THE TIMBERLAND COMPANY

2006 CORPORATE SOCIAL RESPONSIBILITY REPORT

What does it mean to “Make it better”?

At Timberland, we live by a simple challenge and

a common commitment—“Make it better.” Every

day, we apply skill and passion to finding new

ways to improve our products. Strengthening our

relationships with stakeholders. And enhancing

the communities where we live and work.

“Make it better” is straightforward, practical

and common sense. It is a journey and not a

destination. It can be found in small measures of

goodness and in revolutionary breakthroughs in

product technology. It’s the shoes we craft and

the green spaces we restore. And at the end of

the day, our hope is that, through the people and

places we touch, we do our share to create a

better world and a more beautiful planet.

Voices of Challenge 2.0

The Voices of Challenge sections throughout this report give you a flavor of the conversations

that are happening around the world in conferences, coffee shops, factories and boardrooms

about the material environmental and social issues of our industry.

Last year’s Corporate Social Responsibility (CSR) report included essays about these issues

from prominent leaders in other organizations. This year, instead of a series of monologues,

we are offering a dynamic dialogue among a variety of stakeholders. After all, we operate

in a global economy and must be responsive to stakeholders at all levels in order to remain

relevant and competitive in a changing landscape. As you read this report, you will see the

thoughts of a factory employee next to those of the Executive Director of a non-profit or a

senior executive of a large organization. Our hope is that, in this way, our Voices of Challenge

will provide a more nuanced picture of the environment companies operate in as they work

to become more responsible citizens.

The conversation doesn’t stop here. If you want to have your voice heard, tell us what you

think at csrinfo@timberland.com.

Table of Contents

From the CEO

4

The Timberland Footprint

6

Summary of CSR Indicators

8

The Organization

9

Global Human Rights

16

Environmental Stewardship

34

Community Involvement

52

Stakeholder Engagement

70

Report Scope

72

Standard Disclosures

78

2006 CSR report

1

➜ to

➜

Timberland employs 5,500 people worldwide in positions ranging from accounting to retail.

5500

from the CEO

The rhythm and din of shoe making is a sweet music to my ear—I grew up in our

factories. I learned to make shoes alongside real craftsmen, taught by my grandfather

and my dad. I inherited from them a love of the music of factories, and the

responsibility to make the music purposeful and valuable...

Those sounds—machines whirring, metal clanking, animated conversation of men

and women as they stitched and crafted the wonder of a shoe from the canvas

of leather. To some, a cacophony. To me, the daily symphony of progress. Sound,

conversation, connection defined our mission and inspired our community.

Today, that symphony of the factory floor remains a bold crescendo in my Timberland

iPod. The sounds of an engaged community aligned against a common vision. Press

“shuffle” and you’ll hear different rhythms, separate beats. Designers inventing

sustainable products. Employees and consumers reforesting the Horqin Desert in

Inner Mongolia, Marston Vale outside London, and the Bronx with Sustainable South

Bronx. Factory workers in classrooms learning HIV/AIDs education. And my current

favorite—the whoosh of the windmill and the chords of the solar panels as sun and

breeze power Timberland properties around the world.

So before you: a report. Non-toxic ink on recycled paper. Our annual presentation of

rigorous, objective and transparent measures of our performance against key social,

environmental and human rights initiatives. Adhering to the rigorous standards of Global

Reporting Initiative (GRI) and pushed further by our own insistence to define new

standards of excellence and collaboration. Where’s the beat? It’s in here. I respectfully

ask for you to listen to rather than read—the words before you. These are the voices of

suppliers, customers, consumers, employees, community leaders and activists. This is

the 21st century rendition of the rhythm of my grandfather’s factory floor.

Publishing a statement of accountability is necessary, but not sufficient. If we write a

report and fail to initiate a conversation, we have missed an opportunity. And if our

report represents our only venue for engagement, then we have failed. An engaged

community—a convening of stakeholders committed to environmental stewardship,

community strength, global human dignity, and the quality of life for our workers

and those citizens with whom we are privileged to serve—is my intent. Our process

of reporting is not “us” to “you”. This report is a forum for you. React, respond,

challenge, commit. I commit back to you that we will listen and act.

In 20 years we’ve learned that we innovate and drive progress only in collaboration

with others. That sustained change demands connection and commitment. Stepping

into the civic square gains grace and purpose alongside men and women from

industry, community, government and the non-profit field. This report is today’s

evidence of our commitment. But tomorrow—and the day after that—we will invest

equal energy and passion to gain wisdom and challenge from voices around the

world. I am my grandfather’s grandson and know of no other way.

I ask for you to add your voice to those who have so graciously contributed to our

report. And, I express my sincere gratitude for your interest and commitment to our

planet and our global community.

Jeffrey Swartz

President and CEO

The Timberland Company

2006 2006

CSR report

CSR report

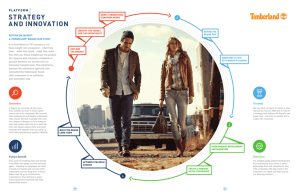

The Timberland Footprint

Framework for Commerce and Justice

Corporate Mission: To equip people to make their difference in the world.

➜ ➜

Core Values: Humanity, Humility, Integrity and Excellence

Bold Goals:

•

Become the authentic outdoor brand of choice by providing inventive and practical products to our consumers

•

Be the business partner of choice by providing distinctive value to our customers

•

Be a top employer of choice globally

•

Be the reference for socially accountable business globally

•

Deliver exceptional financial performance for shareholders

Our Approach

For more than 30 years at Timberland, two things

But gear is not enough. Not when you pursue a global

have endured:

standard for both commerce and justice. As a community

1. Values that are absolute

of men and women, we aspire to stand firmly in the

civic square, committing passion, skill and resources to

2. An enterprise vision that is ambitious and

ideas—and people—that generate civic energy for the

defies expectations

common good. These relationships can be with any of our

As a business, we invent premium, pragmatic solutions

stakeholders, from employees, consumers and business

that challenge aspiration, test personal limits, deliver

and community partners to the media and Wall Street.

a brand truth and exceed expectations of performance,

It’s all part of Timberland’s commitment to sustained,

technology and quality. Timberland equips you—most

positive impact in three strategic areas:

literally—to make your difference in the world.

•

Environmental stewardship

•

Global human rights

•

Community involvement

The CSR Organization at Timberland

CSR Board Committee

CEO

Corporate Culture Officer

Vice president of CSR

external

relations

Transparency

and

accountability

Environmental

Stewardship

Global

Human Rights

Community

Involvement

Critical Issues

As a global brand of footwear, apparel and accessories,

we are held to the highest standards of responsible

corporate citizenship. Our industry is highly scrutinized,

are the important topics our stakeholders have asked for

more information about, through formal and informal

feedback. We’ve even reached out to our competitors,

and they agree on the importance of these issues.

and the recognition factor of our brand adds to this

Organization of the Report

responsibility. National standards and social contracts

While this report represents a comprehensive view of our

differ, which means that we face a highly complex

network of factories, distributors, customers and

consumers. To help make sense of it, we rely heavily on

our stakeholders—that is, consumers, non-governmental

organizations (NGOs), suppliers, shareholders and

our own employees—to help guide us to be a more

accountable corporate citizen.

