Nanostructures_Description - 2013 TACT International Thin

advertisement

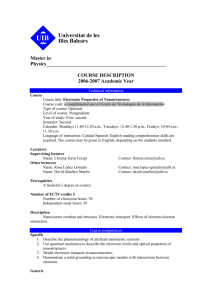

Course: Growth of Self-assembled Nanostructures (the materials science of small things: self-assembly and self-organization) Course Objectives Understand the primary experimental variables and surface reaction paths controlling nucleation/growth kinetics and microstructural evolution during vapor-phase deposition. Learn about the primary classical and quantum effects which controllably alter the properties of increasingly small nanostructures. Understand the mechanisms controlling self-assembly and self-organization during nanostructure growth. Learn how to better design nanostructure growth processes. Course Description The study of nanotechnology is pervasive across widespread areas including microelectronics, optics, magnetics, hard and corrosion resistant coatings, mechanics, etc. Progress in each of these fields depends upon the ability to selectively and controllably deposit nanoscale structures with specified physical properties. This, in turn, requires control -- often at the atomic level -- of nanostructure, nanochemistry, and cluster nano-organization. Deceasing size scales of solid clusters can result in dramatic property changes due to both "classical" effects associated with changes in average bond coordination and, as cluster sizes become of the order of the spatial extent of electron wavefunctions, quantum mechanical effects. The course will start with examples including reduced melting points, higher vapor pressures, increased optical bandgaps, decreased magnetic hysteresis, and enhanced mechanical hardness. Essential fundamental aspects, as well as the technology, of nanostructure formation and growth from the vapor phase will be discussed and highlighted with "real" examples using insights obtained from both in-situ and post-deposition analyses. Nanostructure case studies include: examples of template, size, and coarsening effects: self-assembled Si/Si(001), Cu/Cu(001),TiN/TiN(001), TiN/TiN(111) nano-clusters, examples of controlled template plus strain effects: self-organized Ge wires on Si(111), Ge wires on Si(187 72 81), Au chains on Si(553), InAs metal wires on GaAs(001), insulated metal wires on Si(111), quantum dot engineering: formation, shape transformations, and ordering in self-organized SiGe/Si(001); InAs/GaAs(001), CdSe/ZnSe(001), PbSe/PbEuSe(111), Ag/Pt(111), and MnN/Cu(001) quantum dots, nano-catalysis: Au/TiO2, examples of 3D nanostructures: (Ti,Ce)N/SiO2, TiBx/SiO2, and -TaN/Ta2N/SiO2. Course Content 2 The course provides an understanding of: the classical and quantum effects controlling the dramatic property changes observed in nanostructures as a function of cluster size and dimension (3D 2D 1D) self-assembly and self-organization during film growth from vapor and solution nucleation and growth modes the role of the substrate template and defect structures in mediating growth kinetics the development, and control, of film stress (strain engineering) the use of film stress to controllably manipulate nanostructure other mechanisms (including surface segregation, surfactant effects, lowenergy ion bombardment, cluster coarsening, etc) for controlling nanostructures the design of nanostructures with specified properties. Who Should Attend? Scientists, engineers, technicians, and students involved in deposition, characterization, or manufacturing/marketing of nanostructures and nanostructure deposition equipment. Instructor: Joe Greene, Editor-in-Chief of Thin Solid Films, the D. B. Willett Professor of Materials Science and Physics, University of Illinois, and Past Director of the Frederick Seitz Materials Research Laboratory. Course Materials: Course notes with extensive reference lists provided.