RPH

advertisement

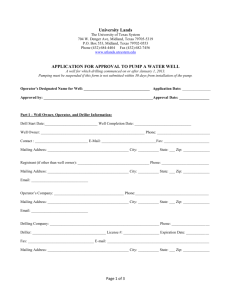

RPH Type series booklet 1316.52-10 G2 Process pumps to API 610, 10th edition and ISO 13709 Standard bearing assemblies B 02 to B 06 Tandem bearing assemblies B 02 to B 06 Cooled/uncooled Mechanical seal Made by KSB Automation products available: • PumpExpert • Hyamaster • hyatronic Fields of Application RPH pumps are mainly used in refineries as well as in chemical and petrochemical plants. Design Horizontal, radially split volute casing pumps in back pull-out design, to API 610, 10th edition, and ISO 13709 (heavy duty), with radial impeller, single-flow, single-stage, centreline pump feet. Pump model with inducer available on request. Designation RPH S1 I 80 - 280 B Type series Material variant Version with inducer Discharge nozzle DN Nominal impeller dia. in mm Special hydraulics (B-hydraulics) Operating Data Pump sizes Capacities Heads Operating pressures DN 25 to 400 Q up to 4.150 m3/h H up to 270 m p up to 51 bar (ASME B 16.5 class 300) for A216 Gr. WCB Higher pressures and flange pressure ratings on request Operating temperatures t -70 to +450 °C down to -110 °C on request Certification Certified quality management ISO 9001. RPH Selection chart 50 Hz n = 2900 1/min 5 4 300 US.gpm 5 10 IM.gpm 20 30 10 20 40 30 50 40 100 50 200 100 300 400 200 200 300 500 400 1000 500 2000 1000 3000 2000 150-450A 50-450 4000 200-450 100-450 80-450 200-450B 150-450B 40-361 80-360 50-360 4000 5000 3000 100-360C 150-360A 100-360A 100 500 400 200-360 150-360B 40-280 40-281 100-280 80-280 50-280 150-280 200-280 200 100-280B 25-230 40-230 50 150-280B 40-231 40 80-230B 40-180 50-180 40-181 150-230 100-230 100-230B 25-180 H [m] 200-280B 80-230 50-230 30 300 150-230B 100 80-180 100-180 80-180B 100-180B 20 50 ft 12 40 1 2 0.3 0.4 3 0.5 Selection chart 50 Hz n =1450 1/min size on request 2 4 1 5 l/s 3 Q[m /h] 2 10 20 3 4 5 30 40 10 50 100 20 30 200 40 50 300 400 100 500 1000 200 300 KE1316.4052/6 RPH Selection chart 60 Hz n = 3500 1/min 5 4 300 US.gpm 5 10 IM.gpm 20 30 10 20 40 30 50 40 100 50 200 100 300 200 400 300 500 400 1000 500 2000 1000 3000 2000 4000 5000 3000 4000 150-360A 200 40-361 50-360 80-360 100-360C 100-360A 200-360 500 150-360B 40-280 40-281 400 50-280 80-280 200-280 100 100-280 300 150-280 25-230 200-280B 40-230 40-231 50-230 100-280B 80-230B 80-230 150-280B 200 100-230 100-230B 50 150-230B 150-230 80-180 ft 25-180 40 40-180 50-180 40-181 100-180 100-180B 80-180B 100 30 H [m] 20 1 2 0.3 0.4 3 0.5 4 1 5 l/s 3 Q[m /h] 2 10 20 3 4 5 30 40 10 50 100 20 30 200 40 50 300 400 100 500 1000 200 300 KE1316.4062/4 Selection chart 60 Hz n =1750 1/min size on request 3 RPH Product Features / Benefits Flanges to all standards up to PN 100 equivalent (ASME Class 600) Max. shaft diameter in acc. with API 610 makes for very long service life of mechanical seal Bearings dimensioned for longer service life than specified by API 610, reducing maintenance expenditure and work Double volute from DN 80 (3 in.) - low radial load and less shaft deflection ⇒ longer service life of bearings and mechanical seal Tandem bearing assembly D01048/2 “Low Nss hydraulics” (Inducer on option) for optimum selection to API Individual adjustment of axial thrust balancing for maximum bearing life. 4 Optional: other labyrinth seal manufacturers (Pro Tech, ...) Optional: fan impeller Seal chamber to API 610 accommodates all mechanical seals to API 682 Steel bearing bracket with integrated cooling fins (fan impeller on option: no cooling water circuit required for high temperatures) RPH Pressure and Temperature Limits Pressure and temperature limits for pressure-retaining components (Bearing brackets B02-B06) 120.00 Max. pump discharge pressure pd [bar] 110.00 A487 Gr. CA6NM 100.00 90.00 A217 Gr. CA15 80.00 70.00 A351 Gr. CD4MCu 60.00 A 216 Gr. WCB 50.00 40.00 30.00 A351 Gr. CF3M / CF8M 20.00 10.00 0.00 --50 0 50 100 150 200 250 300 350 400 450 Operating temperature t °Ξ Average values - the values of individual pump sizes may be higher or lower than the values indicated. (Contact KSB.) Mechanical seals The application limits of mechanical seals depend on the circumferential speed, the material and the fluid handled. Installation to API 682/ISO 21049 and pump design with dry shaft possible. Materials table (Europe) Part No. Description Variant S1 Variant S6 Variant S8 102 Volute casing A 216 Grade WCB A 216 Grade WCB A 216 Grade WCB A 351 Grade CF3M A 217 Grade CA15 A 351 Grade CD4MCu 161 Casing cover (uncooled) P355N P355N P355N A 351 Grade CF3M A 217 Grade CA15 A 351 Grade CD4MCu Casing cover (cooled) A 216 Grade WCB A 216 Grade WCB A 216 Grade WCB A 351 Grade CF3M A 217 Grade CA15 A 351 Grade CD4MCu Variant A8 Variant C6 Variant D1 210 Shaft1) C45+N 1.4021+QT700 1.4462 1.4462 1.4021+QT700 1.4462 230 Impeller JS1025 1.4008 1.4408 1.4409 1.4008 Noridur 1.4593 330 Bearing bracket A 216 Grade WCB A 216 Grade WCB A 216 Grade WCB 411.10 Joint ring 1.4571/Graphit 1.4571/Graphit 1.4571/Graphit 1.4571/Graphit 1.4571/Graphit 1.4571/Graphit 412.37 O-ring FPM (Viton) FPM (Viton) FPM (Viton) FPM (Viton) FPM (Viton) FPM (Viton) 502.01/02 Casing wear ring VG434 VG434 1.4408 1.4408 VG434 1.4539 503.01/.02 Impeller wear ring 1.4027+QT 1.4027+QT 1.4408 1.4408 1.4027+QT 1.4539 542.02 Throttling bush 1.4021+QT700 1.4021+QT700 1.4021+QT700 1.4021+QT700 1.4021+QT700 1.4021+QT700 902.01 / 920.01 Casing bolts / hex. nut 1.7709/1.7258 1.7709/1.7258 1.7709/1.7258 1.7709/1.7258 1.7709/1.7258 1.7709/1.7258 A 216 Grade WCB A 216 Grade WCB A 216 Grade WCB 1) above 250 °C: 1.7709. -10 °C to 250 °C: C45+N -40 °C to +300 °C: 1.4462 5 RPH Materials table (Asia and America) Part No. 102 Description Volute casing Variant S5 A 216 Grade WCB Variant S6 A 216 Grade WCB Variant A8 A 351 Grade CF8M 1)+2) / A 351 Grade CF3M 1) Variant C6 Variant D1 2) A 487 Grade CA6NM A 351 Grade CD4MCu 161 Casing cover (uncooled) A 216 Grade WCB 1) / A 516 Grade 65 2) A 216 Grade WCB 1) / A 516 Grade 65 2) A 351 Grade CF8M 1)+2) / A 351 Grade CF3M 1) A 487 Grade CA6NM A 351 Grade CD4MCu Casing cover A 216 Grade WCB 1) / A 516 Grade 65 2) (cooled) A 216 Grade WCB 1) / A 516 Grade 65 2) A 351 Grade CF8M 1)+2) / A 351 Grade CF3M 1) A 487 Grade CA6NM A 351 Grade CD4MCu A 276 Type 410 H&T 1)/ A 276 Type 410 H&T 1)/ A 434/4140CL.BB 2) A 434/4140CL.BB 2) AISI 329 1) / 1.4462 1)+2) / A 276 Type 316 2) A 276 Type 410 H&T 1)/ A 276 Type 420 2) 210 Shaft 230 Impeller A 216 Grade WCB A 743 Grade CA6NM A 743 Grade CF8M 1)+2) / A 743 Grade CF3M 1) 330 Bearing bracket A 216 Grade WCB A 216 Grade WCB A 216 Grade WCB A 216 Grade WCB A 216 Grade WCB 411.10 Joint ring Spiral wound SS316 -Graphite Spiral wound SS316 -Graphite Spiral wound SS316 -Graphite Spiral wound SS316 -Graphite Spiral wound SS316 -Graphite 412.37 O-ring 502.01/02 Casing wear ring 503.01/.02 Impeller wear ring 542.02 Throttling bush 902.01 / 920.01 Casing bolts / hex. nut DIN 1.4462 A 743 Grade CA6NM A 890 Grade CD4MCu FPM (Viton) FPM (Viton) FPM (Viton) FPM (Viton) FPM (Viton) Cr. Hard 400 1) / AISI 420 Hard 2) Cr. Hard 400 1) / AISI 420 Hard 2) Cr. Hard 400 1) / AISI 420 Hard 2) Duplex 1.4024.19 1) / AISI 420 Hard 2) 1.4024.19 1) / AISI 420 Hard 2) A 743 Grade CF8M+Col.coating1) A 743 Grade CF3M+Col.coating1) AISI 316 2) A 743 Grade CF8M 1) / A 743 Grade CF3M 1) / AISI 316 2) 1.4024.19 1) / AISI 420 Hard 2) Duplex A 276 Type 316 1) / A 276 Type 316 2) A 276 Type 410 H&T 1)/ AISI 420 2) Duplex A 193 Grade B7 / A 194 Grade 2H A 193 Grade B7 / A 194 Grade 2H A 193 Grade B7 / A 194 Grade 2H A 276 Type 410 H&T 1) / A 276 Type 410 H&T 1)/ AISI 420 2) AISI 420 2) A 193 Grade B7 / A 194 Grade 2H A 193 Grade B7 / A 194 Grade 2H 1) KSB Asia 2) KSB America For Nace requirements, contact