Supplementary Information

advertisement

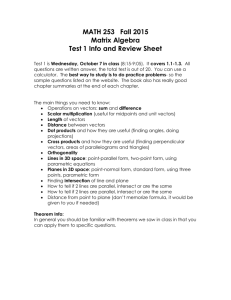

Supplementary Information Far-field super-resolution imaging using near-field illumination by micro-fiber Xiang Hao, Xu Liu*, Cuifang Kuang, Yanghui Li,Yulong Ku, Haijun Zhang, Haifeng Li and Limin Tong State Key Laboratory of Modern Optical Instrumentation, Zhejiang University, Hangzhou 310027, China In the supplementary information material, we provide further explanation on the experimental method and conditions, such as the preparation of the micro-fiber and samples, and the theoretical model, which will provide a deeper insight on the concepts mentioned in the main text. 1. Preparation of microfiber The fabrication of microfiber is simple but needs special cares. The fiber with a micro-diameter (Figure S1) can be fabricated using a flame-heated taper drawing of a standard commercial single-mode fiber. The protective layers of the fiber are peeled off in advance to avoid carbonization and unexpected fracture during heating, while only the core and cladding layers are reserved. A temperature slightly above the melting temperature is required for drawing, so the flame of an alcohol lamp is sufficient; however, turbulence and convection should be carefully avoided to maintain a comparatively uniform temperature in the drawing region. The drawing speed is approximately 10 mm/s during the whole process until the occurrence of a tensile fracture. Thereafter, a very smooth taper transition with a tip diameter of approximately 1 μm will be generated. It should be emphasized that in the experiment, the taper transition below 4 μm cannot exceed 250 μm in length. Otherwise, the tip will be too soft to be 1 positioned accurately. Subsequently, hydrophobic surface treatment, although not strictly essential, is highly recommended to avoid the adhesion phenomenon and improve the movement precision, especially when the sample surface is hydrophilic, e.g., metallic surfaces. Figure S1. 100X microscopic image of microfiber. 2. Preparation of samples Focus Ion Beam (FIB) is an ideal technique to fabricate patterns with sub-wavelength details. It is capable of fabricating nearly all types of materials with a smooth surface. However, extreme attention should be paid when the fabricated material is soft, such as ITO. When a soft substrate is utilized, many problems occur, including a change in the chemical properties and the damage to the surface roughness. However, the most apparent phenomenon observed will be the redeposition of the sample material (Figure S2a), which will become more severe when the milling depth is increased. Although repeated milling will weaken the extent of redeposition, the milling line width will be extended. To attenuate the corresponding damages, an easy solution is to decrease the fabrication current (Figure S2b) which in turn reduces the partial temperature and electron scattering, resulting in limited redeposition, but at the expense of fabrication time. Figure S2. The same pattern “E” etched using different fabrication currents. (a) 5 pA and (b) 1 pA. The FIB system we use is Carl Zeiss Auriga®, Germany, and the fabrication voltage is 30 kV. 2 Furthermore, FIB may face bottlenecks when preparing patterns on highly insulating substrates, for instance, on silica (SiO2). The non-conductive material can significantly enhance electron scattering and makes both imaging and milling inaccurate or even impossible (Figure S3a). To reduce the scattering, a secondary, low energy electron flood gun can be used to provide charge neutralization. If it is difficult to transform the original FIB system, a conductive surface coating, as would be required in a scanning electron microscope (SEM), will be a more economical option. However, in this method, a larger milling depth is required, and the conductive layer should be peeled off upon completion of the FIB fabrication. Figure S3b shows the sample we milled on silica. The material of conductive layer is Cr, with a thickness of 35 nm. The milling depth using the FIB is approximately 100 nm. The chromium etchant we use is CR-7 (9% (NH4)2Ce(No3)6 + 6% HClO4 + 85% H2O) from Cyantek, USA. Figure S3. SEM image of patterns fabricated on insulating substrates. The line pairs directly etched on silica (a) without and (b) with conducting surface coating. It is apparent that conducting surface coating will significantly enhance the performance of FIB when the sample is non-conductive. 