production flow fluctuations - managing risks to

advertisement

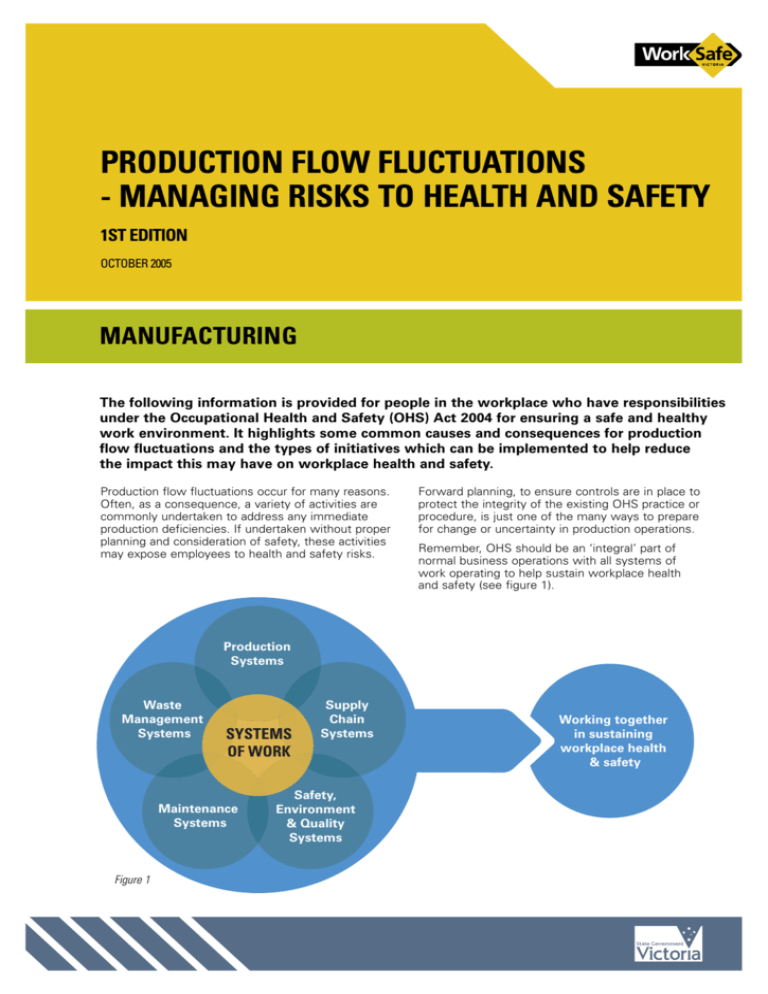

PRODUCTION FLOW FLUCTUATIONS - MANAGING RISKS TO HEALTH AND SAFETY 1ST EDITION OCTOBER 2005 MANUFACTURING The following information is provided for people in the workplace who have responsibilities under the Occupational Health and Safety (OHS) Act 2004 for ensuring a safe and healthy work environment. It highlights some common causes and consequences for production flow fluctuations and the types of initiatives which can be implemented to help reduce the impact this may have on workplace health and safety. Production flow fluctuations occur for many reasons. Often, as a consequence, a variety of activities are commonly undertaken to address any immediate production deficiencies. If undertaken without proper planning and consideration of safety, these activities may expose employees to health and safety risks. Forward planning, to ensure controls are in place to protect the integrity of the existing OHS practice or procedure, is just one of the many ways to prepare for change or uncertainty in production operations. Remember, OHS should be an ‘integral’ part of normal business operations with all systems of work operating to help sustain workplace health and safety (see figure 1). Production Systems Waste Management Systems SYSTEMS OF WORK Maintenance Systems Figure 1 Supply Chain Systems Safety, Environment & Quality Systems Working together in sustaining workplace health & safety PRODUCTION FLOW FLUCTUATIONS - MANAGING RISKS TO HEALTH AND SAFETY PRODUCTION FLOW FLUCTUATIONS IN INDUSTRY 1. Increased overtime, working weekends or running additional shifts The following circumstances can cause production flow fluctuations: • Machine breakdowns resulting in downtime • Suppliers failing to deliver raw materials or components on time • Customers suddenly and significantly increasing their order • Delivery deadlines being imposed from outside which require faster production • Business interruptions due to loss of utilities i.e. electricity or gas Production fluctuations result in the short term need for some or all employees to work increased overtime, over weekends or on additional shifts. • Assessments should be undertaken, in consultation, to identify and control OHS risk when the following is likely to occur: – Reduced supervision to employee ratio – Manual handling tasks being performed over longer periods of time i.e. could the task introduce hazardous manual handling if completed over a longer period of time? – Reduced employee numbers as compared to normal working arrangements – Physical or mental fatigue due to longer working hours or week • Increased exposure to noise and hazardous substances. Where this is likely to happen, adjustment to existing exposure assessments should be made • Access to first aid or medical services should be available over the new working arrangements • Avoid employees or contractors working alone. Where this is not possible, identify the risks involved in working alone (i.e. Job Safety Analysis) and implement appropriate controls • Supervision to employee ratio should be maintained • Ensure access to expertise or services (i.e. maintenance, Health and Safety Representatives and decision makers) is available or alternative arrangements have been made which meet employee and production needs • Ensure employees or contractors are not working in unfamiliar roles or using unfamiliar equipment, unless appropriate supervision and safe systems of work are provided • Incidents i.e. emergencies or quality issues • Stoppages due to industrial action i.e. in-house or at suppliers In addressing the deficiencies caused by production flow fluctuations, the following activities are often undertaken: 1. Increased overtime, working weekends or running