POLA_24472_sm_suppinfo

advertisement

Supporting Information

Crown-ether and Azobenzene-containing LC-polymers: an Influence of

Macromolecular Architecture on Optical Properties and Photoorientation

Processes.

Alexander Ryabchun, Alexey Bobrovsky*, Alexey Medvedev, Valery Shibaev

Faculty of Chemistry, Moscow State University,

Lenin Hills, Moscow, 119991 Russia

e-mail: bbrvsky@yahoo.com

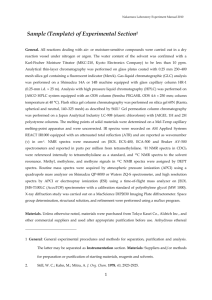

Synthesis 4-({6-[(1-methyleneprop-2-en-1-yl)oxy]hexyl}oxy)benzoic acid (А6)

1st Stage. Synthesis of 4-[(6-hydroxyhexyl)oxy]benzoic acid (A6-OH)

The potassium hydroxide 10.2 g (0.18 mol) in ethanol-water (3:1) was poured to 10 g

(0.073 mol) of 4-hydroxybenzoic acid solution. The resulting mixture was heated with stirring

for an hour, then 12 ml (0.09 mol) 6-chlorohexan-1-ol and 1,6 g (0,01 mol) of potassium iodide

were slowly (dropwise) added. The reaction mixture was heated with stirring under reflux for 72

hours. The solvent was evaporated, the residue was dissolved in water, washed with chloroform

and acidified with hydrochloric acid to pH<7. The precipitate was filtered, washed with cold

water, dried in a vacuum and then recrystallized from ethanol. Recrystallized product was dried

in a vacuum. The yield was 80-90%.

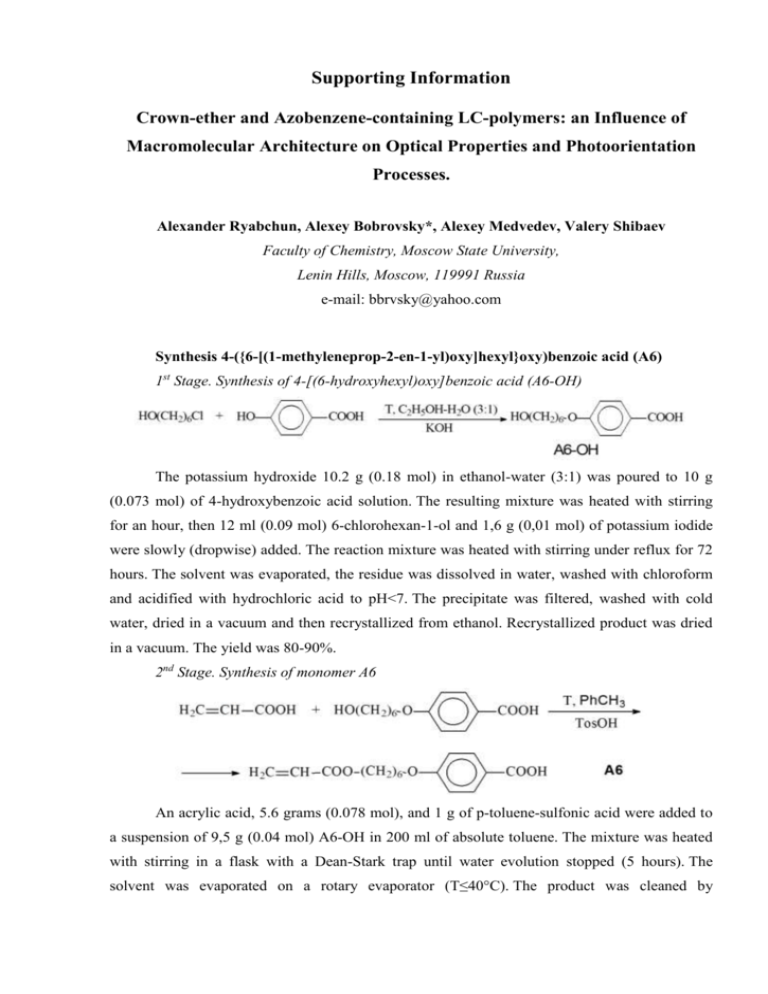

2nd Stage. Synthesis of monomer A6

An acrylic acid, 5.6 grams (0.078 mol), and 1 g of p-toluene-sulfonic acid were added to

a suspension of 9,5 g (0.04 mol) A6-OH in 200 ml of absolute toluene. The mixture was heated

with stirring in a flask with a Dean-Stark trap until water evolution stopped (5 hours). The

solvent was evaporated on a rotary evaporator (T≤40°C). The product was cleaned by

recrystallization

from

ethanol

and

column

chromatography

(silica

gel,

eluent

–

toluene/ethylacetate (9:1)). The yield was 50-70%.

