16 2.5 m A 4.5 m 100 kN C 6m 18 Slide No. 36 Effects of Different Idealized End Conditions Example 9 (cont’d) FAB y At joint A: A 2.5 4.5 θ = tan −1 = 22.62 0 , α = tan −1 = 36.87 0 6 6 θ x α + → ∑ Fx = 0; FAB cosθ + FAC cos α = 0 FAC FAB cos 22.62 + FAC cos 36.87 = 0 FAB = −0.8667 FAC (17) + ↑ ∑ Fx = 0; FAB sin θ − FAC sin α − 100 = 0 FAB sin 22.62 − FAC sin 36.87 − 100 = 0 FAB = 1.56 FAC + 260 (18) Slide No. 37 Effects of Different Idealized End Conditions Example 9 (cont’d) Substituting for FAB in Eq. 17 into Eq. 18, gives − 0.8667 FAC = 1.56 FAC + 260 Thus, FAC = −107.14 kN = 107.14 kN (C) From Eq. 18, with FAC known, we have FAB = 1.56 FAC + 260 = 1.56(−107.14) + 260 = 92.86 kN (T) 19 Slide No. 38 Effects of Different Idealized End Conditions Example 9 (cont’d) Calculate the cross-sectional areas for AB and AC: AAB = π 4 (25)2 = 490.9 mm 2 , AAC = π 4 [(150) − (100) ] = 9817 mm 2 2 2 (a) FS due to Failure by Slip: σ AB = FAB 92.86 × 103 = 189.16 × 10 6 N/m 2 = 189.2 MPa = −6 AAB 490.9 ×10 FSAB = 250 = 1.32 189.16 Slide No. 39 Effects of Different Idealized End Conditions Example 9 (cont’d) σ AC = FAC − 107.14 ×103 = = −10.914 × 106 N/m 2 = 10.914 MPa (C) 9817 ×10 −6 AAC FSAB = 250 = 22.9 10.914 (b) FS due to Failure by Buckling: • Member AC is the compression member with a compressive force of 107.14 kN: π (150)2 − (100)2 = 19.942 ×106 mm 4 I AC = 64 [ ] 20 Slide No. 40 Effects of Different Idealized End Conditions Example 9 (cont’d) (b) FS for Buckling (cont’d): r= L = r 19.942 × 106 I = = 45.07 9817 A (6)2 + (4.5)2 ×1000 = 166.41 (slender) 45.07 π 2 EA π 2 200 ×109 9817 × 10 −6 = = 699.8 × 103 N ≅ 700 kN Pcr = (L / r )2 (166.41)2 700 P FSAC = cr = = 6.53 FAC 107.14 ( )( ) 21