Setup time improvement efforts – SMED - QRM

advertisement

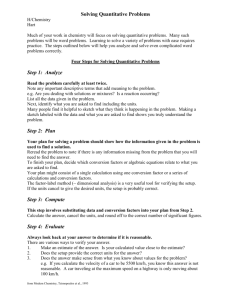

Setup time improvement efforts – SMED Jana Pejchinovska – Hans-Heinrich Glöckner – Aldert van der Stoel – Richard Westerman - Vincent Wiegel Hogeschool van Arnhem en Nijmegen Gebaseerd op het werk van Rajan Suri. Dit werk is vrijgegeven onder voorwaarden van de creative commons Naamsvermelding-GelijkDelen 3.0 Nederland (CC BY-SA 3.0) 1 2 PDCA Title: SMED Version: V0.2 Process: Setup time improvements Owner: Jana Pejchinovska Date: 06.07.2012 Sub-processes: Setup time reduction method Introduction/summary: This modules describes the process of setup time reduction as part of the improvement efforts in lead time reduction. In particular it describes specific technique for reducing setup time (SMED), the main principles and the tools used to achieve the desired results. TIP: Typically initial goal is to reduce setup time by 50%. PLAN 1. Start at a point in the manufacturing system where setup time reduction is needed. • 2. 3. 4. 5. Focus on machine, operation or product family which is considered as bottleneck for most immediate impact. Form an setup reduction team including people who have knowledge of machines and operations, who are affected by the change or have ideas for improvement. Appoint a leader of the improvement team. Educate the leader and the team members on the principles of SMED. Prepare a plan for information gathering to document the features of current setup activities and set goal for reduction. TIP: Use technical Nicholas, J; Competitive Manufacturing Management, 2008 McIntosh, et al, A critical evaluation of Shingo’s SMED Methodology, 2000 McIntosh et al, Changeover Improvement, 2007 documentation and blueprints for machines and tools. ACT/ADJUST Time: Varied, but often lengthy procedure. 0.2 Roles: Machine operators, supervisors, managers, production manager, machine vendors and tool suppliers, marketing, product design. DO 1. 2. 3. TIP: The setup Stage 1: Identify internal and external setup steps reduction process • Checklists should result in • Function checks effective procedure • Die transportation that can be Stage 2: Convert internal setup steps into external standardized in the • Preparing operating conditions in advance future. • Function standardization • Intermediary jigs Stage 3: Streamline all aspects of the operation • Improve storage and transportation • Parallel operations TIP: SMED efforts • Functional clamps should result in • Eliminate adjustments increased production • Least common multiple system capacity and • Mechanization flexibility. Nicholas, J; Competitive Manufacturing Management, 2008 McIntosh, et al, A critical evaluation of Shingo’s SMED Methodology, 2000 McIntosh et al, Changeover Improvement, 2007 CHECK What Who When Status Activity Roles Date PDCA Present new procedure and cost-benfit analysis to management SMED Team Upon approval, implement new procedure for internal setup reduction SMED Team Conduct a follow-up study to determine the impact of the new procedure SMED Team Determine whether further modifications are needed SMED Team 1. 2. 3. Track, chart and post setup time to document the performance. Perform cost-benefit analysis for the new procedure for setup. Explore possibilities for standardizing the setup process TIP: The goal of setup reduction is to maximize the transfer of setup responsibility to operators and minimize machine downtime. Nicholas, J; Competitive Manufacturing Management, 2008 TIP: If some of the steps from this stage do not yield satisfactory results, the previous stage (DO) should be performed again. 3 4 Instructions 5 What and why? • SMED is abbreviation for Single Minute Exchange of Die. • It is a method for reducing the setup time that can be applied in any factory on any machine (from low volume high variety to mass customization and high volume low variety). • The name refers to a single-digit time limit. SMED can be also seen as a goal for reducing the setup time to 10 minutes or less. • Why implementing SMED? – SMED contributes to lead time reduction while maintaining quality. – Faster performance of setup activities allows production in smaller batches, a characteristic of World Class Manufacturing. – Shorter setup times enable flexible manufacturing. – Efforts for setup time reduction help reduce levels of WIP and inventory. 6 Most common setup procedures • Setup processes can vary greatly depending on equipment and type of operations, but there are some commonalities. Accordingly, setup activities can roughly be grouped into four categories: – Collecting, preparing and checking materials before setup and cleaning machine and work station afterwards; – Handling of tools before and after setup (removing, mounting, etc.); – Measuring, setting, calibrating the machine before operation; – Producing test pieces, measuring, adjusting and preparations for production. Stage 1: Identifying internal and external setup steps • Internal setup steps are tasks and activities which are done when the machine or operation is physically stopped • External setup steps are tasks and activities that can be executed while the machine or operation is running. • How to learn and classify the setup steps? – Study of setup procedure through observations, interviews and videotaping of the procedure; – Mapping setup task sequence. TIP: Check the Templates section for an example of Mapping setup task sequence 7 Techniques for separating internal and external setup operations • Using a check list for processes: – The purpose of a checklist is to have explicit overview of the setup procedure and ensure nothing is overlooked. – Checklist contains all the necessary information about setup, sequence of steps, parts and tools, dimensions and measurements, and specifications. – After each setup the workers check off the items in the list to ensure everything is done correctly. • Performing functional checks for machines and tools: – The goal of functional checks is to confirm that machines