GE- GA PRODUCTION: EXCITATION FUNCTIONS, TARGET

advertisement

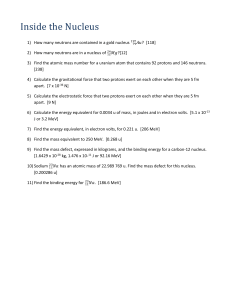

68 GE-68GA PRODUCTION: EXCITATION FUNCTIONS, TARGET PREPARATION AND PC-CONTROLLED RADIOCHEMISTRY SYSTEM R. Adam Rebeles, A. Hermanne, P. Van den Winkel, L. De Vis, R. Waegeneer, Cyclotron Laboratory, Vrije Universiteit Brussel (VUB), Belgium F. Tarkanyi, S. Takacs, Institute of Nuclear Research of the Hungarian Academy of Sciences (Atomki), Debrecen, Hungary M.P. Takacs, Institute of Physics, University of Debrecen, Hungary J-M. Geets, Ion Beam Applications (IBA), Louvain la Neuve , Belgium Abstract Activation cross sections by protons (up to 36 MeV) and deuterons (up to 50 MeV) induced reactions were measured in a stacked foil irradiation using thin Ga-Ni (70/30%) targets. Excitation functions for 68,69Ge are discussed and the results are compared with the literature values and with the theoretical predictions of TALYS nuclear reaction code. High beam power withstanding targets for production of 68Ge by proton irradiation of Ga were developed using electrodeposition of Ga-Ni alloy (70/30%) on thick Cu backings. A PC-controlled radiochemistry system for the production of nca 68Ge was developed. INTRODUCTION The interest for use of 68Ga (T1/2 = 68 minutes, decay β : 89.1 % , EC 10.9 % ) for clinical PET imaging is rising fast in recent years. Evidence for this are the 50 or so talks where application of 68Ga labelled tracers were discussed in the dedicated conference in 2011 in Bad Birka (abstracts in [1]), several presentations in the NRC8 conference held in September 2012 or the discussion in the recent overview article by Qaim [2]. 68 Ga has the advantage that it is shorter lived compared to 18F allowing in principle easier multiple imaging of a patient and reduction of radiation burden. The main advantage comes form the fact that 68Ga can be obtained from a generator system, being the decay product of the long lived 68Ge (T1/2 = 277 d). An overview and detailed information required for production and chemical processing of, among others, 68Ge is discussed in an IAEA document published in 2010 [3]. The preferred production route of 68Ge is through the 69Ga(p,2n)68Ge and 71Ga(p,4n)68Ge reactions, the latter reaction taking place only at higher proton energies (Q = 28.2 MeV). As the melting point of Ga is 29.7°C, centers like Los Alamos National Lab - IPF facility (USA), Brookhaven National Lab - BLIP facility (USA) and Ithemba - Faure (South Africa) use liquid Ga encapsulated in a Nb container as target while in the Russian Federation at Cyclotron Co. Lt. (Obninsk), a Ga-Ni alloy pressed on Cu block serves as target. In collaboration with Ion Beam Applications in Louvain la Neuve (Belgium) the idea is studied to use their commercially available 30 MeV proton cyclotrons for optimized production of parent 68Ge. These + accelerators can deliver high beam intensity (up to 500 µA) and standard 11.7 cm2 Cu block targets with adapted water cooling, irradiated at a 6° beam/target angle, have proven to withstand the high power in prolonged irradiations. The present study involves the following steps needed to set-up a reliable production chain: Optimize reliable high power Ga-targets by electroplating a Ga-Ni alloy with high melting point on Cu block targets. Optimize a computer controlled automated chemistry with high chemical yield and high purity, delivering a nca 68Ge solution acceptable for loading a generator system; Complete the cross section database for reactions of middle energy protons on Ga to identify optimal energy ranges for production of 68Ge and minimization of contaminants; In the frame of our systematic comparison of proton and deuteron induced routes for radionuclide production: study of the excitation function of deuterons on Ga up to 50 MeV; TARGET PREPARATION The set-up and methodology developed earlier