Minutes - Society of Reliability Engineers (SRE)

advertisement

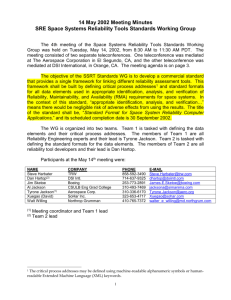

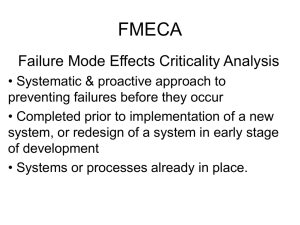

11 June 2002 Meeting Minutes for Space Systems - Dependability Data Transfer Formats Standard Working Group Primary Objective The primary objective of this working group is to develop a commercial standard that provides a single framework for transferring data between tools and the Reliability, Maintainability, and Availability (RMA) database that is necessary to achieve high RMA requirements for space systems. The Extensible Machine Language (XML) shall be used to define the standard transport formats for data that are described in the standard. The title of the standard may have to be changed to, “Space Systems Dependability Data Transfer Formats Standard,” in order for it to be published as an AIAA standard. The draft standard is scheduled for completion by 30 September 2002. To achieve the primary objective of the WG required dividing the WG into two teams. Team 1 consists of reliability analysts and Team 2 consists of tool developers. The Team 1 lead is Tyrone Jackson and the Team 2 lead is Dan Hartop. Team 1 is tasked with (1) defining the data that are critical to the development of a high-reliability space system, and (2) showing why the data is critical by defining the functions in the Systems Engineering Process that use and generate the data. Team 2 is tasked with defining the XML formats for the data. 11 June 2002 Meeting The 6th meeting of the Space Systems - Dependability Data Transfer Formats Standard WG was held on Tuesday, June 11, 2002, from 8:30 AM to 10:30 AM PDT. The meeting consisted of a teleconference that was mediated by Tyrone Jackson at The Aerospace Corporation in El Segundo, CA. The meeting agenda is on page 3. Participants at the June 11th meeting were: NAME Tyrone Jackson(1) Dan Hartop(2) Jim Sketoe Steve Harbater Al Jackson Terry Kinney Robert Poltz Xuegao (David) Walt Willing Kamran Nouri (1) (2) COMPANY Aerospace Corp. DSI Intl. Boeing TRW CSULB Eng Grad College Spectrum Astro Design Analytx SoHar Inc. Northrop Grumman Item Software PHONE 310-336-6170 714-637-9325 253-773-2891 858-592-3490 310-493-7469 719-550-0325 877-327-7550 323-653-4717 410-765-7372 714-935-2900 Meeting coordinator and Team 1 lead Team 2 lead 1 E-MAIL Tyrone.Jackson@aero.org dhartop@dsiintl.com James.E.Sketoe@boeing.com Steve.Harbater@trw.com jacksona@simanima.com Terry.Kinney@specastro.com getreliability@designanalytx.com Xuegao@sohar.com walter_e_willing@md.northgrum.com kamran@itemsoft.com The following individuals are on regular distribution for the SSRT Standards WG Meeting minutes: NAME Mike Canga James Womack John Ingram-Cotton Dave Dylis Eric Gould Jim Kallis Bill Geimer Leo F. Watkins Marios Savva Adamantios Mettas Doug Ogden Rich Pugh Ken Murphy Myron Hecht Rebecca Menes Bob Miller Halil Kilic Kevin P. Van Fleet Hunter Shaw Clarence Meese Craig Day James French Rus Vacante COMPANY NASA JSC Aerospace Corp. Aerospace Corp. RAC DSI Intl. Raytheon Northrop Grumman Lockheed Martin Reliasoft ReliaSoft ReliaSoft Pratt Whitney ARINC Sohar Inc. Sohar Inc. TRW TRW Relex Software Relex Software SRE AIAA AIAA RMA Partnership PHONE 281-483-5395 310-336-7647 310-336-1249 315-339-7055 714-637-9325 310-647-3620 626-812-2783 817-935-4452 520-886-0410 520-886-0366 Ext. 29 520-886-0366 Ext. 41 505-248-0640 323-653-4717X111 323-653-4717X101 310-812-2840 310-814-1998 724-836-8800 x105 724-836-8800 703-264-3849 703-264-7570 703-805-4864 2 E-MAIL michael.a.canga1@jsc.nasa.gov James.M.Womack@aero.org John.Ingram-Cotton@aero.org DDylis@IITRI.ORG egould@dsiintl.com jmkallis@west.raytheon.com William.Geimer@northropgrumman.com Leo.F.Watkins@LMCO.com Marios.Savva@reliasoft.com Adamantios.Mettas@ReliaSoft.com Doug.Ogden@ReliaSoft.com pugh@pwfl.com KMURPHY@arinc.com Myron@sohar.com Becky@sohar.com Robert.Miller@trw.com ha.kilic@trw.com kevin.vanfleet@relexsoftware.com Hunter.Shaw@relexsoftware.com cmeese@nyx.net craigd@aiaa.org jimf@aiaa.org russv@erols.com June 11th Meeting Agenda Time Working Group Administrative Topics 8:30 - 8:45 PDT Take roll Vote to approve the minutes for the April 30th, May 14th, and May 28th meetings Vote to approve proposal for AIAA to sponsor draft standard Time Team 1 & 2 Joint Discussion Topics 8:45 - 9:15 PDT Discuss WG comments on Fault Tree schema 9:15 - 9:30 PDT Identify leads for the other schemas that must be written 9:30 - 10:00 PDT Discuss Section 6, Reliability Analysis Data Models 10:00 - 10:15 PDT Identify leads for the other sections that must be written 10:15 - 10:30 PDT Break Time Team 1 & 2 Separate Discussion Topics 10:30 - 11:30 PDT Teams conduct open discussions using separate teleconferences 11:30 PDT Meeting adjourn 3 Team 1 & Team 2 Joint Discussion Topics Team 1 participants in the June 11th meeting were: Steve Harbater Tyrone Jackson (Team 1 Lead) Terry Kinney Rob Poltz Jim Sketeo Walt Willing Team 1 meet the minimum number of participants required for a Team 1 quorum, and voted to approve the meeting minutes for April 30 th, May 14th, and May 28th. Team 2 participants in the June 11th meeting were: Dan Hartop (Team 2 Lead) Al Jackson Kamran Nouri David Xuegao As a result of a group discussion about the potential benefits of a set of standard names for equipment that is common to generic categories of space systems, the wording for problem #1 was revised in the list of the “Top-10 Space Systems Reliability Program Problems” (see page 7). The original goal of the WG was to produce a Society of Reliability Engineers (SRE) Standard. However, since the SRE does not have an established process for publishing standards, the WG decided to submit a Standard Project Proposal to the American Institute of Aeronautics and Astronautics (AIAA) Standards Executive Council for approval consideration in August 2002. As a result of the WG reviewing the updated Fault Tree Schema that Team 2 constructed, it was decided that Fault Tree Analysis is best used as a selective tool for enhancing the fidelity of FMECA. Therefore, a FMECA Schema needs to be included in the standard. Tyrone volunteered to write a FMECA Schema that shows the conditions under which Fault Tree Analysis should be performed. The WG finalized the outline for the draft standard (see final outline on page 9). At least two members of the WG volunteered to write each section of the draft standard (see names of section writers on page 9). After the meeting, Tyrone e-mailed the AIAA Standard Project Proposal to Bob French. Bob suggested that the title of the draft standard be changed to, "Space Systems - Dependability Data Transfer Formats Standard," or something like that. It seems that in the international community, "Dependability" includes all of 4 the "ilities" that are covered in the outline of the draft standard. The WG will vote on whether to change the name of the draft standard at the next meeting on June 25th. Bob also suggested that all future reviews of the draft standard be limited to within the WG. Lastly, if the WG commits to writing an AIAA standard, then it will inevitably lead to more work because each writer will have to follow the AIAA writing style guide. Action Items 1. Team 1 and Team 2 Action Items – a. Tyrone – Write a FMECA Schema b. All – Begin writing the sections of the draft standard Next Meeting The next SSRT Standards WG Meeting is scheduled for June 25, 2002, from 9:30 AM PDT to 11:30 AM. Both Team 1 and Team 2 are to call the following teleconference number: Teleconference number - (888) 550-5969, pass code 646354 Arrangements have been made for the WG to use NetMeeting concurrently during the teleconference. For those that prefer face-to-face discussions, meeting rooms have been reserved at the following locations: Team 1 meeting room - The Aerospace Corporation, Building D-8, 200 N. Aviation Boulevard, El Segundo, CA 90245-4691 Team 2 meeting room - DSI International, 1574 N. Batavia, Suite 3, Orange, CA 92867 5 Planned Future Meetings Location: The Aerospace Corporation, Building D-8, 200 N. Aviation Boulevard, El Segundo, CA 90245-4691 Date: 2002 6/25 Teleconference 7/16 Teleconference 7/30 Teleconference 8/13 Teleconference 8/27 Teleconference 9/10 Teleconference 9/24 Teleconference Please direct all comments regarding these meeting minutes to: Tyrone Jackson Space Systems - Dependability Data Transfer Formats Standard Working Group Coordinator Tyrone Jackson Reliability & Statistics Office The Aerospace Corporation Ph. (310) 336-6170 Fax (310) 336-5365 Email: Tyrone.Jackson@aero.org 6 Top-10 Space Systems Reliability Program Problems1 1. Valuable RMA lessons learned often are not in a format that is readily assessable or useable by the Reliability Program, or they have become “lessons lost” in an overwhelming mass of engineering information. For example, a useful lesson learned might never be linked to the equipment that it applies if the name that is used to search for information is different than the name recorded in the database. 2. Some reliability critical items often are not identified at all or are not properly controlled. 3. System reliability predictions often do not include probability of occurrence estimates for all relevant failure modes, failure mechanisms, and failure causes. (Probability of induced faults during manufacture or probability of damage during assembly usually is not included in reliability predictions.) 4. The perceived accuracy of high-reliability predictions and dependability/availability predictions often is not supported by (1) input data that is less precise than the result, or (2) equations that are misapplied or incorrect. 