and tools are in good working condition, so there are no delays during internal setup. – Functional checks help prevent unexpected breakdowns or use of damaged tools. • Improving die transportation: – Dies and fixtures should be stored and transported using equipment that is specially dedicated for that purpose (carts, pallets, bins, etc.). – Transportation of dies should be done either by the worker when the machine is running independently or another worker should be assigned to the task. 8 Stage 2: Converting internal setup steps into external • The principal objective of improving setup processes is to reduce the internal setup time and converse tasks done internally into external ones. • The more steps, decisions and adjustments are done while the machine or operation is running the impact on time reduction is bigger. • This stage of SMED is an iterative process where internal setups steps are constantly re-examined to determine if they can be converted into external setup steps. 9 Methods for improvement during Stage 2 • Preparing operating conditions in advance – For example: collect materials or devise accessible way to keep materials close to the machine; keep machine and workspace clean; do positioning of items in advance; adopt new procedure for same operations, etc. • Function standardization: – This is specific type of standardization that focuses only on the functions that are necessary for the setup operations. – Such standardization can be done by breaking the operation into basic functions and then deciding which of the function can be standardized (for example: clamping, centering, dimensioning, etc.). • Using intermediary jigs: – Jigs are tools used to hold and guide the product through the operation. – For faster operation while one piece is being produced, second can be attached to the intermediary jig and produced immediately afterwards without delay. 10 Stage 3: Streamlining all aspects of operation • The goal of this stage of SMED is to minimize and streamline the internal and external setup steps. • After this step a new standardized setup procedure should be available. • Cause and effect diagram and Pareto analysis can be used to simplify and standardize all setup activities. • The efforts from this stage are successful when setup should allow production of virtually any lot size. TIP: The module about Data Analysis provides more insight into these tools. 11 12 Streamlining techniques Some important and practically applicable methods for further improving the internal setup are: TIP: These techniques can be • Improving storage and transportation of parts and tools. combined together for best results. • Implementing parallel operations: – Multiple workers can perform setup tasks simultaneously, for example making adjustments at the front and the back of a large machine. – Parallel operations are team effort that requires coordination of activities and clear communication. • Using functional clamps: – Functional clamps are devices that can be attached to the machine to hold a piece with minimal effort (clamp, pin, spring or similar). • Eliminating adjustments: – Adjustments and test contribute to great portion of the setup time, but they do not represent independent operation. – This can be achieved by keeping the meters and scales clean and calibrated. – In case an adjustment is required the goal is to be accomplished by single motion. 13 Templates 14 Mapping setup task sequence • Mapping the sequence of tasks is useful visual tool that helps list the tasks and activities performed during setup, the order in which they are executed, the worker responsible and their duration. • This visualization can be achieved using a Gantt chart: – Gantt chart is a tool for describing a sequence of activities, by representing collected data in a phases. – At the same time the Gantt chart displays the dependency relationships between activities. 15 Visual representation of mapping tasks • Example of Gantt chart used for mapping: 16 Notices 17 Support This guide was developed as part of the RAAK QRM Project. The grant was awarded by the Foundation Innovation Alliance and financed by the Dutch Ministry of Education, Culture and Science. While developing this guide, we gained extensive experience with the projects that we carried out for various businesses. We wish to thank those businesses and their employees for their efforts. The QRM Center and the founding fathers and sponsors contributed to the development of this guide in a number of ways. Finally, we were grateful for the expertise and experience of Rajan Suri and Ananth Krishnamurthy. 18 Rights This guide is published subject to the guidelines of the Creative Commons, Attribution – ShareAlike version. This means that •you may use this material freely •you must share any modifications that you make with us and with other users •the material itself may not be sold, but may be used in other commercial activities such as training courses and consultancy •that you must state the modified version as your source if you use it (the text to be used for references is presented on the next page) •This applies only to any material that is not otherwise protected by copyright, which is explicitly listed as such. The precise phrasing of the copyright agreement 19 Attribution • This material was developed by HAN University of Applied Sciences. The authors are Jana Pejchinovska, Hans-Heinrich Glöckner, Aldert van der Stoel en Vincent Wiegel. 20 20 References Rajan Suri It’s about time – nederlandse versie Lean lectoraat LeanCircle QRM Centrum @HAN QRM Center @Wisconsin 20 21 23 22 Final considerations • The approach described in this module is based on the concepts in manufacturing and production management, Kaizen, and Lean Manufacturing. • These activities are conducted by the Lean Research Group at the HAN University of Applied Sciences and the QRM Center Europe in Arnhem. • Funding for these activities has been made available from the QRM RAAK Project and the QRM Center Europe in Arnhem.