Influence of grinding productivity on the burn intensity of the ground

advertisement

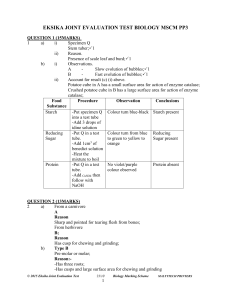

INFLUENCE OF GRINDING PRODUCTIVITY ON THE BURN INTENSITY OF THE GROUND SURFACE D. Ciglar R. Cebalo T.Udiljak Dr.sc. D. Ciglar, University of Zagreb, FSB, I.Lučića 5, 10000 Zagreb Prof.dr.sc. R.Cebalo, University of Zagreb, FSB, I.Lučića 5, 10000 Zagreb Doc.dr.sc. T.Udiljak, University of Zagreb, FSB, I.Lučića 5, 10000 Zagreb Keywords: grinding productivity, grinding defects, grinding burn intensity, grinding surface lightness interval, burn intensity of the ground surface ABSTRACT: The productivity increase of the grinding process expressed by reduced material removal rate can result in incorrect grinding and the consequence is the ground surface burn and occurrence of other grinding defects on the ground surface. The paper studies the burn intensity of the ground surface and other grinding defects in different material samples, depending on the increase of grinding productivity. The ground surface burn intensity has been determined by means of the surface lightness interval, with the upper and lower value, and measurements were carried out on the Image Analysis System LECO2001. The results have shown that the increase in grinding productivity on all the ground material specimens results in an increase of burn intensity, reduction of the surface lightness interval value, and an increase in the change of surface layer hardness and the layer depth of variable workpiece hardness. Therefore, the surface lightness interval values, i.e. the burn intensity of the ground surface can determine the correctness of the grinding process and approximate limited productivity. 1. INTRODUCTION Very small dimensions of separated particles, the characteristic that breaking of one cutting edge does not affect the stability of the process, and the self-sharpening process of the grinding wheel, these are all significant advantages that may insure the future of the grinding processes. The tendency is to achieve the maximum productivity of the grinding process, thus reducing the machining time, and thus making the grinding process a more economic and for the industry a more acceptable one, at the same time meeting the quality requirements of the treated surfaces. The increase of productivity of the grinding process can result in incorrect grinding, i.e. in undesired generation of heat on the workpiece surface, which is much greater than the heat taken away so that the temperature of the workpiece surface layer will rise quickly. 210 D.Ciglar; R.Cebalo; T.Udiljak High temperature affects the integrity of the ground surface, and the notion was introduced in the seventies by M. Field and J. Kahles 1 describing the total quality of the surface which affects the product characteristics, and the most important include: impact strength, fatigue strength (dynamic durability), corrosion resistance, tribological behaviour, dimensional stability, residual stresses, surface roughness, etc. Except influencing the mentioned characteristics of the product, grinding temperature primarily causes thermal and temperature damaging of the ground surface, and the consequences are defects in grinding that occur on the surface or in the sub-surface layer of the workpiece. The grinding defects according to 2,3,4,5,6 may include: burn or oxidation, change in microstructure, change in hardness, residual stresses and generation of thermal cracks. In rough grindings there is a less demanding requirement regarding the quality of the ground surface and little burn of the workpiece surface is allowed, since the resulting thermally damaged layer can be removed by finish grinding, if necessary. However, thermal cracks on the ground workpiece surface are not allowed, since according to [2,6] cracks have the tendency to penetrate into the depth and are very dangerous for the dynamically loaded parts, substantially reducing the dynamic strength of the workpiece, with the possibility of fracture as result of material fatigue. Little intensity of surface burn though, allowed in less demanding grinding processes, will determine the critical conditions of grinding, i.e. the point where the incorrect grinding starts, if there is indication that there is significant dependence between the burn intensity of the ground surface and other grinding defects. For some material specimens, therefore, the dependence will be studied of the ground surface burn intensity and other grinding defects on the increase of grinding productivity. 