Results interpretati..

advertisement

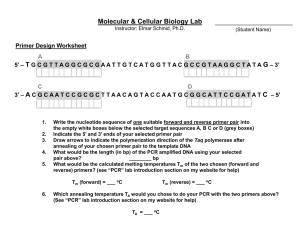

Assay Optimization and Results Interpretation Assay Optimization FFPE DNA EXTRACTION A lot of FFPE protocols have an incubation step at elevated temperatures after the Proteinase K incubation step. This is usually a salt solution at around 95 degrees for about an hour or so. This extra step helps to reverse formalin cross-linking. By reducing the cross-linking, you will get better amplifications and less “degradation”. It is recommended to use Qiagen’s QIAmp FFPE extraction kit, or at least incorporate that extra step. BISULFITE TREATMENT KIT If conversion efficiency is a problem, do not use the “fast” (ie, the Zymo Gold kit) protocols. Qiagen’s Epitect Bisulfite treatment kit not only has excellent conversion efficiency, but also has a stabilization buffer that will protect your bisulfite treated DNA from becoming further fragmented after the treatment. Using this kit, you should be able to retain your BS treated DNA for at least a year before doing the PCR. CONTROLS Always optimize your assays with well-characterized controls. For SNP assays, run several controls of known genotypes and ensure that the Pyrosequencer calls the correct genotype For Quantitative assays, you should perform a “mixing study” during optimization. Mix samples that are as close to 100% of each allele as possible in varying proportions, and run them on the Pyrosequencer to determine the sensitivity of the assay at each site. Qiagen sells excellent universally methylated and unmethylated DNA controls for this purpose. You should get at least 5% sensitivity with a well-designed assay. If you are not getting these results, here are some resources: Optimizing annealing temperature overcomes bias in bisulfite PCR methylation analysis Jean-Pierre J. Issa,Saira Ahmed,Xinli Chen,Yi Guo,Lanlan Shen 10.2144/000112312 BioTechniques, Vol. 42, No. 1, January 2007, pp. 48–58 http://www1.qiagen.com/Products/PyroMarkPCRKit.aspx Controls to run for a new Pyrosequencing assay None of these samples should have peaks in the Pyrogram 1. Template only control-Tests for template loop structures 2. –ve PCR control (i.e. water)-tests for contamination 3. Sequencing primer-tests for sequencing primer dimers 4. Biotinylated Primer-tests for biotinylated primer dimers 5. Sequencing + Biotinylated Primers-tests for interactions between the SP and biotinylated primer 1. Should be a normal PCR product but in the Pyrosequencing plate just put annealing buffer, no Sequencing Primer. 2. Should be a water PCR control which should be processed as a normal sample. NOTE: It is highly advisable to run your No Template Control on each Pyrosequencing reaction. This can be used to check for contamination. On top of this, you will be able to assess nucleotide degradation in the NTC. When a nucleotide begins to degrade, one of the byproducts is Pyrophosphate, which will cause a light peak at each dispensation of that nucleotide, regardless of any incorporation into the growing strand. B7: YGTTTGTYGGTYGTTTTTYGTTTAAAAGGYGGTAAGGAGTYG 54% N/A N/A N/A N/A N/A 2 0 -2 -4 -6 E S G T C G T A 5 G T C A 10 G T C A G 15 T T C G T 20 A A T G T 25 C G T A G A T G T 30 C 35 3. Should have nothing in the PCR plate and Sequencing primer in annealing buffer in the Pyrosequencing plate For MA/ID 1.5uL of 10uM Sequencing primer + 38.5uL Annealing buffer. For HS/MD 0.5uL of 10uM Sequencing primer + 11.5uL Annealing buffer. For Q24 0.75uL of 10uM Sequencing primer + 24.25uL Annealing buffer. 4. Should have nothing in the PCR plate and Biotinylated PCR primer in annealing buffer in the Pyrosequencing plate For MA/ID 1.5uL of 10uM Biotinylated primer + 38.5uL Annealing buffer. For HS/MD 0.5uL of 10uM Biotinylated primer + 11.5uL Annealing buffer. For Q24 0.75uL of 10uM Biotinylated primer + 24.25uL Annealing buffer. 5. Should have nothing in the PCR plate and Sequencing primer + Biotinylated PCR primer in annealing buffer in the Pyrosequencing plate. For MA/ID 1.5uL of 10uM Sequencing primer + 1.5uL of 10uM Biotinylated primer + 37uL Annealing buffer. For HS/MD 0.5uL of 10uM Sequencing primer + 0.5uL of 10uM Biotinylated primer 11uL Annealing buffer. For Q24 0.75uL of 10uM Sequencing primer + 0.75uL of 10uM Biotinylated primer + 23.5uL Annealing buffer) All of these controls should be heated to 80°C and run on the instrument as ‘normal’ samples. Results Interpretation In general, passed results are acceptable. If your results score “Check” or “Fail”, 1. Refer to the “Warnings” in the “Well Information” section to the right of the screen for more details. 2. Right-click the Pyrogram, and choose “Show Histogram” to overlay the theoretical histogram onto the Pyrogram. 3. Right-click the Pyrogram, and choose “Show Reference Peaks”. Typical Warnings “Failed Reference Sequence at Dispensation X” There are times when one particular reference peak will cause background, but this does not effect the variable dispensations or the results of the Pyrosequencing reaction. Assay-Specific Problems-problem peaks can be turned off or modified in the Assay portion of the software, so that the software will analyze each subsequent run with the same parameters. 6 5 4 3 2 1 0 G T C G T G A T A G T C G A T A T G T C G T T G A T T C A G T C G A T G T C A G T C 5 10 15 20 A1: YGT TGGATGYGGATTAGGGYGTTTTTTATTTTYGTYGGGAGTTYGTYG 1% 1% 25 2% 30 3% 35 1% 40 1% 1% 600 500 400 300 200 100 0 E S G T C G T 5 G A T A G T 10 C G A T 15 A T G T C 20 G T T G A 25 T T C A G 30 T C G A T G 35 T C A G T C 40 Dispensation 35 shows a non-specific peak in every sample ran on this assay. Note two things about the reaction. First, all the other reference peaks are concordant with the theoretical histogram. Secondly, the methylation levels are as expected based on mixing studies, and that the levels are relatively the same as the surrounding methylation sites. Therefore, you can be confident that the background peak in dispensation 35 is not affecting the results in the CpG site. You can safely turn off the reference peak at dispensation 35. Click on the blue diamond above the peak to turn it off. I