In this report, we have focused on three critical issues

for our organization:

•

Working hours in factories

•

Global warming

•

Nonprofit partnerships

CSR work, we’ve tried to focus each section around one

of the critical issues bulleted to the left. Each section

opens with a case study that brings the critical issue to

life through a short story. Then, the body provides more

detail on the work Timberland is doing in this area. We

conclude with a collection of outside voices—our Voices

of Challenge—weighing in on the subject matter to

provide context and perspective. It is our hope that these

three issues create general motifs that flow throughout

the report.

Finally, if you still want more information, some of the

sections include a link we’ve provided to a “Make it

better” brief on the subject. There you’ll find a deep dive

These three issues also happen to correlate with three of

into our past, present and future work, as well as best

the pillars of our CSR organization: Global Human Rights,

practices from the industry. We hope it provides you with

Environmental Stewardship and Community Involvement.

a complete picture of how we are dealing with what we

We didn’t come up with these issues on our own. These

feel are the most important issues facing our industry.

2006 CSR report

summary of csr indicators

For the past two years, Timberland has published a set of Key Performance Indicators (KPIs) at the beginning of each

CSR report. While this list has included important metrics, we believe they were an inadequate gauge for overall CSR

success. Currently, Timberland is developing a robust “dashboard” of metrics that will give a better demonstration of

our overall progress on global human rights, environmental stewardship and community involvement. Until we land on

an official KPI list, we commit to including a summary of important indicators in our CSR report.

Indicator

Explanation

2004

2005

2006

2007

Target

Global Human Rights

Coverage

Percent of Factories Assessed94%94%99%

100%

Designation

Percent of “High Priority” Factories

DNT54%50%

45%

Percent of “Partner” Factories

DNT

Frequency of Working Hour Violations in Continued Factory Partners

DNT50%39%30%

Frequency of Ethics Violations in Continued Factory Partners

DNT

18%

12%

10%

Frequency of Wages Violations in Continued Factory Partners

DNT

17%

16%

12%

Percent of Continued Factory Partners with Improved Score

DNT

DNT55%

60%

8.4

12.2

Immediate Actions

1

Score Improvements

25%

29%30%

Environmental Stewardship

Millions of Footwear Pairs using Water-Based

Adhesives in Stockfitting7.0

8.4

Chemicals

Millions of Footwear Pairs using Water-Based

Adhesives in Assembly

Energy

Resources

Systems

1.43.4

4.65.8

Total Metric Tons of Carbon Emissions

25,084

26,854

29,071

NT2

Percent of Energy Purchased from a Renewable Source

4.3%

6%

6.6%

8%

Organic Cotton as a Percent of Total Cotton Purchases

2.1%

2.1%5.7%

Environmental Assessment Score for Tanneries

DNT

DNT

2.533

Environmental Assessment Score for Footwear

DNT

DNT

2.123

Benefit Utilization Rate (BUR): Percentage of

employees that use at least one hour of service

69.7%

Hours Utilization Rate (HUR): The percentage of hours

used for service compared to hours available

28.8%31.1%39%

6.5%

community Involvement

Path of Service™

68%71%75%

46%

Hours Employees Spent Serving in the Community55,008

65,139

80,63298,000

Charitable Giving

Charitable Giving as a Percent of Previous Year’s

Operating Income

2.10%

1.60%

1.68%

Service Impact

Number of Trees Planted

DNT

DNT

DNT = Did Not Track

NT = No Target

1

The 2005 metrics for frequency of Immediate Actions is reflective of all factories, not continued business partners only.

2

We will release a climate change strategy document with targets in Fall 2007.

NT

DNT50,000

The organization

profile

Financial Performance

Our principal strategic goal is to become the authentic

long-term goals, we are focused on driving progress

• Extending enterprise reach through development of

new brand platforms and brand building licensing

arrangements

on these key strategic fronts:

• Expanding geographically

outdoor brand of choice globally. To achieve our

•

Increasing our focus on segregating discrete and

distinct consumer categories

•

Enhancing our leadership position in our core

footwear business

•

Capturing the opportunity that we see for

outdoor-inspired apparel

• Driving operational and financial excellence while

setting the standard for commitment to the community

and striving to be a global employer of choice

Some high-level views of our financial performance in

2006 are included in the graphs below. Please see our

2006 Annual Report on Form 10-K/A for more details

on our financial performance.

REVENUE

DOLLARS IN MILLIONS

$2,000

$1,500

1,501

1,568

2006 Awards

•

Named one of Forbes magazine’s “Best Big Companies

in America” for the 8th year in a row

•

Ranked 6th on Business Ethics magazine’s list of

“100 Best Corporate Citizens”

•

Selected for Fortune magazine’s list of “America’s

Most Admired Companies”

•

9th consecutive year on Fortune magazine’s “100 Best

Companies to Work For”; also listed on Fortune’s Hall

of Fame

•

2006 Points of Light—“Award for Excellence in

Workplace Volunteer Programs”

•

Listed as one of Industry Week magazine’s

“50 Best-Managed Manufacturing Companies”

for the third consecutive year

•

Recognized as one of the “World’s Top Sustainable

Stocks” by SustainableBusiness.com for the third

year in a row.

•

3rd consecutive year on list of “100 Best Companies

$1,000

$500

$0

2004

2005

2006

NET INCOME3

$200,000

DOLLARS IN THOUSANDS

1,566

180,216

$150,000

145,114

$100,000

101,205

$50,000

0

2004

2006

DILUTED EPS3

$3.00

$2.50

$2.00

2005

$2.66

$2.03

$1.50

$1.59

$1.00

for Working Mothers” by Working Mother magazine

$0.50

$0.00

3

2004

2005

2006

As Restated. See our 2006 Annual Report on Form 10-K/A.

2006 CSR report

Economic Indicators

Our contribution to the economic systems in which we

chart attempts to illuminate the economic impact our

operate is fundamental to understanding the basis for

organization has on the local community at significant

sustainability. New in this year’s report, the following

locations of operation4.

Economic Impacts for 2006

Number of

Employees

in 2006

% of Total

TIMBERLAND

Employees

Local

Minimum

Wage (Hourly)5

Entry Wage

(Hourly)6

% of

Minimum

Wage Paid

14%

$5.15

$9.15

177.67%

1773%

$10.55

$10.84

102.75%

1%

N/A

$6.70

N/A

Headquarters

Stratham, New Hampshire

Wexham Springs, England

Singapore

780

52

Distribution Centers

Danville, Kentucky

125

2%

$5.15

$9.15

177.67%

Ontario, California

115

2%

$6.75

$9.45

140.00%

Enschede, Holland

130

2%

$8.67

$8.67

100.00%

1,84332%

$0.73

$0.96

131.51%

Factory

Santiago, Dominican Republic

4

5

6

Significant locations of operation include headquarters, distribution centers and manufacturing facilities.

Local Minimum Wage: Minimum wage refers to compensation per hour or other unit of time for employment allowed under law.

Entry Wage: Entry-level wages are defined by the full-time wage offered to an employee in the lowest employment category. Intern or apprentice wages

are not considered.

Number of

Employees Grade

77 and Above

Number of Employees

Grade 7 and Above

from Local Area

% of Managers

from Local

Community8

Stratham, New Hampshire

222

222

100%

Wexham Springs, England

26

21

81%

Singapore

119

82%

Headquarters

Distribution Centers

Danville, Kentucky

2

150%

Ontario, California

2

2

Enschede, Holland

2

150%

100%

Factory

Santiago, Dominican Republic

7

8

87

88%

Grade 7 employees are senior management and are generally defined as “leadership.”