KSB. Other materials acc. to API--table H1 are available on request! Materials - Table of Comparison Closest Material type Code Material No. Standard ASTM equivalent Cast iron GJS-400-15 GJS-400-18-LT GJL-250 JS1030 JS1025 JL1040 EN 1563 EN 1563 EN 1561 A 536 Grade 60-40-18 A 536 A 48 Class 30 Cast steel GP240GH+N 1.0619+N EN 10213-2 A 216 Grade WCB Cast stainless steel GX5CrNiMo19-11-2 GX5CrNiMo19-11-2 GX2CrNiMo19-11-2 GX2CrNiMo19-11-2 GX3CrNiMoCuN24-6-2-3 GX2CrNiMoCuN25-6-3-3 1.4408 1.4408 1.4409 1.4409 Noridur 1.4593 1.4517 EN 10213-4 EN 10213 EN 10213-4 EN 10213 KSB material data sheet WSZ 2745 EN 10213 A A A A A A Cast chromium steel 12% GX20Cr14+QT GX35CrNiMo25-4 GX7CrNiMo12-1 GX8CrNi12 GXZ5CrNi13-4 GXZ5CrNi13-4 1.4027+QT VG 434 1.4008 1.4107 1.4317 1.4317 SEW 410 KSB material data sheet WSZ 2800 EN 10283 EN 10213-2 EN 10213-2 EN 10283 A 743 Grade CA15 Stainless steel X6CrNiMoTi17-12-2 X2CrNiMoN22-5-3 1.4571 1.4462 EN 10088 EN 10088 A 276 Type 316Ti A 182 Grade F51 Chromium steel X20Cr13+QT700 X20Cr13 X15Cr13 X29CrS13 X12Cr13 X5CrNiMo17-12-2 X4CrNiMoN27-5-2 X2CrNiMoN17-13-3 21CrMoV5-7+QT P355GH 1.4021+QT700 1.4021 1.4024.19 1.4029 1.4006 1.4401 1.4460 1.4429 1.7709+QT 1.0566 EN 10088 EN 10088 KSB material data sheet WSZ 1219 EN 10088 EN 10088 EN 10088 EN 10088 EN 10088 EN 10269 EN 10028-3 A 276 Type 420 AISI 420 Hard A 276 Type 410 Carbon steel C45+N C22+N 1.0503+N 1.0402+N EN 10083 EN 10083 A 576 Grade 1045 A 576 Grade 1020 Cast stainless steel, hard-faced GX5CrNiMo19-11-Colm.6 1.4408-Colm.6 Special brass material CuZn35Ni3Mn2AlPb CW710R Steel for use at elevated temperature 6 A A A A 351 Grade CF8M 743 Grade CF8M 351 Grade CF3M 743 Grade CF3M 351 Grade CD4MCu 351 Grade CD4MCu 743 Grade CA15 217 Grade CA15 487 CA6NN 743 CA6NM A 276 Type 410 H&T A 276 Type 316 AISI 329 A 276 Type 316L A 193 Grade B16 A 351 Grade CF8M-Colm.6 EN 12163 25-180 40-180 25-230 48 6 40-281 40-280 B 02 L 50-180 40-361 40-181 40-230 58 57 75 75 61 71 69 88 6 6,2 7,8 7,7 7,5 7,7 7,9 10,9 B 02 S 50-360 50-280 50-230 95 93 88 10 9,6 9,6 50-450 80-180 17 80-280 80-360 110 100-280 100-230 100-180 28 22,3 17,8 150-230 35 B 05 S 80-450 32,77 kW kW kW kW Max. drive rating at n = 1450 1/min n = 1750 1/min n = 2900 1/min n = 3500 1/min 2 x 7311 B-MUA NU 213 C3 42 55 65 60 116,90 96,86 58,45 48,43 622,63 751,45 5) 375,73 311,32 0,2147 195,75 on request 236,25 5) 118,13 97,88 0,0675 1.5 times the operating pressure or as per API 610 / 10th edition 1) Coolable bearing bracket on request 2) at n = 3500 1/min: 150-360 max. 350 mm; at n = 2900 1/min: 100-450 max. 420 mm; 150-450 max. 430 mm; 200-450 max. 445 mm 3) for triple bearing assembly: 3 identical bearings as indicated, for high inlet pressures 4) Values indicated refer to shaft in material C 45 N, key C 45 K, impeller JS1025 and T < 100 °C; for other materials and higher temperatures please contact KSB 5) Pump sizes 50-450, 80-450, 100-450, 150-450, 200-450 for speed n = 3500 1/min on request by KSB! 79,10 65,54 39,55 0,0226 P/n value 4) Drive °C Max. fluid temp. Temp. limits bar 0,0334 2 x 7309 B-MUA NU 211 C3 32 45 55 50 on request bar Max. test pressure 200-360 150-450 200-280 150-360 22 43,1 19,5 35,5 200--401 40 B 05 L 150--501 200-450 28 23 200--501 32 63 250--401 43 20,9 1140,65 5) 945,11 2 x 7315 B-MUA NU 316 C3 60 75 80 80 570,33 472,56 0,3259 - - B 06 200--670 38 250--630 38 NU 324 C3 95 120 120 100 530 515 520 690 630 719 220 275 275 26 250--710 - - 1489,95 1234,53 0,8514 2 X 7224 B-MUA 120 180 130 180 130 180 220 230 280 140 180 230 280 340 140 190 230 280 150 190 230 190 350 295 355 230 295 235 360 295 360 400 320 400 320 400 520 Pressure limits Max. operating pressure 150-280 12 15,5 14,5 28,5 250--501 111 133 128 130 161 110 136 140 164 160 198 171 204 204 190 222 222 294 280 201, 9 14 12,5 11,5 B 03 80-230 87 110 113 10 150--630 179 224 180 224 180 