1

H NMR (400 MHz, CDCl3, TMS, δ): 7.95 (d, 2H, Ph), 6.93 (d, 2H, Ph), 6.35 (dd, 1H,

CH2=CH), 6.12 (dd, 1H, CH2=CH), 5.81 (dd, 1H, CH2=CH), 4.3 (t, 2H, OCH2), 4.12 (t,

2H, CH2O), 1.3–1.9 (8H, CH2).

Synthesis of monomer М1

Monomer М1 was synthesized using a two-step synthetic route.

In the first step an azobenzene dye was synthesized using standard azo-coupling with

phenol in alkaline media.1 1g (3 mmol) of 4’-aminobenzo-18-crown-6 was dissolved in 10 ml of

hydrochloric acid (1:1). 2N aqueous solution of sodium nitrite (0.211g, 3mmol) was added

dropwise to the resulting solution under cooling and stirring (T≤5oC). After adding all the

sodium nitrite reaction mixture was stirred for another 30 minutes. The resulting solution of

diazonium salt with stirring was slowly added to a solution of phenol (0.287g, 3mmol) in 2N

NaOH (T≤10°C, maintaining a pH≥ 8). After adding all the diazonium salt, the reaction mixture

was acidified with dilute hydrochloric acid, the resulting precipitate was filtered off and dried in

a vacuum. Product was purified by column chromatography (silica gel, eluent - chloroform/

ethanol 3:1). The yield was 0.83 g (52%).

In

the

second

step

0.35

g

(1.2

mmol)

of

previously

(acryloyloxy)hexyl]oxy}benzoic acid (A6) synthesized according to

2

obtained

4-{[6-

was mixed with 0.63 g

(1.5 mmol) of azobenzene dye in nonaqueous THF in the presence of 0.03 g (0.25 mmol) of 4-

dimethylaminopyridine.

To

the

solution

0.35

g

(1.7

mmol)

of

DCC

(N,N′-

dicyclohexylcarbodiimide) cooled by ice with water was added during 1.5 hours. The reaction

was completed after mixing at room temperature for 24 hours. The precipitate of

bicyclohexylurea was filtered and THF was evaporated. The product was purified using column

chromatography (silica gel, eluent – clorophorm/methanol, 15:1). The yield was 0.46 g (55 %

from theory). The obtained monomer was a dark-orange powder with m.p. 55 ºС.

1

H NMR (400 MHz, CDCl3, TMS, δ): 1.26-1.87 (m, 8H, CH2), 3.55-3.85 (m, 12H,

CH2O), 3.97 (m, 4H, CH2CH2O), 4.25 (m, 4H, CH2CH2O), 4.05 (t, 2H, CH2O), 4.17 (t, 2H,

CH2O), 5.81 (dd, 1H, CH2=CHtrans), 6.4 (dd, 1H, CH2=CHcis), 6.12 (dd, 1H, CH2=CH),

6.98 (d, 3H, Ar), 7.33 (d, 2H, Ar), 7.6 (d, 2H, Ar, ortho to –OOC), 7.97 (d, 2H, Ar), 8.15 (d,

2H, Ar, ortho to –COO).

C NMR (200 MHz, CDCl3, TMS, δ):

13

123.70 (C1), 121.0 (C2), 130.70 (C3), 128.62

(C4), 166.45 (C5), 64.55 (C8), 29.05 (C9),

25.79 (C10, C11), 28.61 (C12), 68.18 (C13),

151.79 (C15), 114.42 (C16, C17), 132.43

(C18, C19), 121.48 (C20), 164.35 (C21),

163.50 (C24), 122.46 (C25, C26), 123.82

(C27, C28), 149.29 (C29), 147.10 (C32),

112.34 (C33), 150.30 (C34), 152.71 (C35),

68.9 (C46, C49), 70.65 (C45, 50), 70.8 (C36,

C37, C39, C40, C42, C43). MS (ESI) m/z =

708.2 [M+H]+, 729.5 [M+Na]+, 730.4, 431.5,

292.8.

Synthesis

of

4-[4-(1,4,7,10,13,16-Hexaoxacyclooctadecan-2-yl-

methoxycarbonyl)phenyldiazenylphenyl 4-(6-acryloyloxyhexyloxy)]-benzoate (M-2).

