Distillation Manual

advertisement

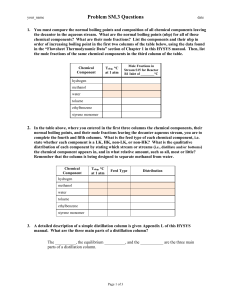

1 MICROCOMPUTER-CONTROLLED DISTILLATION UNIT MANUAL The microcomputer-controlled batch distillation column is an interchangeable 50mm diameter sieve tray column and a packed Raschig ring column that separates 7.5 wt% methanol and water. A tray column is currently in use with eight sieve trays with downcomers. Figure 1: Photograph of Distillation Column A schematic is shown in Figure 2 below. 2 Figure 2: Schematic of Distillation Column A simplified version of this schematic is available by selecting the “Flowsheet” option on the computer. The system features are described below: Temperature readings are available at seven locations: T1 feed tank T2 vapor from feed tank entering column T3 vapor leaving top of column T4 condensate liquid temperature T5 reflux returning to column T6 cooling water into reflux condenser T7 cooling water out of reflux condenser 3 The temperatures are monitored by thermistor sensors in protective pockets and can be observed on the main control unit by setting the multi-position knob to the thermocouple number you want to track. If the setting is maintained at “12”, then all temperatures will be sent to and displayed on the computer. The temperature readings are displayed in Celsius units. The feed tank is made of corrosion resistant stainless steel and has two electrically heated cartridge-type heating elements. The power to these elements can be continuously varied by adjusting the control knob and monitored from the digital watt meter above it. The watt meter will supply power from 0 to 2kW. The feed concentration can be adjusted by adding methanol to the reboiler. The reflux ratio is set using the computer control. The manual control on the main unit does not work when the “12” setting for the temperature readings is selected. If any other temperature setting is chosen, then reflux can be changed manually on the unit if desired. After starting the program on the computer, a menu will allow you to choose between total reflux, varied reflux, programmed reflux “reflux program”, or controlled reflux. The reflux ratio can be varied from 0.01 to total reflux. The pressure drop across the column is recorded from the U-tube manometer. The U-tube manometer is filled with water. The distillate receiver has height markings for approximate measurement of flowrate, when used in conjunction with a stopwatch. The cooling water is available for the distillation column through a cooling water supply. Yellow valve 5 (against the wall) allows for cooling water supply for the condenser. The flow rate for cooling water is set by the rotometer, which is equipped with a black control knob to control the flow. The cooling water flow rate can be varied from zero to 3 L/min. There is a pressure relief valve on top of the condenser to protect the system in the event of a blocked vent or cooling water failure. The “distill” computer program allows for tracking of temperatures and reflux ratio. Additionally, it can also be used to graph data (this is under “Reload Old Data From Disk”), to control the top of the column temperature, or to control the reflux ratio. Data can be saved on a 3 ½ “ PC formatted disk. Methanol concentration can be measured using the Agilent Gas Chromatograph (near the bioreactor) or refractometer. Sample vials with caps are used to inhibit methanol distillate samples from evaporating before they are measured for concentration using the refractometer. The level control unit on top of the main control unit is presently not working, so it is unplugged. 4 The “distill” program has a virus associated with it. When you are saving data onto a disk, the virus will be saved on that disk as well. Use caution before using the disk again. Open the disk on a university computer or a computer will reliable anti-virus software. The management is currently working on eliminating the virus. The “distill” program will not save data that is saved in a file name longer than 8 characters. This causes the program to crash. The management is also looking into fixing this issue. The file that you save only consists of temperature readings vs. time. It is advisable that you write down the temperature readings occasionally as there is a chance you may lose your file (will not be saved) if it is large. Recycle all methanol and water samples by putting them back into the reboiler. There is no need for waste jars or containers for this experiment – all methanol and water collected goes back into the reboiler. Be sure to put all calibration samples back into the reboiler when you are finished with the lab rotation. If this does not occur, a substantial deduction will be taken from your grade. Safety considerations: 1. NEVER start/run the column without cooling water. 2. The reboiler is hot. Avoid touching it unless necessary. Use a heat-safe glove when touching the reboiler. 3. The column has an insulating jacket that can be held open to make observations, but should be left on to avoid excessive heat loss and potential burns. 4. NOTHING must go down the drain when using this column. Contents in sample containers and the distillate receiver must be placed back into the reboiler. Methanol is a serious groundwater contaminant and any spills result in severe fines for the university. Alert the lab manager immediately when you encounter any possible methanol leaks or spills. 