additional shifts 2. Increasing plant speeds 3. Assembling previously unavailable parts out of sequence 4. Introducing additional casual or hired labour 5. Rescheduling preventive maintenance, tool box meetings, safety audits or training 6. Changes to supervision or increasing employee to supervisor ratio MANAGING THE RISKS TO HEALTH AND SAFETY Production flow fluctuations will happen periodically, irrespective of how well things are planned. Below are some important points to consider when managing risks to health and safety due to unexpected fluctuations. • Investigate what can cause production fluctuations both internally and externally. Review past production schedules/sheets for evidence of fluctuations. Look for trends, seasonal peaks or early indicators. Which areas of production seem to be effected the most and why? Identifying areas within production which are ‘safety critical’ and most vulnerable to unexpected change is another good starting point • Develop plans or strategies on how to best control identified fluctuations before they occur • Implement controls to prepare your production operations for fluctuations. For example, establishing an area for out of sequence assembly so that all the necessary equipment and facilities are readily available when required • Monitor implemented risk controls to determine ongoing effectiveness 2 2. Increasing plant speeds Plant (including support equipment such as forklifts, conveyors, cranes etc) may be working faster than normal and employees may be expending more effort to keep up. • Assessments should be performed, in consultation, to identify, assess and control any new or increased OHS risk due to increased pace of work i.e. pace of work may increase/introduce risks of developing Musculoskeletal Disorders (MSD)* • Ensure Health and Safety Representatives and employees affected are consulted before increasing pace of work • Plant and process should be audited prior to speed increases to ensure its capabilities are suited to the new pace of work • Preventative maintenance program/plans should be modified to take into consideration the increased pace of work * Refer to WorkSafe Victoria’s publication Manual Handling in the Automotive Industry (March 2005) and Manual Handling Code of Practice (CoP No.25 April 2000) WORKSAFE VICTORIA / PRODUCTION FLOW FLUCTUATIONS_MANAGING RISKS TO HEALTH AND SAFETY PRODUCTION FLOW FLUCTUATIONS - MANAGING RISKS TO HEALTH AND SAFETY 3. Assembling of previously unavailable parts out of sequence 5. Rescheduling preventative maintenance, tool box meetings, safety audits or training Parts which were previously unavailable are now assembled out of sequence or off line. • A risk assessment (i.e. Job Safety Analysis) should be completed, in consultation, before out of sequence assembly commences • Ensure systems have been developed to ensure production assembled out of sequence is safely managed back into mainstream production or completed off line. For example, a vehicle which is moved off line to have a late part fitted, but has no brakes yet installed, is not able to be moved until appropriate measures are taken to ensure its safe progression • Ensure equipment normally available at the assembly work station is also available at the out of sequence assembly point • Ensure out of sequence work stations don’t interfere or impinge on adjoining work stations or production areas • Ensure additional equipment or labour is made available particular to the out of sequence assembly required Rescheduling planned preventative maintenance, tool box meetings, safety audits or training due to immediate production demands or deficiency. • Plant and process which is ‘safety critical’ should be identified in advance and arrangements made to ensure this plant is carefully monitored and maintained