In the first step, azo dye 3 was synthesized by the azocoupling reaction of paminobenzoic acid with phenol in an alkaline medium.1

In the second step, the hydroxy group of azo dye 3 was protected with

chloroethoxyformate according to a standard procedure. 3

The third step involved the formation of acid chloride 5 by the reaction of compound 4

with thionyl chloride.3

In the fourth step, triethylamine (2 mL) was added to a solution of 2-hydroxymethyl-18crown-6 (0.29 g, 1 mmol) in anhydrous THF (30 mL). Then acid chloride 5 (0.4 g, 1.2 mmol)

was added dropwise to the reaction solution cooled with ice water for 1 h. The progress of the

reaction was monitored by TLC. Within 12 h after the beginning of the reaction, the precipitate

of triethylamine hydrochloride that formed was filtered off, and THF was evaporated. The

compound was purified by column chromatography (chloroform as the eluent). The yield of

compound 6 was 0.4 g (70%).

In the fifth step, the hydroxy group was deprotected with ammonia to prepare phenol 7.3

In the last step, monomer M-2 was synthesized. For this purpose, A6 (0.09 g, 0.0003

mol), compound 7 (0.2 g, 0.4 mmol), and 4-dimethylaminopyridine (0.01 g) were dissolved in

anhydrous THF (15 mL). Then DCC (0.09 g, 0.42 mmol) was added to the solution cooled with

ice water for 1.5 h. The reaction mixture was kept at ~20 °C for 24 h. The progress of the

reaction was monitored by TLC. The precipitate of dicyclohexylurea that formed in the course of

the reaction was filtered off, and THF was evaporated. The product was purified by column

chromatography (toluene-ethyl acetate, 1:1, as the eluent). The yield was 0.11 g (65%), mp =

58oC. IR, ν/cm–1:2926, 2861 (CH2), 1700 (C=O), 1610 (CH2=CH), 1587, 1490 (C=C, Ar), 1263

(COC, ArOR), 1118 (COC). 1H NMR (400 MHz, CDCl3, TMS, δ): 1.26-1.87 (m, 8 H, 4

CH2), 3.4-3.75 (m, 21 H, CH, 10 CH2O), 4.00-4.52 (m, 8 H, 4 CH2O), 5.78 and 6.37 (both d, 1 H

each, CH2=CH), 6.15 (dd, 1 H, CH2=CH), 7.01 (d, 2 H, Ar), 7.48 (d, 2 H, Ar), 7.72 (d, 2 H,

Ar), 8.15 (d, 6 H, Ar).

Synthesis of 1,4,7,10,13,16-Hexaoxacyclooctadecan-2-ylmethyl-4-[6(acryloyloxy)hexyloxy]benzoate (M-III).

Dicyclohexylcarbodiimide (0.29 g, 1.4 mmol) was added to a solution of A6 (0.29 g, 1

mmol),

2-(hydroxymethyl)-18-crown-6

(Merck)

(0.35

g,

0.0012

mol),

and

4-

dimethylaminopyridine (0.02 g) in anhydrous THF (30 mL) cooled with ice water for 1.5 h. The

reaction mixture was kept at ~20 °C for 24 h. The progress of the reaction was monitored by

TLC. After completion of the reaction, the precipitate of dicyclohexylurea that formed was

filtered off, and THF was evaporated. The product was purified by column chromatography

(toluene-ethyl acetate, 1:1, as the eluent). The yield was 0.34 g (60%) mp=52 ºС. IR, ν/cm-1:

2936, 2856 (CH2), 1720 (C=O), 1632 (CH2=CH), 1600, 1512 (C=C, Ar), 1256 (COC,

ArOR), 1168 (COC). 1H NMR (400 MHz, CDCl3, TMS, δ): 1.26-1.87 (m, 8 H, 4 CH2), 3.383.75 (m, 21 H, CH, 10CH2O), 4.05-4.52 (m, 8 H, 4 CH2O), 5.77 and 6.35 (both d, 1 H each,

CH2=CH), 6.14 (dd, 1 H, CH2=CH), 6.91 (d, 2 H, Ar), 7.9 (d, 2 H, Ar).

1. Vogel, A.I.; Tatchell, A.R.; Furnis, B.S.; Hannaford, A.J.; Smith, P.W.G. Vogel’s textbook of

practical organic chemistry; Longman Scientific & Technical: England, 1989; pp 948-950.

2. Portugall, M.; Ringsdorf, H.; Zentel, R. Macromol Chem 1982, 183, 2311.

3. Boiko, N.; Zhu, X.; Bobrovsky, A.; Shibaev, V. Chem Mater 2001, 13, 1447-1452.