AdhesiveLubricant105Spec

ChemMasters

Installation Guidelines

Adhesive Lubricant 105 is a solution of neoprene rubbers in aromatic solvent with plasticizers and acid interceptors.

1.0 General

1.1 Scope

This specification covers the performance characteristics and application procedures for providing a solution of neoprene rubbers in aromatic solvent with plasticizers and acid interceptors.

1.2 Material Description

The material shall be a solution of neoprene rubbers in aromatic solvent with plasticizers and acid interceptors. The material should lubricate and bond in one step and dry rapidly.

1.3 Typical Applications

A. Provides lubrication of neoprene compression seals for insertion into concrete pavement

B. Bonds the neoprene seals into the joint

C. Lubricant and adhesive for smaller pavement seals

1.4 Limitations

A. Do not allow to freeze. Condition material to 70 ° F./21° C., prior to application.

B. Application guidelines for the neoprene compression seals supercede these directions.

C. When an adhesive lubricant complying with ASTM D-4070 is required, Lube

Plus 4070 should be used.

1.5 Quality Assurance

The repair contractor shall have experience and proficiency specific to the repair type and shall be approved by the engineer and the material supplier. The material supplier shall provide job service as required to assure proper handling and installation of materials. The field representative shall instruct as needed to assure that handling, mixing, placing and finishing of materials are in accordance with specifications.

1.6 Delivery, Storage and Handling

The product shall be delivered in the original, unopened containers. It shall be labeled with the manufacturer’s name, product name and lot number. Materials should be stored at the job site under dry conditions and at a temperature of

40° F., (4° C.) to 90° F. (32° C.).

1.7 Environmental Requirements

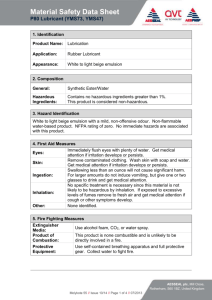

All materials used for the repair work shall be VOC compliant. The manufacturer shall supply the appropriate material safety data sheets upon request.

2.0 Materials

2.1 Approved Materials and Manufacturers

2.1.1 Product Standard

Adhesive Lubricant 105, as manufactured by ChemMasters, 300 Edwards Street,

Madison, Ohio, 44057-3112, 1-800-486-7866, is considered to conform to the requirements of this specification and shall be the lubricant used. Adhesive

Lubricant 105 is a solution of neoprene rubbers in aromatic solvent with plasticizers and acid interceptors.

2.1.2 Substitutions

No submittals for substitutions will be accepted after the bid date. All submittals must be made in writing to the engineer with supporting technical data sheets and test data showing complete equivalent performance.

2.2 Packaging/Coverage/Estimating

2.2.1 Packaging

Adhesive Lubricant 105 is available in 55 U.S. gallon/208 Liter drums and 5 U.S. gallon/18.9 Liter pails, shipped 36 per pallet shrink wrapped.

2.2.2 Estimating Guide

Application rate of Adhesive Lubricant 105 will vary with the size of the seals.

Consult the seal manufacturer for an application rate with the particular seal you are using. Typical coverage is 150-225 linear feet of seal per gallon/12-18 linear meters per liter.

2.3 Storage:

Store tightly sealed containers in cool, dry area away from direct sunlight or sources of heat. Shelf life of properly stored material is one year from date of manufacture.

2.4 Engineering Properties

2.4.1 Drying Time:

Complies with the requirements of ASTM D-2835 with a working time of a minimum 10 minutes and drying time of 20 minutes at 70 ° F/ 21° C.

2.4.2 Solids: 25%

2.4.3 Flash Point: 45

° F./6° C.

2.4.4 Weight: 7.8 lbs./gal 0.93 Kg/L

2.5 Accessory Materials as manufactured by ChemMasters, 300 Edwards Street,

Madison, Ohio, 44057-3112, 1-800-486-7866, is considered to conform to the requirements of this specification.

3.0 Execution

3.1 References

A. Adhesive Lubricant 105 exceeds the requirements of ASTM D-2835

B. Refer to ChemMasters MSDS and Technical Data Sheets

3.2 Surface Preparation:

Be sure the joint is clean and dry. Adhesive Lubricant 105 should be applied liberally to the neoprene compression seal or to the pavement joint prior to inserting the seal into the joint. Apply by hand or machine. Wear gloves while handling. The rate of application will depend upon the design of the compression seal. The seal must be inserted into the joint immediately following the application of the Adhesive Lubricant 105. The directions and recommended application rate of the neoprene compression seal manufacturer take precedence over these directions where the two are in conflict.

3.3 Clean-up

Tools and equipment used in the application of Adhesive Lubricant 105 should be cleaned with toluene, xylene or a blend of the two.