for plating of Tl (for 201Tl production); Zn (for 67Ga), and Cd (for 111In) production targets used at IBA Cyclone 30 accelerators and for different type of targets used in research [4, 5, 6] served as basis. The system consist of a cylindrical plating vessel, allowing insertion of 4 targets carriers, power supplies and control units, custom made at VUB [7]. Pre-treatment of the copper target carriers To ensure good adhesion to the Cu carrier special care must be taken in preparation of the copper substrate (brushed with fine abrasive wool, polished with fine abrasive papers and diamond pastes, removal of metallic particle or traces of grease by ultrasonic cleaning). Next the Woods nickel strike is applied. The surface of the Ni strike is larger (22.1 cm2) compared to the actual surface of the Ni-Ga alloy (11.7 cm2). The exact composition of the nickel strike bath as well as the operation conditions are described in the ASTM standard B281-88 (reapproved 2001). Activation of that strike immediately before starting the Ni-Ga plating is done in diluted sulphuric acid (10 mA/cm2, 3 min). More detailed information about the activation method can be found in ASTM standard B343-92a (reapproved 2004). Electrodeposition of the gallium-nickel target layer The Ni-Ga target layer was deposited, simultaneously on 4 Cu carriers, by using the AC Constant Current Electrolysis technique (AC-CCE) applying a cathodic chopped sine wave form. The net cathodic plating current density was 34.2 mA/cm2 (plating area 11.7 cm2). In the acidic plating bath the Ni and Ga species exist as NiSO4 and Ga2(SO4)3 respectively. The bath was prepared by dissolving 31.6 g Ga2O3 in 150 ml (27%) H2SO4. Under heating (200ºC) and vigorous stirring about 99% of the Ga2O3 was dissolved in 14 hours. The solution was filtered, de-ionized water was added until a volume of 450 ml was obtained and the pH is stepwise adjusted to 1.5 by addition of concentrated ammonia. Under gently heating to 45°C, 17.7 g of NiSO4*6H2O were added and the solution transferred to the cylindrical electroplating vessel. During the electrolysis the pH drop is compensated for by addition of diluted NH4OH by means of a peristaltic pump coupled with associated feedback electronics and a pH meter. Up to 51 mg/cm2 of Ga-Ni alloy were deposited within 6.5 h hours, resulting in a thickness of the target layer of 104 µm. In a 6º beam/target angle geometry this results in an energy degradation of about 10 MeV for incident protons with energy in the 26-28 MeV range. As the depletion ratio of the plating bath is limited (to 24.1% for Ni and to 9.5% for Ga) the composition of the deposited alloy varies only slightly (± 3%) with the thickness of the layer in the 100 mg to 800 mg Ga-Ni/target range. The alloy composition was determined by anodic stripping voltammetry to be 30% Ni(±) - 70% (±3%) Ga by weight. EXCITATION FUNCTIONS AND THICK TARGET YIELDS Experimental conditions The cross sections were measured by using stacked foil irradiation technique followed by non destructive γspectrometry with general experimental procedures as described in several of our recent publications [8, 9]. The targets were Ga-Ni alloy (70/30%) prepared by using the electroplating technique previously described on Au (25 µm, for deuteron experiment) or Cu (12.5 µm, proton experiment) foils as backing material. The nominal thickness of the Ga-Ni layer was 17.3 µm (deuteron experiment) or 13.2 µm (proton experiment). In the stack irradiated with 50 MeV deuterons at the CGR930 cyclotron in Louvain la Neuve (LLN), 22 Ga-Ni targets on Au backing were interleaved with 55 Al (98 µm and 49.6 µm) and 15 Ni (23.9 µm) monitor/degrader foils. Second stack consisting of 20 Ga-Ni alloy on Cu backing targets, interleaved with Tl/Cu “degraders” was irradiated with a 36 MeV proton beam of the CGR560 cyclotron at Brussels (VUB). In this