If the location is in the US, then employees from that region (Northeast) are considered local. If the location is outside of the US, then local means any manager

from that country.

EXPANSION

New Brand: Say Hello to howies

A thoughtful, authentic brand. A carefully crafted blend of innovative products.

Provocative ideas. And a meaningful dialog with the consumer. That is the basic

philosophy of howies, an edgy line of men’s and women’s apparel emanating from a humble locale in Cardigan

Bay, Wales, UK. They are also maniacally concerned for the planet, the lives of their consumers and finding ways

to “ask a different question.” About the world we live in. The businesses we build. And the values we share. They

are not your typical company.

And they’re perfect for Timberland. In late 2006, we welcomed howies into the Timberland family. Immediately,

it was obvious that we’d found a great fit. We were drawn to howies because it’s a smart, fast-moving, lean,

consumer-centric enterprise that also happens to be values-driven. We also saw a unique opportunity to reach

new consumers and new markets from their youthful platform. The joining of our two organizations is a marriage

of boot, brand and belief. More importantly, it’s a true testament to our vision. Our passion. And the individuals

committed to making it better—and making a difference in the world.

To find out more about this exciting brand, please go to www.howies.co.uk.

New Brand: GoLite®

In June 2006, Timberland announced the introduction of a new line of

advanced footwear for trail-running enthusiasts under the GoLite® brand. The

GoLite® footwear line is inspired by the extreme challenges of sky runners and

their need for ultra-light, technically advanced footwear. According to GoLite co-founder and CEO Kim Coupounas,

“Our companies share many values, including our dedication to excellence, innovation and being good corporate

citizens. We are honored to be working with a company that is a global leader in premium-quality footwear and

corporate social and environmental responsibility.”

To find out more about this brand, please go to www.golite.com.

Integrating SmartWool into the Timberland Culture

Shoes and socks. What could be a more natural pairing? There was a lot more to our acquisition of SmartWool than the

natural match-up of our products, though. We wanted to grow with a company whose values fit with us, too.

Last year was the first time after the acquisition for SmartWool to be part of Timberland’s annual Serv-a-palooza—one of our

pillar service events. In September 2006, 5,500 Timberland employees around the world strapped on their boots and went

out into the community to “make it better.” More than 50 SmartWool employees in Steamboat Springs, Colorado, joined the

event with gusto, donating more than 300 hours—and braving the rain—to refurbish housing for the elderly. Plus, in Boulder,

Colorado, all eight SmartWool employees spent the day building a multi-use trail.

Their enthusiasm proved to us once and for all that we’d found a partner who could not

only help us sell great products, but also help to advance our CSR strategy, too.

2006 CSR report

11

Governance

A Culture of Responsibility from

Top to Bottom—and Vice Versa

Corporate Social Responsibility at Timberland. This

At Timberland, we think a top-down, bottom-up approach

Directors, who will meet regularly with the CSR leadership

is the best way to integrate social and environmental

team to help set the strategic agenda and hold the

awareness into all levels of the company. Let’s start at

team accountable for their actions. We believe this new

the top of our organization. We have a CEO who is deeply

structure will leverage additional resources and leadership

committed to the concept of “Commerce and Justice”—

toward achieving our CSR goals.

that is, a responsibility to generate revenue while at the

same time making positive changes in the communities

and environment where employees live and work. This

set of values naturally trickles down to influence all

company decisions—major and minor.

And from the bottom up? We do everything we can to

help employees make a difference in the world. We

start by doing our best to make sure that every new

hire is passionate about Corporate Social Responsibility

group is made up of four members of our Board of

To learn more about our corporate governance, including

the charter for the new CSR committee, please go to the

Corporate Governance section on our Web site.

Public Policy

Our passion for civic action inspires our approach to

building strong communities and a healthy planet. There

are a few fundamental tenets:

•

First and foremost—and always—our programs must

reflect our values of humanity, humility, integrity and

excellence. These words must be made real by our

actions and attitudes.

•

The “how to”—across environmental stewardship,

global human rights and worldwide community

involvement—is also constant. In other words, we

rely on a collaborative process based on a common

vision and multi-sector partnerships built on aligned

values to create enduring change.

•

Finally, results must be measurable and

transformative. And on occasion, we hope, visionary.

(CSR). Soon after they’re hired, all new employees at our

corporate headquarters perform a day of service. That

way, right away, they can understand how we partner

with local communities to “Make it better.” In addition,

they’re exposed to our values in a variety of activities.

Employee-initiated charity drives. Volunteer service fairs.

Environmental “lunch and learns.” And the Community

Impact Center in our headquarters cafeteria, which

highlights recent CSR activities.

Taking Responsibility

at the Very Top

The issues we embrace as an enterprise and as a

In the past, the influence of our Board of Directors has

community are complex and far reaching. Our passion for

guided the development of our CSR strategies. For global

the planet compels us to turn our attention and expertise

human rights. Community investments and engagement.

toward the area of global warming. Our desire to increase

And environmental stewardship. In addition, our Audit

civic participation requires us to ensure the strength and

Committee has received formal reports of our Code of

credibility of City Year9. Our belief that values are not

Conduct assessments of our contract factories—and the

local to our commercial markets, but rather are a global

remediation work that’s being done.

responsibility, engages our community in stopping the

What’s new for 2007 is that we’ve instituted a formal

CSR Committee that will provide guidance for all

genocide in Darfur and alleviating the pain and anguish

along the Gulf Coast.

We are not political or partisan. We do not financially

support candidates, political campaigns or Political Action

Our passion for the planet

compels us to turn our

attention and expertise toward

the area of global warming.

Committees. But we deeply honor public service—in fact,

we revere it. We know that sustained change requires

policy decisions and investments that support the will of

the people. Our approach to affecting policy is to raise

awareness, model innovation and compel action—always

through collaboration. We invite and encourage civic

discourse and engagement by politicians, policy experts,

industry partners, employees and consumers.

9

12

A non-profit organization dedicated to building a stronger democracy by engaging diverse groups of 17- to 24-year olds in National Service.

2006 CSR report

Global Warming

Global warming is one of the most critical issues our company faces. As such, Timberland has developed a

coordinated and comprehensive approach to policy around this issue. In New Hampshire, we screened An

Inconvenient Truth and hosted environmental experts and a “green” fair to raise visibility for both policy and

options for sustainable improvements. We partner with industry colleagues, including the Outdoor Industry

Association (OIA), to share our priorities and commitment with elected leaders. Our President and CEO

Jeff Swartz joined global business leaders convened by The Climate Group for a meeting with British Prime

Minister Tony Blair and California Governor Arnold Schwarzenegger to share best practices and to encourage

policy leadership. We joined The Climate Group in requesting that German Chancellor Andrea Merkel raise

global warming as a priority of the G-8 Summit in 2007. We actively share best practices and innovations

in environmental stewardship with industry partners and elected leaders. And we raise awareness for

consumers and encourage their action and activism through our retail stores from Regent Street in London

to Diamond City in Osaka. Our annual Earth Day, range of sustainable apparel and footwear, product

packaging and messaging, and in-store communication reflect the core of our belief—that informed citizens

are the greatest lever for change. Their voice, their actions and their leadership drive and inspire change

all over the world.

