Oil Retention Basin Spreadsheet User`s Guide

advertisement

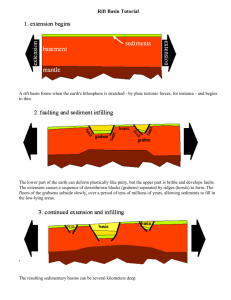

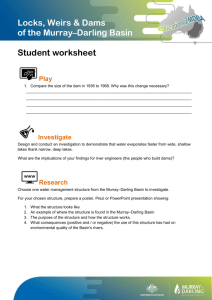

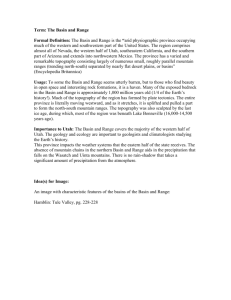

SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 1 of 14 1.0 PURPOSE This design guide explains how to use the SPCC Oil Retention Basin Spreadsheet to analyze existing SPCC containment systems and to design new containments. This supplements the SPCC Plans and Facility Improvements Design Criteria Memorandum (DCM No. C-1.3 Rev. 1). SPCC facility improvements decrease the probability of an oil spill discharging into navigable waters. 2.0 SCOPE The SPCC Oil Retention Basin Spreadsheet (Spreadsheet) contains two worksheets, “Existing/New SPCC Basin Storage” and “Existing/New SPCC Flow-Through Analysis”. “Existing/New SPCC Basin Storage” computes the spill retention capacity in an existing basin and checks the storage adequacy for a new basin design. “Existing/New SPCC Flow-Through Analysis” checks the storm water flow-through requirements. The application of this user’s guide for specific projects shall be as directed by the Responsible Engineer (RE). 3.0 GLOSSARY OF TERMS Above-base storage Volume of oil stored above the highest floor elevation. Allowable Oil Storage Volume of oil that can be contained in the basin. Back Wall Back wall in weir system. Base Storage Volume stored below the highest floor elevation. Basin Capacity Volume of fluid that can be contained in the basin. Basin Floor Rectangular floor at bottom of basin. Bermed Area Area enclosed within the berm system. Cut-off Wall (see Skimmer Wall) Highest Point Highest basin floor elevation compared to top of weir elevation. Lowest Point Lowest basin floor elevation compared to top of weir elevation, typically at the weir location. Oil Specific Gravity The specific gravity of the equipment mineral oil is set at 0.85, the nominal value for transformer oils. Overflow Weir Wall that regulates the outflow rate from and the maximum water level within the oil retention basin. Perimeter Wall Outermost wall of weir system. Skimmer Wall Wall that regulates the flow and separation of water and/or oil upstream of the outlet structure. Sluice Slot Flow passage below the skimmer wall. Spill Quantity The volume of oil and/or water to be retained. It is equal to the maximum of the following (based on reference 3, Section 5.2.3): 1) 110% of oil volume of largest container 2) 10% of total aggregate oil volume (<100,000 gal) Weir (see Overflow Weir) SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 2 of 14 4.0 ANALYSIS CASES Note: Existing basins: Analyze Cases A and B below to determine the allowable oil storage of the existing SPCC system based on site-specific conditions. New basins: Analyze all three cases. Refer to Sections 5.1.3.2 and 6.1.2 for definitions of variables in the figures below. Basins in areas of high water table should be checked for buoyancy. 4.1 CASE A: Oil spill into empty basin with no overflow Analyze/design the basin or berm system to contain the maximum of the following: 1) Spill quantity equal to 110% of oil volume in largest container 2) Spill quantity equal to 10% of total aggregate oil volume (<100,000 gal) B' Perimeter Wall M C How B Skimmer Upstream Invert A D=How+C' h Weir v Back Wall C' D' F Figure 4.1 Case A B' How Hew Z’ B A C' or Creq Skimmer D = d12 C' 4.2 CASE B: Oil spill when existing basin water level is at top of overflow weir With the basin full of water, analyze/design the basin or berm system to contain the spill quantity listed in Section 4.1. Because the oil has a specific gravity of 0.85, the spilled oil remains behind the skimmer wall and above the existing water level, which is to the top of overflow weir. This condition determines the upper limit of the underflow weir. To prevent the oil from mixing with water, a pressure balance between the