3. Selection of laser source At least two facts should be carefully considered when the working wavelength of the laser source is selected. First, the spatial frequency needs to be able to shift back to the propagation domain of optical system. This requires the following inequality to be satisfied, Nk km Nk km k0 , where k0 is the n n wave vector of the working wavelength. Furthermore, the possible values of N should be unique to a specific kΛ; otherwise, a single kΛ will correspond to two different frequencies in the image, which will brings additional chaos in the final image generated. In practice, N = 1 is always considered in advance, because it is simpler in mathematical description, while the signal collected at this diffraction order is comparatively stronger. Furthermore, the wave vector band can also achieve “one-to-one” conversion, which is essential in an imaging system. As claimed in the main text, N = 1 can be expected when 3 (km ke ) 2 k km ke . For the frequency (or wave vector) conversion to be in a controllable fashion, i.e., a “one-to-one” conversion, it is necessary to pre-estimate the frequency scale of sample. In the experiment, surface contamination causes the most evident problem that deteriorates the quality of image, and the problem is more serious when the coherence of the probing light is too high. On the other hand, the light radiated by a super-continuum laser source is non-polarized with a broadband; hence, it is more convenient to introduce the super-continuum laser source in the experimental system. 4. The system The system we built to realize the hypothesis uses a Nikon Eclipse® i80 multi-functional optical microscope, Japan, with a 100X, NA = 0.8 objective lens (Figure S4). The microfiber is a flame-heated taper drawing of a commercial single-mode fiber (Newport F-SV-C, USA), whose operation and cut-off wavelengths are 633 nm and 500~600 nm, respectively. The broader end of the fiber is fastened to a piezoelectric positioning stage (Thorlabs MAX311/M, USA), such that the position of fiber can be controlled with high precision, while the tip adheres to the surface of the sample for detection. To decrease the coherence of the source, the broadband illumination light coupled into the fiber is obtained from a supercontinuum laser source (Fianium FemtoPower 1060, UK), while a 500~800 nm bandpass filter is inserted in the optical path. The CCD we use to record the image is Nikon Ds-Ri1, Japan. 4 Figure S4. System photo in the experiment. 5. Visual image formation Although the image can be directly observed and confirmed from the experiment, the formation of the visual image is still confusing unless the physical mechanism can be explained theoretically. A qualitative strategy, which has already been used in Ref. [16] of the main text to describe the imaging process of a microsphere super lens, is ray tracing of Poynting vectors. Specifically, the visual image is generated if the Poynting vectors are reversely extended. Based on the simulation by FDTD Solutions (Lumerical Solutions, Inc.), the energy flow can precisely be calculated, as shown in Figure S5a. Except the image above the micro-fiber can directly be simulated (Figure S5b), the images at and below the sample surface will be the results of reverse ray tracing and thus be the visual ones (Figure S5c~d). The reason for this phenomenon is that the image observed by the CCD is actually the far-field projection of light power instead of actual intensity distribution at the same position. Any interface in the propagation path will inevitably change the directions of Poynting vectors. Therefore, the existence of micro-fiber makes the images at and below the sample’s surface visual. Furthermore, what is similar to geometrical optics, the best imaging plane is defined as the position where the Poynting vectors from the same 5 object point are re-concentric. As the Poynting vectors escaping from the micro-fiber are divergent in the free space, the Poynting vectors can interact only when they are reversely extended. Hence, it is not surprising that the best image is virtual, and the position will be located below the sample’ surface. Figure S5e~g are the images captured at the same positions in practical experiment, which accord well with the theoretical prediction. Figure S5. Ray tracing of Poynting vectors of our method. (a) Theory of visual image formation. (b)~(d) are the numerical simulation results of the images observed (b) above, (c) at and (d) below the sample’s surface, while (e)~(g) are the corresponding images captured at the same positions in practical experiment. 