2. GRINDING DEFECTS One of the first defects in grinding that occurs on the workpiece ground surface is burn or surface oxidation. According to 7 all metals and alloys (except gold) form an oxide layer, but in many cases at lower temperatures this reaction is very slow. In alloys the oxidation products are much more complex, since alloy components can form chemical compounds and the resulting oxide layer is a heterogeneous mixture of different particles at the alloy surface, i.e. chemical composition of the workpiece marginal layer is changed. It is difficult to say which oxide compound will be formed on the surface of the alloy, but it is certain that the thickness of the oxide layer affects the absorption and reflection of light, and thus the oxide colour changes with the increase of the oxide layer thickness. It has been proven that the oxide layer thickness increases with the increase in duration and temperature of oxidation. According to 8, the change in colour of the workpiece surface during grinding is caused by surface oxidation due to high grinding temperatures. This leads to the conclusion that with higher burn intensity the grinding temperature is higher, oxide layer thicker and the colour of the machined surface darker. Influence of Grinding Prod. on the Burn Intensity of the Ground Surface 39 In the work, according to 9, the burn intensity of the ground surface is determined based on the colour of the machined surface of the material specimen, i.e. by quantifying the lightness interval of the surface after grinding, carried out on the Image Analysis System LECO2001, Figure 1. Figure 1 – Image Analysis System LECO 2001. The LECO 2001 device is installed at the Laboratory for Material Science at the Faculty of Mechanical Engineering and Naval Architecture, Zagreb, and according to [10], the basic components of the Image Analysis System are: light microscope, two CCD cameras (black&white), Leco 386 computer, Leco Image processor, colour image monitor, colour text monitor (VGA card), printer, 2001 main program. By means of the black&white camera the device has the possibility to record the material specimen surface, to analyse its lightness and to use the histogram in order to present the grey scale level of the recorded surface. The value of lightness interval, according to the grey scale level of certain points of the recorded and analysed surface can range, by standardised 8 bit BMP format, between 0 and 255, with the value 0 denoting black, and the value 255 denoting white of a certain point. The histogram provides readings of the grey scale level values which encompass the majority of the points from the analysed surface and these values determine the interval of the surface lightness. The lower value of the surface lightness interval describes the darker colour in the image, and the upper value is the lighter colour. In order to determine the burn intensity of a ground surface the lower value of the surface lightness interval is more relevant since it describes the more burned ground surface of the material specimen. Another defect in grinding considered in this paper is the change in the hardness of the surface layer of the ground surface. As in the case of burn, the change occurs due to high temperatures of surface heating and due to quick cooling of the surface by conducting heat towards the interior of the workpiece. Workpiece heating and cooling results in the change of hardness of the surface layer and in structural transformations in 410 D.Ciglar; R.Cebalo; T.Udiljak the solid state. These structural transformations are basically the same as with the thermal processing treatment, only that the heating rate is greater in grinding. Faster cooling of the workpiece layer is accomplished by self-cooling, since basic conditions are met that the cold workpiece core is a sink large enough for transmission of heat into the interior of the workpiece. Due to these changes, in grinding of tempered steel, depending on the level of grinding temperature, the hardness can be increased compared to the reference value (hardening) or decreased in relation to the reference value (softening) The increase in the hardness of the ground workpiece surface layer is a consequence of either creating an untempered martensite (UTM), i.e. re-tempering or conversion of residual austenite into the secondary martensite, i.e. secondary hardening. The reduction of the surface layer hardness of the ground workpiece resulted from producing tempered martensite (OTM), and it is present at lower grinding temperatures. The thickness of the layer of variable hardness is approximately proportional to the volume of heat supplied to that surface, and it is related to the heat affected zone (HAZ). It is important to know the HAZ thickness because this is, in fact, really the thickness of the damaged workpiece layer. 