Tullow Oil Slot Addition

advertisement

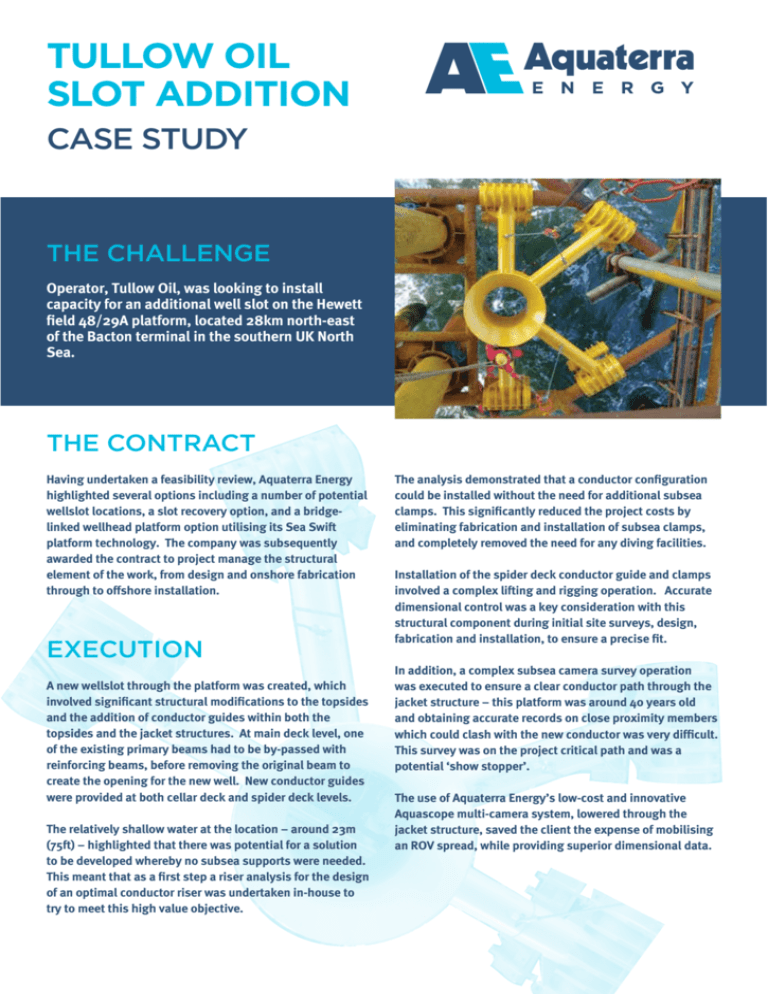

tullow oil slot addition case study THE CHALLENGE Operator, Tullow Oil, was looking to install capacity for an additional well slot on the Hewett field 48/29A platform, located 28km north-east of the Bacton terminal in the southern UK North Sea. THE CONTRACT Having undertaken a feasibility review, Aquaterra Energy highlighted several options including a number of potential wellslot locations, a slot recovery option, and a bridgelinked wellhead platform option utilising its Sea Swift platform technology. The company was subsequently awarded the contract to project manage the structural element of the work, from design and onshore fabrication through to offshore installation. EXECUTION A new wellslot through the platform was created, which involved significant structural modifications to the topsides and the addition of conductor guides within both the topsides and the jacket structures. At main deck level, one of the existing primary beams had to be by-passed with reinforcing beams, before removing the original beam to create the opening for the new well. New conductor guides were provided at both cellar deck and spider deck levels. The relatively shallow water at the location – around 23m (75ft) – highlighted that there was potential for a solution to be developed whereby no subsea supports were needed. This meant that as a first step a riser analysis for the design of an optimal conductor riser was undertaken in-house to try to meet this high value objective. The analysis demonstrated that a conductor configuration could be installed without the need for additional subsea clamps. This significantly reduced the project costs by eliminating fabrication and installation of subsea clamps, and completely removed the need for any diving facilities. Installation of the spider deck conductor guide and clamps involved a complex lifting and rigging operation. Accurate dimensional control was a key consideration with this structural component during initial site surveys, design, fabrication and installation, to ensure a precise fit. In addition, a complex subsea camera survey operation was executed to ensure a clear conductor path through the jacket structure – this platform was around 40 years old and obtaining accurate records on close proximity members which could clash with the new conductor was very difficult. This survey was on the project critical path and was a potential ‘show stopper’. The use of Aquaterra Energy’s low-cost and innovative Aquascope multi-camera system, lowered through the jacket structure, saved the client the expense of mobilising an ROV spread, while providing superior dimensional data. RESULTS The project was seen as a great success by Tullow Oil - it was completed on schedule, within budget and, most importantly, safely. Aquaterra Energy believes that this project showcases the opportunities that can be realised, particularly in mature fields. Many older structures are heavily used with little space for expansion, however, the innovative creation of a new wellslot can result in significant cost savings when compared to a subsea development or a new satellite platform. Jim McGilvray, Project Manager for Tullow Oil said: “We have had excellent service with no surprises from Aquaterra Energy on this project, which included the construction of a new platform conductor slot and carrying out an associated tricky sub-sea structural survey. “We have seen thorough, detailed engineering, delivered professionally, on time and within budget. I have recommended Aquaterra Energy to all of my engineering colleagues within Tullow Oil and to friends in other companies. It’s refreshing to work with such professional people.”