2006 CSR report

13

PEOPLE

Our Employees

Passion. Purpose. These are two characteristics that make Timberland unique. We invite and invest in people who

share our values and passion to make a difference by doing well as a business and doing good in the community.

Our people—and the ways we engage them on our journey—are of the utmost importance in our aspiration to be an

employer of choice. The task of balancing the capability of our organization to support dynamic business growth while

keeping our employees effectively engaged continued to be a key area of focus in 2006. Please see below for updated

global employee and safety statistics for 2006.

AVERAGE TENURE FOR FULL TIME EMPLOYEES10

8

35

7.2

6

38.1 39.0 39.1

5.1

3.9

5.2

32.8 32.1

28.7

25

5.4

5.1

AGE

4.8

4

37.8 37.5

34.8

30

5.5

YEARS

AVERAGE AGE OF FULL TIME EMPLOYEES10

40

4.2

27.7 27.8 27.5

20

15

2.4

2

2.4

2.5

10

5

0

Distribution

Center

Manufacturing

2005

2004

6000

5000

EMPLOYEES

EMPLOYEES

4000

5000

4000

3000

2000

2000

0

0

Retail Stores

1000

17821782

379 379

385 385

1531 1531

16291629

1642

0

2004

1642

2004

1655

2005

200511

100%

Manufacturing

Manufacturing

1610

1610

11

60%

Office

Office

Retail

Retail

1820

1820

Office

2005

GLOBAL COMPOSITION OF LEADERSHIP12

Male

67%

64%

64%

33%

36%

36%

2004

2005

2006

40%

1690

20%

2006

0%

1690

2006

0.4%

3.1%

GLOBAL 2006 DIVERSITY

11.9%

American Indian or Alaskan

Unknown

15.9%

Black (not of Hispanic origin)

Hispanic

Asian or Pacific Islander

0.1%

68.7%

Charts include full time and part time employees.

We closed our Puerto Rico factory in December of 2005.

12

Leaders are defined as senior managers (grade 7) and above.

10

11

14

2006 CSR report

Retail Stores

2006

80%

Distribution

Distribution

407407

1655

Manufacturing

2004

DISTRIBUTION OF TIMBERLAND EMPLOYEES

1611 1611

Distribution

Center

2006

DISTRIBUTION OF TIMBERLAND EMPLOYEES

6000

3000

1000

Office

White (not of Hispanic origin)

Female

As part of our annual Serv-a-palooza event, Timberland employees, in conjunction with Habitat for Humanity,

built homes for families displaced by Hurricane Katrina.

Health and Safety

The Lost Workday Injury and Illness (LWDII) rate averages the amount of lost-time incidents (i.e. time away from work

or a return to work with medical restrictions) for every 100 employees. In 2006, the rate of “lost work days due to

injury or illness” occurrences (LWDII) was 3.3. This statistic represents all U.S. operations (including retail, corporate

headquarters, Ontario and Danville distribution centers and SmartWool locations) and our Caribbean manufacturing

plant located in the Dominican Republic.

In 2006, we continued to invest in improving our health and safety efforts globally. Timberland makes every effort to

reduce and eliminate work-related incidents at all of its locations. This includes employing safety professionals at our

world headquarters and Caribbean operations. Corporate Health and Safety works with sites globally to identify the

causes of work-related incidents and develop measures to improve the overall safety of our work environments.

5

4

LWDII US AND CARIBBEAN

4.4

LDWII

3

3.2

3.3

2005

2006

2

1

0

2004

2006 CSR report

15

FOCUS ON

The Challenge of Working Hours

Just about everyone wants to do the right thing. The trouble is, sometimes people don’t agree on what the

right thing is. We discovered this firsthand as our sourcing needs took us to new corners of the globe where

working with migrant workers opened our eyes to this sometimes conflicting viewpoint.

When Pou Yen (PY) China began producing shoes for Timberland, they had already developed their own

strategy for corporate citizenship that focused on worker rights. As is our standard procedure, we asked

them to accept our Code of Conduct, as well. One component of the code is a restriction on total working

hours. No more than 60 hours a week. And no more than 12 hours a day.

That’s when something happened that defied expectations. Resistance. From some of the workers. They

wanted the extra overtime, so that they could earn more money. The factory actually had to teach workers

about the restrictions put forth by the Code and put policies and procedures in place to ensure compliance.

Pou Yen has learned from this experience. About the challenges that occur when brands have conflicting

codes of conduct. Or when production issues cause delays. The choice is often a costly one. Spend money

to air freight the shipment. Or allow excessive overtime.

One method PY employed to improve results was placing the power to approve overtime above the required

standard solely in the Operating Director’s hands. That way, even though excessive overtime isn’t entirely

eliminated, it is strictly controlled. Today, the workers at PY know their rights and more readily accept

the working hours restrictions. In addition, the corporate responsibility team offers personal development

courses to provide workers with more options for spending their free time.

Still, adhering to Timberland’s working hours requirement remains a challenge. 70% of our footwear

factories had violations of working hours standards that required immediate action in 2006, according to

our Code of Conduct. We see this as a persistent challenge in our supply chain and commit to working with

factories to improve the results.

Want to learn more about our working hours violations in the supply chain?

See our Make it better brief for a deeper dive on this issue.

GLOBAL HUMAN RIGHTS

progress report: Global human rights

Goals for 2006results

Rating

Expand Our Assessment Collaborations

We piloted joint assessments with another brand at three factories

in Turkey and two in India. Feedback from the factories was generally

positive and we learned ways to improve the process. In 2007, all

regions will be looking for opportunities to conduct joint assessments

with brands in shared factories.

Improve Workplace Conditions

We saw a 4% increase in the number of factories scoring Partner.

Likewise, the number of factories scoring High Priority decreased by

4%. 84 factories raised their scores from 2005, improving on average

by 34%. However, while improvements were seen, there were also 61

factories that scored lower in 2006 (an average decline of 23%).

Form Strategic Partner Relationships

A pilot with Verite to have workers take the lead in the assessment

process was deployed in two factories in China. We have not yet rolled

this out to other factories.

Focus Our Community Efforts

In 2006, community-based projects were ongoing in the following

countries: Dominican Republic (continuing education program, food

assistance program, physically challenged employment program);

Turkey (parenting skills development); Bangladesh (CEPZ project with

CARE for training on women’s rights and labor laws, health and hygiene

promotion, and micro-finance facilities); and China (Verite pilot of a

model for having workers conduct social compliance assessments).

Key:

no improvement

making progress

achieved objective

Taking Responsibility within Our Supply Chain

Fair. Safe. Non-discriminatory. We strongly believe

To accomplish these goals, we’re striving to make

people everywhere deserve those basic rights in the

changes that will create a workplace that embodies our

workplace. It’s not always easy to accomplish—

four corporate values. Humanity. Humility. Integrity.

especially when you’re dealing with more than 175,000

And Excellence. To support this effort, our assessors are

workers in 35 countries worldwide. Because we own only

focused on sustaining social and environmental changes

one of the approximately 300 factories that manufacture

through education and training. Finally, we recognize

Timberland® products, we don’t always have direct

that industry change cannot be made by Timberland

control over the practices of our vendors and suppliers.

alone. We want to share best practices with others in

But we do work hard to choose business partners who

our industry, to improve the quality of life for workers

share our beliefs, then work with them to operate under

throughout our supply chain.

the standards set forth by our Code of Conduct.