fluids must be maintained. The pressure balance is defined by Z′= (d12-A- C ′)/0.85 + C′, where C′ is the user defined freeboard (refer to section 6.1.2 for definition of d12). The following two conditions are used to maintain the pressure balance: 1) Condition 1: If Z′< B – C′ 2) Condition 2: If Z′ > B – C′, a required freeboard, Creq, must be provided to prevent oil from flowing over the skimmer wall (refer to section 6.1.3 for definition of Creq). Figure 4.2 Case B SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 3 of 14 B' 4.3 CASE C: Storm overflow only, no oil spill Design all basin or berm systems to pass the design storm (25-year return period) runoff in combination with no oil. The design should include a basin or berm dewatering system. The dewatering system may be gravity or pump operated. The system (pipes, valves, pumps, or other devices) should be capable of dewatering a full basin or berm within one hour or less. The outlet flow capacity should exceed the design storm runoff (see Section 5.2.5 for outlet variables). d a A F C b Hinitial D B E D' M Figure 4.3 Case C SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 4 of 14 5.0 USER INPUT Note: A star appears to the right of an input value when the input does not meet the normal minimum requirement (see Section 6.1.3). A larger value must be entered. A pound sign appears in the input cell or to the right of an input cell when an invalid number (either too large or too small) is entered. Check to make sure that the correct input values were entered. 5.1 Sheet 1: Oil Storage Input Note: Sheet 1, “Existing/New SPCC Basin Storage”, calculates the amount of oil to be contained and the allowable oil storage. 5.1.1 Select Spreadsheet Type Note: Check one of the following options. If both or none of the options have been selected, the spreadsheet title will print “Check Spreadsheet Selection”. Existing Basin Analysis = Select this option if you are analyzing an existing basin. The Sheet 1 title will print “Existing SPCC Basin Storage” and Sheet 2 will print “Existing SPCC Basin Flow-Through Analysis”. New Basin Design = Select this option if you are designing a new basin. The Sheet 1 title will print “New SPCC Basin Storage” and Sheet 2 will print “New SPCC Basin Flow-Through Analysis”. 5.1.2 Oil Input Data Amount of Oil in Largest Container (gal) = If the amount of oil in the largest container is larger than ten percent of total oil, input gallons of oil in largest container from Attachment #1 “Inventory and Spill Prediction Table” of the specific substation SPCC Plan, or as provided by the RE. Otherwise, input “N.A.” for not applicable or leave this cell blank. Ten Percent of Total Aggregate (gal) = If ten percent of total oil is larger than the amount of oil in largest container, input ten percent of the total aggregate from Attachment #1 “Inventory and Spill Prediction Table” of the SPCC Plan. Otherwise, input “N.A.” for not applicable or leave this cell blank. 5.1.3 Basin Input Data 5.1.3.1 General Input Average wall slope, h/v = Input the ratio of the horizontal length divided by vertical length of sloped portion surrounding the basin (if applicable). If slopes differ, use the average value of all side slopes. If the wall slope is vertical, enter “0”. X (ft) = Longer inside basin dimension, based on a rectangular shape, as shown in Figure 5.1 Y (ft) = Shorter inside basin dimension, based on a rectangular shape, as shown in Figure 5.1 L (ft) = Inside width of Weir shown in Figure 5.1 L is typically between 1 and 10 ft. For smaller weirs, L typically ranges from 1 to 3 ft. As L increases, the following decrease: 1) Minimum requirement for A (see Section 6.1.3) 2) Required head, E, from “Time of Concentration” (see Section 6.2.4) X d1 Y L L d4 A d3 d2 Figure 5.1 Basin Plan View SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 5 of 14 5.1.3.2 Elevation View