230 278 278 343 180 230 286 343 430 190 235 286 350 190 235 295 240 430 355 440 295 365 295 450 360 456 504 408 509 404 504 636 48 6 100-360 Shaft deflection as per API 610, 10th edition motor--end 3) pump-end mm mm motor--end at coupling mm pump-end mm -min. diam. at bearings mm -max. diam.2) mm mm inlet diam. in seal chamber mm outlet width Units 100-450 Shaft deflection Bearings Shaft diameter Impeller Bearing bracket1) Pump sizes 40-231 RPH pumps are in compliance with the following standards: API 610 / 10th edition ISO 13709 Technical Data RPH 7 RPH Pump sizes DN Nominal impeller diameter Discharge nozzle 180 25 X 40 X 50 X X X X X 80 X X1) X1) X1) X1) 100 X X1) X1) X1) X1) X1) X1) X1) X1) X1) 181 230 231 280 281 X X X 360 361 401 450 501 630 670 710 X X 150 X Bearing bracket B 02 S 200 X B 02 L X1)2) X1)2) 250 B 03 B 05 S X1) X1)2) X1) X1)2) X1)2) X1)2) B 05 L X1)2) X1)2) X1)2) B 06 1) Casing with double volute 2) Complementary sizes, only 4-pole drive possible Pump casing Radially split, consisting of volute casing and casing cover. The casing cover can be heated or cooled, if required (optional). Volute casing with casing wear rings. Casing cover with casing wear rings (depending on axial thrust balancing). Centreline pump feet. To reduce the hydraulic radial forces acting on the shaft and bearings, which increase with pump size and head, the casing of pumps with DN 80 and above has a double volute (except for pump sizes 80-180 and 100-180). Nozzle positions Axial inlet; on complementary sizes (see above) radial discharge pointing vertically upwards, otherwise tangential discharge. Balancing Balancing of axial thrust by sealing gap and balancing holes (if required). Minimum flow Unless specified otherwise in the individual characteristic curves, the following applies: Qmin = 0.1 . Qopt. for short operation Qmin = 0.3 . Qopt. for continuous operation Inducer To improve the NPSH value, the pumps can be supplied with inducer. Pump designation: RPHI. Bearing lubrication Bearing Oil fill in l bracket B 02 0.9 B 03 1.8 Bearing bracket B 05 B 06 Oil fill in l 2.5 5.7 Lubricating oil types C 46 DIN 51 517 or SAE 20 W/ 20 HD shall be used. On the standard pump design, the bearing bracket is uncooled. A coolable bearing bracket is available as special pump design. The bearings are oil bath lubricated. An oil thrower can be fitted (please contact KSB Pegnitz). Oil mist lubrication is also possible. A triple bearing design is available for handling extreme operating conditions. NPT threads are provided for cooling liquid connection, constant-level oiler, oil drain and vent plug. The bearings are designed for at least 25,000 operating hours as per API 610/10th edition. During pump standstill the oil level can be checked against the mark next to the oil level sight glass. Shaft seal The pump is fitted with mechanical seals. The mechanical seal chamber is designed in acc. with API 610, 10th edition. Mechanical seals are provided in cartridge design only (API 682)! 8 Barrier liquid / Flushing liquid Barrier liquid: (general) Barrier liquid is used to isolate the pumped fluid from the environment. The space between the mechanical seals must be supplied with a liquid from an external source which is suitable for mixing with the fluid handled. Pressurized dual mechanical seal: The pressure should be approx. 1.5 bar higher than the pressure pw to be sealed off. For bearing bracket B 02, 2 to 3 l/min of barrier liquid will be required. For bearing brackets B 03 to B 06, a barrier liquid rate of 4 to 7 l/min will be required. The heat generated at the seal faces can only be dissipated if the barrier liquid is circulated. This can be achieved by means of forced circulation using a pump or a pumping ring in the mechanical seal or natural circulation using the thermosyphon effect (gravity). Please contact KSB Pegnitz if the mechanical seal chosen is not equipped with a pumping device. Flushing liquid: Flushing liquid is used to prevent the penetration of solids into the seal chamber when pumping abrasive fluids. A possible flushing liquid is the pumped fluid itself, if it is free of solids, or an externally supplied liquid which is suitable for mixing with the pumped fluid. Flushing the shaft seal requires approx. 