2006 CSR report

17

Timberland’s Influence in the Supply Chain

Since our last CSR report, stakeholders have asked us

(the majority of the steps and/or more capacity than the

to further clarify who we include in our assessment

prime supplier), we believe this subcontractor should

process. In summary, all suppliers (including “non-core”

be assessed. Sewing, knitting and certain assembly

product suppliers and indirect subcontractors)

operations are considered to be integral to product

are required to adhere to our Code of Conduct. We

manufacturing and so are included in the assessment

reserve the right to assess any supplier, but will initially

schedule. Among those who are not automatically

limit our assessment schedule to manufacturers of

included in our assessment schedule are subcontractors

“core products” (i.e., footwear, apparel, gear and

who do cutting only, wash houses and mills. Efforts to

key/long-term licensed goods such as belts, watches,

work with other brands to monitor further upstream in

product care and eyewear). Assessments of raw material

the supply chain are being considered.

and component suppliers are limited to tanneries and

footwear component suppliers that have global

sourcing contracts.

Our primary vendors are required by contract to ensure

that the Code of Conduct is applied by suppliers

and subcontractors we do not assess. Our assessors

Subcontractors to these primary vendors must be

do review the process through which these primary

approved by Timberland, but may or may not be

vendors communicate and monitor their suppliers’ and

included in our assessment schedule. For example,

subcontractors’ adherence to our Code.

if a subcontractor completes most of a Timberland order

timberland Factories Worldwide

country

number of factories

Argentina

8

Hong Kong

Austria

1

India

Bangladesh

1

Brazil

Bulgaria

number of factories

3

country

South Korea

number of factories

14

27

Sri Lanka

1

Indonesia

2

Swaziland

1

Italy

3

Taiwan

3

Japan

2

Thailand

2

15

7

17

Mexico

2

Tunisia

103

Morocco

7

Turkey

Dominican Republic

7

Pakistan

15

U.K.

2

Egypt

3

Peru

1

USA

16

El Salvador

1

Philippines

1

Venezuela

France

3

Portugal

2

Vietnam

Honduras

2

Romania

2

Canada

China

18

country

2006 CSR report

8

13

1

15

Factory Growth

In 2006, we finished our second full year of the new

100%

assessment process. In total, our assessors performed

311 assessments on 296 factories13. This represented

year, compared to 2005. Of these 311 assessments,

our external monitoring firm (Cal Safety Compliance

Corporation) conducted only 24% (or 75 assessments),

FACTORY COVERAGE

a 47% increase in assessments for the calendar

80%

as opposed to 38% in 2005. Coverage of our factory

ASSESSMENT COVERAGE

94%

94%

2004

2005

98.7%

60%

40%

20%

base increased in 2006 to approximately 99%, just

short of our goal of 100%. The factories that did not

receive an assessment are explained below.

0%

2006

factories missing assessment in 2006

countrybusiness unitexplanation

Vietnam

Licensee

This factory produced City Year backpacks in 2006—but we don’t plan further production.

Production proceeded without Code of Conduct authorization or a Code of Conduct

assessment. Facility then denied assessor access to conduct an assessment, citing no

future Timberland production planned at the facility.

Pakistan

Licensee

Timberland assessor had scheduled an assessment but became ill while in Pakistan, and the

assessment was canceled. External monitoring agency was contracted to conduct assessment.

Factory denied access, citing there was no current Timberland production occurring at the facility.

Licensee confirmed the factory would no longer be producing for Timberland in the future.

India

Licensee

Upon being hired in March 2006, the Timberland assessor for India attempted to schedule

an assessment. Factory denied access, citing no Timberland business was occurring there at

that time. Licensee confirmed that the factory was not going to be producing for Timberland

in the future.

Fiji

SmartWool

An assessment was scheduled in Fiji for December 4th and 5th by Timberland’s external

assessment agency. The week prior to the assessment, a travel advisory was issued, citing

all non-essential travel to the region was to be avoided due to the potential for a political

coup. The assessment was canceled and could not be rescheduled in 2006. Vendor will not

be producing for Timberland in 2007.

We want to share best practices with others in our industry,

to improve the quality of life for workers throughout our supply chain.

The only Timberland-owned factory is located in Santiago, Dominican Republic.

13

2006 CSR report

19

In 2006, our supply chain grew to 300 factories. As

recent contract with Phillips-Van Heusen (to produce

you can see in the chart below, growth was seen across

most of Timberland’s North American apparel) and the

all of our business units. Our 12 Licensees represented

addition of Timberland PRO® apparel to licensees. The

the greatest growth and now represent 38% of our

42 additional Licensee factories, along with the addition

supply chain, with 112 factories (up 5% from 2005).

of SmartWool’s supply chain, accounts for 75% of the

We see this trend continuing in 2007 in light of our

increase in factories.

300

112

100

60

40

23 24

18

23

21

21

25

0

r

Sm

ar

tW

oo

Su

pp

lie

en

se

e

Lic

ea

r

0

otw

2006

Di

2005

29

7 7

HQ

2004

23

l

Ta

nn

ery

20

50

2006

50 52

ibu

tor

100

2005

70

Fo

150

80

str

227

Ap

pa

rel

261

200

0

120

As

ia

NUMBER OF FACTORIES

250

SUPPLY CHAIN GROWTH (FACTORIES RECEIVING ASSESSMENT)

FACTORIES IN OUR SUPPLY CHAIN

NUMBER OF FACTORIES

300

An updated listing of the factories in our supply chain can be found at www.timberland.com/factorylist.

So what do all these numbers mean? The most important

The second theme shown by these numbers is that, as

trend we see is growth in our supply chain. Although

the number of assessments has grown, our assessors

we are working to develop longer business relationships

have had less time to spend on remediation. In 2007

within our supply chain, there has been a proliferation of

we will be looking to apply new models of collaboration

factories this year—especially in our Licensing and new

(with other brands and with staff from our supply chain

brands division (i.e. SmartWool). While new brands will

and human resource departments) to allow for increased

inevitably increase the size of our supply chain, we see

focus on remediation.

working with our Licensees to reduce factory churn as an

opportunity for improvement.

SmartWool Integration

New in 2006, all SmartWool factories were rolled into our Code of Conduct program.

21 of the 22 factories that made SmartWool® products in 2006 received assessments.

The one factory that did not get an assessment is explained in the chart on page 19.

Tip: Reducing your footprint

Carry your own refillable

water bottle instead of buying

single-use plastic bottles.

In 2003, only about 12% of water bottles were recycled. That

means 40 million bottles a day were simply thrown away.

The Code We Live By

At Timberland, we have been manufacturing in our own factories for three generations. When we

manufacture in other people’s factories, we live by the same beliefs we practice in our own. We know

that we can make high-quality products in a way that respects the basic human rights of the craftspeople

who work on the factory line. In fact, we insist on it—wherever anyone works on Timberland® products,

around the world.

Whenever we work with these third-party contract manufacturers, our Code of Conduct is just as

important as our purchase order. From the beginning of the process, we only work with factories that

commit to the standards our Code insists on—no matter how challenging those standards appear to be.