Dimensions Note: Refer to Figures 4.1 through 4.3 for illustrations of the following variables. A (in) = Sluice slot height, usually 3” minimum Dependent on required head, E (refer to Section 6.2.4 for definition of E) B (in) = Skimmer wall height B′(in) = Height difference between top of perimeter and top of skimmer wall If no perimeter wall exists, enter “0” for B′. F (ft) = Horizontal distance between weir and skimmer wall F is typically between 1.5 and 10 feet. For construction space requirements, F is usually not less than 18 inches. For small weirs, with the approval of the RE, F may be less than 18 inches, but in no case shall F be less than A+3”. If the weir system is outside of the basin, enter a negative value so the spreadsheet can either add or subtract this volume from the total volume (depending on analysis case). D (ft) = Weir wall height Measured from top of weir wall to the basin invert at the weir C′(in) = Freeboard from top of oil to top of weir or skimmer wall, typically 1”, or as provided by the RE M (ft) = Horizontal distance between weir wall and outlet pipe in the perimeter wall Measured from the inside of the perimeter wall to the upstream side of the weir wall If the weir system is outside of the basin, enter a negative value. The spreadsheet will subtract this volume from the total volume, since this portion does not contain oil. If no back wall exists, enter “0” for M. 5.1.3.3 Depth Measurements Note: The top of weir in this section is defined as the elevation at the top of the weir wall. Depths d1 to d4 represent depths from the top of weir wall elevation to the measured ground elevation below the top of weir wall elevation. Refer to Figure 5.1 for a plan view of basin depths. For an example of how input depths d1 through d4 are calculated, refer to Figure 5.2 below. If the ground elevation is flat, enter the same values for all depths (should be equal to the weir wall height). If only two depths on opposite ends of the basin are measured, enter them into cells d1 and d3. Since an average depth will be taken from d1 and d2 (d12) and from d3 and d4 ( d34), you may also enter the same depth for d2 as d1 and enter the same depth for d4 as d3. d1 = Distance from top of weir elevation to lowest ground elevation in basin d1 = D = Top of weir elevation – Lowest basin elevation d2 = Distance from top of weir elevation to second lowest ground elevation in basin d2 = Top of weir elevation – Second lowest basin elevation d3 = Distance from top of weir elevation to second highest ground elevation in basin d3 = Top of weir elevation – Second highest basin elevation A d Top of Weir EL 100.00’ 1 C ' d4 = Distance from top of weir elevation to highest ground elevation in basin d4 = Top of weir elevation – Highest basin elevation Third lowest basin EL 99.00’ d3 EL = 100.0’-99.0’ = 1.00’ Figure 5.2 Example of Depth Measurement, d3 SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 6 of 14 5.2 Sheet 2: Flow-through Input Note: Sheet 2, “Existing/New SPCC Basin Flow-through Analysis”, determines whether the basin flow capacity meets the storm water flow-through requirements for Cases A and B for existing basins and Case C for new basins. 5.2.1 Table 2. Drainage Parameters 5.2.1.1 Surface Type Basin Surface Area (sq.ft) = Horizontal projected area of the SPCC containment basin including side slopes Foundation Area (sq.ft) = The total surface area of foundations within the upstream drainage area Paved Area (sq.ft) = The total area of paved surface within the drainage area Gravel Area (sq.ft) = The total area of gravel surface within the drainage area Soils Area (sq.ft) = The total area of soil surface within the drainage area 5.2.1.2 Runoff Coefficient (C) Gravel = Input appropriate runoff coefficient, typically 0.75, or as provided by RE. Soils = Input appropriate soil coefficient, typically 0.50, or as provided by RE. 