Thomas Flexible Disc Couplings

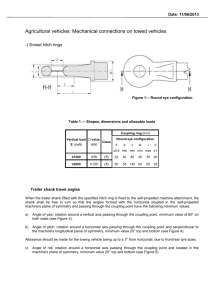

advertisement