263 - Tissue paper production from recovered paper

advertisement

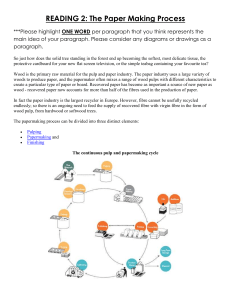

MANUFACTURING PROCESS OF TISSUE PAPER FROM RECOVERED PAPER Authors: Enma Pérez Chacón, Sebastián O. Pérez Báez, Juan A. Peña Quintana and Mª de la Concepción F. Ling Ling Dpto. de Ingeniería de Procesos - E.T.S.I.I. Universidad de Las Palmas de Gran Canaria. Abstract The aim of this paper is to design a plant in order to obtain tissue paper from recovered paper. Keywords: tissue paper, recovered paper, manufacturing process. 1. Introduction The great development of paper is due to the relationship utility/price that has allowed it to assert over other materials in several uses but, above all, to the fact that it is a natural, recyclable and biodegradable product, very important aspects in a society worried about the environmental damage and the maximum exploitation of the resources. The consumption of paper may be considered indicative of the growth rate of a country, as it is a product closely linked to culture, education, communication, commerce, transport, health and hygiene. Within the properties that allow to define paper, one of the most used is grammage, which is defined as the mass of the paper surface unity expressed in grams per square metres, this measure is very important because the regulation of the paper pulp in the machine depends on it. Besides, the paper trade is carried out in terms of this property. Among the numerous kinds of paper that exist in the market, there are the ones known as tissue, within which a wide range of low grammage sheets are included. The sanitary tissue, to which this paper refers, includes facial and toilet tissues, towels and paper napkins. Tissues are single-use products, which guarantees an optimum level of hygiene, The main functions of these types of paper are to protect, to absorb, to clean and to dry. In Spain, the consumption of this kind of paper in the year amounted to 513.600 tons, that confronted with the sum of 284.300 tons in 1996, it means an increase of 81%. With regard to the growing consumption of paper carried out by the society, it is necessary to have available big quantities of raw material that allow to satisfy the demand; this is the reason why it is important the recovery and reuse of the paper and corrugated cardboard wastes that are daily generated. 2. The sustainable cycle of paper All paper plants recover their own wastes and most of them, for many years, have had as a total or partial raw material the so-called old, recovered, used paper or simply scrap paper. Nowadays it is more frequent to refer to this raw material as secondary fibres. The interest for the use of recovered paper is due to several reasons: Economic reasons. The recovered paper used as raw material is generally cheaper. Lack of space in the landfills. Paper and corrugated cardboard are a very important constituent in the content of domestic rubbish : 50% in USA. 40% in Europe and, finally, 30% in Spain. The reuse of paper and corrugated cardboard wastes implies a reduction of the volume occupied in the landfills. Ecological reasons. The raw material for the paper industry is paper pulp that is generally obtained from the trees. Although the industry encourages the reforestation, some people have presented it as one of the main agents of its destruction. Motivated by this propaganda, some consumer groups wish to use recycled papers. Legal reasons. Due to the previous causes, some countries have included in their legislation the obligatoriness for some kinds of papers to be manufactured with, at least, a certain amount of recycled fibres. 3. The industrial paper sector in the Canary Islands According to the National Classification of Activities in 1993 (SNCA-93), the paper sector is divided into two big groups: a) Paper industry (SNCA 21), which is subdivided into: Manufacturing of paper pulp, paper and corrugated cardboard. Manufacturing (transformation) of paper and corrugated cardboard articles. b) Edition, graphic arts and reproduction of engraved base (SNCA 22), that comprises: Edition of books, magazines, newspapers, etc. Printing, binding, etc.. Due to the differences that exist between industrial processes, as well as their settlement in the Canary Islands, these are going to be classified into three different groups: Manufacturing of paper and corrugated cardboard. Transformation of paper and corrugated cardboard. Graph arts. According to what has been published by the Canarian Government, through its Consejería de Política Territorial y Medio Ambiente (Territorial policy and Environment), among all of them, only the two last groups are present in the archipelagoThe sector of pulp and paper manufacturing is inexistent in the Canary Islands, this is an aspect that has to be considered from the point of view of wastes generation and management because the absence of this type of installations blocks the possibility of carrying out a local recycling process of recovered paper that has to be exported to the mainland or to the international market. This is the reason why, in this paper, it is proposed the design of a plant for manufacturing tissue paper from a raw material totally composed by recycled material. The selection of the type of paper that is going to be manufactured has been based on the study of the figures of importation to the Canary Islands, and according to these data, tissue paper is the kind of paper whose importation implies the