irrespective of fluctuations in production – safety first! • Where reschedules are unavoidable, short term corrective actions should be instigated in consultation with the affected Health and Safety Representative and employees, i.e.: – Increase preliminary maintenance inspections – Alternative tool box or shop floor communication arrangements – Ensure scheduled safety audits or training is rescheduled in the shortest possible time frame 4. Introducing additional casual or hired labour* Inexperienced or unfamiliar labour is introduced into the work place. • A comprehensive induction program should be provided to all new casual or hired labour • Ensure casual or hired labour are assigned tasks which match their level of competency and have demonstrated that competency to the satisfaction of supervision or front line management • Casual or hired labour should be part of a Designated Work Group (if formed) and encouraged to raise health and safety concerns with supervisor, line manager and Health and Safety Representative where elected * Refer to WorkSafe Victoria’s publication – Placing Workers In Safe Workplaces: Safety management systems guide for labour hire agencies 6. Changes to supervision or increasing employee to supervisor ratio Additional staff (casual or permanent) is employed and/or changes in supervision has occurred due to new temporary shift arrangements introduced to address deficiencies caused by production fluctuations. • Allocated supervision should ensure adequate tools or equipment is readily available and in place to provide safe operating conditions (i.e. Personal Protective Equipment is being worn as required by safe operating procedures) • Allocated supervision should be able to appropriately induct new employees (including casual labour) or contractors into the workplace, if required • Allocated supervision should be able to train in task specific performance, inform on safe work practices and monitor this on an ongoing basis • Ensure allocated supervision has the necessary experience and training required to deal with OHS issues or concerns WORKSAFE VICTORIA / PRODUCTION FLOW FLUCTUATIONS_MANAGING RISKS TO HEALTH AND SAFETY 3 PRODUCTION FLOW FLUCTUATIONS - MANAGING RISKS TO HEALTH AND SAFETY IN SUMMARY • Fluctuations in production may increase risks to employee health and safety • Prepare a control plan in advance for safely managing deficiencies caused by production fluctuations • Make OHS an integral part of your business operations NEED MORE INFORMATION? For more information on how to make your workplace safe and healthy, contact WorkSafe on 1800 136 089 or visit www.worksafe.vic.gov.au ACKNOWLEDGEMENTS This guide has been developed using information identified by the Motor Vehicle and Parts Industry following a workshop held in August 2004. Thank you to the Motor Vehicle & Parts OHS Working Group and Industry for its assistance in the development of this document. WORKSAFE VICTORIA Advisory Service 222 Exhibition Street Melbourne 3000 Phone . . . . . . . . . . . . . . 03 9641 1444 Toll-free . . . . . . . . . . . . . 1800 136 089 Email . . . . . info@workcover.vic.gov.au Web . . . . . . www.workcover.vic.gov.au The information contained in this publication is protected by copyright. The Victorian WorkCover Authority hereby grants a non-exclusive licence in this publication to the recipient of this publication on the condition that it is not disseminated for profit. The Victorian WorkCover Authority encourages the free transfer, copying and printing of the information in this publication if such activities support the purposes and intent for which the publication was developed. WorkSafe Victoria is a division of the Victorian WorkCover Authority VWA968/01/09.05 4 WORKSAFE VICTORIA / PRODUCTION FLOW FLUCTUATIONS_MANAGING RISKS TO HEALTH AND SAFETY