Datasheet

advertisement

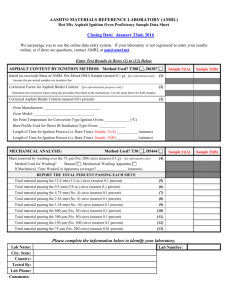

AMRL 2015 Asphalt Mixture Solvent Extraction Samples 83 and 84 Data Sheet Closing Date: January 7th, 2016 We encourage you to use the online data entry system. Or, you may fax 240-436-4899 or mail your data sheet to: John J. Malusky, AMRL 4441 Buckeystown Pike, Suite A, Frederick, MD 21704. If your laboratory is not registered to enter your results online, or if there are questions, contact AMRL at psp@amrl.net or call 240-4364900. Note Regarding the Samples: Be aware that samples 83(A) and 84(B) are not identical. Also, the outside of the box is labeled samples 83(A) and 84(B). The samples inside the box are labeled only (A) or (B). The sample labeled (A) is sample 83. The sample labeled (B) is sample 84. Enter Test Results in Rows (1) to (20) Below ASPHALT CONTENT: Select the Box to show the Method Used - T164 , D2172 , T319 Sample 83(A) Sample 84(B) Sample 83(A) Sample 84(B) Sample 83(A) Sample 84(B) Sample Mass, assume moisture free (nearest 0.1 g): for informational purposes only ...................................(1) Percent Asphalt (nearest 0.01 percent): ..........................................................................................................(2) MECHANICAL ANALYSIS: Select the Box to Show Method Used - T30 , D5444 Washing Method? Manual , Mechanical Washing Apparatus If Mechanical, Time Washed in Apparatus (average)?_____________ (minutes) Mass removed by washing over 75-μm (No. 200) sieve (nearest 0.1 g): for informational purposes only ....(3) REPORT THE TOTAL PERCENT PASSING EACH SIEVE: Total material passing the 12.5-mm (½ in.) sieve (nearest 0.1 percent) ..........................................................(4) Total material passing the 9.5-mm (3/8 in.) sieve (nearest 0.1 percent) ..........................................................(5) Total material passing the 4.75-mm (No. 4) sieve (nearest 0.1 percent)..........................................................(6) Total material passing the 2.36-mm (No. 8) sieve (nearest 0.1 percent)..........................................................(7) Total material passing the 1.18-mm (No. 16) sieve (nearest 0.1 percent)........................................................(8) Total material passing the 600-μm (No. 30) sieve (nearest 0.1 percent) .........................................................(9) Total material passing the 300-μm (No. 50) sieve (nearest 0.1 percent) .......................................................(10) Total material passing the 150-μm (No. 100) sieve (nearest 0.1 percent)......................................................(11) Total material passing the 75-μm (No. 200) sieve (nearest 0.01 percent)......................................................(12) (Item #12 includes: Mass removed by washing + Material in pan + Mineral matter + Increase in mass of filter) RECOVERY AND TESTING OF ASPHALT RESIDUE BY ABSON METHOD: Select the Box to Show the Method Used – R59 , D1856 Penetration of Residue at 25°C, 100 g, 5 s (nearest unit): Method Used? – T49 Kinematic Viscosity of Residue at 135°C (mm2/s, 4 sig. figures): Method? – T201 , D2170 ........ (14) Viscosity of Residue at 60°C (Pa·s, 4 sig. figures): Method? – T202 , D2171 ........ (15) G* / sin δ at 64°C tested as original binder (nearest 0.01 kPa): Method? – T315 , D7175 .........(16) BY ROTAVAPOR METHOD: , D5 Select the Box to Confirm the Method Used - D5404 Penetration of Residue at 25°C, 100 g, 5 s (nearest unit): Method Used? – T49 .......(13) , T319 , D5 ........(17) Method? – T201 , D2170 .........(18) Viscosity of Residue at 60°C (Pa·s, 4 sig. figures): Method? – T202 , D2171 .........(19) G* / sin δ at 64°C tested as original binder (nearest 0.01 kPa): Method? – T315 , D7175 .........(20) Kinematic Viscosity of Residue at 135°C (mm2/s, 4 sig. figures): Please complete the information below to identify your laboratory. Lab Name: City, State: Country: Tested By: Lab Phone: Comments: Lab Number: