Study on Sulfidation Roasting and Flotation of Refractory Lead

advertisement

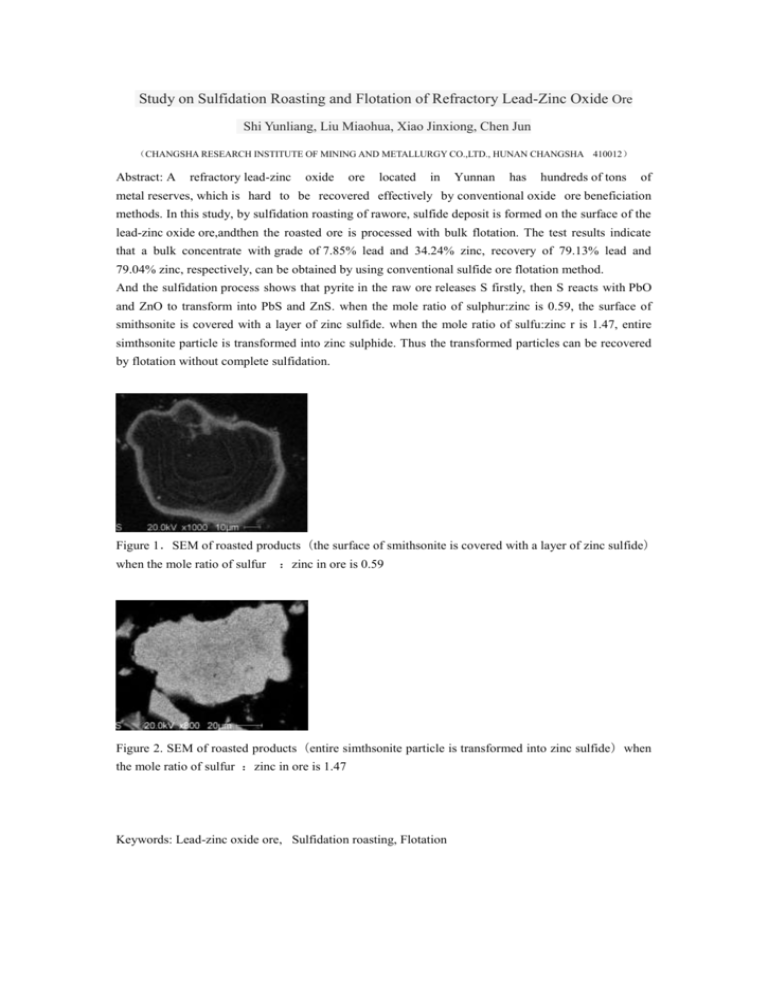

Study on Sulfidation Roasting and Flotation of Refractory Lead-Zinc Oxide Ore Shi Yunliang, Liu Miaohua, Xiao Jinxiong, Chen Jun (CHANGSHA RESEARCH INSTITUTE OF MINING AND METALLURGY CO.,LTD., HUNAN CHANGSHA 410012) Abstract: A refractory lead-zinc oxide ore located in Yunnan has hundreds of tons of metal reserves, which is hard to be recovered effectively by conventional oxide ore beneficiation methods. In this study, by sulfidation roasting of rawore, sulfide deposit is formed on the surface of the lead-zinc oxide ore,andthen the roasted ore is processed with bulk flotation. The test results indicate that a bulk concentrate with grade of 7.85% lead and 34.24% zinc, recovery of 79.13% lead and 79.04% zinc, respectively, can be obtained by using conventional sulfide ore flotation method. And the sulfidation process shows that pyrite in the raw ore releases S firstly, then S reacts with PbO and ZnO to transform into PbS and ZnS. when the mole ratio of sulphur:zinc is 0.59, the surface of smithsonite is covered with a layer of zinc sulfide. when the mole ratio of sulfu:zinc r is 1.47, entire simthsonite particle is transformed into zinc sulphide. Thus the transformed particles can be recovered by flotation without complete sulfidation. Figure 1.SEM of roasted products(the surface of smithsonite is covered with a layer of zinc sulfide) when the mole ratio of sulfur :zinc in ore is 0.59 Figure 2. SEM of roasted products(entire simthsonite particle is transformed into zinc sulfide)when the mole ratio of sulfur :zinc in ore is 1.47 Keywords: Lead-zinc oxide ore, Sulfidation roasting, Flotation