Of course, a Code of Conduct and good intentions alone do not ensure compliance. That’s why we have

a team of dedicated employees who regularly assess the performance of our supplier partners against

these requirements. When factory conditions don’t meet them, we ask the management of that supplier

to remedy the situation, offering assistance and guidance as needed. We work with the factory through a

remediation plan to make improvements. Progress is tracked and monitored by our assessors. Timeframes

are established that are reasonable and realistic, and we make working with factories to implement

change a priority, rather than leaving the factory. But if factory management is not willing to commit to

making improvements, we have no choice but to disengage from that supplier—after we consider how our

decision affects workers.

In early 2006, Timberland made the difficult decision to leave a Chinese factory that accounted for 17%

of our production14. It was a bitter pill to swallow—especially since our business relationship had lasted

ten years. The decision wasn’t difficult only for Timberland. The jobs of hundreds of workers in China

were put at risk when Timberland ceased production in the factory. And because we weren’t able to

“Make it better” for them, as an advocate for a workforce that too often lacks the ability to protect

itself, we failed.

Our leaving a factory in China is in no way an indication of a change in our business strategy or a shift

away from our values. This partnership failed, but we are not failing. If anything, we’re moving ahead with

a resolution to stand more firmly by our values, learn from our mistakes and look for new opportunities to

pursue our agenda of commerce and justice.

14

Production numbers based on 2005 data.

2006 CSR report

21

The assessment

assessment results

Definition of an Assessment

•

Remediation. Once the comprehensive, systemic

In 2005, we moved from an audit to an assessment.

action plan is developed, additional, ongoing support

The assessment process consists of these basic phases:

and assistance are provided to the factories as they

implement their remediation action plans. Assessors

•

•

Assessment. Assessments look at root causes and

partner with the factory throughout the remediation

systemic gaps in addition to individual findings, and

process, right through to completion. Sharing best

workers are afforded more opportunities to share their

practices. Analyzing management knowledge and

thoughts by participating in information-gathering

skill levels. Helping to build capacity. And ensuring

sessions.

adequate awareness, desire and knowledge at the

Action Planning. During this process, assessors help

factory managers analyze the root causes of issues.

factory to self-manage Code of Conduct matters

effectively.

Identify gaps in management systems. And develop

With each assessment, and receipt of an agreeable action

action plans that not only address what our assessors

plan, Timberland business units may begin or continue

have discovered, but also aim to prevent problems

from occurring again. This comprehensive process

includes considering the impact of any proposed

changes, deciding how to overcome obstacles or

production for the next 12 months. After 12 months, the

Code of Conduct approval expires, and an assessment

is required to continue production. As described above,

throughout those 12 months, remediation assistance and

potential resistance, communicating changes to

support are provided by our assessment team, as needed,

everyone affected by them and measuring—and

to encourage improvements.

celebrating—success along the way.

Factory Designations

The performance, skills and competencies of our factories

In 2006, we saw marginal improvement in our designation

are scored against a set of standards. When the assessment

scores. The number of Partner factories increased by

is completed, factories are given one of three designations,

4 percentage points, while our High Priority factories

based on their score:

decreased by 4 percentage points. In addition, we were

•

Partner: No Immediate Actions found and

encouraged to see that more than 50% of our supplier

infrastructure for continuous and sustainable

factories in the U.S. and Canada region reached Partner

workplace improvements exists.

status—something that did not happen in 2005.

Acceptable: No high risk findings, but improvements

•

are needed.

•

High Priority: High risk violation(s) found in

the factory.

ASSESSMENT

SCORES

ASSESSMENT SCORES

60%

50%

54%

2006

highLEVEL

level ASSESSMENT

assessment results

2006

HIGH

RESULTS

51%

High Priority

2005

40%

2006

28%

30%

20%

21%

21%

25%

0%

22

High Priority

2006 CSR report

Acceptable

51%

28%

21%

10%

Partner

Acceptable

Partner

assessment

(number OF

of FACTORIES)

Factories)

ASSESSMENT designation

DESIGNATION by

BY business

BUSINESS unit

UNIT (NUMBER

100%

80%

44%

37%

18%

9%

40%

43%

20%

79%

58%

47%

Apparel

(55)

29%

Partner

32%

56%

Acceptable

High Priority

38%

38%

25%

Asia HQ

(7)

12%

24%

43%

60%

0%

7%

14%

14%

22%

56%

33%

22%

Distributor

(24)

Footwear

(29)

Licensee

(112)

Supplier

(23)

SmartWool

(21)

Tannery

(25)

assessment

designation

(number

factories)

ASSESSMENT

DESIGNATION by

BY region

REGION (NUMBER

OFof

FACTORIES)

100%

15%

17%

17%

80%

26%

13%

22%

20%

40%

39%

45%

44%

55%

Partner

60%

20%

0%

59%

70%

61%

Acceptable

100%

30%

40%

61%

80%

55%

30%

Greater

China (99)

East Asia

(23)

Southeast

Asia (30)

Indian SubContinent

(43)

20%

17%

North Africa

& Middle

East (18)

SubSaharan

Africa (1)

Europe

(29)

High Priority

36%

28%

US &

Mexico,

Canada (18) C. America,

Caribbean (10)

South

America

(25)

Real and sustainable change in the factories takes time. We

on remediation should help to improve human rights in our

are encouraged by the incremental change—but the sheer

supply chain, and we hope to show that improvement in our

number of factories in the High Priority category reminds us

2007 results.

that there is much work left to be done. Our increased focus

Scoring

Distribution. One explanation is that Timberland is one step

Factory designations serve as a broad categorization of

removed from these factories. In Footwear, for example,

our factories. For us, improvement can only be gauged

our supply chain has direct contractual relationships with

by annual improvements in assessment scores among the

the factories that are making our products. For Licensees,

factories with whom we have had continued business.

we have a contract with the Licensee who, in turn, has

In 2006, these “continued business” factories represented

52% of our supply chain. In other words, almost half of

our supply chain

2006 FACTORY BASE

consisted of

chain does limit some of our influence. This being said, the

moment our assessor enters the factory—it doesn’t matter

if it is footwear, apparel or a Licensee—the assessment and

remediation processes are the same.

factories that were

New Factories

new to us. We can’t

show progress

the contract with their factory base. This extra link in the

Continued Business

52%

48%

In 2007, we will be trying new models of communication,

to facilitate direct interaction between the Code of Conduct

in a factory with

department and the Licensee partners. Our hope is that this

whom we have no

increased interaction will enable stronger improvements with

history. Nothing

these partners.

changes by conducting an assessment—change happens with

progress

byCONTINUED

continued

business

PROGRESSseen

SEEN BY

BUSINESS

30

time, patience and persistence and is strengthened when a

25

relationship develops between the assessor and the factory.

20

In general, we have seen improvements in factories where

FACTORIES

remediation. Our experience has shown that remediation takes

we’ve done business for longer than a year. The following

chart shows that, for the most part, Timberland business

5

units have seen a majority of their factories improving

0

19

18

15

10

their scores. That has not been the case for Licensing and

26

13

8

2

10

12

4

3

1

Asia HQ

Apparel

Distributor

Improved Score

13

12

Footwear

Licensee

Supplier

5

Tannery

Worse Score

2006 CSR report

23

Immediate Actions

To be treated humanely. To be treated equally. And

to be treated with respect and honesty. Basic human

rights—one of the cornerstones of our assessment

process. In our assessment process we call human

rights violations “Immediate Actions” (IAs) to call

attention to the severity of the situation. Immediate

Action violations require an immediate commitment

4%

3%

2%

1%

from factory management to cease/desist such practices.

