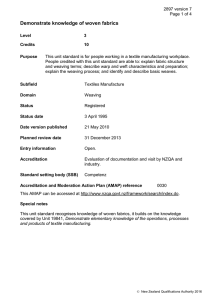

2903 Weave fabric

advertisement

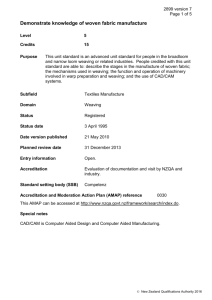

2903 version 7 Page 1 of 3 Weave fabric Level 3 Credits 6 Purpose This unit standard is for people working in the weaving industry. People credited with this unit standard are able to: demonstrate knowledge of the weaving loom and loom operation; operate the loom efficiently and safely to produce product to specification; identify and rectify faults; repair warp and weft breaks; and maintain a clean work area. Subfield Textiles Manufacture Domain Weaving Status Registered Status date 3 April 1995 Date version published 21 May 2010 Planned review date 31 December 2013 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0030 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Competence will be demonstrated on the type of loom installed in the workplace. 2 Plant safety practices comply with Health and Safety in Employment Act 1992 and workplace procedures. 3 Workplace productivity and quality requirements will be met. 4 CAM is Computer Aided Manufacturing. New Zealand Qualifications Authority 2016 2903 version 7 Page 2 of 3 Elements and performance criteria Element 1 Demonstrate knowledge of a weaving loom and weaving faults. Performance criteria 1.1 Sections of a loom are identified and described in terms of their function and operation described. Range 1.2 warp, headle shafts, reed, weft insertion mechanism, break detectors, colour selection and lifting mechanism, selvedge formation mechanism, cloth roller. Faults caused during weaving are identified, their cause stated and the corrective action described. Range pattern, colour, draft, lifts, sley, double picks, broken picks, missing picks, floating weft, floating warp, snarls, loops, cut weft, cut warp, selvedge, thick yarn, thin yarn, oil or grease, tight warp, reed marks, slack warp ends, slack weft, slubs, over twisted yarn, undertwisted yarn, streaky dyeing, wrong reverse, headle shaft down. Element 2 Operate a loom. Performance criteria 2.1 Loom parts and operating conditions that are safety risks are identified and the procedures for minimising or eliminating the risks are described. 2.2 Loom is operated in accordance with machine requirements and plant operating procedures. Range 2.3 controls identified, weft creel maintained, warp breaks mended, weft breaks mended, pieces woven to length. Weaving faults and machine malfunctions which occur during processing are identified and action taken according to workplace practice. Range pattern, colour, draft, lifts, sley, double picks, broken picks, missing picks, floating weft, floating warp, snarls, loops, cut weft, cut warp, selvedge, thick yarn, thin yarn, oil or grease, tight warp, reed marks, slack warp ends, slack weft, slubs, over twisted yarn, undertwisted yarn, streaky dyeing, wrong reverse, headle shaft down. New Zealand Qualifications Authority 2016 2903 version 7 Page 3 of 3 2.4 Instrumentation, control devices and CAM systems are operated according to workplace practice. Range 2.5 devices installed on loom in workplace. Records are kept according to plant procedure. Element 3 Keep loom and work area clean. Performance criteria 3.1 Weaving area is kept clean according to operating procedures. 3.2 Loom is kept clear of oil and other contaminants so that the fabric and yarns are not marked. 3.3 Loom is cleaned at the end of a batch according to plant requirement and in accordance with plant safety procedures. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016