3 to 5 l/min of flushing liquid. The pressure of the flushing liquid should be approx. 1 bar higher than the pressure pw being sealed. Preferred mechanical seals: cartridge seals based on standardized mechanical seals to EN 12756 or mechanical seals to API 682 can be fitted. RPH Coating and Preservation (to AN 1865) RPH RPH RPH RPH Material class S-1, C-6 S-1, C-6 A8 A8 (Europe) < 150 °C ≥ 150 °C < 150 °C ≥ 150 °C N N N N 1 7 0 0 1 7 1 7 1 7 1 7 W W U U Key: Treatment of unmachined parts Coating - pressure-retaining parts Coating - bearing bracket, baseplate Coating - motor Preservation N = reaction primer; wetted components without first primer coat (internal and external) 0 = without finish coat 1 = synthetic enamel RAL 5002, ultramarine blue 7 = aluminium paint (synthetic resin base) RAL 9007 aluminium-grey U = steel shot blasting W = rinsed with water repellent; bright parts liable to rust with protective coating The following acceptance tests may be performed at extra charge: Performance test API 610 1 measuring point / 5 measuring points Performance test ISO 9906/1 1 measuring point / 5 measuring points Performance test ISO 9906/2 1 measuring point / 5 measuring points Performance test ISO 9906/2A 1 measuring point / 5 measuring points NPSH test 1 measuring point/ 5 measuring points Warranties are given within the scope of the valid delivery conditions. External Nozzle Forces and Moments Discharge nozzle Acceptance Tests / Guarantees Suction nozzle Each pump is subjected to a performance test, and its duty point is guaranteed according to ISO 9906/2. Requirements as per API 610, section 4.3, fulfilled. The nozzle forces stipulated in API 610 are exceeded. Pump p sizes i Suction nozzle Discharge nozzle Forces (in N) Moments (in Nm) Fx Fy Fz 1780 1430 1160 2560 920 460 1780 1430 1160 2560 920 1780 1430 1160 2560 50-180 50-230 50-280 50-360 50-450 2670 2140 1780 80-180 80-230 80-280 80-360 80-450 3560 2840 100-180 100-230 100-280 100-360 100-450 6230 25-180 25-230 40-180 40-230 40-280 40-181 40-231 40-281 40-361 150-230 150-280 150-360 150-450 150-501 150-630 200-280 200-360 200-401 200-450 200-501 200-670 250-401 250-501 250-630 250-710 Fres Mx My Mz Forces (in N) Moments (in Nm) Mres Fx Fy Fz Fres Mx My Mz Mres 710 1250 1430 1160 1780 2560 920 460 710 1250 460 710 1250 1430 1160 1780 2560 920 460 710 1250 920 460 710 1250 1430 1160 1780 2560 920 460 710 1250 3860 1900 950 1440 2570 1430 1160 1780 2560 920 460 710 1250 2320 5110 2660 1360 2010 3600 2140 1780 2670 3860 1900 950 1440 2570 4980 4090 8960 4610 2360 3530 6270 2850 2310 3560 5110 2660 1360 2010 3600 9790 7560 6230 13850 7050 3530 5150 9420 4980 4100 6230 8970 4610 2360 3530 6270 13350 10680 8900 19270 10030 4880 7590 13490 7560 6230 9790 13850 7060 3530 5150 9420 16000 13340 10680 23410 12200 5960 9220 16412 10680 8900 13340 19267 10040 4880 7600 13505 Coordinate axes as per API 610. 