greatest expenses to the archipelago. This proposal pretends to pay special attention in evaluating the possibility for producing tissue paper within the framework of respect to the environment, that is to say, obtaining it only from recycled material, with a minimizing of water and energy consumption, as well as the optimisation of the waste management, not only for reducing them, but also to integrate them in the adequate or reusing circuits. This last objective is reinforced by the European Directive 1999/31 about waste disposal and its statal application through Decree 1481/2001, in which is included the need for avoiding valuable wastes to arrive at landfills starting from this present year. The manufacturing process of tissue paper from scrap paper includes a series of stages. It is fundamental for paper fibres to be recovered without any damage, so that the physical, chemical and optical qualities will be equivalent to those present in the paper obtained from virgin fibres. The manufacturing of tissue paper and, in general, of any kind of paper can be divided into three main stages: Pulp preparation Paper preparation Handling or converting In this paper, it has been chosen to integrate jointly pulp and paper preparation. The first one includes the pulp preparation circuit: its aim is to obtain a homogeneous pulp with characteristics adequate for the paper desired to be obtained as product. The main objectives of this first stage are raw material purification and pulp whitening. These operations are always carried out trying to obtain the maximum recovery and reuse of the process water and the thickening of the generated rejections. 4.- Process effluent treatment In the development of the recycling process of paper in order to obtain tissue paper, two main objectives are necessary to take into account: firstly, losses have to be minimized and, secondly, the plant effluents have to be treated in order to keep the environmental impact to a minimum and, above all, non-polluting. All the operations whose purpose is to close the process will produce a double benefit: a more efficient use of the resources and a reduction of the polluting charge. So, the most effective way to reduce losses is the recirculation and reuse of the waters. Despite the fact that the internal installations of the process water treatment are taken into account in the pulp preparation section as well as in the paper preparation one, it is considered necessary the installation of a sedimentation stage of the waters in order to allow, on the one hand, the maximum amount of treated water to incorporate again to the process so that the water cycle will be closed to a maximum, thus, optimising the consumption of fresh water and, on the other hand, the optimisation of the unavoidable waste with a maximum respect to the environment. The pollutants present in the effluent of the paper recycling plant come fundamentally from the additives that the raw material contains, that is to say, the recovered paper. The additives are normally non-fibrous in their manufacture in order to give the product the characteristics that it must show; it is used additives such as alumina, gluing agents, mineral charges, starches and colourings. These are extracted from the manufacturing process through the water, thus generating the suspended solids and the BOD typical of the effluent. The additives mostly used in the paper industry, Table I, constitute the process water pollutants of the recycling process. Table I., Additives mostly used in the paper industry Additive Application Alumina To control pH, to fix additives on the fibers, to increase retention Gluing agents (resins) To control penetration of liquids Dry resistance agents To communicate rigidity and tearing resistance (starches) Humidity resistance To communicate humidity resistance (wipes) resins Charges (kaolin, talc) To improve optical and printing properties Colouring matters To give the desired colour (colourings, pigments) Retention aids To improve retention of fines and charges Fibre deflocculants To improve sheet formation Antifoaming agents To improve drainage and sheet formation Drainage aids To increase drainage on the fabric Optical whiteners To improve the apparent whiteness The gluing process is applied to a great amount of paper types in order to give resistance to the penetration of fluids. Starches, which are the gluing agents par excellence, are glucose polymers that are obtained from different plants; these are the main cause of the characteristic BOD of the effluent. Charges are finely divided white mineral particles that are added to the paper manufacturing compositions in order to improve the physical and optical properties of the sheet. Nearly all the colourings used in the paper industry are organic compounds (minerals are not frequent), that are rarely eliminated from paper; which is carried out in the whitening process is a change of colour in them by varying the bonds between carbons through oxidation. It is considered a press to reduce the humidity of the rejections before carrying them to the landfill sites and a clarifier to reduce the content of suspended solids of waters before disposing them to the sewerage system of the industrial area. Thus, in this case, it has been chosen to include only the physical-chemical treatment (primary) of the purifying plant that usually comes with every paper industry. It has to be pointed out that, although the design of an entire