R07

advertisement

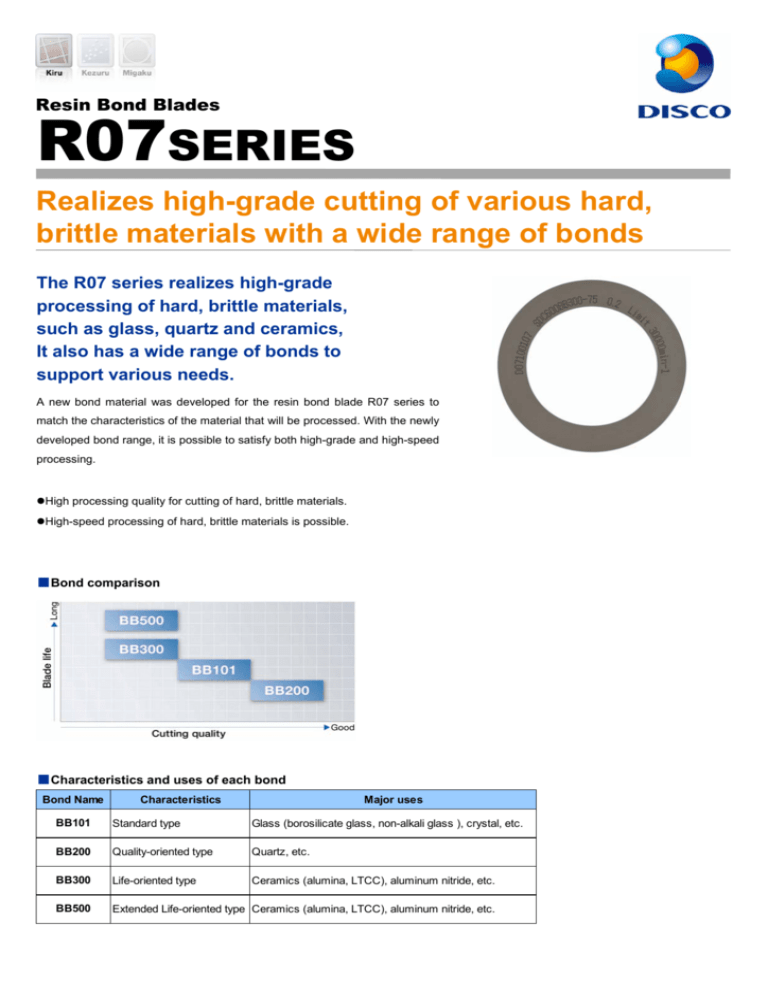

Resin Bond Blades R07SERIES Realizes high-grade cutting of various hard, brittle materials with a wide range of bonds The R07 series realizes high-grade processing of hard, brittle materials, such as glass, quartz and ceramics, It also has a wide range of bonds to support various needs. A new bond material was developed for the resin bond blade R07 series to match the characteristics of the material that will be processed. With the newly developed bond range, it is possible to satisfy both high-grade and high-speed processing. High processing quality for cutting of hard, brittle materials. High-speed processing of hard, brittle materials is possible. ■Bond comparison ■Characteristics and uses of each bond Bond Name Characteristics Major uses BB101 Standard type Glass (borosilicate glass, non-alkali glass ), crystal, etc. BB200 Quality-oriented type Quartz, etc. BB300 Life-oriented type Ceramics (alumina, LTCC), aluminum nitride, etc. BB500 Extended Life-oriented type Ceramics (alumina, LTCC), aluminum nitride, etc. Resin Bond Blades R07SERIES Specifications R07 - SDC 600 - BB101 - 75 SD SDC 180 220 240 280 320 340 360 #180 #220 #240 #280 #320 #340 #360 400 500 600 700 800 1200 O.D. Concentration Bond*1 50 BB101※2 BB200 75 85 BB300 100 BB500 Grit size Grit type*1 54 × 0.2 A2 × 40 #400 #500 #600 #700 #800 #1200 Thickness Thickness accuracy A2 ±0.005 A3 ±0.010 A4 ±0.015 Special AS specification (mm) I.D. *1 Combinations Bond BB101 BB200 BB300 BB500 Grit type SDC SD, SDC SDC SDC :*2: BB101 is an improved version of the BB100 bond. Currently, DISCO recommends the BB101 bond. Note: #180-800 is usable only for SDC. Experimental Data ■Borosilicate glass cutting process (BB101 bond) ■Quartz cutting process (BB200 bond) Achieves smaller chipping than the existing blade for both the front and backside, and longer blade life. Achieves smaller chipping than the existing blade for both the front and backside, and longer blade life. Backside chipping Top side chipping 1 00 50 0 BB101 Current 200 150 150 100 100 50 50 250 BB101 BB2 0 0 Current Blade life 200 150 100 50 0 0 0 Current BB101 Backside chipping 200 chipping (μm) Blade Life (Current type=100) 1 50 chipping (μm) Blade life 250 Blade Life (Current type=100) Top side chipping 2 00 Cu rren t BB2 0 0 Cu rren t BB200 Current :Quartz 1.1 mmt :New R07-SD400-BB200-75 :Current P1A851 SD400R10MB01 Spindle revolution :20000 min-1 Feed speed :5 mm/s Size :54 x 0.2 x 40 mm :Borosilicate glass 0.7 mmt :New R07-SDC600-BB101-75 :Current P1A851 SD600R10MB01 Spindle revolution :20000 min-1 :10 mm/s Feed speed :54 x 0.1 x 40 mm Size Workpiece Blade Workpiece Blade ■Alumina ceramics cutting process (BB300, BB500 bond) The chipping is about the same for both the front and backside chipping as the existing blade, however it achieves longer blade life. Top side chipping Backside chipping Blade life 200 Blade Life (Current type=100) 250 chipping (μm) 150 100 50 0 BB500 BB300 Current BB500 BB300 Current :96% Al2O3 100 x 100 x 0.5 mmt :Current P1A851 SDC400R10MB01 :R07-SDC400-BB300-75 :R07-SDC400-BB500-75 Spindle revolution:30000 min-1 Feed speed :10 mm/s Size :54 x 0.15 x 40 mm Workpiece Blade 200 150 100 50 0 BB500 BB300 Current When ordering To use these DISCO blades and wheels (hereafter precision tooling) safely... Please contact a DISCO representative with your product needs such as type, wheel size, and quantity. When you place the first order with us, please explain application information such as materials to grind, sizes, machine, type, and other specification. We are ready to help you to determine which is our most appropriate product type for your application. Due to improvements in our products, it is possible that product specifications may be changed without advanced notice. Please confirm the product specifications with a DISCO representative. www.disco.co.jp • • • • • • • • • • Please read carefully and follow the instructions below to prevent any accidents or injuries. USE a safety cover (nozzle case, cover), equipped as a standard accessory, to avoid injury. DO NOT EXCEED the specified rpm limit indicated on the precision tooling. FOLLOW the instruction manual of the equipment to mount the precision tooling properly. DO NOT DROP OR HIT the precision tooling. This may cause breakage or injury. Always CHECK the precision tooling for chipping or any other damage before starting to use it. DO NOT USE the tooling if there is any damage. READ the operation manual of the cutting/grinding equipment before use. DO NOT USE the precision tooling with modified or customized equipment. DO NOT USE precision tooling that has a different size from the one recommended for your equipment. DO NOT USE the precision tooling for any other purpose than grinding, cutting, or polishing. Always USE water or coolant to prevent precision tooling damage. 2014.12