5. Gloves, safety glasses, and long pants should always be worn when using the column or working in the lab. 6. It is the column user’s responsibility to be aware of the health and safety risks of the chemicals involved with this unit. Every user must look up the MSDS for every chemical they are in contact or potentially in contact with. Start –up procedure: 1. If distillate is in the distillate receiver tank (clear tank with cm markings), empty into the reboiler using the valve under the distillate receiver tank. Before emptying the reboiler, remove the reboiler cap to let air in. Close the valve when finished and replace the cap. 2. Be sure the reboiler is at least 2/3 full of liquid but no more than 4/5 full before starting. Liquid level can be observed from the sight tube on the side of the reboiler. 3. Take a sample from the reboiler by opening the valve on the bottom. Check the concentration. If the concentration is lower or higher than desired, add methanol 5 or water to the reboiler until the desired concentration is achieved. The “For Your Use” jerrican next to the distillation column contains ~7.5 wt % methanol and should be used. Avoid using straight methanol. Replace the cap to the reboiler when ready to start the column. 4. Slowly open yellow valve #5, the cooling water supply main valve. 5. Open the rotometer valve to ~3 L/min to allow cooling water into the condenser. After a few moments, cooling water should be draining out of the other side of the condenser and into a drain on the floor. 6. Turn on power to the unit using the on/off switch. Be sure the temperature select knob is at “12” so that temperature signals are sent to the computer. 7. Start the computer. At the C:\> prompt, type “distill”. 8. Choose #2, “Use another mixture”. 9. At the function choice menu, select 1. Scan New Data to run the column. 10. On the main control unit, select the reboiler power (kW). 11. Follow the instructions on the screen to select total reflux, continuous reflux, controlled reflux, etc. Once these choices are entered, the column will begin operation and a screen with the temperatures and reflux ratio will be displayed while the experiment is in progress. 12. Data will be saved to the inserted disk after the run is complete and the user has exited from the temperature display screen. 13. Be alert and check for methanol leaks and smells for the duration of the experiment. Shutdown Procedure: 1. Save data from previous run. Never use a file name that is more than 8 charaters long otherwise the program will crash. 2. Turn down the reboiler power to zero. 3. Shut off main control unit power. 4. Exit from computer. At C:\> prompt, shut off computer and monitor. 5. Let cooling water flow for 10 minutes until all distillate has been drained from the condenser. Close rotometer valve. Slowly close main cooling water valve to avoid causing a water hammer. 6. Drain all collected distillate from the distillate receiver into the reboiler tank by opening the valve below the distillate receiver. Important - close valve when finished. Likewise, dump all methanol/water samples used for concentration analysis into the reboiler. Important – use a glove when touching the reboiler! 7. Be sure to leave the refractometer clean for next time use. 8. Be sure all glassware is clean and/or properly disposed. Make sure the bench space is clean and organized. 9. If at the end of your rotation there are sample vials with methanol waste, your grade will lowered, as then your instructor must empty your waste for you. 6 Details on the University of Tennessee - Chatanooga Remote Distillation Column: The 12 stage continuous/batch distillation column at the University of Tennessee separates methanol and water. The column can be viewed via live webcam and operated remotely. Though it can be run batch or continuous, continuous operation is recommended so UIUC batch runs can be compared against it. The control panel for remote operation can be found: http://distillation.engr.utc.edu/ (Note: a free LabVIEW plug-in needed in other to view the control panel. A link is on that page to download it.) The tutorial can be found at: http://chem.engr.utc.edu/webres/stations/Dist-tutorial.html Please email Professor Jim Henry (jim-henry@utc.edu) to tell him how to improve the tutorial if you have suggestions. Students at UTC must be contacted before a run begins to charge the feed tank and reboiler. The feedstock is about 11% methanol. To operate the column, three variables can be specified: 1. Reflux (expressed as a % of condensate that is refluxed) 2. Feed pump rate (expressed as a setting number on the pump that can be converted to volume flow rate with a calibration curve) 3. Heat to reboiler (in watts). While the experiment runs, data graphs of temperatures, power, pump settings, cooling water conditions can be observed. Concentrations are not measured. Instead, they must be calculated using temperature. The login and password for the live webcam are: Login: emcs Password: 329 To not overload the UTC students (or yourselves) with work, please only perform 9 total remote runs on the UTC column per rotation. 7 Using the Agilent 6850 Gas Chromatograph Steps for running a sample: 1. Turn on the GC unit using the power switch on the left side. 2. Wait until Initialization is complete (displayed on unit’s screen) This takes only about 20 seconds. 3. Go to computer and double click on “Instrument 1 Online” to start program 4. Go to “View”, then “Method and Run Control” 5. Go to “Run Control”, then “Sample Info”, an input box should pop up. - Input Operator Name - Under Data File, choose Manual - Make a subdirectory for yourself or your group - Put in a file name under Signal 1 (The program will automatically put all data for the run in a .xls file in your subdirectory) - For Sample Parameters, choose Front - Location Vial 1 - Choose a name for your sample - Don’t choose anything for sample amount or ISTD Amount - Multiplier is 1, Dilution is 1 - Place any comments in the comments box. - When finished, click on “Run Method” (not “OK”) 6. Choose the method: For distillation choose “Ethanol.M” for your method. You can do this from the pull down tab at the top of the screen. This tells the computer the split ratio, oven temperature, inlet temperature, flow rate, etc. If you would like to edit this method and use a different temperature or split ratio, etc. you are more than welcome to do so, however DO NOT override the “Ethanol.M” method. Save it as a different method. If you choose not to edit the “Ethanol.M” method, be sure to say “No” when the computer asks you whether you want to save the changes to the method. 7. After the oven and inlet are heated up, you should see “Waiting for Injection” on the computer screen in hot pink. 8. Preparing your sample for injection: - Find the “Distillation” syringe. - Rinse the syringe with your sample by drawing a sample into the syringe and discharging it onto a Kimwipe. Do this 7-10 times. - Pump your sample in and out of the syringe 7-10 times to eliminate bubbles and to ensure a consistent sample. - Draw a 0.5 μL sample into the syringe and check to make sure there are no bubbles 8 9. Check the GC unit’s screen and make sure it reads, “Ready for manual injection”. 10. Place syringe needle into inlet port (green port on top of GC) by firmly pushing the needle inside the port without pushing down the plunger. Be very careful not to bend the needle! 11. Once the needle is inside the port, quickly and smoothly push down the syringe plunger, remove the syringe, and hit “Start” on the GC unit immediately. 12. The computer screen should now be reading “Run in Progress”. 13. The sample peaks should appear within two and a half minutes after injection on the computer screen. Each run takes 10 minutes. You can stop the run before 10 minutes are up by going to “Abort.” 14. At the end of 10 minutes, a black and white graph of the spectrum should appear on the screen. Scrolling down, there will be a breakdown of the Peak #, Retention Time, Width, Area, Height, and Area Percent. 15. To run another spectrum, repeat steps 5-12. Important: You must replace the septum every 40 injections. To replace septa: 1. 2. 3. 4. 5. 6. 7. 8. Wait until the GC has cooled down. Make sure you are wearing gloves. Using your fingers (not a wrench) twist off the green cap from the injection port. Notice the orange rubber septa. From the first drawer in the cart beneath the GC there is a plastic bag with tweezers. Using tweezers, remove the orange septa. Pop out an Agilent septa from the blue package right next to the GC. Place the side with the hole on the top, the side without a hole facing down. Replace the green cap by screwing down just finger tight. To go back and look at old spectra: 1. Go to “View”, then “Data Analysis”. The data from the last run should pop up. 2. Go to “File”, then “Load Signal”, look for your run, and click OK. 3. To then run another sample, go to “View”, then “Method and Run Control”. Do steps 5-12 above. To save .xls data files onto a floppy or Zip: 1. 2. 3. 4. On the desktop, double click on the folder “Shortcut to Data” Find your folder, your specific runs, and the .xls file for each run Drag and drop onto a floppy or Zip. When opening up the .xls files, look under the “Peak” tab for all pertinent information such as retention time and peak area. To shut down: 9 1. 2. 3. 4. Close “Instrument 1 Online” and “Instrument 1 Offline” (if open) software. Shut off the power to the GC unit using the switch on the left side. Do not adjust any gas cylinder pressures or close any valves. Do not shut off the computer. Using the Refractometer to measure Refractive Index 1. Place a few drops of your sample onto the prism and close the top 2. Swivel the light source in front of the prism. 3. Looking though the eyepiece, find two cross hairs in the shape of an "X" across the field, as well as two vertical cross hairs at the middle of the field. 4. Adjust large knob on side until half of the field is "dark" while the other half is "light". The edge of the "dark" area (or where the "dark" area meets the "light" area) should be adjusted so that they meet directly in the middle of the X of the cross hairs. 5. The knob on the center of the machine achromatizes the field. To get an accurate reading, only black and white should be seen. 6. Once both knobs have been adjusted, the switch on the left side of the machine should be flipped down so that a measurement scale appears in the field of the eyepiece. Using the two vertical cross hairs, a reading for the refractive index can be taken. Marina Miletic August 17, 2005