experiment the Cu backings were used for monitoring. All base foils used were of high purity (> 99.5%) and were provided by Goodfellow (UK). The targets were mounted in Faraday cup like target holders provided with a long collimator. The beam current was kept constant at about 100 nA (± 5 %) during the 4060 min irradiation. After dismantling of the targets and a 1 to 4 h cooling period, the activity of the induced radionuclides was assessed by HPGe γ-spectrometry, without chemical separation. Optimal and accurate identification and quantification of full energy peaks of short and longer lived activation products was performed in several measurements at different times after EOB with varying sample – detector distance. Typical dead-times were between 5 and 0.5 %. Energy dependent detector efficiency was determined by repeated measurements using calibrated standard sources and a fit allowing knowledge of the efficiency at any γ-ray energy (see [8]). Data Analysis The initial irradiation characteristics (incident energy and particle flux) were derived from the accelerator settings and from the integrated charge measured on the Faraday cup. These parameters were further adapted taking into account the analysis of the monitor reactions nat Cu(p,x)62Zn, respectively natAl(d,x)24,22Na. A very good overlap of measured and recommended excitation functions was obtained after changing the estimated incident proton energy from 36.5 MeV to 36.7 MeV and increasing the current by 25%, while for the deuteron beam no change in energy was needed and the beam current was increased by 5%. The SRIM 2006 code was used for estimation of the energy degradation in each foil of the stacks [9]. The incident energy was estimated with an uncertainty of ± 0.2 MeV. Due to the variations in foils thickness and energy spread, the uncertainty in the median energy estimation is increasing along the stack, reaching a maximum of 1.2 MeV for protons and 2 MeV for deuterons respectively in the last foils. Decay and spectrometric characteristics of the investigated radionuclides were taken from Nudat2 [10]. The uncertainties regarding the cross section values were estimated by extracting the positive square root from the sum all individual contributions into quadrature. The following individual uncertainties are taken into account: absolute abundance of the used gamma rays (1-5 %), determination of the peak areas including statistical errors (1-5 %), the number of target nuclei including nonuniformity (5 %), detector efficiency (5%) and incident particle intensity (5 %). The total uncertainty is evaluated at 8-13 %. Theoretical calculations The experimental results were compared with data retrieved from the online TENDL2011 library, based on calculations with the 1.4 version of the TALYS code family [11, 12]. A priori calculations, without any optimization of the input parameters, were performed for each stable target isotope separately and where appropriate, a weighted sum of the contributing reactions was made and represented on the figures. Results Although more than 20 γ-emitting radionuclides were identified as activation products, only results for 68,69Ge will be discussed here together with earlier published experimental data and values from the theoretical calculation. Proton induced reactions In Fig. 1 our new results for the natGa(p,xn)68Ge excitation function are compared to the values of Levkovskii [13] (values corrected by 20%) and Porile et al. [14]. The agreement up to 35 MeV between these 3 data sets is fair, be it that the Levkovski data are at the low side and some outlying points of Porile et al. [14] are noted . A fit made to our new values results in a maximal cross section that is slightly higher than what is published in the online version of TECDOC-1211 [15]. Figure 2: Excitation function for natGa(p,xn)69Ge, comparison with literature