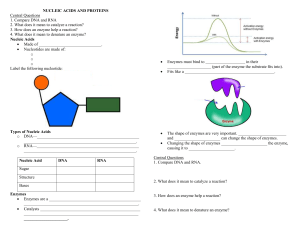

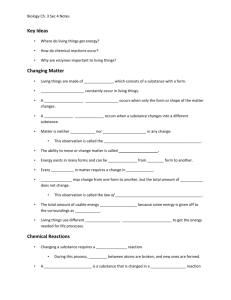

2.3 Entrapping Enzymes

advertisement