Bituminous Set Installation

advertisement

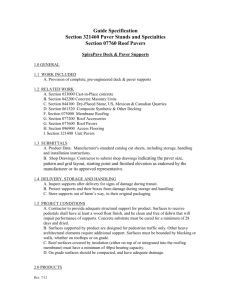

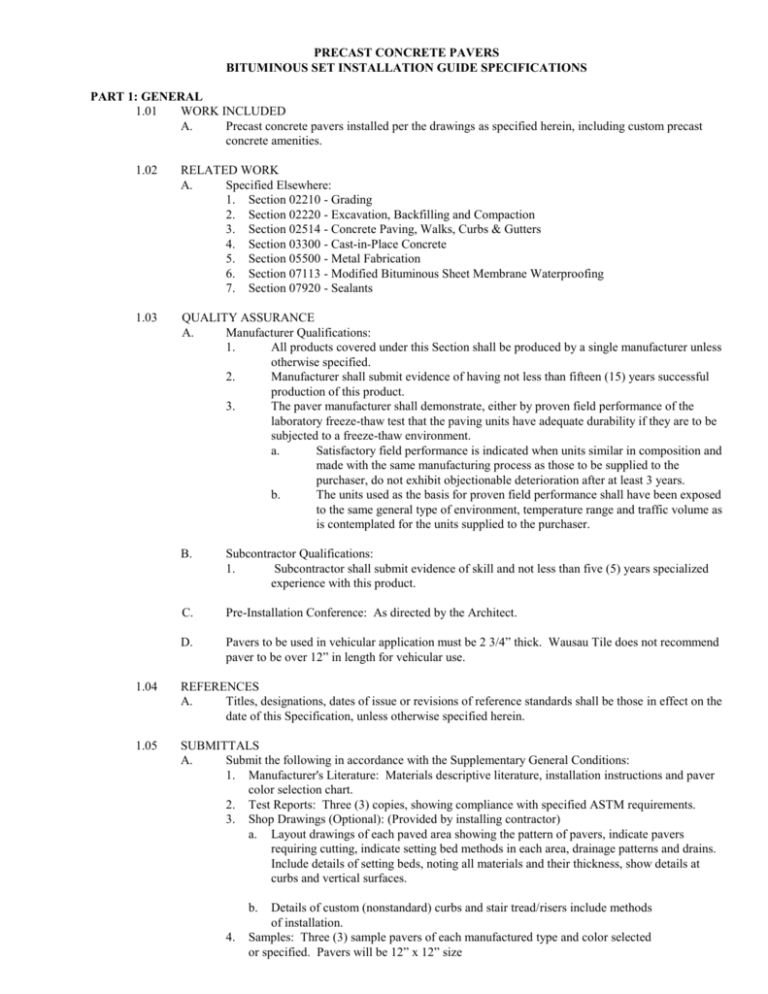

PRECAST CONCRETE PAVERS BITUMINOUS SET INSTALLATION GUIDE SPECIFICATIONS PART 1: GENERAL 1.01 WORK INCLUDED A. Precast concrete pavers installed per the drawings as specified herein, including custom precast concrete amenities. 1.02 RELATED WORK A. Specified Elsewhere: 1. Section 02210 - Grading 2. Section 02220 - Excavation, Backfilling and Compaction 3. Section 02514 - Concrete Paving, Walks, Curbs & Gutters 4. Section 03300 - Cast-in-Place Concrete 5. Section 05500 - Metal Fabrication 6. Section 07113 - Modified Bituminous Sheet Membrane Waterproofing 7. Section 07920 - Sealants 1.03 QUALITY ASSURANCE A. Manufacturer Qualifications: 1. All products covered under this Section shall be produced by a single manufacturer unless otherwise specified. 2. Manufacturer shall submit evidence of having not less than fifteen (15) years successful production of this product. 3. The paver manufacturer shall demonstrate, either by proven field performance of the laboratory freeze-thaw test that the paving units have adequate durability if they are to be subjected to a freeze-thaw environment. a. Satisfactory field performance is indicated when units similar in composition and made with the same manufacturing process as those to be supplied to the purchaser, do not exhibit objectionable deterioration after at least 3 years. b. The units used as the basis for proven field performance shall have been exposed to the same general type of environment, temperature range and traffic volume as is contemplated for the units supplied to the purchaser. B. Subcontractor Qualifications: 1. Subcontractor shall submit evidence of skill and not less than five (5) years specialized experience with this product. C. Pre-Installation Conference: As directed by the Architect. D. Pavers to be used in vehicular application must be 2 3/4” thick. Wausau Tile does not recommend paver to be over 12” in length for vehicular use. 1.04 REFERENCES A. Titles, designations, dates of issue or revisions of reference standards shall be those in effect on the date of this Specification, unless otherwise specified herein. 1.05 SUBMITTALS A. Submit the following in accordance with the Supplementary General Conditions: 1. Manufacturer's Literature: Materials descriptive literature, installation instructions and paver color selection chart. 2. Test Reports: Three (3) copies, showing compliance with specified ASTM requirements. 3. Shop Drawings (Optional): (Provided by installing contractor) a. Layout drawings of each paved area showing the pattern of pavers, indicate pavers requiring cutting, indicate setting bed methods in each area, drainage patterns and drains. Include details of setting beds, noting all materials and their thickness, show details at curbs and vertical surfaces. b. 4. Details of custom (nonstandard) curbs and stair tread/risers include methods of installation. Samples: Three (3) sample pavers of each manufactured type and color selected or specified. Pavers will be 12” x 12” size 1.06 DELIVERY, STORAGE AND HANDLING A. Deliver and handle precast concrete pavers in such a manner as to prevent damage. Units shall be stored above ground on pallets. Pallets shall be clean and non-staining. All damaged or otherwise unsuitable material shall be immediately removed from the job site. 1.07 MOCK-UP INSTALLATION A. Prior to the start of precast concrete paver work construct mock-ups of each type of paver size and pattern area for the Owner and Architect to review. The mock-ups will be at the project site at a location mutually agreed to by the Owner and Contractor. B. Construct the mock-up installations a minimum 4 foot x 4 foot area of typical precast concrete units and slabs with all setting beds, joints, edge and curb details as shown on the Drawings. C. After review of the mock-ups, they should be retained and used as a standard of quality for the precast concrete paver work. At completion of the work remove the mock-up installations and related materials from the project site. If the mock-ups are incorporated in the actual construction, record their actual locations and sizes on the actual built record drawings for the project. PART 2: PRODUCTS 2.01 MATERIALS A. Precast Concrete Pavers - Manufactured by Wausau Tile Inc., Wausau, WI 800-388-8728, 715-359-3121, Fax: 715-359-7456 www.wausaupaving.com Email: wtile@wausautile.com 1. 