GROWTH – DEDICATED CALL – 7/99

advertisement

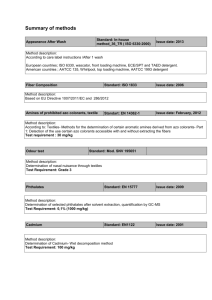

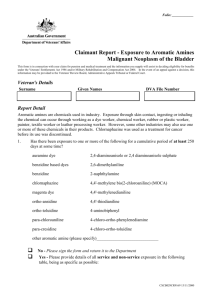

GROWTH – DEDICATED CALL – 10/00 TOPIC IV.21 Azo dyes in leather 1. CONFORMITY WITH THE WORK PROGRAMME The present topic is in conformity with the thematic programme Competitive and Sustainable Growth (1.1.3) within the first activity of the Fifth Framework Programme. It addresses research objective 6.3 Support to the development of Certified Reference Materials (CRMs) in that it demands a feasibility study for a CRM that can be used for quality control in chemical measurements. Specifically this will be a certified reference material for European standards that is needed in support of directives and Community policies, in particular in the field of health care. The requested CRM will be used as a tool to verify the performance of analytical methods of industrial importance. 2. KEYWORDS azo dyes, banned aromatic amines, leather, certified reference material, feasibility study, material preparation, homogeneity study, stability study, methods testing, interlaboratory trial, quality control 3. SUMMARY OF OBJECTIVES AND JUSTIFICATION Leather is a raw material for a wide range of products which satisfy basic needs of consumers in Europe. The volume of production and trade is high. Consequently, the European leather industry, which consists mainly of SMEs, is of great economic and social importance. In trade the leather raw materials, semi-products and finished products have to meet certain specifications. Measurements are performed in order to ascertain that the commodities satisfy these requirements. The measurements include tests for chemicals which may be used or formed in different stages of the manufacturing process and which may pose a threat to human health. As trade in leather commodities takes place within and outside the EU common market, the analytical measurements carried out in different laboratories need to be reliable and comparable. Therefore the objective of this feasibility study is the development of the ability to analyse, to produce and to certify a reference material for certain aromatic amines in leather due to the use of azo dyes. The aims are (1) to optimise methods of analysis, (2) to prepare preliminary test batches of different leather samples, (3) to carry out interlaboratory trials in order to test method performance using different types of leather, (4) to test for homogeneity of the test batches and (5) to perform stability studies. DC 10/00/Topic IV.21/ Pg 2 4. BACKGROUND 4.1. Aromatic amines The carcinogenic effect of certain aromatic amines on humans has been known for a long time. However, in the past experts have propounded the opinion that these substances cannot exercise any carcinogenic effects when used as coupling components for azo dyes, as they are not bio-available in coupled state. In recent years experimental studies have led to a revision of this view. While the intact azo dyes are in fact biologically inactive, the living organism is able to reduce them to the corresponding aromatic amines by enzymes from intestinal bacteria and from the liver 1. This means that certain azo dyes used in textiles and leather pose a risk of cancer for both consumers and workers. 4.2. Legal aspects In view of these considerations Germany took the lead in adopting a legislation on aromatic amines2. Other member states of the European Union have already followed this move and have introduced or notified national legislation banning azo dyes able to release certain carcinogenic aromatic amines by splitting of the azo bond. In order to harmonise the situation a proposal for an amendment of Council Directive 76/769/EEC relating to restrictions on the marketing and use of certain dangerous substances and preparations (azocolourants) was already presented by the Commission in December 1999. This proposal is currently discussed in the European Parliament. 4.3. Analysis of aromatic amines in leather At present only a German DIN method3 (and a similar Dutch standard) for the analysis of aromatic amines in leather samples exists. Although the method is currently used world-wide, as no alternative is available, it is not commonly accepted yet due to e.g. poor reproducibility. For this reason the European Commission published a dedicated call in December 1996 with the intent to develop a harmonised test method. The resulting EU project Development of a harmonised test method for the detection of certain aromatic amines in leather due to the use of azo dyes (SMT4-CT97-2194) started its work in the beginning of 1998 and will be finished by the end of June 2000. The results of the project will be made available to potential proposers. In the course of this project different analysis steps were investigated. For the first time leather samples with a known content of azo dyes, which by reductive cleavage produce forbidden amines, were prepared. An interlaboratory trial with 13 participants was carried out using these leather samples. 1 F. Rafii, C. E. Cerniglia "Reduction of Azo Dyes and Nitroaromatic Compounds by Bacterial Enzymes from the Human Intestinal Tract" Environmental Health Perspectives, Vol. 103, Suppl. 5 (1995) 17-19 2 Zweite Verordnung zur Änderung der Bedarfsgegenständeverordnung vom 15. Juli 1994 / BGB1, Jg 1994, Teil 1 3 DIN 53316 "Prüfung von Leder - Nachweis bestimmter Azofarbstoffe in Leder" Beuth Verlag, Berlin DC 10/00/Topic IV.21/ Pg 3 The overall method developed within the project eliminates certain risks associated with the DIN method and shows a good reproducibility and inter-laboratory comparability. Furthermore it could already be proven that the production of leather samples containing a defined amount of amines is possible. Therefore the chances of success for the proposed feasibility study are high. 5. ECONOMIC AND SOCIAL BENEFITS The present topic addresses simultaneously all three socio-economic objectives of the RTD activity Measurements and Testing. Main emphasis lies on the first objective Prenormative research and technical support of standardisation which aims at the development of certified reference materials needed in support of Community policies, in particular for the implementation of directives. The topic furthermore refers to the second objective The fight against fraud in that it improves current measurement and testing methods that are needed in order to protect the health of citizens. In addition it addresses the third socio-economic objective Improvement of quality insofar as it aims at the improvement of generic measurement and testing methods as well as of international comparability of measurements. The requested Certified Reference Material is supposed to establish the comparability of measurement results throughout Europe. Hence it is a key element in ensuring the accuracy and reliability of measurements that are required in order to control the quality of products provided by industry and to monitor the safety of European citizens. In addition to protection of public health it assists the implementation of a directive necessary to preserve the internal market. This action falls within the exclusive competence of the Community, as established by Council Directive 76/769/EEC. 6. SCIENTIFIC AND TECHNOLOGICAL OBJECTIVES The objectives of the feasibility study are (1) to optimise methods of analysis for certain aromatic amines in leather due to the use of azo dyes, (2) to prepare preliminary test batches of different leather samples, (3) to carry out interlaboratory trials in order to test method performance using different types of leather, (4) to test for homogeneity of the test batches and (5) to perform stability studies. Method optimisation 6.1 Method optimisation The existing analysis method(s) have to be optimised and simplified. The aim is a reliable, robust and well characterised method which will assure comparability of measurement results throughout Europe. A representative number of forbidden and non-forbidden amines have to be used for the experiments. It has to be properly investigated whether and to what extent the measurement results (e.g. the extraction efficiency) depend on the type of leather used. Particular attention has to be given to the question of false positive results. Additional work has to be done on the extraction step and the subsequent purification of the extracts. Especially modern methods such as ASE (accelerated solvent extraction), SFE (supercritical fluid extraction) and MAE (microwave assisted extraction) should be employed aiming to improve the extraction efficiency. DC 10/00/Topic IV.21/ Pg 4 6.2. Preparation of preliminary test batches Preliminary test batches containing known amounts of azo dyes, which by reductive cleavage release forbidden aromatic amines, have to be prepared. The concentration level of forbidden amines should not exceed 100 mg/kg in the leather so as to be in the same order of magnitude as possible false positives. It will be necessary to prepare different kinds of leather representative for several applications. Especially different tanning procedures should be taken into account (e.g. chrome, vegetable, and aldehyde tanned leather). Furthermore different dyeing auxiliaries and fatliquoring and waterproofing agents could be used. The matrices have to be selected in co-operation with the leather industry. 6.3. Interlaboratory trials Preliminary interlaboratory trials should be carried out in order to evaluate the developed method(s). Each such round should use a different (similar but not identical) test material. The interlaboratory trials have to be followed by a detailed technical discussion of the method(s) used and precautions taken, so as to identify and eliminate the technical causes of possible discrepancies. Synthetic solutions containing pure amines in methanol have to be distributed together with the leather samples in order to check the laboratory performance. 6.4. Homogeneity tests Homogeneity tests of the preliminary test batches have be performed. The methods for homogeneity testing should be optimised aiming at maximum reproducibility. 6.5. Stability studies The stability tests of the leather material should include, for a period of at least 6 months, the periodic analysis of samples stored at various temperatures, e.g.: a temperature in the range of 0 to 5 °C (refrigerator) a temperature around 20 °C (room temperature) an elevated temperature at which bacteria will grow easily (this should be around 35 °C) a higher temperature (for example 60 °C). Furthermore the stability testing could take into account a possible photolysis by UV light and degradation due to the presence of oxygen. It seems advisable to store the leather samples in the dark and to keep them dry. The results of the EU project Development of a harmonised test method for the detection of certain aromatic amines in leather due to the use of azo dyes (SMT4-CT972194) have to be taken into account. DC 10/00/Topic IV.21/ Pg 5 7. TIME SCALE Project duration should not exceed 24 months. DC 10/00/Topic IV.21/ Pg 6 Addendum to the supporting document for all topics related to the development of Certified Reference Materials (CRMs) Introduction Research in support of the development of CRMs is an objective of the Growth Programme. The modality for this research is a shared cost action on RTD (cf work programme Competitive and Sustainable Growth). The guidelines for the submission of the proposal are laid down in the Guides for Proposers. In addition to the requirements for research on a specific topic that are laid down in the supporting document*, there are general requirements for the development of CRMs. These requirements are described below and are in addition to the general requirements for shared cost actions, as described in the guides for proposers and the model contract. The requirements have been divided in 2 major parts: I) Description of the work This part concentrates on the technical requirements of the research as well as the reporting requirements in view of the future certification. II) Implementation of the objectives of the research The research on CRMs consists of the development of the ability to produce and certify reference materials that are fit for purpose. The planned exploitation of the results has to aim at the production and certification of the reference material(s) in accordance with prevailing international quality standards. * The dedicated call system enables the Commission to identify priority topics that have been forwarded under the call for the expressions of interest. The supporting document that has been used to evaluate the topic now serves as a reference document to the proposers for the preparation of the proposal. DC 10/00/Topic IV.21/ Pg 7 I) Description of the work Research on CRMs consists of the development of the ability to produce and certify reference materials. The actual production of the CRM is not part of the research but is part of the exploitation of the result(s). In the first phase of the research project the certification strategy should be elaborated (development of the materials and methods for characterisation), in the second phase of the research project the ability to produce and certify should be demonstrated and finally the specifications for the final CRM should be set. The development of a CRM normally consists of 4 major parts: 1) development of the know-how required to produce (and package) the future CRM 2) development of the methods needed for future certification of the material 3) demonstration of the feasibility of the CRM production (production of a small batch + mimicking its certification) 4) reporting of detailed and realistic specifications for the future CRM 1. Development of the know-how required to produce (and package) the future CRM specify the sort of material that is most likely to meet both the targets laid down in the supporting document and be suitably homogeneous, stable, safe to handle, and acceptable in cost identify the options available for selecting / preparing such a material take into account special storage and / or transport requirements existing for certain types of materials develop of methods for production / selection and preparation, homogenisation, stabilisation, protection and packaging of material as required, to enable the production of a CRM which will be fit for purpose if a material needs to be altered substantially (e.g. freeze drying), or when it is artificially spiked with the substance of interest, it is necessary to check if the material behaves in the same manner as the routine samples when applying the relevant methods of measurement. Ensure the availability of a suitable reconstitution procedure if a material will need reconstitution DC 10/00/Topic IV.21/ Pg 8 2. Development of the methods needed for future certification of the material Certification can be performed according to different criteria. The research will define which certification route, following internationally recognised quality requirements and standards, will be followed. Certification on the basis of pure substances If the CRM is a pure substance the preparation methods should be such that the presence of impurities are reduced to a minimum. Additionally the substance should be tested for impurities by carefully selected methods at least in two laboratories. Certification on the basis of preparation data When dealing with a synthetic CRM and a quantity which is directly related to (or depends in a well-established way on) composition, examine if preparation under metrological conditions and certification on that basis (e.g. using gravimetric data) is possible Identify nevertheless a method of