Consumer acceptance and market development

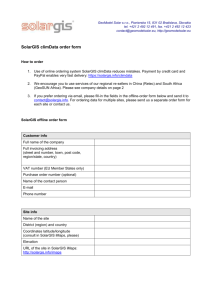

advertisement