2. 3. 4. 5. 6. 7. 8. B. Name: Wausau Pavers Size: As selected Finish and Color: choose from EcoPremier, UltraFace, Textured Granite, Textured Sand, Stoney Creek, Granitex, ExpoStone, ExpoGranite, Exterior Terrazzo, SeaShell, CoolSeries, Washed Glass, Blasted Glass, Detectable Warning, Ballast Portland Cement: ASTM Specifications C150 Aggregates: All aggregates used will be normal weight aggregate, conforming to ASTM Specifications C33. Coloring: Coloring used shall conform to ASTM Standards where applicable. Performance requirements: based on 23 13/16” sq x 2” thick and standard mix design. a. Compression Strength: Each unit shall have a compression strength of 8,000 psi with no individual unit less than 7,000 psi when tested in accordance with ASTM C140. (based on 23 13/16” sq x 2” thick) b. Water absorption: Shall not be greater than 6% according to ASTM C140. (based on 23 13/16” sq x 2” thick) c. Flexural Strength: Not less than 800 psi per ASTM 293. (based on 23 13/16” sq x 2” thick) d. Freeze/thaw: Durability of the paver shall meet the freeze/thaw tests in accordance with ASTM C-1260. Specimens, when tested, shall have no breakage and not greater than 1% loss in dry weight of any individual unit when subject to 50 cycles of freeze/ thaw. e. Load Carrying Capacity: Pavers shall support a minimum concentrated load of 1,850 lbs when pressure is applied to a paver supported on four (4) corners. WT CL96 (based on 23 13/16” sq x 2” thick) f. Sizing: Permissible variations in dimensions shall not differ by more than 1/16 inch from width, height, length or thickness. Standard units are manufactured with a 3/16 inch bevel on all four (4) sides of finished surface. Unit shall conform to a true plane and not differ by more than 1/16 inch in either concave and/or convex warpage. Pavers to be used in vehicular applications must be 2 ¾” thick. Wausau Tile does not recommend paver to be over 12” in length for vehicular use. Asphalt Setting Bed Materials: 1. Asphalt Cement: ASTM D 3381, viscosity grade AC-10 or AC-20. 2. Fine Aggregate: Clean, hard sand, free of organic matter, uniformly graded from coarse to fine, all passing the No. 4 sieve meeting the gradation requirements when testing in accordance with ASTM C 136. 3. Mixing: Provide plant mixed asphalt setting bed by combining dry fine aggregate (approximately 93 percent) and hot asphalt cement (approximately 7 percent) and heat to approximately 300 degrees F. Provide each ton of setting bed material apportioned by weight with the approximate ratio of 145 lbs. of asphalt to 1,855 lbs. of sand. C. Setting Bed Primer: Cut back asphalt, ASTM D 2028, grade as recommended by the asphalt paving manufacturer. D. Asphalt Adhesive: Standard neoprene modified asphalt adhesive containing oxidized asphalt combined with 2% neoprene and 10 percent long fibered mineral fibers with a softening point of 155 degrees F. E. Joint Filler Materials: Sand conforming with ASTM C 144 with 100 percent passing a No. 16 sieve. Pre-formed Asphalt Joint Filler: ASTM D 994, 1/2 inch thick, for expansion joints which are not sealed one of the following: 1. Code 1301, W.R. Grace & Co.; I. 2. Asphalt Expansion Joint, W. R. Meadows, Inc. 3. Elastite Asphalt Expansion Joint, The Celotex Corporation. F. PART 3: EXECUTION 3.01 INSPECTION A. Examine all surfaces to receive the parts of the work specified herein. Verify all dimensions of in-place and subsequent construction. Notify the Contractor in writing of conditions detrimental to the proper and timely completion of the work. Do not proceed with the work until unsatisfactory conditions have been corrected, Installation of precast concrete pavers and associated construction constitutes acceptance of the adjacent and underlying construction. 3.02 INSTALLATION OF BITUMINOUS SETTING BED A. Place solid steel 3/4 inch thick control bars directly on the base or slab. Install shims under bars for minor adjustment of depth and finish paver elevations and slopes. Space bars approximately 11 feet apart and parallel to each other to serve as guides for strike-off boards. B. Place asphalt setting bed at not less than 200 degrees F. in panels between control bars on the primed concrete slab or binder course to not less than 3/4 inch compacted thickness. Spread material and strike off by pulling the material with a 12 foot long x 2 inch x 6 inch wood board several times to produce a smooth firm and even setting bed. Add fresh material in low, porous spots after each pass of the strike-off board. After each panel is complete remove and advance the first control bar to the next panel position in readiness for placing and striking adjacent panels. Fill in depressions left by the control bar and any shims. C. Roll setting bed with a roller (not over one ton in weight) to a nominal depth of 3/4 inch thick while it is still hot. Add additional material to adjust thickness required and to allow for setting of pavers to finish elevations and slopes. 