HR5 - Faculty of Medicine

advertisement

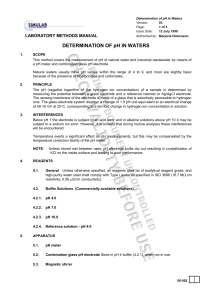

OHS026 Safe Work Procedure Faculty/Division Medicine Document number STGCL.SWP.29.1 (replaces MED SOP 5.1) School/ Divisional Unit St George Clinical School Initial Issue date Current version 1.0 15th April 2005 Current Version Issue date 04/03/2010 Next review date March 2012 The Writing Safe Work Procedures Guideline (OHS027) should be consulted to assist in the completion of this form. Safe Work Procedure Title and basic description Title: Safe Work Procedure for Operation of pH Meter Description: This Safe Work procedure describes how to operate a Schott CG 843P pH Meter Associated risk assessment title and location: STGCL.RA.29.1 Describe the activity or process Calibration Procedure 1. Use two commercially available (Ajax Fine Chemicals or other company) buffer solutions for this procedure: 2. Ph 7.0 ± 0.5 (colour code green) 3. Any other buffer solution, either pH 4.0 (colour code red) or pH 10 (colour code blue) 4. From the original stock of the commercially available buffer solutions pH 7.0 (green) and either pH 4 (red) or pH 10 (blue), transfer a small aliquot (approx 20ml of each) into 2 x 50ml falcon tubes. Keep the buffer solutions ready. Do not pour back used buffers into original stock. Use fresh buffers each time! 5. Check that the refilling hole of the pH electrode with liquid electrolyte is open and that the slide gate integrated in the electrode head is in position 1. 6. Press the <on/off> key to turn the meter on. 7. Press the <CAL> key repeatedly until ASY and the CONCAL function display appear. 8. Carefully remove the pH electrode from the storage buffer solution and rinse well with distilled water. Do not rub dry. 9. Submerse the pH electrode approximately 4cm into the first calibration buffer solution pH 7.0 ± 0.5 (green) and gently shake, do not use the electrode as a stirring device! Wait for approximately 30 seconds. 10. Press the <run/enter> key. The measured pH value appears on the display. 11. Set the nominal pH value of the calibration buffer solution (at the current displayed temperature) by pressing the <> <> keys. pH value reference data compensated for temperature is located on the side of each commercially available pH buffer solution. 12. Press the <run/enter> key. The value of the asymmetry (mV) and the sensor symbol appear on the display. 13. Press the <run/enter> key. SLO(pe) appears on the display. 14. Thoroughly rinse the electrode with distilled water. Do not rub dry. 15. Submerse the pH electrode approximately 4cm into the second calibration buffer solution e.g. pH 10.0 ± 0.5 (blue) and gently shake, do not use the electrode as a stirring device! Wait for approximately 30 seconds. 16. Press the <run/enter> key. The second measured pH value appears on the display. 17. Set the nominal pH value of the second calibration buffer solution (at the current display temperature) by pressing the <> <> keys. pH value reference data compensated for temperature is located on the side of each commercially available pH buffer solution. 18. Press the <run/enter> key. The value of the slope (mV/pH) appears on the display. The sensor symbol shows the evaluation of the electrode after the two-point calibration. 19. Press the <run/enter> key. The value of the asymmetry (mV) appears on the display again. 20. The unit is now calibrated and ready for use. To return to the measuring mode, press the <pH> key. 21. Once you have finished your measurements. Rinse the electrode with distilled water and immerse it back into the storage buffer solution. 22. Turn the pH meter off by pressing the <on/off> key. 23. If required KCl (3 mol/l) must be used for refilling of the pH electrode. ___________________________________________________________________________________________________________ ___________ Page 1 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 Calibration Information / Purpose 1. pH electrodes age and this changes the asymmetry (zero point) and slope of the pH electrode. As a result, an inexact measured value is displayed. Calibration determines the correct values of the asymmetry and slope of the electrode and they are stored in the instrument. Thus, you should calibrate at regular intervals. ConCal is the conventional two-point calibration procedure with 2 freely commercially available buffer solutions used for this purpose. 2. The range of pH measure is usually calibrated between pH 7 – pH 10 using commercially available standard 7 & 10 pH buffers. If desired pH is < 7, you may need to calibrate by using standard 4 & 7 pH buffers and then recalibrating back to the range of 7 – 10 pH after using. 3. Temperature influences ph therefore please refer to the side label of the commercially available stock solution to obtain correct pH value for each standard. 4. The storage buffer solution is to be replaced monthly and the calibration buffer solutions used fresh each time you perform a calibration. Calibration should be performed monthly as a minimum to ensure accuracy of readings. 5. The pH combination electrode contains a liquid electrolyte (KCl 3 mol/l). This must not be allowed to evaporate and is required to be full at all times. It is easily refilled using the KCl refilling solution bottle provided. Operation of pH Meter 1. Wear wear longsleeved Lab Gown, closed shoes, gloves, splash goggles. 2. Press the <on/off> key to turn the meter on. The display test appears briefly and automatically defaults to the pH measurement mode. If not select the pH-measuring mode by pressing the <pH> key. 3. Carefully remove the pH electrode from the storage buffer solution and rinse well with distilled water. Do not rub dry. 4. Check that the refilling hole of the pH electrode is open and that the slide gate integrated in the electrode head is in position 1. 5. Submerse the pH electrode into the test sample approximately 4cm and gently shake, do not use the electrode as a stirring device! Wait for 30 seconds before taking readings. 6. Press the <pH> key until pH appears in the status display. 7. The pH value appears on the display compensated for temperature. Adjust the pH of your solution with either NaOH (5M) or HCl (5M) as necessary – Caution strong acids and bases are highly corrosive so check MSDS before opening and wear longsleeved Lab Gown, closed shoes, gloves, splash goggles. 8. Rinse the electrode with distilled water and immerse it back into the storage buffer solution. 9. Turn the pH meter off by pressing the <on/off> key. List all resources required including plant, chemicals, personal protective clothing and equipment, etc Trained Personnel pH meter Long sleeved Lab Coat Gloves (type will depend on the acids / bases used) Splash Goggles Closed Footwear List potential hazards and risk controls including specific precautions required Hazard: Chemicals to be used Risk Control 1: Longsleeved Lab Gown, Closed Shoes, Gloves (type depending on chemical) Splash goggles Hazard: Chemical Spill Risk Control 1: Avoid clutter on the bench to minimize possibility of spill Risk Control 2: Adequate ventilation required ___________________________________________________________________________________________________________ ___________ Page 2 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007 List emergency shutdown instructions Turn the pH meter off by pressing the <on/off> key. List clean up and waste disposal requirements Rinse the electrode with distilled water and immerse it back into the storage buffer solution after every use. List legislation, standards and codes of practice used in the development of the SWP Operating Manual for laboratory pH meter CG 843P MSDS for specific chemicals STGCL.SWP.27.1 – Chemical Spillage Procedure Supervisory approval, training, and review Supervisor: Professor Beng Chong Signature: Plant custodian: Professor Beng Chong Signature List competency required – qualifications, certificates, licencing, training - eg course or instruction: Training required in this Safe Work procedure, Hazardous Substance Training SWP review date: March 2012 Responsibility for SWP review: Sinead O’Reilly ___________________________________________________________________________________________________________ ___________ Page 3 of 3 Safe Work Procedure Date Effective: 01/01/2007 Uncontrolled document when printed Current Version: 1.2, 15/08/2007