would try not to turn off more than 1 reference peak per CpG site. The software prefers to have ~6 good reference peaks on either side of the variable position, but one less is ok. “Possible Dispensation Error at dispensation X” This error shows up when there is a “shoulder” on the peak. If the nucleotide droplet does not go directly into the well, you may see this. This usually seen more often when the tips are nearing the end of their useful lives, so changing out the tips can usually get rid of most of these errors. It is not uncommon to see ~1-2 dispensation errors/96 well plate. Use of NDTs instead of CDTs has been shown to reduce the number of dispensation errors slightly, because the liquid droplets are much smaller. However, NDTs are much more difficult to keep from clogging completely, and their useful life is much shorter in general than CDTs. "Uncertain due to low signal to noise ratio (overall)." If you were to zoom in on a “negative dispensation”, you would see that the baseline has some variation. If your signal is too small, the ratio of this variation to your signal could end up looking like real methylation, or failed bisulfite conversion. The easiest way to get higher sensitivity is to increase the peak heights. You want your singlebase reference signal to be at least 100RLU’s, preferably 150-200 for an HS system; at least 40 RLUs, preferably 50-70 RLUs for a Q24 system. You can have the software flag any sample below a certain threshold by editing the Peak Height Threshold in the Analysis Parameters. Low signal is usually caused by using too little PCR product. You can add more PCR product to the reaction to increase the signal. The total volume of Binding Buffer, Beads, Water and PCR product should be 80ul. If you add more amplicon, decrease the water. The PyroMark PCR kit was optimized to amplify Pyrosequencing targets at the greatest efficiency. "Uncertain reference sequence pattern(overall)" This is a serious warning, and is usually caused by secondary structure in the reaction. If the reference pattern is completely off, you are probably not interrogating the correct sequence. If this warning occurs in all samples, you probably need to redesign the assay. "Uncertain due to high CpG pattern deviation" or "....CpG sum deviation". The sum deviation and pattern deviation warnings are very severe, because they are problems with the CpG site itself. There is a little information in the help section of the software: The stringency of the warnings for CpG pattern deviation and CpG sum Stringency deviation can be set to Low, Normal (default) or High. A high stringency level Levels narrows the allowed deviation. CpG pattern The deviation between the measured peak pattern in the CpG site and the deviation theoretical peak pattern of the determined methylation. CpG sum deviation If the deviation is higher than the set stringency level allows, the warning Uncertain/Failed due to high CpG pattern deviation is triggered during the analysis. Whether the warning will yield a Check or Failed quality assessment for the CpG result, depends on the magnitude of the deviation. The deviation between the measured sum of all the peaks in the CpG site and the theoretical sum (based on the single peak height). If the deviation is higher than the stringency level allows, the warning Uncertain/Failed due to high CpG sum deviation is triggered during the analysis. Whether the warning will yield a Check or Failed quality assessment for the CpG result, depends on the magnitude of the deviation. The stringency levels are adjustable, and depend on how accurate you need to be with your calls. If you are just looking for large methylation changes, you can set the stringency a little lower. BISULFITE CONVERSION CONTROLS You may have several possible sites in which you can set a control for bisulfite conversion. You want to determine which site is most accurate, and turn the other sites into regular reference peaks. Your methylated and unmethylated control mixing study will give you an idea of which bisulfite controls are most accurate. Also remember that not all Ts that are flagged are possible bisulfite controls. You need to check the Genomic sequence to make sure that the T was a C prior to bisulfite treatment. The software calculates the bisulfite conversion quality by taking the ratio of the peak in bisulfite conversion position to the average single-base reference peak. At the Analysis setup tab, under Analysis Parameters, you will see that if that value is between 4.5% and 7%, the software will score the sample as “Check”, and if it is greater than 7%, it will score the sample as “Fail”. If your bisulfite conversion control is failing, you should first determine why. Sometimes it is not completely due to the bisulfite conversion, but more due to the dispensation order and sequence in that region. Homopolymers, genomic sequence, and background Bisulfite controls that are part of homopolymers may be less accurate than others. For instance, let’s take two theoretical genomic sequences, TTTC and CCCC. For simplicity’s sake, let’s say our single-base reference peak is 100RLUs. The fully converted sequence should have a 400RLU peak at the T dispensation and 0RLU peak at the C dispensation. But say you had 90% conversion: For TTTC, you would have a T peak around 390 and a C peak at 10. This would show up as 10% conversion failure But for CCCC, the T peak would be 360, and the C peak would be 40. This would show up as 40% conversion failure (Remember-ratio of the peak in bisulfite conversion position to the average single-base reference peak). Placement of conversion control relative to genomic sequence Even if you are not using all possible Ts as your “conversion control” you are still advised to dispense Cs at each possible site where a C has changed to a T, in order to keep all templates “In Phase”. Dispense the bases in the order that they came in the genomic sequence. For instance, if the genomic sequence were TTTC, it would make sense to put the control after the T dispensation. If it were CTTT, put the C before the T. If it were CCTC, then dispense CTC.