Article - IEA Greenhouse Gas R&D Programme

advertisement

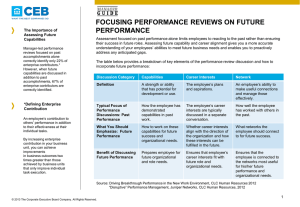

2nd Oxyfuel Combustion Conference Chemical-looping combustion using biomass as fuel Stefan Penthora*, Tobias Prölla, Hermann Hofbauera a Vienna University of Technology, Getreidemarkt 9/166, 1060 Vienna, Austria Keywords: Chemical-looping combustion, Biomass, Dual circulating fluidized beds, Alternative Fuels 1. Introduction and theoretical background Chemical-looping combustion (CLC) originally proposed by Lewis et al. [1] in 1951, is an innovative combustion technology where the fuel does not get in contact with combustion air (unmixed combustion, see Figure 1). A CLC reactor system consists of two separate reactors: air reactor and fuel reactor. The necessary oxygen for the oxidation reaction is transported from the air reactor two the fuel reactor via a solid oxygen carrier, avoiding the energy demanding gas-gas separation step inherently. The general reaction in the fuel reactor is: The re-oxidation reaction in the air reactor can be written as: Thus, the exhaust gas stream of the fuel reactor contains only CO2 and H2O while the exhaust gas stream of the air reactor contains N2 and excess O2. Taking these advantages in consideration, CLC is seen as a promising approach for capturing carbon dioxide from combustion processes [2]. Figure 1: Principle of chemical looping combustion. 2 The CLC concept for gaseous fuels has already been demonstrated at relevant operating conditions using oxygen carriers based on nickel [3,4]. However, a satisfying solution for the direct use of solid fuels in a CLC process has not been proposed yet. When it comes to direct use of solid fuels in CLC several difficulties additional to CLC using gaseous fuels have to be faced [5]. First, the solid fuel needs to be decomposed into its gaseous compounds. While devolatilization is rather fast, the gasification of the char has been identified as the limiting step [6]. Further, the char particles are expected to be well mixed with the oxygen carrier and transportation of a part of the char particles to the air reactor cannot be avoided. After decomposition, the gaseous compounds need to have sufficient contact with the oxygen carrier and time to react. Finally, ash and inert content has to be separated from the oxygen carrier and discharged from the system. Suitable oxygen carriers for solid fuel CLC can be natural minerals like ilmenite (FeTiO3). They are economically and environmentally sound and have a high reactivity towards CO and H 2 [7]. High reactivity towards CH4, like it is the fact with Ni, is not regarded as very important. With the possibility of releasing oxygen to the gas phase, oxygen carriers using the CLOU (chemical looping with oxygen uncoupling) effect [8] are also a possible choice for solid fuel CLC. 2. Possible ways using biomass in a CLC process Because of its combustion characteristics, using biomass seems to be an appropriate intermediate step in the development of direct coal CLC. At operating temperatures of the Fuel reactor (900 °C) biomass has a very high volatile content (up to 85 % of the dry organic matter) [9]. Regarding char conversion and transportation to the air reactor biomass looks promising since its char shows very high reactivity compared to char from coal [9] and additionally, biomass is carbon neutral. Since biomass does not contain fossil carbon, biomass-CLC with subsequent CO2 storage can be a tool for selective removal of carbon from the atmosphere. Generally, there are two different approaches using biomass as fuel for CLC. The first one combines two technologies already demonstrated: biomass steam gasification at atmospheric pressure and CLC using the product gas as fuel. However, for usually small scale biomass plants, handling four fluidized bed reactors (two for steam gasification plus two for chemical-looping combustion) seems very complex. Another option is to integrate the gasification step into the CLC reactor system and to use the biomass directly as fuel for the CLC process. The requirements for devolatilization and char gasification would be theoretically met by a reactor configuration according to Figure 2 [5]. The fuel reactor section consists of three distinct zones for devolatilization, char gasification and oxidation of the gaseous products. If these three functional zones