5.2.2 Time of Concentration Note: Refer to Section 6.2.3 for time variable definitions. Tc (minutes) = Input closest time duration, TD CLOSE, computed at the end of Table 4. Tc is set equal to the rainfall duration interval,TD , closest to the corresponding total time, Ttot. Ttot is the rainfall runoff travel time from the most remote part of the substation through the basin and over the outflow weir. For Ttot values less than 5 minutes, set Tc equal to 5 minutes, the minimum duration interval. As Tc increases, the calculated minimum diameter, d min, and the design storm inflow, Qin des decrease (refer to Section 6.2.5 for definitions of dmin and Qin des ). Percent Full (%) = Percent of water already contained in the basin when the design storm begins. The RE should determine the Percent Full based on site specific conditions. 0% means the basin is empty and 100% means the basin is full when rainfall begins. As Percent Full increases, the time to fill the basin, Tfill, and total time, Ttot, decrease. 5.2.3 Table 3. Time Constants for Flow to Basin Overland Flow Length (ft) = Longest length between ridge and ditch flow Ditch Flow Length (ft) = Longest total length of ditch flow from beginning of ditch to the basin SG = Ground slope in feet per foot. SG is calculated by dividing the change in substation ground elevation, ∆ZG, by the corresponding length, LG, which is equal to either Loverland or Lditch. SG = ∆ZG/LG SG varies on the order of 0.005 to 0.03, for both overland flow and ditch flow. 5.2.4 Table 4. Short Duration Rainfall Blank Space next to Table 4. Title: Enter letter, number (under station bsn no) and station name found on the “Precipitation Depth-Duration-Frequency” Table from the California Department of Water Resources, Short Duration Precipitation Depth-Duration-Frequency Data Table (ref. 1). If no station name is listed, use the station order number. Storm Frequency (yr) = Input 25-year return period. De (in) = Input the depth-duration data, for the corresponding return period from ref. 1. SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 7 of 14 5.2.5 Discharge Outlet Discharge of Outlet = Select “Ditch”, “Pipe”, or “Pump” from the list box. Ditch: Fluid flows over the overflow weir, out of the weir system, and into a ditch or open area located outside the weir system. No additional input is required. Delete any entered input. Pipe: Fluid flows over the overflow weir, out of the weir system, and through a downstream pipe. Enter all input described below in this section. Delete any input entered in the cells below “Design storm inflow, Qin des”. Pump: Fluid flows over the overflow weir, out of the weir system, and through a downstream pump system. Enter the manufacturer’s pump capacity, P cap (in gpm), or as provided by RE. Delete all other entered input. Manning’s roughness coefficient “n” (ref.2) Concrete/Steel: n = 0.012 PVC: n = 0.010 CMP: n = 0.023 Drop of outlet pipe, a (ft) = Vertical distance between inverts at each end of outlet pipe Run of Outlet pipe, b (ft) = Horizontal length of outlet pipe Outlet Pipe Diameter, d (in) = Inner diameter of outlet pipe Pump Capacity, Pcap (gpm) = Manufacturer’s pump capacity, or pump capacity as provided by RE 6.0 CALCULATED OUTPUT Note: If a non-integer output (e.g. #NUM, ##, #VALUE!) appears in an output cell, an invalid input was entered. Check to make sure that the correct input values were entered. 6.1 Sheet 1: Oil Storage Output Note: Sheet 1, “Existing/New SPCC Basin Storage”, calculates the amount of oil to be contained and the allowable oil storage. 