If an assessor finds one of these violations, the factory

receives an automatic “High Priority” designation—

alerting Timberland management to the severity of

the violation(s). In 2006, there were a total of 221

Immediate Actions found in our supply chain. The chart

below15 shows the distribution:

IMMEDIATE ACTIONS IN OUR SUPPLY CHAIN

4%

2%

1%

3%Hours

18%

18%

52%

IMMEDIATE ACTIONS IN OUR SUPPLY CHAIN

Forced Labor

Wages

Discrimination (0%)

Ethics

Free Association

(0%)

Wages

Discrimination (0%)

Harrassment

Pregnancy Test

(0%)

Ethics

Free Association (0%)

Hours

Refuse Assess

Child Labor

Harrassment

52%

20%

Forced Labor

Pregnancy Test (0%)

Refuse Assess

Child Labor

20%

Immediate Action

Description

Working HoursTotal hours exceed 60 hours per week, 12 hours per day or more than 6 days consecutively

Ethics

Falsification of documents, willful violation of law, unethical business or financial practices

Minimum Wage

Legal minimum wage not being paid

Harassment

Verbal, physical or psychological

Discrimination

Based on race, religion, gender, color, age or other personal characteristics

Minimum Age

Under the country minimum age or 16, whichever is higher

Forced LaborPrison or debt-bonded labor

Refuse Assessment (0%)

Factories refuse an assessment

Pregnancy Testing (0%)Performed and/or results used in workplace for employment applications, promotions or other work-related decisions

Freedom of Association (0%)

Deny the right to freely associate and bargain collectively

As was the case in 2005, the top three IAs were working

hours, wages and ethics. Anyone can see by looking at

this chart where we need to focus our efforts. Working

hours infractions are the most frequently found IAs in

our supply chain—and they are growing (up from 48%

last year). Our code puts a restriction on total working

hours to 60 hours in a given week or 12 hours in a given

day and no more than 6 days consecutively. To date, we

have found that this is a difficult rule to enforce in our

supply chain 100% of the time. But it also represents a

critical issue that our team must grapple with.

15

As a company, we are working hard to reduce all IAs.

To learn more specifically about working hours, please

download our “Make it better” brief on Working Hours,

which provides a deep analysis of what we are doing to

rectify this issue. Also, see our “Voices of Challenge”

section to hear what voices outside of Timberland have

to say about it. After all, we don’t claim to have all the

answers—we invite comments and challenges. To raise

your voice, email us at csrinfo@timberland.com.

If you have any additional questions about the findings in this chart, please email us at csrinfo@timberland.com

The Evolution of our factory

monitoring process

What’s the difference between an audit and an

we expanded this monitoring of environmental

assessment? To us, an audit is an impartial observation,

compliance to all footwear and apparel suppliers. We

while an assessment is an effort to understand the root

wanted to measure how our factories were managing

cause of a problem and then work in partnership to seek

chemicals, water, waste and energy efficiency. The

improvements.

result is a scorecard that allows assessors to monitor

Assessments

In 2005, a new monitoring process was unveiled that

and encourage improvement in environmental practices

throughout our supply chain.

focused on assessment. Under this new process, our

assessors are no longer seen as “compliance police”—

instead, they are recognized as partners in identifying

and resolving issues and addressing worker needs.

Through this collaborative process, our assessors have

forged positive and powerful relationships with both

factory management and workers—a partnership that

continues after the assessment is completed.

One ongoing challenge with this new approach is getting

factory management to look at issues systemically. For

“The [Timberland Code of Conduct] program approach

focuses on the lives of the workers and on the impact

of the employer on the local community, which is

reflected in a deep assessment approach, a focus on

root cause issues, and in an ongoing, collaborative

effort to drive continuous improvement.”

Ryan Lynch

Eastern Regional Manager

Cal Safety Compliance Corporation

more than a decade, they have been exposed to multiple

brands’ compliance audits, creating corrective action

plans to fix individual findings. What they haven’t been

asked to do in the past is to develop systemic action

plans—in other words, identifying root causes to issues

and developing systems that not only correct individual

findings, they also ensure that similar issues are caught

and/or prevented in the future. This kind of analysis

takes time—time to teach and time to conduct. In

fact, it can take so much time, it can seem as though

we’re willing to wait for issues to be corrected—and

that can send the wrong message to factory managers.

Some issues require immediate action, with a systemic

prevention plan to follow. The challenge then becomes

getting factory management to develop a systemic

prevention plan after the issue has already been fixed.

How We Measure Environmental Performance

Environmental responsibility was written into our Code

of Conduct in 2002. In 2003, we began environmental

compliance audits of our tanneries. In 2005, at the

Our Newest Initiative: Addressing Civic Engagement

In the third year of the assessment program, we’ve

decided to evolve the process even further. We’re now

ready to address the last piece of our CSR mission:

civic engagement. Beginning in 2007, questions are

being added to our assessment questionnaire regarding

suppliers’ community investment and service activities.

Through these questions, we believe we’re creating

an opportunity to inform, inspire and engage each

other. Recognizing and acknowledging factory partners

who share our passion to make a difference in their

communities. And identifying opportunities to further

the ripples of civic engagement worldwide.

With this final addition to our assessment questionnaire,

our process has evolved to an overall CSR assessment,

encouraging factories to “Make it better”—both inside

their factory and out.

same time that we switched from audits to assessments,

2006 CSR report

25

Why We’re Collaborating

with Other Brands

Imagine for a moment that you’re a manager for a factory

that produces footwear or apparel for multiple brands.

Throughout the year, you are visited by each of these

brands multiple times to review over and over again

the factory’s policies, procedures and documentation.

Industry surveys indicate that factories on average

undergo 25 audits a year. With an audit every other

week—who has time to focus on remediation? In 2006,

at the invitation and facilitation of Levi Strauss &

Co., a group of brands joined together to discuss this

issue. Though we may be competitors, all brands and

buyers share a common goal of setting a basic level of

The Goals of Collaboration

Here, more specifically, is what we hope to achieve

through brand collaboration during the assessment

process:

1. Improve factory performance on Code-of-Conduct

standards through consistent communication from

all brands served by the factory;

2. Create a more sustainable process by reducing

duplication in a number of areas, including

monitoring, follow up, factory training and capacity

building programs; and

3. Reduce the resource load on factory management

by eliminating duplication in all of these

same areas.

compliance in our factories—and, ideally, motivating

How well has collaboration worked so far? Through

continuous improvement beyond it. So why not join

a global initiative prompted by Levi Strauss & Co.,

resources and work together rather than duplicate

Timberland piloted the idea in three shared factories—

efforts? Why not visit factories together rather than

two in Turkey and one in India.

subjecting them to multiple audits? Why not pool

resources and work together to assist with remediation?

Fewer assessments, allowing for increased time

and focus on making change. That is the idea

behind sharing in the assessment process with

competitive brands.