values and theoretical values Deuteron induced reactions In Fig.3 we compare the results of this work for 68Ge production by deuteron irradiation of natGa to the data points published by Karpeles [17]. These literature values are about 25% higher than ours but show overall the same dependence on energy. Compared to protons the maximum for the deuteron reaction on 69Ga occurs at about 6 MeV higher energy and the cross section value is about 25% lower. In the energy range studied no clear contribution from the reaction on 71Ga can be seen. The TENDL2011 prediction is, like for protons, shifted to lower energy and underestimates the maximal value. A slight increase in the theoretical excitation function, due to 71Ga(d,5n)68Ge, is seen between 40 and 50 MeV. Figure 1: Excitation function for natGa(p,xn)68Ge, comparison with literature values and theoretical values Although it concerns simple (p,2n) and (p,4n) reactions the TENDL2011 prediction shows a shift to lower energy and too low maximal values. For production of 69Ge some discrepancies exist between our new measurements and the literature data (see Fig. 2). In the 10-15 MeV region our data are energy shifted compared to the values of Levkovski [13] (corrected values by 20%) but the agreement in the higher energy region is excellent. The new data are also lower than what was published by Porile et al. [14] obtained by weighted summation of results on enriched 69Ga and 71Ga targets. In the low energy region (up to 5 MeV) the new data overlap with the values of Johnson et al. [16]. The results of TENDL2011 for the (p,n) and (p,3n) reactions agree here very well with our experimental values. Figure 3: Excitation function for natGa(d,xn)68,69Ge, comparison with literature values and theoretical values The excitation function for production of 69Ge is very similar for deuterons and protons although, as expected, a shift towards higher energy occurs (Fig. 3). The TENDL2011 values represent well the shape of the function but the predicted maximal value for the 69 Ga(d,2n)69Ge reaction is 50% higher than the measured one. Thick targets yields Liquid/liquid extraction of nca 68Ge into toluene From fits to our experimental results thick target yields were calculated and presented in Fig. 4. For the nat Ga(p,x)68Ge the present results confirm the IAEA TECDOC-1211 recommended yields. The difference of 10 percents is within experimental uncertainties. From Fig. 4 it is clear that deuteron induced production of 68Ge on Ga targets is not interesting as the expected yield is lower than for proton irradiation, thicker targets are needed and higher deuteron energy are required. At the end of the stripping process the solution is transferred into the extractor by means of a high-speed peristaltic pump. The PVDF Extractor is fitted with a magnetic Teflon-coated stirring bar and a microconductivity phase sensor at the outlet. Two electromagnets surrounding the extractor body in an appropriate geometry generate a magnetic rotating field causing the magnetic stirring bar to rotate when 50Hz current is applied through the coils of the magnets. An inlet tube mounted in the cover plate allows introduction of reagents by means of a peristaltic pump, a second tube in the cover plate is connected to a gas-trap to collect any radioactive component escaping from the extractor and nitrogen pressure can be applied through a third tube connected to a nitrogen canister via a valve. Upon addition of 16 ml toluene, 3.3 ml HCl 10 N is added to the extractor followed by 16 more ml of toluene. Mixing of both phases is achieved by vigorous stirring (3 min). During this mixing more than 97% of the 68Ge is selectively transferred into the toluene phase as 68GeCl4. Next, separation of both phases under gravity force is allowed for 15 min whereupon the aqueous phase is transferred to the waste applying 50 mb nitrogen pressure and opening the extractor outlet valve. Back-extraction of 68 Ge into the aqueous phase (20 ml 0.05 N HCl) is done in a similar way. The aqueous phase containing the 68Ge is transferred to a Temporary Storage Vial (TSV). Figure 4: Thick target yields for production of 68Ge by proton and deuteron irradiation of natural gallium PC-CONTROLLED RADIOCHEMISTRY SYSTEM FOR THE PRODUCTION OF 68 GE The set-up, described in the following sections, is similar to what was developed in collaboration with IBA earlier for production of 64Cu [18]. Target dissolution Upon bombardment and appropriate cooling down, the irradiated target is mounted in the heated flow-through stripper (fitted with a polycarbonate window closed by means of compressed air). As stripping solution 27 ml mixture of H2SO4 (11.45M ) and HNO3 (1.04N) acid is re-circulated 30 min through a loop built up from a recycling vial, a peristaltic pump and the flow through stripper connected by Teflon tubing through an appropriate combinations of valves. The stripper is heated up to 100°C. As during the next separation step (extraction of 68Ge into toluene) NO gas bubbles may disturb the proper separation of organic and aqueous phases in the microconductivity sensor cell at the outlet of the extractor, the NO is reduced to N2 gas showing a limited solubility in aqueous solutions. Therefore after 30 min of dissolution, 4 ml of 10% sulfamic acid is slowly (1ml.min-1) added into the recycling vial and the recirculation continued for 30 more min. The quantity of copper dissolved during the entire stripping process is always much less than 250 mg. Final purification by ion exchange chromatography The removal of possible metallic trace impurities (Ga, Ni, Cu …) is done by means of cation exchange chromatography using Dowex-50 WX4 200-400 mesh resin in the H+ form. The polycarbonate column used for this purpose has a bed volume of 5.2 ml and is fitted with a conductivity phase sensor/ 3/2 way valve at the inlet while the outlet is directly connected to the Volume Measuring Unit (VMU). The solution from the TSV is pumped to the column at a flow-rate of 0.77 ml.min-1. In 0.05 N HCl, metallic impurities are exchanged for protons as the solution moves through the column. Volume measuring and sterilization The neutral 68GeCl4 passes into the eluate that is directly collected in the VMU. The latter is fitted with a moving needle conductivity sensor mounted in the top plate and reads the volume (after appropriate calibration) with a resolution of 100 μl. Samples for chemical and gamma-spectrometric analysis are taken from the VMU by means of a peristaltic pump. After sampling, the bulk solution is transferred to a penicillin vial using a peristaltic pump/0.22 μm filter combination. Yield and purity of the bulk solution Tracer experiments using the shorter lived 69Ge (T1/2 = 39 hr) tracer revealed a mean yield of 90% (Table 1). The total chemistry time amounts to 2.5 hr. Mean bulk impurities measured by Stripping Voltammetric Analysis are quite acceptable: Cu: 0.15ppm; Ni: 0.06ppm and Ga: 0.14ppm (Table 2). Table 1: Overview of 69Ge losses during radiochemistry Target Plate Dissolution window Recycling vial Acid waste Organic waste Extractor % % % % % % 0.19 0.51 0.11 4.67 0.45 1.10 0.10 0.52 0.22 2.57 0.50 1.15 0.13 0.71 0.30 2.16 0.27 1.57 0.09 0.61 0.19 1.28 0.57 1.09 0.13 0.59 0.21 2.67 0.45 1.23 Test Nr 1 2 3 4 Mean Table 2: Chemical purity of the bulk solution Test Nr 1 2 3 4 Mean Cu ppm 0.161 0.140 0.213 0.101 0.15 Ni ppm 0.064 0.083 0.045 <0.04 0.06 Ga ppm 0.114 0.110 0.245 0.074 0.14 CONCLUSIONS In order to make optimized production of nca 68Ge, parent for a 68Ge-68Ga generator, possible using commercially available 30 MeV proton cyclotrons, we developed high quality Ga-Ni alloy (70/30%) targets. The targets can withstand 350°C and are electroplated in 6.5 h from an