wastewater plant would have been a better solution, it has not been considered within this project because it is not included in its goals. The primary treatment will consist in a settling process that, apart from separating the suspended particles which are heavier than water by gravity action (and a small part of BOD), will allow to obtain a sludge with such a solids concentration that it could be handled and treated easily. Although flotation by dissolved air is other alternative for the primary treatment, it has been chosen the sedimentation by gravity because of the advantages that it shows: it is relatively insensitive to the variations of flow and solids concentration, it needs little attention and maintenance and its operation presents a low cost. In the circuit of pulp preparation, it is carried out all the different operations that are going to produce a homogeneous pulp with adequate characteristics. The main objectives for this first stage are the purification of the raw material (separation and elimination of the ink and the rest of pollutants from the fibres) and the whitening of the pulp. These operations are carried out with the maximum recovery and reuse of the process water and the adequate thickening of the generated rejections. Three stages of purification allow the separation of the impurities from the pulp. The first stage consists in a centrifugal purification of the thick pulp where the pollutants with a bigger specific weight are separated by leaving them after the first vast purification realized in the disintegration system. The second stage is a purification by holes and slots at a lesser consistency in which the polluting particles are classified by their shape, eliminating those with flat shape (purification by holes) and those with three-dimensional shape (purification by slots). Finally, the centrifugal purification will be in charge of separating the impurities of small size according to their specific weight. The first stage has a great separation efficiency; it is the rejection of each one which passes to the following stage, while the accepted part goes back to the previous stage. The deinking process is fundamentally carried out through the flotation mechanism as it shows a water consumption much lesser than the washing method, in the same way that an efficiency between 80-95% and greater potential capacity to reduce the content of sticky substances originated by adhesive products nonsoluble in water. Nevertheless, they pass with the part accepted in the previous stages of purification and this is the reason why a dispersion stage is added before the whitening. With all these disposal stages, it is assured adequate separation efficiencies that guarantee the correct operation of the paper machine. The chemical products used are alkali, oxidant agents and a tensoactive agent such as a sodium soap or a synthetic detergent whose purpose is to carry out two functions: one as a foaming product, and the other one as a collector. The rejections of the deinking plant are constituted by charges, fibres, fines and inks into equal parts. This rejection is discharged as an alkaline effluent, pH between 8,5 and 10, with some features such as: suspended solids: 1000-4000 mg/L; BOD5: 10 kg/ton (500-600 mg/L); COD: 23 kg/ton (1100-1600 mg/L). The total amount of wastes that are generated throughout the manufacturing process of cellulose and paper is classified in the European Catalogue of Wastes (ECW) as nonhazardous. The management policy of the sector with respect to the process wastes consists, firstly, in its minimization through the quality control of the raw material and improvements in the manufacturing process and, secondly, in its recycling or energetic valorisation. The average rate of generation of deinking sludges is of 20% in solid matter on recovered paper used as a raw material and a ratio of 25% in solid matter on the obtained product. There are different ways to valorise the deinking sludges that maintain a common objective: to convert the wastes in resources. This is the reason why it is applied several techniques and wastes management lines in agricultural sectors, in the industry as a raw material or alternative fuel, (ceramic and cement sectors), as in the energetic valorisation. References ASOCIACION NACIONAL DE FABRICANTES DE PASTA, PAPEL Y CARTÓN (ASPAPEL), Informe medioambiental. 2002. El ciclo sostenible del papel ASOCIACIÓN ESPAÑOLA DE NORMALIZACIÓN Y CERTIFICACIÓN (AENOR) UNE-EN-643 2002 AEPO Ingenieros consultores S.A. y Trazas Ingeniería S.L. 2001. Estudio de composición y caraterización de las basuras urbanas en la Comunidad Autónoma de Canarias Instituto Canario de Estadística (ISTAC) www.istac.rcanaria.es Plan Integral de residuos de Canarias. Decreto 161/2001. Viceconsejería de Medio Ambiente del Gobierno de Canarias McKinney , R.W,J, 1995. Technology of paper recycling. Chapman and Hall Smook, G.A. 1990. Manual para técnicos de pulpa y papel. Tappi Press García Hortal, J.A. 2001 Fundamentos del destintato por flotación (I). Condiciones químicas. Ingeniería Química García Hortal, J.A. 2001. Fundamentos del destintado por flotación (II). Proceso de destintado. Ingeniería Química Colom Pastor, J.F. y Torres López A.L. 1992. El destintado del papel. Escuela Técnica Superior de Ingenieros Industriales de Tarrasa. Universidad Politécnica de Cataluña Celulosa e papel. Tecnología de fabricación del papel Vol. II 1998. Deparatamento de divulgación de IPT