In all cases, the idea and the process received

overwhelming support from factory management. They

appreciated the prospect of fewer assessments, as well

as consistent expectations and requirements from both

brands. They also saw the presence of two assessors

from different brands as an opportunity to brainstorm

While the intent of our actions is altruistic, joint

about new ideas and solutions to complex issues. And

assessments and remediation efforts do have possible

extra ears and eyes during assessments made factory

legal implications. We are mindful of the importance of

management more responsive to issues and reinforced

safeguarding each brand’s relationship with its supplier

remediation activities.

and ensuring that our combined actions don’t create

legal liabilities. Our sole purpose in collaborating with

brands in shared factories is to enable the factory and

the brands to work together. To improve workplace

conditions. And achieve mutual standards of ethics in

an efficient, effective and sustainable manner. You may

be sure, however, that each brand continues to make

independent business judgments and sourcing decisions.

In other words, the results were positive. And we aim

to do more collaboration with more brands in the years

to come.

Positive results aside, there is much work left to be

done. The success of the experience depended heavily

on the two brands’ assessors spending time together in

advance of their joint assessments to compare Codes

of Conduct. Assessment techniques. Action planning

methodologies. And remediation processes. It was

important that these guidelines be agreed upon early

on. Otherwise, collaboration runs the risk of confusing

the factory and/or making one brand’s requirements or

expectations more important than the other’s.

The success of the experience depended heavily on the two brands’ assessors spending

time together in advance of their joint assessments to compare Codes of Conduct.

Assessment techniques. Action planning methodologies. And remediation processes.

26

2006 CSR report

Voices: Levi Strauss & Co. on Brand Collaboration

Brand collaboration has been a goal for the apparel and footwear industry since the early 1990s, when

companies began to implement their supplier codes of labor practice. Over the years, various “top-down”

approaches have been implemented, but none realized the full promise of a truly collaborative approach to

factory monitoring.

In late 2005, Levi Strauss & Co. (LS&CO.) published our supplier list, believing that greater transparency

in the supply chain could lead to improved working conditions in apparel factories worldwide. One

very specific goal of that effort was to encourage collaboration among buyers in shared factories. Upon

publication, we reached out to a number of brands, including Timberland, asking them to review our list

and consider how we might work together in shared factories.

In 2006, we began to work with 15 companies, including Timberland, in 70 suppliers. Through exchange

of monitoring reports, joint monitoring visits, remediation discussions, and joint training programs, we have

already seen positive results. By working with other committed brands, we were able to reduce monitoring

in shared suppliers by 25 percent in 2006. This allowed us to direct resources that would otherwise have

been spent on monitoring toward working with suppliers on training, development of management systems,

and other sustainable solutions to labor issues.

While this work is still in its infancy, we are extremely encouraged by the results thus far, and the

committed engagement of other leading and highly respected brands such as Timberland. We continue to

learn from our brand colleagues and suppliers in this work.

Going forward, we invite other brands, monitoring initiatives, and civil society organizations to join

this work. Together, we hope we can more effectively use our collective resources to drive positive and

sustainable change for the benefit of workers in our suppliers.

Michael Kobori

Vice President, Global Code of Conduct

Levi Strauss & Co

2006 CSR report

27

Empowering Workers in the

Assessment Process

In July 2006, a new project was launched in

collaboration with Verite, an independent non-profit

organization monitoring international labor rights, in

two large factories in China. Called the Participatory

Social Compliance Assessment (PSCA), the project was

designed to create a mechanism for factory workers

themselves to conduct ongoing Code of Conduct

assessments of their factories. The idea behind the

project was that getting workers more involved in

identifying and solving Code of Conduct issues would

ultimately improve workplace labor conditions. The

initiative involves three phases:

Phase I: Surveys. Three surveys were distributed to

factory management and supervisors, enabling them

to ascertain perceptions regarding the factory in three

areas: Organizational Culture, CSR Management System

and Communication Practices. Factory workers were also

given the opportunity to participate in a base-line survey

to collect information regarding their awareness of CSR

issues and their views on key issues. Factory working

conditions. Labor issues. And industrial relationships.

Phase II: Training. Factory managers, supervisors and

representatives selected by the workers next took part in

a series of training sessions. Totaling approximately 35

hours and customized according to survey results, these

courses were aimed at equipping participants with an

understanding of CSR. They also taught the leadership

and interpersonal skills necessary for participants to

conduct social compliance assessments effectively.

Feedback from managers indicated that most of them

thought the training was very helpful in learning how to

integrate CSR into the factory’s operations—and support

a successful PSCA project into the future.

development of these tools commencing in early 2007,

the initial PSCAs are expected to be completed by the

worker groups in the summer.

Environment, Health & Safety

in the Assessment Process

Last year, many stakeholders asked us why

Environmental, Health & Safety (EH&S) issues weren’t

included in our list of “Immediate Actions”—our list

of issues that require an immediate response and

commitment from the factory as they represent the most

severe violations of basic human rights. In response,

here’s how EH&S fits in our assessment process.

Health and safety have been included in Timberland’s

Code of Conduct (and related monitoring program)

from the start. We require that workplaces be safe

and healthy, based on the recognized standards of the

International Labour Organization (ILO) and national

laws. We don’t just mean work environments. We also

mean residential facilities provided to workers. In 2002,

we expanded our Code to address the environmental

impact of manufacturing, requiring suppliers to

be responsible in that regard. In 2005, we began

monitoring—and scoring—environmental compliance.

Although environmental, health and safety matters

are not included in our list of “Immediate Actions,”

EH&S matters do represent a significant portion of our

assessment process and are captured in our scoring

system as either “High Priority” or “Continuous

Improvement.” We simply don’t authorize production

with suppliers who have unaddressed High Priority

issues. And in order to allow production to commence or

continue, a written remediation plan that addresses all

High Priority violations must be approved by our Code of

Conduct department. The action plan for High Priority

matters can’t exceed 6 months—and some issues must

Phase III: Keeping the Process Going. The final phase

be resolved within 2 months or less, or even immediately

of the project is to create a process and set of tools

stopped. And suppliers who have medium- to high-risk

for worker representatives to use in conducting social

EH&S findings cannot score Partner, just like suppliers

compliance assessments. This includes incorporating a

with Immediate Action violations.

mechanism for adding workers to the process. With the

“My hope is for PSCAs to help in enhancing mutual trust between

management and workers, changing workers’ behavior, and

increasing their sense of responsibility.”

COO of Chinese Factory participating in pilot phase of PSCA project

28

2006 CSR report

Statistics Tell the Story

In every assessment, the findings surrounding each

Of the 269 questions reviewed during an assessment,

Root Subject are analyzed, and their overall risk is

60% involve EH&S (87 questions pertain to health and

calculated16. Of the 223 factories cited for Emergency

safety matters, 76 to the environment). The chart below

Planning & Fire Safety, less than 5% were found to be

provides a snapshot of how the factories we use stacked

high risk and 36% were found to be the lowest risk.

up with regard to EH&S.

Number of

factories cited

root subject

percentage of

factories assessed

Emergency Planning & Fire Safety

22375%

Physical Agent Exposure/Hazard Mitigation

17459%

Chemical Agent Exposure/Hazard Mitigation

132

45%

Environmental Management

85

29%

Sanitation/Hygiene

78

26%

Medical Service

74

25%

Structural Integrity

37

13%

Beyond Monitoring

Our ultimate goal: improve the lives of workers. We know

safety of the workplace. This microfinance operation has

there are limitations to how assessments can impact

a number of important benefits:

workers’ lives. Sometimes their lives outside the factory

are a part of the issues they face while at work. Knowing

this, we turn to local organizations who are experts in