3. EXPERIMENTAL RESEARCH The study of burn intensity of the ground surface and other grinding defects regarding productivity of the grinding process, i.e. in various values of reduced material removal rate was carried out on four different materials Č3840, Č6980, Č4150 and Č4770. These tool steels were used to produce test tube specimens of 15x10x30mm dimensions, i.e. 10x10x30mm for material specimen Č6980. Test tubes of selected material specimens were thermally treated (hardened and tempered) according to the manufacturer’s instructions. The specimens were ground by straight peripheral down cut grinding without cooling, on a surface grinding machine “DOALL G – 10”. For the pre-selected material specimens, according to [11], the surface grinding wheel of the company SWATY was selected, with the grinding wheel designation PA120/1EF14/5V40. The dressing of grinding wheel cutting surface was done by single-point 2 Ch diamond, with the edge radius of 0.2mm, in three passings. The depth of diamond penetration was measured at every passing, it is constant and amounts to 0.03mm, and the diamond cutting feed is 0.1mm/revolution. Using the above conditions the topography of the grinding wheel cutting surface was obtained described by the number of static cutting edges which amounts to Ns=3.59mm-2. The speed of the machining surface during the study was 0.0685m/s, and the peripheral wheel speed was constant and amounted to 40m/s. The change in the reduced material removal rate value during the grinding process was achieved by changing the value of the grinding depth. With the grinding depths of 0.01mm, 0.05mm, 0.1mm and 0.18mm, the following values of reduced material removal rate were obtained: Qbr=0.685 mm3/smm, Qbr=3.425 mm3/smm, Qbr=6.85 mm3/smm and Qbr=12.33 mm3/smm. By grinding of selected material specimens, of each one separately, Influence of Grinding Prod. on the Burn Intensity of the Ground Surface 59 under the mentioned conditions and values of the reduced material removal rate, the surface of the material specimens was obtained as presented in Figure 1. a) b) c) Figure 1. Surfaces of the ground material specimens. d) In Figure 1 (a to d), the material specimens are arranged top downwards in the following order: Č3840, Č6980, Č4150 and Č4770. It is clear in Figure 1 that grinding with higher value of reduced material removal rate provides stronger surface burn in all material specimens, which is seen from the darker surface of the specimens. Image Analysis System LECO2001 was used to determine the burn intensity of the ground surface of the material specimens in Figure 1, and the quantified values of the lightness interval of the ground surfaces of material specimens are presented in Table 1. Table 1 – Lightness interval values of the ground surfaces of material specimens. first measurement SURFACE LIGHTNESS INTERVAL second third fourth measurement measurement measurement WORKPIECE MATERIAL 195 – 215 155 – 180 170 – 195 135 – 160 60 – 95 40 – 60 55 – 90 20 – 40 Č3840 Č6980 185 – 205 180 – 200 120 – 145 150 – 185 55 – 75 65 – 85 20 – 40 35 – 65 Č4150 Č4770 Table 1 shows that the surface lightness interval values of the ground material specimens, that were ground with low value of reduced material removal rate, are several times greater than those in which grinding was carried out with greater productivity. It may be concluded that the surface lightness interval values match well the burn intensity of the 610 D.Ciglar; R.Cebalo; T.Udiljak ground surface, so that unburned workpieces have higher value of surface lightness interval and lower value of surface lightness interval describes the more burned ground surface of the material specimens. In order to study the connection between burn intensity of the ground surface and other defects, i.e. in order to state which specimen surface presented in Figure 1 shows the correctly and which the incorrectly ground material specimens, other indicators will be studied that show incorrect grinding conditions. The change in surface layer hardness of the ground surface and the depth of the layer of variable hardness i.e. the HAZ depth were studied. In the first grinding, where Qbr=0.685 mm3/smm, i.e. where high values of surface lightness interval of the ground material specimens were determined, the Vickers hardness test measurement did not show change in the surface layer hardness on any of the material specimens, and the grinding is considered correct. Vickers hardness test measurement on material specimens in Figure 1b shows negligible change in surface layer hardness. In all material specimens the softening of the ground surface occurred. In Č3840 approximately 2.9%, in Č6980 approximately 1%, and in Č4150 and Č4770 approximately 2.4%. The depth of the variable hardness layer, i.e. the softening depth in all the material specimens is less than 0.03mm. Since change of hardness and depth of the variable hardness layer are small, this grinding at Q br=3.425 mm3/s mm can be regarded as correct. On material specimens ground at Qbr=6.85 mm3/smm (Figure 1c), the change in hardness and depth of variable hardness layer are not negligible. In material specimens Č3840, Č6980 and Č4770 surface softening was determined, whereas material specimen Č4150 showed hardening of the surface itself, but the layer beneath it softened. Reason for the reduction in surface layer hardness of material specimens Č3840, Č6980 and Č4770 is the tempering of the primary martensite due to the grinding temperature. The specimen material Č3840 has the maximum depth of the softened layer approximately 0.13 mm and surface