5. The number of job openings for reliability analysts is steadily decreasing, and as a result, the number of filled positions is insufficient to adequately support an increasing number of space system development projects. This situation often has lead to reliability assessment methods being improperly applied, untimely, or not cost-effective. 6. Many commercial reliability assessment tools have major shortcomings that may not be obvious to the casual reliability analyst (e.g., inaccurate equipment failure rate models, unverifiable parameters in equations, high misapplication rates, etc.). 7. Often, insufficient funding is provided to perform all of the tasks necessary for a HighReliability Program. (Some customers and managers believe that high-reliability can be tested-in more cost-effectively than it can be designed-in.) 8. Different approaches are being used across the space industry to perform reliability assessment tasks that are called by the same name, but which often serve different purposes. (Inconsistency in reliability assessment practices has become a major problem since DoD canceled military standards in the mid 90’s.) 9. Some customers’ believe that all dependability/availability predictions for space vehicle constellations are too conservative. (The basis of this belief is rooted in historical evidence that shows contingency procedures of ground operations are very effective for extending the useful life of a space vehicle far beyond it’s predicted meanlife. This phenomenon has resulted in many customers buying more space vehicles than necessary to meet the dependability requirements of the constellation.) 10. Often it is difficult for an organization to assure that the latest versions of the reliability assessment models match the latest configuration of the space system 1 This list of top-10 problems was determined by an internal working group survey. 7 design. Part of this problem is because reliability assessment tools generally do not label every element in the model with the date and time its was created. 8 Final Outline (06-11-02) Space Systems - Dependability Data Transfer Formats Standard Table of Contents Section 1 – Introduction (Tyrone) 1.1 General 1.2 Scope 1.3 Purpose 1.4 Reference Documents 1.5 Definitions 1.6 General Requirements for Interchanging Data with a RMA Database Section 2 – RMA Requirements Data - Data Transfer Format A (Terry and Tyrone) Section 3 – Functional Data Models - Data Transfer Format B (Dan and Kamran) Section 4 – Physical Data Models - Data Transfer Format C (Tyrone is to ask RAC and NASA for input) Section 5 – Stress Parameters Data Models - Data Transfer Format D (Jim, Steve, and Walt) Section 6 – Reliability Analysis/FMECA Data Models - Data Transfer Format E 6.1 – Reliability Analysis Data Models - Data Transfer Format E1 (Kamran, David, and Al) 6.2 – FMECA Data Models - Data Transfer Format E2 (Rob and Tyrone) Section 7 – Maintainability/Failure Analysis Data Models - Data Transfer Format F 7.1 – Maintainability Analysis Data Models - Data Transfer Format F1 (Jim and Rob) 7.2 – Failure Analysis Data Models - Data Transfer Format F2 (Rob and Tyrone) Section 8 – Dependability and Availability Analysis Data Models - Data Transfer Format G 8.1 – Dependability Analysis Data Models - Data Transfer Format G1 (Terry and Walt) 8.2 – Availability Analysis Data Models - Data Transfer Format G2 (Terry and Walt) Section 9 – Similar System/Component Experience Data - Data Transfer Format H 9.1 – RMA Design Concerns & Rules - Data Transfer Format H1 (Steve and Tyrone) 9.2 – Sneak Clues - Data Transfer Format H2 (Steve and Tyrone) Appendix A – Space Systems Life Cycle Reliability Process Guide (Tyrone) 9 Reliability, Maintainability & Availability Assessment Model Flow Format B Requirements to Functional Model Mapping 2.4.2 Format A System & Subsystem RMA Reqs. Data 2.4.1 Format C Functional to Physical Model Mapping 2.4.2, 2.4.4, 2.4.5, 2.4.6 Format D Functional & Physical to Stress Parameters Model Mapping 2.4.9 Format E Format H Functional, Physical, Stress Parameters & Maintainability/ Failure Analysis to Reliability Analysis/FMECA Model Mapping 2.4.7, 2.4.8, 2.4.9, 2.4.10 Format F Similar System/ Component Experience Data 2.4.3 Functional, Physical, Stress Parameters & Reliability Analysis/FMECA to Maintainability/Failure Analysis Model Mapping 2.4.10 Format G DATA TRANSFER FORMATS: A - RMA Requirements Data B - Functional Models C - Physical Models Test & Field Failure Data F - Maintainability/Failure Analysis Models F1 - Maintainability Analysis Models F2 - Failure Analysis Models D - Stress Parameters Models G - Dependability/Availability Analysis Models G1 - Dependability Analysis Models G2 - Availability Analysis Models E - Reliability Analysis/FMECA Models E1 - Reliability Analysis Models E2 - FMECA Models H - Similar System/Component Experience Data H1 - RMA Design Concerns & Rules H2 - Sneak Clues 10 Reliability Analysis/FMECA & Maintainability/Failure Analysis to Dependability/ Availability Model Mapping 2.4.10