6.1.1 Oil Output Data Oil to be contained (gal) = The maximum of the following: 1) 110% of oil in the largest container 2) 10% of total aggregate oil volume Oil to be contained (cu.ft) = Gallons of oil to be contained divided by 7.48 gallons per cubic foot 6.1.2 Basin Output Data Note: Refer to Figures 4.1 to 4.3 from Section 4 for illustrations of the following variables. C (in) = Height from inside bottom of weir to top of perimeter wall C = A + B + B′ D′ (in) = Height difference between top of perimeter wall and top of weir wall D′ = C –D d12 (in) = Average basin depth on weir side of basin. Takes the average of depths d1 and d2 and is typically equal to the weir height (see Figures 6.1 to 6.4). d12 = (d1 + d2) / 2 or d12 = d1 (if only two depths are measured) d34 (in) = Average basin depth on opposing side of basin. Takes the average of depths d 3 and d4 (see Figures 6.1 to 6.4). d34 = (d3 + d4) / 2 or d34 = d3 (if only two depths are measured) SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 8 of 14 6.1.3 Normal Minimum Requirements Note: The minimum values calculated from the equations below are required for adequate containment. A (in) = Depth of flow over the weir plus freeboard A = E + C′ (refer to Section 6.2.4 for calculation of E) B (in) = The maximum of the following: 1) The weir wall height from Cases A or 2) For Case B the maximum of the following two conditions are used to maintain a pressure balance between the fluids. The variable Z′, where Z′= (d12-A- C ′)/0.85 + C′, defines the pressure balance. The Z′ and Z′(condition 2) variables apply only to Case B. a) Condition 1: If Z′ < B- C′, then B = Z′ + C′ b) Condition 2: If Z′ > B- C′, then B = Z′(condition 2) + Creq. For condition 2, a required freeboard, Creq, must be calculated to prevent oil from flowing over the skimmer wall. In addition, a new pressure balance, Z′ (condition 2), must be defined using the calculated required freeboard. Creq = (d12 – A - 0.85 x B + 0.85 x C′)/0.15 Z′ (condtion 2) = (d12 – A - Creq)/0.85 + Creq 1) B = D MAX 2) MAX a) B = Z′ + C′ b) B = Z′(condition 2) + Creq F (ft) = One (1) foot plus sluice slot height F = 1’ + A D (ft) = The maximum of the following: 1) The height of oily water from Case A, How Case A (see Section 6.1.4.1), plus freeboard or 2) The height of oily water from Case B, which equals the maximum of the following two conditions used to maintain a pressure balance between the fluids. The variable Z′, where Z′ = (d12 – A- C′)/0.85 + C′, defines the pressure balance. a) Condition 1: If Z′ < B- C′, then D = ( A + C′ ) + ( Z′ - C′ ) x 0.85 b) Condition 2: If Z′ > B- C′, then D = ( A + Creq ) + ( Z′(condition 2) - Creq) x 0.85 1) D = How Case A + C′ MAX 2) MAX a) D = ( A + C′ ) + ( Z′ - C′ ) x 0.85 b) D = ( A + Creq ) + ( Z′(condition 2) - Creq ) x 0.85 SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: Condition 1 9 of 14 Condition 2 ∆Zo > A d34 A A ∆Zo D=d12 d34 A A D=d12 CASE A C' C’ C' C’ ∆Zo < A ∆Zo Figure 6.2 Figure 6.1 Z’ < B – C’ Z’ > B – C’ d34 ∆Zo Z' A A D=d12 d34 Z' C' or Creq C’ C’ C ' C' or Creq AA D=d12 CASE B C ' ∆Zo > A + C’ or A+Creq (sub-condition 2) ∆Zo < A + C’ or A + Creq (sub-condition 1) ∆Zo Figure 6.3 SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. Figure 6.4 © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 10 of 14 6.1.4 Table 1. Oil Storage Summary Note: The critical oil storage value has “GOVERNS” printed to the right. 6.1.4.1 Height of Oily Water in the Basin, How Note: How is the height of oily water at the weir system location. 1) CASE A: Height of oily water equals the weir wall height, D, minus the user defined freeboard, C′ How = D – C′ 2) CASE B: The height of oily water depends on the pressure balance and whether the oil must be prevented from flowing over the skimmer wall. For condition 1, How is equal to Z′ minus the user defined freeboard C′. For condition 2, the pressure balance must be maintained to prevent oil from spilling over the skimmer wall. Thus, How is equal to Z′(condition 2) minus the calculated required freeboard, Creq. Condition 1: If Z′ < B – C′, then How = Z′ – C′ Condition 2: If Z′ > B – C′, then How = Z′(condition 2) – Creq 6.1.4.2 Gross Oil Storage