softening of 18.3%. The least softening of the surface of 5.2% and the least depth of the softened layer of approximately 0.05mm was obtained from material specimen Č6980, whereas in the material specimen Č4770 the softening was 8.2%, and the HAZ depth approximately 0.12mm. In specimen of material Č4150 the grinding temperature at the very surface of the specimen caused the conversion of the residual austenite into the secondary martensite and thus hardening of 3.8%, but a little further from the grinding surface only the tempering of the primary martensite occurred, i.e. OTM generated, and this layer softened by approximately 7.7%. The total depth of the variable hardness layer is approximately 0.11mm. It may be noted that the percentage of the hardness change compared to the initial hardness and depth of the variable hardness layer are different in ground material specimens. This is understandable, since regardless of the fact that all the selected material specimens belong to the group of tool steels, according to 12,13,14 their chemical composition, microstructure, thermal-physical properties and behaviour during grinding certainly differ. In grinding of all material Influence of Grinding Prod. on the Burn Intensity of the Ground Surface 79 specimens at Qbr=6.85 mm3/s mm, the hardness of the surface layer of the ground area significantly changed and since depths of variable hardness layers are large, this grinding may be regarded as incorrect. In the fourth measurement in grinding the material specimens with maximum value of reduced material removal rate of Qbr=12.33 mm3/smm, (Figure 1d), again the hardness of the surface layer was reduced, i.e. the ground surface softened in materials Č3840, Č6980 and Č4770. The specimen material Č3840 has the highest percentage of surface layer softening of 25.7% and the greatest depth of the softened layer and the HAZ depth amount to approximately 0.14mm. Specimen material Č4770 has a lower percentage of softening 9%, and approximately same depth of the softened layer of 0.14mm, whereas specimen material Č6980 has the least percentage of softening 5.8% and the least depth of softened layer of approximately 0.07mm. Only in the material Č4150 the surface of the specimen hardened, since the hardness of the surface layer increased compared to the initial hardness by approximately 13.6%. The depth of the variable hardness layer is also quite large and amounts to approximately 0.1mm. Since in this measurement also the hardness of the surface layer hardness and the depth of the variable hardness layer changed significantly in all the material specimens, it may be concluded that the surface of the ground specimens in Figure 1d represents again an incorrect grinding process. This is confirmed by the study of the occurrence of thermal cracks on the ground surfaces of material specimens. The magnetic method using black particles has determined the presence of thermal cracks only in the third and fourth measurement, i.e. in grinding with the value of reduced material removal rate of Qbr=6.85 mm3/smm and Qbr=12.33 mm3/smm, and only on the surface of material specimen Č4150. Figure 2 shows the recorded thermal cracks on the ground surface of the material specimen Č4150 in the third and fourth measurement. Figure 2. Cracks on the material specimen Č 4150 ground at Qbr=6.85 mm3/smm and Qbr=12.33 mm3/smm. Figure 2 shows that the thermal cracks on the ground surface of the material specimen Č4150 are in fact perpendicular to the direction of grinding and have a form of a net. They tend to penetrate into the depth of the workpiece, and therefore are very dangerous and cannot be allowed in grinding. Only with material specimen Č4150 are 810 D.Ciglar; R.Cebalo; T.Udiljak Surface lightness interval 180 160 140 120 100 Č3840 80 60 40 20 0 3,425 6,85 100 90 80 70 60 50 40 30 20 10 0 Change of hardness, % thermal cracks understandable, since only this grinding surface hardened, shown by hardness measurements. Testing of thermal cracks has confirmed the inaccuracy of the grinding process of material specimen Č4150 in the third and fourth measurement, i.e. grinding with the value of reduced material removal rate of Q br=6.85 mm3/smm and Qbr=12.33 mm3/smm. Based on the results of previous measurements, the next four diagrams show for each material specimen the dependence of the burn intensity of the ground surface i.e. surface lightness interval and the change in hardness of the subsurface layer of the ground specimen on the value of the reduced material removal rate. The burn intensity of the ground surface is presented by the lower surface lightness interval value, and the change in hardness is determined with relation to the initial hardness and expressed in percentages. 12,33 3 Reduced material removal rate, mm /s mm 160 Č6980 Surface lightness interval 140 120 100 80 60 40 20 0 3,425 6,85 100 90 80 70 60 50 40 30 20 10 0 Change of hardness, % Diagram 1. Dependence of the surface lightness interval and the change of hardness on reduced material removal rate , Č3840. 