6. Magnification factor of visual image There is undoubtedly a magnification in the visual image of sample as compared to the original pattern of the sample. The total magnification factor stems from both the geometric and spatial frequency magnification, and can be expressed as M M g M f M1 M 2 M f (1) where M1 and M2 are the geometric magnification factors of the objective lens and the microfiber (the microfiber can be considered as a cylindrical lens), respectively. M f out k is used to describe kout the spatial frequency magnification. 7. Contrast of visual image In the practical system, the quality of the final image, especially the resolution and contrast, will be significantly influenced by many aspects. As mentioned earlier, a larger refractive index of the 6 microfiber can convert a higher spatial frequency to the propagation one, which will result in a theoretically better resolution capacity. Some materials are indeed transparent in the visible spectrum while possessing a ultra-high refractive index, such as TiO2 with n 2.4 . However, it should be noted that the refractive index cannot be infinitely increased to pursue higher resolution, nor is it realistic to achieve a larger viewing field by increasing the diameter of the microfiber. The electromagnetic field distribution in any optical fibers can be explicitly derived by Maxwell’s equations1. Due to the high numerical aperture of nano/microfiber, vectorial models are required to precisely calculate the corresponding mode properties. The eigenvalue equations can thus be written as2 m2 [ 1 1 n2 1 1 J 'm (U ) 1 K 'm (W ) n 2 J 'm (U ) K 'm (W ) ][ ] [ ][ ] U2 W2 U2 W2 U J m (U ) W K m (W ) UJ m (U ) WK m (W ) (2) where m is the mode number, U 2 (k 2 n2 2 )a 2 , W 2 ( 2 k 2 )a 2 , a is the radius of the core, and J and K are two kinds of Bessel functions. A microfiber with a fundamental field mode is presented in Figure S6a. The analysis becomes more complex when the microfiber is adjacent to the substrate, because the coupling effect will strongly influence the field distribution. In this situation, the properties of the substrate, including the refractive index and surface roughness, will be significant factors that need to be considered. It does not seem be possible to derive an analytical expression to describe such a field; however, the numerical method, such as finite-difference time-domain (FDTD) algorithm3, is still useful to calculate the power distribution, as shown in Figure S6b. Figure S6. Power distribution (Poynting vectors) in the cross section of a microfiber. (a) The fundamental mode power distribution in a microfiber. (b) The power distribution of the same microfiber when it deposit on the substrate. Compared to the fundamental mode, the position of peak power is slightly lower, while more power is coupled out into the substrate. 7 It is conceivable to claim that the magnitude of the intensity of the evanescent field will be proportional to the contrast of the image. Hence, even when the possible chromatic dispersion and material absorption followed with a high refractive index are deliberately ignored, the quality of image will still deteriorate owing to the reduction in contrast when the refractive index increases. This phenomenon can be ascribed to a lower fractional power of evanescent filed. We define the ratio parameter as a 0 Sd A (3) Sd A where S E H is a Poynting vector, and a is the diameter of microfiber. The corresponding trend is shown in Figure S7a. The ratio parameter will decrease drastically with a larger refractive index and/or with a larger diameter size. This can also be confirmed experimentally. When the same Blu-ray disk chip is observed, the contrast values are 0.69 (Figure S7b) and 0.33 (Figure S7c) when the 2.5 μm microfibers are SiO2 ( n 1.5 ) and ZnO ( n 1.9 ), respectively. Here, the contrast is defined as contrast I max I min I max I min (4) where Imax and Imin are the maximal and minimal intensity values, respectively. The evanescent field can also be considerably strengthened by shrinking the diameter of microfiber, but the corresponding decrease in the viewing field will make the observation difficult. It is noteworthy to mention that although a much wider viewing field can be expected by using solid immersion lens (SIL), the contrast will be no better than 0.15 (Figure S7d), which makes the actual resolution lower than the theoretical one. 8 Figure S7. Contrast analysis of microfiber based super-resolution imaging and comparison with SID. (a) The ratio of evanescence vs. the diameter of microfiber. (b~d) The image of blu-ray disk generated by (b) SiO2 microfiber, (c) ZnO microfiber and (d) SIL, respectively. 8. Vector composition For the vectors ke , k and kout , Figure 1, in fact, only shows the simplest situation, that with all vectors along the same direction. When the directions are different, kout can only be calculated by the vector composition rule, as sketched in Figure S8. However, no matter how the vectors are composited, | k || km || kout | should be a premise, if super-resolution is expected. In the typical case when ke and k are perpendicular, | kout | | ke |2 | N k |2 | k | , super-resolution cannot be realized. Hence, for the method proposed here, the micro-fiber must scan along at least two perpendicular directions to generate a complete image in the focal plane. Figure S8. Vector composition if super-resolution can be expected. 9 It should also be noted that when ke and k point to diverse directions, kout will not be parallel to either of them; hence, it is possible that the directly observed image by the micro-fiber is different from the original sample. Even when all the vectors are parallel, it would be necessary to consider a continuous series of frequencies when the sample is complex. In this situation, a part of the frequencies may fail to convert to the propagation mode, which results in the loss of details. Although the whole series of frequencies can be converted, the magnification factors will be different with diverse original frequencies. Hence, the image directly observed by the micro-fiber will be disordered, which illustrates that a digital process is required to reconstruct the true image. Figure S9. Frequency conversion when a continuous series of frequencies is considered. It is believed that in this situation, more complex digital process is required to reconstruct the true image, because (a) the frequency may partially be converted outside the propagation mode, and (b) the magnification factors will be different with diverse original frequencies, which will result in the chaos of directly observed image. 9. Comparison among our method, SIL and oil immersion objective It is an illusion that our method, SIL and oil immersion objective share the similar physical mechanisms. The oil/solid immersion based approaches cannot fundamentally break the diffractive barrier. They achieve a higher resolution just by increasing the NA of system. Therefore, the Abbe formulae 0.61λ/NA will be the theoretical limit for oil/solid immersion. Our method, on the other hand, is based on the near-field and frequency shift; hence, so the theoretical limit can be below 100 nm even when the illumination light is within the visible spectrum. The most convincing witness to support this argument can only be the experiment. We use the oil immersion objective, solid immersion lens (SIL), and our microfiber to observe the same sample. The 10 sample is the line pairs etched on the Si substrate, which we have already used in the experiment illustrated in our main text. The other devices we use are as follows: In the oil immersion objective system: ----------------Microscope: Olympus IX71; Objective: Olympus UPlanSApo 100×/1.4NA oil CCD: Andor iXon3; illumination source: white light with 500~800 nm filter ----------------In the SIL system: ----------------Microscope: Nikon eclipse i80; Objective: Nikon 100×/0.8NA CCD: Nikon Ds-Ri1; illumination source: white light with 500~800 nm filter SIL: Edmund Optics S-LAH79 Lens (Diameter: 2mm, refractive index: 2.0) ----------------The result of the comparison is shown in Figure S10. For both oil immersion objective and SIL, the smallest gap that can be discerned will be approximately 150 nm, while our method can obtain the detail even when the width of the gap is 75 nm, as claimed in our main text. Furthermore, the differences in the mechanisms can indirectly influence the image generated. For the oil immersion objective and SIL, the line pairs present as the “dark stripes”, while by our method, the line pairs are bright, surrounded by the black background. 11 Figure S10. Experimental images of the same samples using FIB/SEM, our method, SIL and oil immersion objective, respectively. The gap between the line pairs are illustrated above, while the line width is maintained as 150 nm. Our method can discern detail of approximately 75 nm; however, for SIL and oil immersion objective, the resolution limits will be approximately 150 nm, although mediums with larger refractive indexes are used. REFERENCES 1 A. W. Snyder and J. D. Love, Optical waveguide theory. (Chapman & Hall, New York, 1983). 2 L. Tong, J. Lou, and E. Mazur, Opt. Express 12 (6), 1025 (2004). 3 F. X. Gu, H. K. Yu, P. Wang, Z. Y. Yang, and L. M. Tong, Acs Nano 4 (9), 5332 (2010). 12