Amount Note: The gross oil storage calculation is based on a prismatically shaped basin with constant side slopes. The basin floor slope, ∆Zo, is calculated by taking the difference between opposing average basin depths, d12 and d34, and is defined as ∆Zo = d12 - d34 (refer to Figures 6.1 through 6.4 for illustrations of ∆Zo). For a sloped floor, ∆Zo equals a non-zero value. For a flat floor, ∆Zo equals zero. 6.1.4.2a Two Slope Conditions Note: The gross oil storage for each case is determined by calculating a base and above-base storage, both depend on the floor and sidewall slopes. 1) CASE A: a) Condition 1: Defines a small floor slope. Difference between d12 and d34 is less than or equal to sluice slot height. ∆Zo < A b) Condition 2: Defines a large floor slope. Difference between d12 and d34 is greater than the sluice slot height. ∆Zo > A 2) CASE B: Since Case B has two conditions to maintain the pressure balance behind the skimmer wall, the following two slope sub-conditions are considered: a) Condition 1: If Z’ < B – C′, then i) Sub-condition 1: ∆Zo < A + C’ ii) Sub-condition 2: ∆Zo > A + C’ b) Condition 2: If Z’ > B – C′, then i) Sub-condition 1: ∆Zo < A + Creq ii) Sub-condition 2: ∆Zo > A + Creq SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 11 of 14 6.1.4.2b Base storage, Vbase (gal) = Calculates the volume of storage available below the highest floor elevation. It is based on the floor area, floor slope, and side slope. Vbase = Xo/∆Zo * [(Yo*∆Zo2)/2 + (S*∆Z3)/3] + (S*Yo*∆Z2)/2 + (2*S2*∆Z3)/3 1) CASE A: For both slope conditions defined in 6.1.4.2a, the lower limit is d 12, the average basin floor depth at the weir side of the basin. The upper limit is ∆Z o, the difference between d12 and d34. 2) CASE B: a) Condition 1: b) Condition 2: i) Sub-Condition 1: No base storage is calculated because the floor slope is small. ii) Sub-Condition 2: The lower limit is zero. The upper limit is A + C′. For simplicity, the overall base storage is calculated by subtracting the base storage for Case B from the base storage for Case A. i) Sub-Condition 1: No base storage is calculated. ii) Sub-Condition 2: The lower limit is zero. The upper limit is A + Creq. For simplicity, the overall base storage is calculated by subtracting the base storage for Case B from the base storage for Case A. 6.1.4.2c Above-base Storage, Vabove-base or Va.b. (gal) = Calculates the storage above the base storage. The volume equation is derived by integrating from zero to dz’: Areaabove-base = (X + S x ∆Zo) x (Y + S x ∆Zo), where S = wallslope, ∆Zo = d12 – d34, and dz’ = vertical height of oily water from ∆Zo or the entire height of oily water Basin S x ∆Zo S x ∆Zo X Y + S x ∆Zo Figure 6.7 Above-base Area 1) CASE A: For both slope conditions defined in 6.1.4.2a, the lower limit is d34, the higher basin elevation. The upper limit is the defined freeboard C'. The difference between d34 and C' equals dz'. Above-base storage, Vabove-base (gal) = (Xo + S x ∆Zo) x (Yo + S x ∆Zo) x dz' + S x (dz' 2) x [(Xo + S x ∆Zo) + (Yo + S x ∆Zo) + 4 x S x dz'/3] – 0, If M<0 dz’ x L x M, If M>0 “M-TERM” – F x L x dz’, If F<0 0, If F>0 “F-TERM” x 7.48 gal/ft3 M-Term: The portion of the weir system between the back and weir wall, (horizontal distance M), which does not store oil. If M is outside of the basin or less than zero (negative value), subtract zero since this volume does not contribute to the total oil storage. If M is inside the basin or greater than zero (positive value), this part of the weir system does not store oil, but still occupies space in the basin. Thus, to reflect the correct oil storage in the basin, subtract dz’ x L x M from the total oil storage. SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 12 of 14 F-Term: The portion of the weir system between the weir and skimmer wall, (horizontal distance F), which can store oil. If F is outside of the basin or less than zero (negative value), this part of the weir system can still store oil. Therefore, F x L x dz’, must be added to the total oil storage. If F is inside the basin or greater than zero (positive value), subtract zero since the volume of oil in this part of the weir system is already accounted for in the total oil storage. 