16330 Medium Voltage Metal - Enclosed Load Interrupter

advertisement

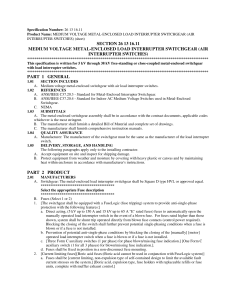

SECTION 16330 MEDIUM-VOLTAGE METAL-ENCLOSED LOAD INTERRUPTER PART 1 - GENERAL 1.01 SUMMARY A. Provisions of Division 01 apply to this section B. Section Includes: C. 1.02 1. Medium voltage load interrupter metal enclosed switchgear, single or multiple section line-ups as described and as indicted on Drawings and specified herein. 2. Equipment shall be manufactured and tested in accordance with IEEE C37.20.3 IEEE standard for metal-enclosed interrupter switchgear (ANSI), and NEMA SG6 power switching equipment. Equipment shall comply with California Electrical Code. Related Sections: 1. Section 16125: Medium-Voltage Cables, Splices and Terminations. 2. Section 16275: Medium-Voltage Transformers. 3. Section 16360: Unit Substations. SUBMITTALS A. Provide in accordance with Division 01. B. Shop Drawings: Shop Drawings shall include a front elevation, dimensions, make, and electrical ratings of all components. C. Installation Instructions: Submit approved manufacturer's written installation instructions, including recommendations for handling, storage and protection. PART 2 - PRODUCTS 2.01 LOAD INTERRUPTER SWITCHGEAR A. Switches shall be quick-make, quick-break, 3-pole, 2-position with a stored energy spring mechanism to provide quick switch operation independent of the PROJECT NAME SCHOOL NAME 4/7/2006 MEDIUM-VOLTAGE METAL-ENCLOSED LOAD INTERRUPTER 16330-1 handle speed. A viewing window shall be installed in switch enclosure and located to enable visible inspection of switch poles from outside enclosure. B. Complete metal enclosed switchgear shall be rated as indicated on Drawings with fault close, momentary ratings capable of withstanding short-circuit stresses. C. High-voltage fuses and non-disconnecting fuse mountings shall be accessible only through a separate door mechanically interlocked with load break switch, to insure the switch is in open position when fuses are accessible. A key interlocking system shall also be provided to prevent fuse access door from being opened unless switch is open, and to prevent switch from being closed unless fuse access door is closed. Switch designs with full height fuse access doors shall have a solid barrier covering area of main cross bus and/or line side of switch. Metal screen barriers are not permitted. Energized parts shall not be within normal reach of opened doorway. Four single full length inter-phase barriers shall isolate three phases of the switch from each other and from enclosures. Fuses shall be current limiting type of self contained design to limit available fault current stresses on system. Fuses shall be affixed in position with provisions for removal and replacement from front of gear without use of special tools. Provisions for padlocking in open and closed position shall be provided. D. Utility company metering section shall be furnished with mounting and wiring instrument transformers and meters, as required by the serving utility company. E. Enclosure frame and internal barriers shall be fabricated of code gage and finished with 2 coats of medium gray, ANSI No. 451, paint applied over a rust-inhibiting phosphate primer. 2.02 SWITCHGEAR CONSTRUCTION A. Switch bays shall be separately constructed cubicles assembled to form rigid freestanding units. Adjacent bays shall be securely bolted together to form an integrated rigid structure. Top and rear covers shall be removable. Individual units shall be braced to prevent distortion. Installation shall adhere to zone 4 Seismic Requirements. B. Provisions shall be furnished to allow for convenient extension of both main bus and ground bus to adjacent bays, which may be added in future. Main crossover bus is to be furnished and supported from top of enclosure on NEMA glass polyester insulators. Ground bus shall run continuously through entire line-up and shall be securely fastened to the steel frame of each bay. C. Metal enclosed gear shall be fully assembled and tested at factory prior to shipment. Large line-ups shall be split to permit normal shipping and handling as well as for ease of installation at the Project site. PROJECT NAME SCHOOL NAME 4/7/2006 MEDIUM-VOLTAGE METAL-ENCLOSED LOAD INTERRUPTER 16330-2 D. Outdoor units shall be furnished in NEMA 3R enclosures designed with sloped drip-proof roofs. Cubicles shall be furnished with door-in-door construction. Outer doors shall open to normal switch doors and operating handles. Switchoperating handles shall not be exposed to weather and will be operable regardless of weather conditions. Furnish the front with a bulkhead type door along with 3point latch and vault type handle with provisions for padlocking. Cubicles are to be designed to allow front and rear access and do not require routing of line side or load side connections in front of switch/fuse compartment. Padlocks shall be furnished for doors and keyed to Corbin No. 60 keys. PART 3 EXECUTION 3.01 INSTALLATION A. Cable terminations shall be as indicated in Section 16125: Medium-Voltage Cables, Splices, and Terminations. B. Furnish Spare Fuses: One spare fuse shall be furnished for each fusible switch installed. Spare fuse shall be of type and rating as those installed. C. Where free-standing equipment is installed at exterior locations or in locations below grade, concrete pads shall be provided as described under Section 03300: Cast-In-Place Concrete. Anchor bolts for freestanding equipment shall be designed to meet code seismic requirements. Equipment shall be anchored to new slabs with four 1/2 inch x 3-1/2 inch expansion bolts per section; 1/2 inch anchored bolts shall be tested to withstand 100 foot-pounds of torque. D. Follow manufacturer's instructions for receiving, handling, storage and installation of switchgears. E. Provide two sets of manufacture’s recommended service and maintenance documents. 3.02 PROTECTION A. 3.03 Protect the Work of this section until Substantial Completion. CLEANUP A. Remove rubbish, debris, and waste materials and legally dispose of off the Project site. END OF SECTION PROJECT NAME SCHOOL NAME 4/7/2006 MEDIUM-VOLTAGE METAL-ENCLOSED LOAD INTERRUPTER 16330-3