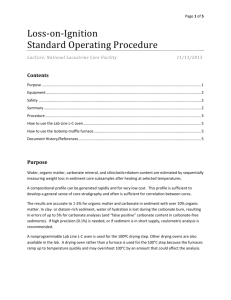

Loss On Ignition - University of Cambridge Department of Geography

advertisement

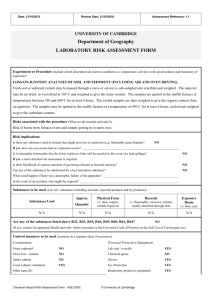

Loss-on-Ignition Protocol (V. 1.2) University of Cambridge Department of Geography Physical Geography Laboratories Equipment Balance - 2 or 3 decimal place, eg. in 1g, 10% accuracy = 0.1g, 1% accuracy = 0.01g, 0.1% accuracy = 0.001g Crucibles of an appropriate size for the samples - differently numbered Desiccator - with purple silica gel, if white put in 105oC oven for 6 hours to dry out. Drying oven - Must be booked in advance! Heat proof gloves. Muffle Furnace - capable of up to 1000oC - Must be booked in advance! Tongs. Trays & stack - capable of withstanding 1000oC. Volumetric Sampler. If you have large batches of samples, using a Sartorius balance connected to a pc is a useful way to speed up collection of data. Protocol (%water, bulk density, %organic, %calcium carbonate, %silicate residue) Clean dry, numbered porcelain crucibles are weighed empty. Approximately 1g of wet sediment is placed in the crucible, and the wet weight recorded. If bulk density of the sample is required a calibrated 1 cm3 brass volumetric sampler should be used and the sample should be weighed, allowing mass per unit volume to be calculated. Crucibles should then be placed on trays, the tray rack may be required if large numbers of samples are being processed. The samples are dried for 6 hours (until constant weight is achieved) usually overnight at 105oC in either the Drying Oven or Muffle Furnace. Remove trays carefully using the heat proof gloves. Use tongs to place crucibles in desiccator until they reach a temperature at which they can be handled safely. The desicator prevents the absorption of water from the atmosphere and therefore weight gain. Then weigh samples again. The samples are transferred to a muffle furnace then heated to 550oC for at least six hours (overnight), the furnace should then be reduced to ~100oC, when this temperature has been reached samples should be allowed to cool in a desiccator to a temperature at which they can be safely handled, then weighed. The samples are then returned to the furnace and heated to 950oC for at least six hours (overnight) the furnace should then be reduced to ~100oC, when this temperature has been reached samples should be allowed to cool in a desiccator to a temperature at which they can be safely handled, then weighed. Results The weight loss when the samples are dried at 105 oC (wet weight - dry weight) represents of the amount of pore-water held within the sample. The percentage of water should be expressed as a proportion of the wet weight. If the volume of the sample taken is known then the "Bulk Density" can be calculated from this, expressed as weight of sample per unit volume, e.g. g/cm3 (g cm-3). The weight loss between 105 and 550oC as a percentage of the total original dry sample weight is the % organic material. This probably also includes water loss from clay minerals, this is likely to be a insignificant addition. The weight loss between 550 and 950oC is representative of the amount of CO2 released from the sample. This can be used to calculate the amount of CaCO3 present in the sample by using the ratio between the molecular weights, expressed as a percentage of the total original dry sample weight this is the % carbon. Calculation (molecular weights in brackets) Ca (40.08) + C (12.01) + O3 (3 x 16.00) = CaCO3 (100.09) C (12.01) + O2 (2 x 16.00) = CO2 (44.01) Removed between 550 - 950 oC Ca (40.08) + O (16.00) = CaO (56.08) Remains in sample So to calculate the quantity of CaCO3 the weight of CO2 lost must be multiplied by a factor to account for the CaO remaining in the sample. CaCO3 (100.09) / CO2 (44.01) = 2.274 So the part of the sample that is represented by the CaO is 2.274 times that of the known CO2. So to calculate the quantity of CaCO3 in a sample the weight lost between 550 - 950 oC must be multiplied by 2.274. The weight of the residue remaining after 950oC, minus the adjustment for carbon, as a percentage of the total original dry sample weight is expressed as the % silicate residue. % Coal When analysing samples for CCRU a slightly different method is used. The samples are prepared as above, and dried at 105oC, but then heated to 400oC and 480oC instead of 550 and 950oC. This distinguishes between organic matter, and coal.