2) CASE B: Only the F term changes from the equation used for Case A. – 0, L x dz’, If F>0 If M<0 ― a) Condition 1: i) Sub-Condition 1: No base storage is calculated because the ground elevation slope is small. ii) Sub-Condition 2: The lower limit is C′. The upper limit is Z′. The difference between Z′ and C′ equals dz'. b) Condition 2: i) Sub-Condition 1: No base storage is calculated. ii) Sub-Condition 2: The lower limit is ∆Zo. The upper limit is Z′(condition2). For this sub-condition, dz' equals ∆Zo plus A minus Z′(condition2). Above-base storage, Vabove-base (gal) = (Xo + S x ∆Zo) x (Yo + S x ∆Zo) x dz' + S x (dz' 2) x [(Xo + S x ∆Zo) + (Yo + S x ∆Zo) + 4 x S x dz'/3] 0, If F<0 x 7.48 gal/ft3 “M-TERM” dz’ x L x M, If M>0 Fx “F-TERM” M-Term: (same as Case A above) F-Term: This portion of the weir system does not store oil. If F is outside the basin, subtract zero since this part does not contribute to the total oil storage. If F is inside the basin, this part of the weir system does not store oil, but still occupies space inside the basin. Thus, to reflect the correct oil storage in the basin, subtract F x L x D from the total basin volume. 6.1.4.2d Gross Oil Storage , Vtot (gal) 1) CASE A: For both slope conditions, the gross oil storage equals the sum of the base and above-base storage. Vtot = Vbase Case A + Vabove-base Case A 2) CASE B: For both conditions used to maintain the pressure balance, the gross oil storage is calculated with the equations below. For sub-condition 2, the gross oil storage is computed using values from Case A. Sub-Condition 1: Vtot = Vabove-base Case A Sub-Condition 2: Vtot = Vbase Case A – Vbase Case B + Vabove-base Case B 6.1.4.2e Percent Storage (%) = Percentage of oil volume in largest container Case A: 110% Case B: 110% 6.1.4.2f Allowable Oil Storage (gal): The allowable oil storage determines if the basin has sufficient storage. Since the gross oil storage includes the corresponding percent storage per Case, the allowable basin oil storage equals the gross oil storage divided by the percent storage: Allowable Oil Storage (gal) = Gross Oil Storage (gal) ÷ Percent Storage/100 6.2 Sheet 2: Flow-Through Output SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Note: Page: 13 of 14 Sheet 2, “Existing/New SPCC Basin Flow-Through Analysis”, determines if the basin flow capacity meets the storm water flow-through requirements for Cases A and B for existing basins, and Case C for new basins. 6.2.1 Table 2. Drainage Parameters CxA : Calculates values for each surface type by multiplying Runoff coefficient (C) times Drainage Area (A) Total CxA = Sum of CxA 6.2.2 Table 3. Constants for Flow Time to Basin Manning’s “n” = An assigned constant dependent on surface roughness For overland flow, n = 0.03 typically. For lined ditch flow, n = 0.012 typically. 6.2.3 Table 4. Short Duration Rainfall Time Duration Intervals, T D (minutes) = Time duration intervals (minutes) of rainfall concentration taken from Ref. 2. The first 3 intervals are usually the most critical. Rainfall intensity, i (in/hr) = The magnitude of rainfall measured in inches per hour. When D e input values are not available, enter 0.00 inch. The intensity (I) is then extrapolated using the following formulas: I (in/hr) = K/T log I (in/hr) = log K – nlogT (minutes) Storm inflow, Qin (cfs) = Total CxA from Table 2, times the corresponding rainfall intensity, I, divided by 43200 (from 60 sec/hr x 12 in/ft): Qin = Total CxA x I 43200 Time to Fill Basin, Tfill (minutes) = Time required to fill the basin. Takes the