would be built as separate fluidized bed reactors, the system appears again very complex. Thus, considerations regarding proper reactor design for direct solid fuel CLC need to deal with the integration of these three zones into one reactor in a most simple way. Figure 2: Theoretical reactor system for direct solid fuel CLC. Pennthor, S., Proell, T., Hofbauer, H./ Energy Procedia 00 (2016) 000–000 3 3. Design considerations for an appropriate reactor system for direct biomass CLC A proposal for an appropriate and promising reactor design meeting the requirements mentioned above has been made by Pröll and Hofbauer [5] (see Figure 3). This multistage circulating fluidized bed riser approach is based on the already successfully applied dual circulating fluidized bed (DCFB) system for gaseous fuel CLC [10]. By applying ring-type flow obstacles along the height of a CFB riser, the gas solid contact is increased and the formation of a core-annulus profile is prohibited [11]. Combining this approach with the DCFB concept, the reoxidized bed material from the air reactor can enter the fuel reactor close to the top and establish a counter-current flow of the particles and the gas. Figure 3: Proposed reactor design for direct biomass CLC (Steam fluidized loop seals: ULS-Upper loop seal, ILS-Internal loop seal, LLS-Lower loop seal). The final paper will contain detailed design consideration of a multi stage circulating fluidized bed reactor concept based on mass and energy balances, experimental data from both, biomass gasification and gaseous fuel CLC experiments and kinetic data of biomass conversion. 4. Conclusions Two different methods of using biomass in a chemical-looping process have been proposed: combining biomass gasification with CLC for gaseous fuels and direct solid fuel CLC. Since the first method seems too complex for typically small scale biomass plants, direct biomass CLC seems to be first choice. However, satisfactory solutions for direct solid fuel CLC have not been demonstrated yet. This paper presents detailed design considerations based on mass and energy balances and on experimental data from biomass gasification and CLC pilot plants. 5. References [1] [2] [3] [4] Lewis, W.K., Gilliland, E.R., Sweeney, W.P., 1951, “Gasification of carbon: metal oxides in a fluidized powder bed“, Chemical Engineering Progress 47(5), 251-256. Bolland, O., 2006, “Fundamental thermodynamic approach for analyzing gas separation energy requirement for CO2-capture processes”, in: Proceedings of the 8th International Conference on greenhouse Gas Control Technologies (GHGT-8), Trondheim, Norway. Pröll, T., Kolbitsch, P., Bolhàr-Nordenkampf, J., Hofbauer, H., 2010, “Operation of a chemical looping pilot plant up to 150 kW fuel power”, in: Les Rencontres Scientifiques de l’IFP – 1st international Conference on Chemical Looping – 17-19 March 2010, Lyon – Proceedings. Linderholm, C., Mattisson, T., Lyngfelt, A, 2009, “Long-term integrity testing of spray-dried particles in a 10-kW chemical-looping combustor using natural gas as fuel”, Fuel 88(11), 2083-2096. 4 [5] [6] [7] [8] [9] [10] [11] Pröll, T., Hofbauer, H., 2010, “A dual fluidized bed system for chemical looping combustion of solid fuels”, in: Proceedings of the AIChE Annual Meeting 2010, Salt Lake City, Utah, U.S.A., November 7-12. Leion, H., Mattisson, M., Lyngfelt, A., 2007, “The use of petroleum coke as fuel in chemical-looping combustion”, Fuel 86, 12-13. Mattisson, T., Johansson, M., Lyngfelt, A., 2006 “CO2 capture from coal combustion using chemical-looping combustion – Reactivity investigation of Fe, Ni, and Mn based oxygen carriers using syngas”, in: Proceedings of 31st International Technical Conference on Coal Utilization & Fuel Systems, Clearwater, U.S.A. Mattisson, T., Lyngfelt, A., Leion, H., 2009, “Chemical-looping with oxygen uncoupling for combustion of solid fuels”, International Journal of Greenhouse Gas Control, 3, 11-19. Reed, T.B., 1981, “Biomass gasification”, Noyes Data Corporation, New Jersey. Pröll, T, Kolbitsch, P, Bolhár-Nordenkampf, J., Hofbauer, H., 2009, „A novel dual circulating fluidzed bed system for chemical looping processes“, AIChe Journal 55(12), 3255-3266. Bu, J., Zhu, J.-X., 1999, “Influence of ring-type internals on axial pressure distribution in circulating fluidized bed”, Canadian Journal of Chemical Engineering 77(1), 26-34.