9 RPH Recommended Spare Parts Stock for 2 Years’ Operation to DIN 24 296 Part No. Description 210 230 320.02 322.01 330 433 Shaft Impeller Angular contact ball bearing (set) Cylindrical roller bearing Bearing bracket Mechanical seal Spring-loaded ring Seat ring O-rings Secondary seals at seat ring Spring (set) Casing wear ring Impeller wear ring Throttling bush Other sealing elements 502.01/.02 503.01/.02 542.02 --- Dimensions Number of pumps (including stand-by pumps) 2 3 4 5 6 and 7 8 and 10 and 9 more Quantity of spare parts 1 1 1 2 2 2 20 % 1 1 1 2 2 2 20 % 1 1 2 2 2 3 25 % 1 1 2 2 2 3 25 % 1 2 pcs. 2 3 4 5 6 7 90 % 2 3 4 5 6 7 90 % 2 3 4 5 7 9 100 % 2 3 4 5 7 9 100 % 1 1 1 1 2 2 20 % 2 2 2 3 3 4 50 % 2 2 2 3 3 4 50 % 1 1 2 2 2 3 30 % 4 6 8 8 9 10 100 % Pump dimensions I = Middle of pump foot II = Middle of DN1, shaft 2) 3) 1) Not for material variant S and bearing bracket B 06 Pump size Weight Bearing Pump dimensions Shaft end d1 Ø bracket kg 25-180 116 25-230 131 B 02 S B 02 S 40-180 40-181 40-230 40-231 40-280 40-281 40-361 122 136 138 158 197 195 249 B 02 S B 02 L B 02 S B 02 L B 02 L B 02 L B 02 L 50 50 50 50 50 50 50 40 40 40 40 40 40 40 130 130 130 140 140 140 150 50-180 50-230 50-280 50-360 50-450 80-180 80-230 80-280 80-360 80-450 153 240 289 347 441 242 264 317 361 547 B 02 L B 03 B 03 B 03 B 03 B 03 B 03 B 03 B 03 B 05 S 80 80 80 80 80 100 100 100 100 100 50 50 50 50 50 80 80 80 80 80 100-180 100-230 100-280 100-360 100-450 150-230 150-280 150-360 150-450 289 303 345 477 576 369 461 533 659 B 03 B 03 B 03 B 05 S B 05 S B 03 B 05 S B 05 S B 05 L 150 150 150 150 150 200 200 200 200 100 100 100 100 100 150 150 150 150 200-280 575 200-360 683 200-450 804 B 05 S B 05 L B 05 L 250 200 230 1070 1109.5 260 840 879.5 250 200 230 1070 1109.5 275 840 879.5 250 200 250 1090 1129.5 310 840 879.5 5) d1 Ø n6 10 4) longer shaft for fan cooling = for pressurized tandem seals = for ”back-to-back” seals DN1 DN2 a 40 25 120 40 25 120 c 736 736 c’ 772 772 e f f’ 105 616 652 125 616 652 746 750 746 760 760 760 770 782 786 782 796 796 796 806 105 110 130 135 160 160 195 616 620 616 620 620 620 620 652 656 652 656 656 656 656 40 40 40 40 40 40 40 250 250 265 265 290 290 305 130 130 136 146 146 150 150 420 420 460 460 540 540 640 320 320 360 360 440 440 540 0 0 0 0 0 0 0 150 770 806 155 885 910 170 900 925 170 900 925 180 910 935 175 920 945 170 900 925 180 910 935 190 920 945 200 1040 1079.5 120 140 170 200 245 140 160 180 210 260 620 730 730 730 730 745 730 730 730 840 656 755 755 755 755 770 755 755 755 879.5 50 50 50 50 50 60 60 60 60 60 265 265 290 310 365 290 290 300 310 370 150 150 150 150 150 170 170 170 170 170 470 510 550 650 750 510 550 590 650 760 360 400 440 540 640 400 440 480 540 650 185 170 170 200 210 200 200 230 230 170 175 200 225 270 210 225 250 280 745 730 730 840 840 730 840 840 840 770 755 755 879.5 879.5 755 879.5 879.5 879.5 70 70 70 70 70 80 80 80 80 325 325 335 355 385 235 365 365 415 190 170 190 190 190 200 200 200 200 590 590 650 730 860 730 730 780 870 480 480 540 590 720 590 590 640 720 930 900 900 1040 1050 930 1040 1070 1070 955 925 925 1079.5 1089.5 955 1079.5 1109.5 1109.5 g1 h2 m1 n1 n3 n6 r 40 230 130 420 320 0 185 40 255 130 460 360 0 205 188 198 215 220 238 248 275 k6 32 32 Foot bolts l t u y i1 m2 n2 s1 80 35 10 140 30 60 380 17.5 80 35 10 140 30 60 420 17.5 32 32 32 32 32 32 32 80 80 80 80 80 80 80 35 35 35 35 35 35 35 10 10 10 10 10 10 10 140 140 140 140 140 140 140 30 30 30 30 35 35 35 60 60 60 60 70 70 70 380 380 420 420 500 500 600 17.5 17.5 17.5 17.5 17.5 17.5 17.5 0 0 0 0 0 0 20 20 15 20 220 32 230 42 255 42 285 42 325 42 235 42 265 42 290 42 325 42 375 605) 80 110 110 110 110 110 110 110 110 140 35 45 45 45 45 45 45 45 45 64 10 12 12 12 12 12 12 12 12 12 140 140 140 140 140 140 140 140 140 180 35 35 35 45 45 45 45 45 45 45 70 70 70 90 90 90 90 90 90 90 420 460 500 600 700 460 500 540 600 710 22 22 22 22 22 22 22 22 22 22 25 30 30 25 30 45 40 40 35 275 285 315 340 395 330 355 385 420 110 110 110 140 140 110 140 140 140 45 45 45 64 64 45 64 64 64 12 12 12 18 18 12 18 18 18 140 140 140 180 180 140 180 180 180 50 50 50 55 55 50 60 60 55 100 100 100 110 110 100 120 120 110 540 540 600 670 800 670 670 720 800 26 26 26 26 26 33 33 33 33 90 395 230 870 720 50 400 605) 140 64 18 180 55 110 800 90 395 230 910 760 60 430 605) 140 64 18 180 55 110 840 90 435 230 970 820 50 475 605) 140 64 18 180 55 110 900 