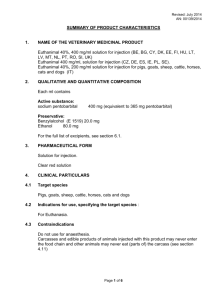

Use of Non-pharmaceutical Grade Pentobarbital

advertisement

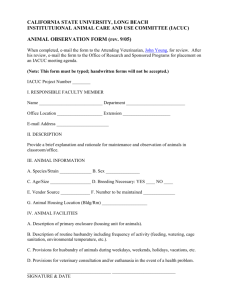

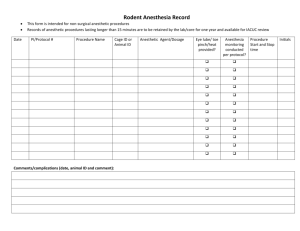

INSTITUTIONAL ANIMAL CARE AND USE COMMITTEE (IACUC) POLICY ON THE USE OF NON-PHARMACEUTICAL GRADE PENTOBARBITAL AS AN ANESTHETIC AGENT (NEW DEC 2012) PURPOSE The purpose of this document is to describe the necessary information to obtain IACUC approval for the use of non-pharmaceutical grade sodium pentobarbital. This document also provides guidance on acceptable methods for preparation and use. BACKGROUND Sodium pentobarbital is a popular injectable anesthetic in laboratory animals. It was once marketed as a veterinary anesthetic but is no longer available. The availability of pharmaceutical grade pentobarbital (Nembutal) is unreliable and inconsistent, rendering it essentially unavailable for use in animal research. POLICY IACUC approval is required. Justification for the use of non-pharmaceutical grade pentobarbital must be approved in the IACUC protocol under ‘Agents’. Scientific justification must be provided for the inability to use other pharmaceutical-grade anesthetics. In order to use non-pharmaceutical grade pentobarbital sodium, it must be prepared in a sterile manner and used within 7 days of preparation. Both the powder and diluted solutions must be stored and documented according to the campus controlled substances policy. Standard Operating Procedure (SOP) Preparation of Sodium Pentobarbital injection for use as an anesthetic agent (survival or nonsurvival procedures): When drugs or chemicals are formulated for injection, they must be prepared in a sterile manner. Sterile constituents (e.g. sterile drug or chemical, sterile diluents, etc.), a sterile container, and a means of keeping the preparation sterile are required. Sterile injection vials are preferred as they make it easier to load a syringe and allow removal of solution without exposing the contents to contaminants. Diluents or vehicles should be from the list of acceptable components (below). Exceptions to the approved list must be included in the protocol in order to be evaluated by the IACUC on a caseby-case basis. Containers must be labeled with the drug, concentration, date of preparation, and the date of expiration. Prepared solutions must be passed through a sterile syringe filter (0.22μ or finer) at the time of preparation. This can be done in the process of transfer to an injection vial. If there is any question about the sterility of a prepared or stored solution, it must be discarded. IAC12 (12/2012) Drug solutions prepared and stored properly in a suitable injection vial must be used within 7 days of preparation. Prepare only as much as can be used in a reasonable period of time. Drugs must be stored properly. Solutions must not be used if they are cloudy, discolored, precipitated, or have become otherwise altered in appearance since initial preparation. Any solution remaining after 7 days must be disposed of properly. Expired drug disposal: Expired drug containers must be labeled "expired—awaiting disposal—do not use in animals" and stored separately from drugs in use. Controlled substances cannot be discarded without appropriate approval. Expired controlled substances must continue to be stored in an approved secure cabinet or safe until picked up by EH&S. Controlled Substances Program information: http://or.ucsf.edu/ehs/7662-DSY/8295-DSY.html Controlled Substances Pick Up information: http://or.ucsf.edu/ehs/7662-DSY/7663-DSY.html Pyrogenicity is a potential experimental variable that researchers should be aware of when using non-pharmaceutical grade drugs. Pyrogens, such as endotoxin, may cause fever when injected into an animal. Sterility by filtering does not ensure that pyrogens are not present. The core temperature of animals anesthetized with non-USP pentobarbital sodium solution should be monitored for increases potentially due to pyrogens. Acceptable solvents/diluents/vehicles: 1. Propylene glycol USP 2. Ethyl alcohol USP 3. Water for injection USP Recipe for 100 ml pentobarbital sodium: INGREDIENTS • 6 Gm pentobarbital sodium USP Reagent or analytical grade may be substituted if USP is unavailable. Purity must be > 97% • 10 ml ethanol (95%) USP • 40 ml propylene glycol USP • Water for injection USP qs 100 ml • Sodium hydroxide USP or hydrochloric acid USP as required bringing pH to ~ 9.5 MIXING The mixing process should be performed in a certified Class II biosafety cabinet. Masks, gloves, and lab coats are to be worn during preparation. • Dissolve the pentobarbital powder in ethanol. • Add 25 ml of water for injection (but only after the pentobarbital is completely dissolved); mix thoroughly. • Add 40 ml propylene glycol; mix. • Bring to final volume (100 ml) with water for injection. Adjust pH as required. IAC12 (12/2012) • Sterilize by filtration in the biosafety cabinet • The pentobarbital sodium concentration in the final solution is 60 mg/ml. NOTES • • Use must be recorded as a Schedule II controlled substance. Recipe may be proportionally adjusted to produce smaller quantities of final product Resources Licensed pharmaceutical compounding companies may provide pharmaceutical-grade agents to researchers who are able to supply a DEA Researcher License in lieu of veterinary license. A DEA-222 form is required for the transfer of controlled substances. The following list of companies is supplied as a resource, but other appropriately licensed pharmacies can be utilized (contact a LARC veterinarian for guidance). The Institutional Animal Care and Use Committee (IACUC) cannot endorse these pharmaceutical firms, nor can it guarantee that these firms will continue to supply these pharmaceuticals in forms suitable for animal studies. The expiration date for compounded agents is 30 days only so careful planning is important. . • Abbotts Compounding Pharmacy, Inc. Berkeley, CA: abbotts@pacbell.net •Zeeh Pharmaceutical Experiment Station, School of Pharmacy, University of WisconsinMadison: http://pharmacy.wisc.edu/zstation • TW Medical: http://www.twmedical.com/ • PCCA (Professional Compounding Centers of America): http://www.pccarx.com IAC12 (12/2012)