1. 2. 3.03 If setting bed is installed greater than 1 1/2 inch thick, place in two equal lifts. Place the second lift immediately after the first to assure bond between lifts. If pavers are not installed immediately after setting bed, provide protection of setting bed with minimum 1/2 inch plywood sheet laid on the setting bed with butted joints. Repair all damage to the setting bed prior to installing pavers. PAVER AND SLAB INSTALLATION A. Install precast concrete pavers, slabs and curbs in locations, patterns and at elevations and with slopes for surface drainage as shown on the Drawings. Install precast concrete pavers, slabs and curbs in accordance with the manufacturer's printed installation instructions and the final reviewed shop drawings. B. Apply neoprene-modified asphalt adhesive on the cured setting bed by squeegeeing or troweling. If troweled on, use a trowel with serrations not exceeding 1/16 inch depth. Place adhesive to not more than 1/16 inch thickness over the total surface of the setting bed. Do not begin installation of pavers, slabs and curbs until adhesive is dry to the touch. 3.04 C. Lay out pavement in 30 foot working area modules. Set precast concrete pavers, slabs and curbs by hand on dry adhesive in patterns shown on the Drawings with hand tight joints 1/16 to 1/8 inch wide joints and uniform top surfaces. D. Field cut precast concrete pavers in accordance with manufacturer's recommendations for methods, equipment and precautions. E. Maintain accurate alignment and check for creep and shrinkage. Make adjustments to creep and shrinkage within the 30 foot module area. F. Sweep fine dry sand over pavement surface to fill joints immediately after installing pavers, slabs and curbs on setting bed. Brush in sand until joints are completely filled, remove surplus sand. Do not allow traffic on installed pavers, slabs or curbing until the joints have been filled. G. Protect newly laid pavers, slabs and curbs with plywood panels on which workers stand. Advance protective panels as work progresses but maintain protection in areas subject to continued movement of materials and equipment to avoid creating depressions or disrupting alignment of installed pavers, slabs and curbs. H. Install the specified joint filler where precast concrete pavers, slabs and curbs abut curbs, other vertical surfaces and other construction. CLEANING AND PROTECTION (Responsibility of end user) A. Remove and replace pavers which are loose, chipped, broken, stained or otherwise damaged, or if units do not match adjoining units as intended. Provide new units to match adjoining units and install in same manner as original units, with same joint treatment to eliminate evidence of replacement. B. Cleaning: Remove mortar stains and all other types of soiling from exposed paver surfaces, wash and scrub clean. C. Efflorecense is a naturally occurring white residue or stain on the surface of new concrete. The residue can be cleaned or will dissipate naturally with time. D. Provide final protection and maintain conditions in a manner acceptable to installer, which ensures paver work being without damage or deterioration at time of substantial completion. 3.05 BACKFILLING A. After the precast concrete paving is completed, backfill the spaces along the edges of the walks, metal edging and pavements to be required elevations with material reviewed by the Testing Laboratory. The Material shall then be compacted until firm and the surface neatly graded, with allowance made for top soil. 3.06 INSTALLING STAIR TREAD/RISERS A. Install precast stair tread/risers in accordance with the final reviewed shop drawings. B. 7/13 Anchor each unit using stainless steel dowels to the supporting structure. Provide not less than two dowels per each unit. In addition, dowel each unit to the previously installed unit to assure against movement of each and the installation. Grout solid all dowels in precast units and the supporting construction.