governing oil storage volume from sheet 1, divides it by the storm inflow corresponding to the duration time, and then multiplies it by the Percent Full. If the Percent Full amount equals 100%, the basin is full and the T fill value will print as “---“. Tfill = V (ft3) x Percent Full Qin (cfs) x 60sec/min 100 Time to Reach Basin, T to basin (minutes) = Time for drainage to flow from the furthest point in the substation drainage area to the basin. The time to reach the basin equals the time for overland flow plus the time for ditch flow. Tto basin = Toverland + Tditch, where Toverland = Longest travel time required to flow between ridge and ditch flow, and Tditch = Longest time required for ditch flow from beginning of ditch to basin Toverland = (0.67 x n x Loverland)/(SG1/2), SG = ∆ZG/L [Kerby’s equation] Tditch = Lditch/Velocity, where Velocity = Q/A = Q/1.5yo2, Q = 1.486AR2/3SG1/2 / n (Manning’s equation), A= 1.5 x yo2 and R = A/Pwet Total Time, Ttot (minutes) = Sum of time to fill basin and time to reach basin Ttot = Tfill + Tto basin Closest Time Duration, TD CLOSE (minutes) = Time duration (TD) closest to the total time of travel (Ttot) from the most remote part of the substation drainage area through the basin and over the outflow weir. This value equals the Tc input value in the “Time of Concentration” table described in Section 5.2.2. SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights SUBSTATION CIVIL ENGINEERING GUIDE Subject: CEG-3 Approved By: Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet User’s Guide 1 Revision: SED Civil DFW Effective Date: 02/10/05 Electronically Approved Page: 14 of 14 6.2.4 Outflow Weir Head Required Head, E (in) = Head necessary to pass the required design storm inflow, Qin des, over the broad crested outflow weir: E= Qin des 3L 2/3 6.2.5 Discharge Outlet Type Pipe: All output values described below are printed. Pump: Only “Pump capacity” and “Design storm inflow” values are printed. Ditch: Only “Design storm inflow” value is printed. Slope of pipe (s) = Drop of outlet pipe, a, divided by run of outlet pipe, b: Note: Pipe flow is based on the assumption of a free outlet (not submerged) and free inlet (no head). s = a/b Minimum outlet pipe diameter, Dmin (in) = Dmin = ( (n/0.093) x (48/d)1/6) x (8 x b x (Qin2) )1/5 3.14162 x 32.2 x a Pipe outflow capacity, Qcap (cfs) = Qcap = 1.486 x s1/2 x 3.1416 x (d/12)2 n 4 x x d 48 12in/ft 2/3 Design storm inflow, Qin des (cfs) = Using the input time of concentration value, Tc, from the “Time of Concentration” table (see Section 5.2.2), the corresponding Qin value is selected as required flow capacity. For Ditches: If Qcap > Qin des, “Outflow capacity OK” will print. If Qcap < Qin des, “Required Ditch Capacity Must Be > Qin des” will print. For Pipes: If Qcap > Qin des, “Outflow capacity OK” will print. If Qcap < Qin des, “Overflow capacity insufficient” will print. For Pumps: If Pcap > Qin des, “Outflow capacity OK” will print. If Pcap < Qin des, “Pump outflow capacity < Qin des” will print. Pump capacity, Pcap (cfs) = Pcap = Pump Discharge (gpm) 448.8 7.0 REFERENCES 1. California Dept. of Water Resources. (1988). Short Duration Precipitation Depth-Duration-Frequency Data Table. Sacramento: California Department of Water Resources. 2. Linsley, R.K., Kohler, M.A., and Paulhus, J.L.H. (1975). Hydrology for Engineers. New York: McGraw-Hill. 3. Pacific Gas and Electric Company. (2004). Design Criteria Memorandum: Spill Prevention Control and Countermeasure (SPCC) Plans and Facility Improvements, DCM No. C-1.3 Rev. 1. Oakland: Pacific Gas and Electric Company. 4. Pacific Gas and Electric Company. (2004). Spill Prevention Control and Countermeasure (SPCC) Oil Retention Basin Spreadsheet. Oakland: Pacific Gas and Electric Company. SPCC Oil Retention Basin Spreadsheet User’s Guide.doc reserved. © 2004 by Pacific Gas and Electric Company. All rights