1 Scientific and Technological Committee for the Biobased Economy

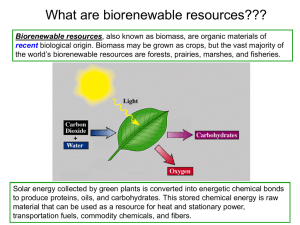

advertisement