Safe Work procedure

advertisement

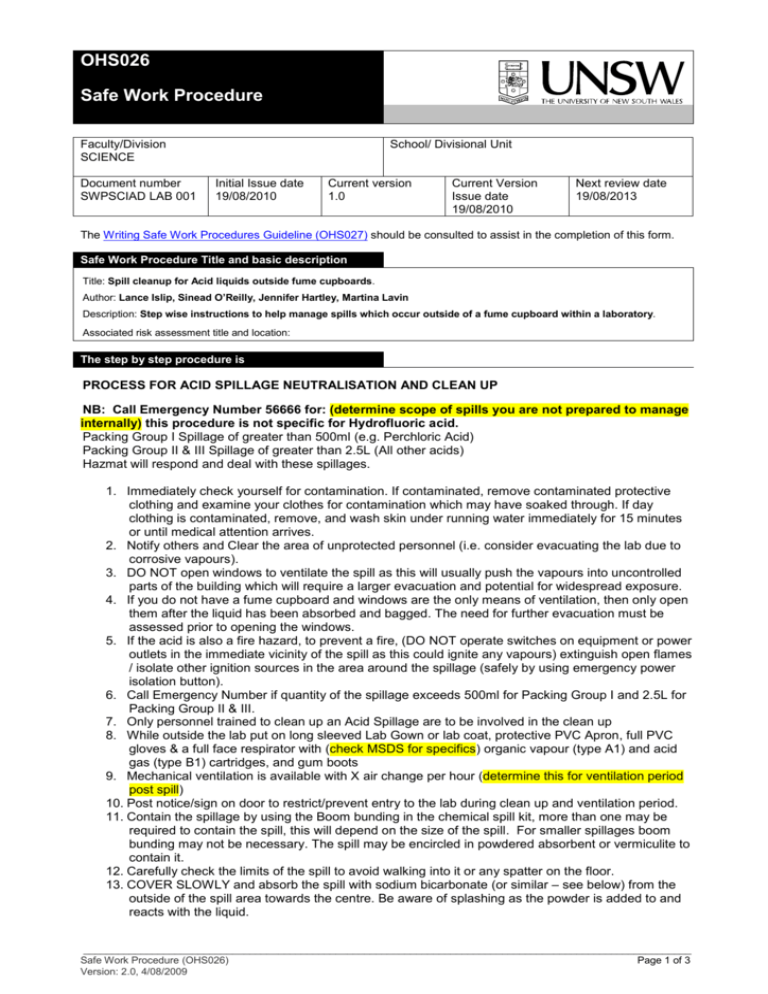

OHS026 Safe Work Procedure Faculty/Division SCIENCE Document number SWPSCIAD LAB 001 School/ Divisional Unit Initial Issue date 19/08/2010 Current version 1.0 Current Version Issue date 19/08/2010 Next review date 19/08/2013 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Spill cleanup for Acid liquids outside fume cupboards. Author: Lance Islip, Sinead O’Reilly, Jennifer Hartley, Martina Lavin Description: Step wise instructions to help manage spills which occur outside of a fume cupboard within a laboratory. Associated risk assessment title and location: The step by step procedure is PROCESS FOR ACID SPILLAGE NEUTRALISATION AND CLEAN UP NB: Call Emergency Number 56666 for: (determine scope of spills you are not prepared to manage internally) this procedure is not specific for Hydrofluoric acid. Packing Group I Spillage of greater than 500ml (e.g. Perchloric Acid) Packing Group II & III Spillage of greater than 2.5L (All other acids) Hazmat will respond and deal with these spillages. 1. Immediately check yourself for contamination. If contaminated, remove contaminated protective clothing and examine your clothes for contamination which may have soaked through. If day clothing is contaminated, remove, and wash skin under running water immediately for 15 minutes or until medical attention arrives. 2. Notify others and Clear the area of unprotected personnel (i.e. consider evacuating the lab due to corrosive vapours). 3. DO NOT open windows to ventilate the spill as this will usually push the vapours into uncontrolled parts of the building which will require a larger evacuation and potential for widespread exposure. 4. If you do not have a fume cupboard and windows are the only means of ventilation, then only open them after the liquid has been absorbed and bagged. The need for further evacuation must be assessed prior to opening the windows. 5. If the acid is also a fire hazard, to prevent a fire, (DO NOT operate switches on equipment or power outlets in the immediate vicinity of the spill as this could ignite any vapours) extinguish open flames / isolate other ignition sources in the area around the spillage (safely by using emergency power isolation button). 6. Call Emergency Number if quantity of the spillage exceeds 500ml for Packing Group I and 2.5L for Packing Group II & III. 7. Only personnel trained to clean up an Acid Spillage are to be involved in the clean up 8. While outside the lab put on long sleeved Lab Gown or lab coat, protective PVC Apron, full PVC gloves & a full face respirator with (check MSDS for specifics) organic vapour (type A1) and acid gas (type B1) cartridges, and gum boots 9. Mechanical ventilation is available with X air change per hour (determine this for ventilation period post spill) 10. Post notice/sign on door to restrict/prevent entry to the lab during clean up and ventilation period. 11. Contain the spillage by using the Boom bunding in the chemical spill kit, more than one may be required to contain the spill, this will depend on the size of the spill. For smaller spillages boom bunding may not be necessary. The spill may be encircled in powdered absorbent or vermiculite to contain it. 12. Carefully check the limits of the spill to avoid walking into it or any spatter on the floor. 13. COVER SLOWLY and absorb the spill with sodium bicarbonate (or similar – see below) from the outside of the spill area towards the centre. Be aware of splashing as the powder is added to and reacts with the liquid. __________________________________________________________________________________________________________ Safe Work Procedure (OHS026) Page 1 of 3 Version: 2.0, 4/08/2009 14. Check pH of the mixture with Litmus paper, if litmus paper indicates that the mixture is still acidic add more sodium bicarbonate and retest with litmus to make sure the pH is neutral. 15. Collect the neutralized spillage using a dustpan and plastic spatulas or scoops and place into a suitable resealable bucket, or if a very small spill a smaller container or the bags provided in the spill kits can be used instead. 