12,33 3 Reduced material removal rate, mm /s mm Diagram 2. Dependence of the surface lightness interval and the change of hardness on reduced material removal rate , Č6980. 140 Č4150 Surface lightness interval 120 100 80 60 40 20 0 3,425 6,85 100 90 80 70 60 50 40 30 20 10 0 99 Change of hardness, % Influence of Grinding Prod. on the Burn Intensity of the Ground Surface 12,33 3 Reduced material removal rate, mm /s mm 160 Č4770 Surface lightness interval 140 120 100 80 60 40 20 0 3,425 6,85 100 90 80 70 60 50 40 30 20 10 0 Change of hardness, % Diagram 3. Dependence of the surface lightness interval and the change of hardness on reduced material removal rate , Č4150. 12,33 3 Reduced material removal rate, mm /s mm Diagram 4. Dependence of the surface lightness interval and the change of hardness on reduced material removal rate , Č4770. Diagrams 1 to 4 show that in all the material specimens the increase in the value of reduced material removal rate causes reduction in the lower surface lightness interval value, and increase in hardness change. Since the lower surface lightness interval value represents the burn intensity of the ground surface, this means that only in higher burn intensity of the ground surface of material specimens substantial change in the hardness of subsurface layer occurs, and also great depth of the variable hardness layer. In that case, the ground surface of the material specimen Č4150 shows also thermal cracks. It 1010 D.Ciglar; R.Cebalo; T.Udiljak has thus been confirmed that there is a dependence between the burn intensity of the ground surface and other grinding defects, so that the lower value of the surface lightness interval can determine the correctness of the grinding process and the approximate limited productivity, i.e. approximate value of the reduced material removal rate satisfying the quality of the ground surface. 4. CONCLUSION The results of research lead to the conclusion that the grinding process with low value of reduced material removal rate (low productivity), causes little surface burn of the material specimen, and high values of surface lightness interval. By substantial increase in the productivity of the grinding process, all the material specimens show greater burn, have darker surface and substantially lower lightness interval values. It may be concluded that the surface lightness interval matches well the burn intensity of the ground surface, since non-burned workpieces have greater value of the surface lightness interval, whereas lower value of the surface lightness interval describes a more burned ground surface of the material specimen. It may be further concluded that there is a significant dependence between the intensity of the ground surface burn and other grinding defects, since the results show that only in the case of greater burn of the ground surface is there substantial change in the hardness of the surface layer and large depth of the variable hardness layer, and in material specimen Č4150 it came even to thermal cracks on the ground surface. Finally, it may be concluded that ground surface lightness interval can be used to determine the correctness of the grinding process. That is, it may be concluded that there is a certain critical lightness interval of the ground surface and a critical burn of the ground surface on the basis of which the approximate limited productivity can be determined, up to which the grinding process is still correct. 5. LITERATURE [1] [2] [3] [4] [5] [6] M.Field, J.Kahles ; Rewiew of Surface Integrity of Machined Components, Annals of the CIRP Vol. 20/2/1971., str. 153-163. R. Cebalo, Suvremena tehnologija brušenja, Zadarska tiskara, Zagreb 1993. M. C. Shaw, A.Vyas, Heat Affected Zones in Grinding Steel, Annals of the CIRP Vol. 43/1/1994., str. 279 –282. International standard ISO 6507-3, first edition 11.01.1989. H. K. Tönshoff, E. Brinksmeier, Determination of the Mechanical and Thermal Influences on Machined Surfaces by Microhardness and Residual Stress Analysis, Annals of the CIRP Vol. 29/2/1980., str. 519 – 530. A. Gilardoni, A. Orsini, M. Tacconi, Gilardoni Handbook – Nondestructive Testing NDT, Gilardoni S.p.A., Mandello Lario (Como), Italy, 1981. Influence of Grinding Prod. on the Burn Intensity of the Ground Surface 119 [7] [8] [9] [10] [11] [12] [13] [14] O.Kubaschewski, B.E.Hopkins; Oxidation of Metals and Alloys, Butterworths, London, 1962. W.B.Rowe, S.C.E.Black, B.Mills, H.S.Qi, M.N.Morgan, Experimental Investigation of Heat Transfer in Grinding, Annals of the CIRP Vol. 44/1/1995., str. 329 – 332. D.Ciglar, Doktorat, Zagreb 1999. LECO 2001 Image Analysis System Operator’s Manual, Version 2.01, Kirchheim 1992. Katalog Swaty – Maribor Katalog Željezare Ravne Physical Constans of some commercial steels at elevated temperatures, The british iron and steel research association, Butterworths scientific publications, London 1953. Böhler – Edelstahlhanduch 2.0, Böhler – Edelstahl GMBH, 1989.