36 36 36 42 42 42 605) 605) 42 605) 605) 605) RPH Complementary sizes RPH Bearing brackets B 05/B 06 I = Middle of pump foot II = Middle of DN1, shaft 2) 3) 1) Not for material variant S and bearing bracket B 06 Pump size Weight Bear- Pump dimensions ing bracket kg 150-501 150-630 DN1 DN2 a c 4) longer shaft for fan cooling = for pressurized tandem seals = for ”back-to-back” seals Shaft end d1 Ø c’ f f’ g1 h2 m1 n1 n3 n6 r 516 B 05 L 200 150 180 1040 1079.5 860 899.5 90 500 180 960 820 0 370 1190 B 06 200 150 250 1385 1435 1135 1185 90 670 310 1200 1020 60 465 k6 605) 955) l Foot bolts t u y i1 m2 Drain line n2 s1 z 300 300 300 300 250 250 250 250 240 200 300 300 1100 1060 1390 1380 1139.5 860 899.5 1099.5 860 899.5 1440 1090 1140 1430 1080 1130 90 90 90 90 600 670 750 800 210 210 310 310 1160 1200 1200 1460 1000 1040 1020 1280 0 0 70 0 425 475 485 560 605) 605) 955) 955) r1 a1 140 64 18 180 60 120 900 33 165 0 315 63.5 170 100 25 250 105 210 1120 36 260 85 412.5 80 200-401 528 B 05 L 250 200 190 1055 1094.5 865 904.5 90 510 180 960 820 0 390 605) 140 64 18 180 60 120 900 33 165 200-501 676 B 05 L 250 200 200 1045 1084.5 845 884.5 90 560 180 1060 920 0 420 605) 140 64 18 180 60 120 1000 33 165 200-670 1440 B 06 250 200 250 1380 1430 1130 1180 90 670 310 1360 1180 0 485 955) 170 100 25 250 105 210 1280 36 260 250-401 734 B 05 L 250-501 926 B 05 L 250-630 1500 B 06 250-710 1630 B 06 e1 140 64 18 140 64 18 170 100 25 170 100 25 180 180 250 250 75 75 105 105 150 150 210 210 1080 1120 1120 1380 33 33 36 36 165 165 260 260 0 0 0 330 64.5 360 78.5 425 73 0 0 0 0 365 412 425 500 105 102 108 122 5) d1 Ø n6 11 RPH Connections - Vapour) Single-acting mechanical seal with quench supply Mechanical seal: dual seal (unpressurized tandem arrangement) Mechanical seal: dual seal (pressurized tandem arrangement) Mech. seal in back-to-back arrangement API-Standard Vapour) Connection from DN 80 Description 1M NPT 1/2-14 NPT 1/2-14 Pressure gauge 3M NPT 1/2-14 NPT 1/2-14 Pressure/vacuum gauge 5B NPT 1/2-14 NPT 1/2-14 Venting1) 6B Casing drain 2) DN15 ASME B16.5 7B NPT 1/2-14 NPT 1/2-14 Cooling liquid drain 3) 7E.1 / 7 A.1 NPT 1/2-14 NPT 1/2-14 Cooling liquid inlet/outlet 7E.2 / 7 A.2 NPT 1/2-14 NPT 1/2-14 Cooling liquid inlet/outlet 10B NPT 1/2-14 NPT 1/2-14 Barrier liquid drain 10E.1/10A.1 1) 2) 3) 4) up to DN 50 NPT 1/2-14 NPT 1/2-14 4) Barrier liquid inlet/outlet NPT 1/2-14 4) Barrier liquid inlet/outlet 10E.2/10A.2 NPT 1/2-14 11E.1 NPT 1/2-14 NPT 1/2-14 Flushing liquid inlet 11E.2 NPT 1/2-14 NPT 1/2-14 Flushing liquid inlet 12E.1/12A.1 NPT 1/2-14 NPT 1/2-14 Circulation liquid inlet/outlet 12E.2/12A.2 NPT 1/2-14 NPT 1/2-14 Circulation liquid inlet/outlet 13B NPT 1/2-14 NPT 1/2-14 Oil drain 13D NPT 1/2-14 NPT 1/2-14 Vent plug 24B NPT 3/8-18 NPT 3/8-18 Quench liquid drain 24E.1/24A.1 NPT 3/8-18 NPT 3/8-18 Quench liquid inlet/outlet 24E.2/24A.2 NPT 3/8-18 NPT 3/8-18 Quench liquid inlet/outlet 27B NPT 1/2-14 NPT 1/2-14 Buffer liquid drain 27E.1/27A.1 NPT 1/2-14 638 NPT 1/4-18 NPT 1/2-14 4) NPT 1/4-18 Buffer liquid inlet/outlet Constant-level oiler only if required; the pump is self-venting for version with drain line please refer to the general assembly drawing not for uncooled design NPT 3/4-14 on bearing brackets B05 and B06 12 Single-acting mechanical seal (API 23) RPH General assembly drawings Material class S, cooled/uncoooled Bearing brackets B 02 to B 05 uncooled D01040/3 cooled When ordering spare parts, please always specify: Type series, works No. (stamped on the name plate and on the suction nozzle flange), year of construction, quantity required, part No., description, material, fluid handled, general assembly drawing No. and mode of dispatch. Part No. 102 Description Volute casing 161 Casing cover 210 230 Shaft Impeller 320.02/550 2) Angular contact ball bearing 322.01 Cylindrical roller bearing 330 Bearing bracket (compl.) 