16. Thoroughly rinse the floor or site of Acid Spillage with water and dispose of rinse water down the sink. Some mild detergent should be added to remove residual contamination. 17. Wash contaminated gloves prior to removal and wash hands thoroughly. Put on clean disposable gloves and remove other PPE. Contaminated PPE should be washed and cleaned ASAP. Do not remove respirator until you have left the laboratory. 18. The laboratory where the spillage occurred should be allowed to ventilate for up to 60 minutes, if needed, to remove hazardous vapours still present and can then be re-opened. 19. Label the waste as follows: Acid Name & Concentration, Sodium Bicarbonate, broken glass (if smashed Winchester included), Chemical Spillage Boom/pads (if used). 20. Organise for Chemical waste disposal by the usual method. 21. The person who spilled the acid or a witness should complete an online incident report via MyUNSW. 22. Used contents of the Spill Kit must be replaced immediately or at least within 24 hours. Resources required including plant, chemicals, personal protective clothing and equipment, etc Trained Personnel Sodium Bicarbonate, calcium hydroxide, calcium carbonate / Disinfectant Litmus Paper Spill Kit including Boom Bunds Long Sleeved Laboratory Gown, PVC Aprons, Gum Boots, Splash Goggles, Long PVC Gloves Medium & Large Full face Respirator with organic vapour (type A1) and acid gas (type B1) cartridges, Resealable Bucket with Lid and Dustpan Ventilation Mop and bucket of water to rinse the floor Potential hazards and risk controls including specific precautions required Hazard: Acid – Corrosive on skin contact Long sleeved Lab coat, PVC Gloves, PVC or plastic chemical apron Gum Boots, Full Face Mask or Full face shield with brow guard and chin guard Hazard: Inhalation of Vapour Wear Respirator with appropriate cartridge (refer to MSDS) such as organic vapour (type A1), acid gas (type B1) & Formalin cartridges, Evacuation of laboratory and adjacent areas as necessary, room ventilation via fume cupboard Hazard: Formation of Carbon Dioxide Gas upon neutralization Low risk Adequate ventilation required Hazard: fire turn off/remove sources of ignition, cover spill with absorbent, ventilate room, avoid static discharge, no synthetic materials in clothing, notify emergency services Emergency shutdown instructions for the plant or process It is advisable to turn off nearby equipment as corrosive vapours may be drawn into them and cause damage. Refer to individual plant procedures for emergency shutdown steps. __________________________________________________________________________________________________________ Safe Work Procedure (OHS026) Page 2 of 3 Version: 2.0, 4/08/2009 Emergency procedures for fire, spill or exposures Fire: Cover the fire with a fire blanket if it can be fully contained underneath the blanket otherwise use a fire extinguisher. Carbon dioxide or dry powder is suitable. Be prepared for re ignition, especially if equipment is involved: do not leave the scene unless fumes or smoke become hazardous. Spill: see above spills procedure Exposure: remove contaminated protective clothing and examine your clothes for contamination which may have soaked through. If day clothing is contaminated, remove, and wash skin under running water immediately for 15 minutes or until medical attention arrives. Clean up and waste disposal requirements As above Legislation, standards and codes of practice used in the development of the SWP NSW Occupational Health and Safety Act 2000 NSW Occupational Health and Safety Regulation 2001 Code of Practice for Control of Workplace Hazardous Substances MSDS for spilt acid UNSW Chemical Spills Guideline AS3780: 2008 The storage and handling of corrosive substances Approval, training, and review Competency required –: demonstrated ability to follow this procedure Training in the hazards associated with and safe handling of Acids Area Supervisor: Signature: Plant custodian: Signature SWP review date: Responsibility for SWP review: __________________________________________________________________________________________________________ Safe Work Procedure (OHS026) Page 3 of 3 Version: 2.0, 4/08/2009