measurement that can be used as an independent check for large errors Certification on the basis of measurements - method-dependent quantities If the quantity to be certified is defined on the basis of a specific (standard) sample treatment or method of measurement, certification will be based on statistical processing of results produced by a sufficient number of laboratories (e.g. 12 - 15), which follow strictly the standard protocol but include all variability which is allowed by the protocol (do not use common sources of calibrants, reagents, ... unless these will be available to the future CRM users and prescribed in the protocol). Such protocol may have to be developed Work may be necessary to achieve an acceptable level of reproducibility Certification on the basis of measurements - method-independent quantities As error-free, matrix-independent, calibration-independent methods are exceptional, the basis for certification will usually be an agreement between different methods and different laboratories, applied under conditions of independence which rule out the risk of a common systematic error. Methods with a high potential for matrixindependence and/or calibration-independence (e.g. IDMS for determining polyisotopic elements) should be included if available it may be necessary to perform a substantial collaborative method improvement (to achieve the required level of agreement between methods and between laboratories), or even research (method development) to achieve the required ability to measure. Guidance for collaborative method improvement is given in the BCR Guidelines* * Guidelines for the production and certification of BCR reference materials, available from the Commission on request (E. Michel, tel: 32/2-295.11.33, fax: 32/2-295.80.72, email: ellen.michel@cec.eu.int ) DC 10/00/Topic IV.21/ Pg 9 3. Demonstration of the feasibility of the CRM production prepare a small batch of material, similar to that intended to be prepared as a CRM, using the method intended to be used to prepare the actual reference material Check the fitness for purpose: form, shape or texture of the material; if applicable, contamination (air, moisture, vapours, dust and dirt, micro-organisms etc.) homogeneity stability (the analyte / measurand as well as the matrix) safety of packaging when exposed to shocks, extreme temperatures and other possible causes of damage during storage and transport ease of opening and use lyophilisation and reconstitution procedures Guidance for homogeneity and stability testing is given in the BCR Guidelines. Use the test batch to mimic the certification of a future CRM in a measurement campaign, designed as a certification exercise (see BCR Guidelines) If the results show that a CRM prepared and certified as in the test round is not good enough, then the development work (1. or 2. above) must be recommended 4. Reporting of detailed and realistic specifications for the future CRM The reporting requirements are set in the guidelines for reporting. In addition to the Final Technical Report the coordinator should prepare an overview of all the results, as foreseen in the Technical Implementation Plan. In this report the outcome of the research that sets the boundaries for the future CRM production should be given preferably in the form of a technical data sheet. It should contain the following information: form / type of samples (with preference for individually packed portions for single use) lyophilisation and reconstitution procedures specify bottling, labelling, packing, storage and transport requirements identify any legal restrictions on the transport of such material and need for safety labelling, collect data for material safety data sheets magnitude of the quantity of interest (acceptable range) acceptable uncertainty on the certified value for an individual sample (this includes at least: acceptable uncertainty on the mean value for the entire batch, and acceptable level of inhomogeneity of the batch) method requirements (if the CRM is method dependent) acceptable magnitude of other quantities an estimate of the quantity of CRM that should be produced as well as an estimate of the production costs. DC 10/00/Topic IV.21/ Pg 10 II) Implementation of the objectives of the research As for all shared cost contracts the contractors are obliged to exploit the knowledge arising from the project. In the case of research on CRMs the contractors are, among others, obliged to assure that the CRM is produced and certified within a reasonable time limit (article 10 of Annex II General Conditions of model contract). The "Technological Implementation Plan" (TIP), which has to be prepared in any RTD project of the 5th Framework Programme, shall explain the actions planned to assure that results of the project will be exploited. In case of CRMs this TIP has to outline the strategy for the CRM production, certification and marketing within a reasonable time frame, at a reasonable cost and according to internationally recognised quality requirements. A draft TIP has to be available at the project midterm. Options, ranging from production by the consortium to production by a third party or the Commission, will be explored in consultation with the Commission Services.