acidic bath in the standard set-up developed at VUB. Four targets can simultaneous be prepared and good quality targets with thicknesses ranging from 100 to 130 µm alloy are currently obtained. This is sufficient to degrade incident beams of 28-26 MeV protons by about 10 MeV in the 6° beam/target angle geometry mostly used around the IBA Cyclone cyclotrons. This ideal energy range was derived from the upgraded data set for cross sections of the natGa(p,xn)68Ge reaction where our new results confirm the earlier experimental results and the thick target yields published in the IAEA TECDOC1211. For an irradiation of 21 days at 300 µA on target a batch yield of 2.9 Ci can be obtained. Deuteron induced production of 68Ge on Ga targets is not interesting as the expected yield is 30% lower than for proton irradiation, thicker targets are needed and higher deuteron energy are required. For handling of the irradiated targets an automated, PC controlled separation-purification chemistry has been developed. In four steps (dissolution in H2SO4/HNO3, extraction in toluene, back extraction in diluted HCl and final purification over a cation exchange chromatographic column), nca 68Ge is obtained in 25 ml 0.05 M HCl. The full procedure was performed several times using 69Ge as tracer and showed a reproducible overall yield of about 90%.Mean bulk impurities measured are quite acceptable: Cu: 0.15 ppm; Ni: 0.06 ppm and Ga: 0.14 ppm. REFERENCES [1] F. Rösch, World Journal of Nuclear Medicine, 10 (2011) 26 [2] S.M. Qaim, Radiochimica Acta, 100 (2012) 635 [3] IAEA Radioisotopes and radiopharmaceuticals series, N° 2: Production of long lived parent nuclides Volatilized 69Ge % 0.21 0.04 0.11 0.00 0.09 Chromatographic unit % <0.1 0.04 0.07 0.04 0.06 Bulk yield 69Ge vs reference solution % 92.41 90.07 93.42 91.37 91.82 for generators: 68Ge, 82Sr, 90Sr and 188W. IAEA Vienna (2010) [4] R. Adam-Rebeles, P. Van den Winkel, L. De Vis, Appl. Radiat. Isotopes 65 (2007) 995 [5] R. Adam-Rebeles, “Optimization of accelerator based radionuclide production”, PhD thesis presented at the Vrije Universiteit Brussel (2011) [6] A. Hermanne, L. Daraban, R. Adam Rebeles, A. Ignatyuk, F. Tarkanyi, S. Takacs, Nucl. Instr. Methods B 268 (2010) 1376 [7] A. Hermanne, R. Adam Rebeles, F. Tárkányi, S. Takacs, M. Takacs, A. V. Ignatyuk, Nucl. Instr.Methods B 269 (2011) 2563 [8] A. Hermanne, S. Takacs, F. Tarkanyi, R. AdamRebeles, A. V. Ignatyuk, Appl. Radiat. Isotopes 70 (2012) 2763 [9] J.F. Ziegler, M.D. Ziegler, J.P. Biersack, SRIM2006, http://www.srim.org [10] National Nuclear Data Center, USA, http://www.nndc.bnl.gov [11] A.J. Koning, S. Hilaire, S. Goriely, TALYS-1.4, A nuclear reaction program, User manual, Consultancy Group (NRG), Petten, The Netherlands, (2011) [12] A.J. Koning, D. Rochman, TENDL-2011 TALYSbased Evaluated Nuclear Data Library, Nuclear Research and Consultancy Group (NRG), Petten, The Netherlands, Release date December 8, 2011, http://www.talys.eu/tendl-2011 [13] V.N Levkovskii, Activation cross sections for the nuclides of medium mass region (A = 40-100) with protons and a particles at medium (E = 10-50 MeV) energies (Experiments and systematics). Inter-Vesi Moscow, (1991) – EXFOR A0510 [14] N.T. Porile, H. Tanaka, H. Amano, Nuclear Physics 43 (1963) 500 [15] F. Tarkanyi, S. Takacs, K. Gul, A. Hermanne, M.G. Mustafa, M. Nortier, P. Oblozinsky, S.M. Qaim, B. Scholten, Yu. N. Shubin, Z. Youxiang, Charged particle cross section database for medical radioisotope production: diagnostic radioisotopes and monitor reactions. IAEA TECDOC-1211, IAEA, Vienna (2001), http://www-nds.iaea.org/medical/. [16] C.H. Johnson, C.C. Trail, A. Galonsky, Physical Review B, 136 (1964) 1719 [17] A. Karpeles, Radiochimica Acta 12 (1969) 212 [18] R. Adam Rebeles, P. Van den Winkel, A. Hermanne, L. De Vis, R. Waegeneer, J. Radioanalytical and Nuclear Chemistry 286 (2010) 665