360.01/.02 502.01/.02 1) 503.01/.02 1) 507.01/.02 542.02 638 831.02 904.38 922.01 99-9 Bearing cover Casing wear ring Impeller wear ring Thrower Throttling bush Constant-level oiler Fan impeller (optional) Grub screw Impeller nut Complete set of sealing elements Scope of supply with joint ring 411.10, casing wear ring 502.01, stud 902.01, grub screw 904.03, plug 916.01 (not shown, instead of drain line), hex. nut 920.01 with joint ring 411.10, O-ring3) 412.01/.31, casing wear ring 502.021), hex. head bolt 901.30, stud 902.15, grub screw 904.041), plug 916.16, hex. nut 920.15 with keywayed nut 920.21, lockwasher 931.01, key 940.01/.02 with impeller wear ring 503.01/.02, grub screw 904.06/.07, joint ring 411.31/.32/.67 (optional), lockwasher 931.02, with ring 550 (adjusting washer) with protective cage 169.10, bearing cover 360.01/.02, gasket 400.01, O-ring 412.22, constant-level oiler 638, oil level sight glass 642, pipe 710.22, hex. head bolt 901.31/.37, vent plug 913.03, plug 916.46, socket head cap screw 914.01 with gasket 400.01, O-ring 412.22, socket head cap screw 914.01 grub screw 904.03/.041) grub screw 904.06/.071) grub screw 904.41/.42 with fan hood 832, fan hub 485.02, grub screw 904.33 (not shown) 1) for impellers with balancing of axial thrust only 2) for bearing brackets B03 and B05 only 13 RPH Bearing bracket B06 All material classes, cooled and uncoooled uncooled D01042/3 cooled When ordering spare parts, please always specify: Type series, works No. (stamped on the name plate and on the suction nozzle flange), year of construction, quantity required, part No., description, material, fluid handled, general assembly drawing No. and mode of dispatch. Part No. 102 Description Volute casing 161 Casing cover 210 230 Shaft Impeller 260 320.02 322.01 330 Impeller hub cap Angular contact ball bearing Cylindrical roller bearing Bearing bracket (compl.) 360.01/.02 502.01/.02 1) 503.01/.02 1) 507.01/.02 542.02 550.87 638 831.02 904.38 906 931.02 99-9 Bearing cover Casing wear ring Impeller wear ring Thrower Throttling bush Disc Constant-level oiler Fan impeller (optional) Grub screw Impeller screw Lockwasher Complete set of sealing elements 1) for impellers with balancing of axial thrust only 2) for cooled design only 14 Scope of supply with joint ring 411.10, casing wear ring 502.01, stud 902.01, grub screw 904.03, plug 916.01 (not shown, instead of drain line), hex. nut 920.01 with joint ring 411.10, O-rings 412.01/.312), casing wear ring 502.021), hex. head bolt 901.30, stud 902.15, grub screw 904.041), plug 916.16/.18/.19, hex. nut 920.15 with keywayed nut 920.21, lockwasher 931.01, key 940.01/.02 with impeller wear ring 503.01/.02, grub screw 904.06/.07, joint ring 411.31/.32 (optional) with protective cage 169.10, bearing cover 360.01/.02, gasket 400.01, O-ring 412.22, constant-level oiler 638, oil level sight glass 642, pipe 710.22, hex. head bolt 901.31/.37, vent plug 913.03, plug 916.46, socket head cap screw 914.01 with gasket 400.01, O-ring 412.22, socket head cap screw 914.01 grub screw 904.03/.041) grub screw 904.06/.071) grub screw 904.41/.42 with fan hood 832, fan hub 485.02, grub screw 904.33 (not shown) RPH Design Variants D01044 Bearing bracket, cooled Inducer D01047 Special pump design with thrower D01043 D01044 Pump design with plug 916.01 Tandem bearings Special pump designs for high inlet pressure Part No. 508.01 904.20 916.01 Description Oil thrower Grub screw Plug 15 RPH Oil mist lubrication D01127 D01126 Performance curves 1316.52-10 15.03.2009 For individual characteristic curves, refer to offer curves 1316.451 and 1316.461. Subject to technical modification without prior notice. Heatable casing KSB Aktiengesellschaft P.O. Box 1361 • 91253 Pegnitz • Bahnhofplatz 1 • 91257 Pegnitz (Germany) Tel. +49 9241 71-0 • Fax +49 9241 71-1793 www.ksb.com