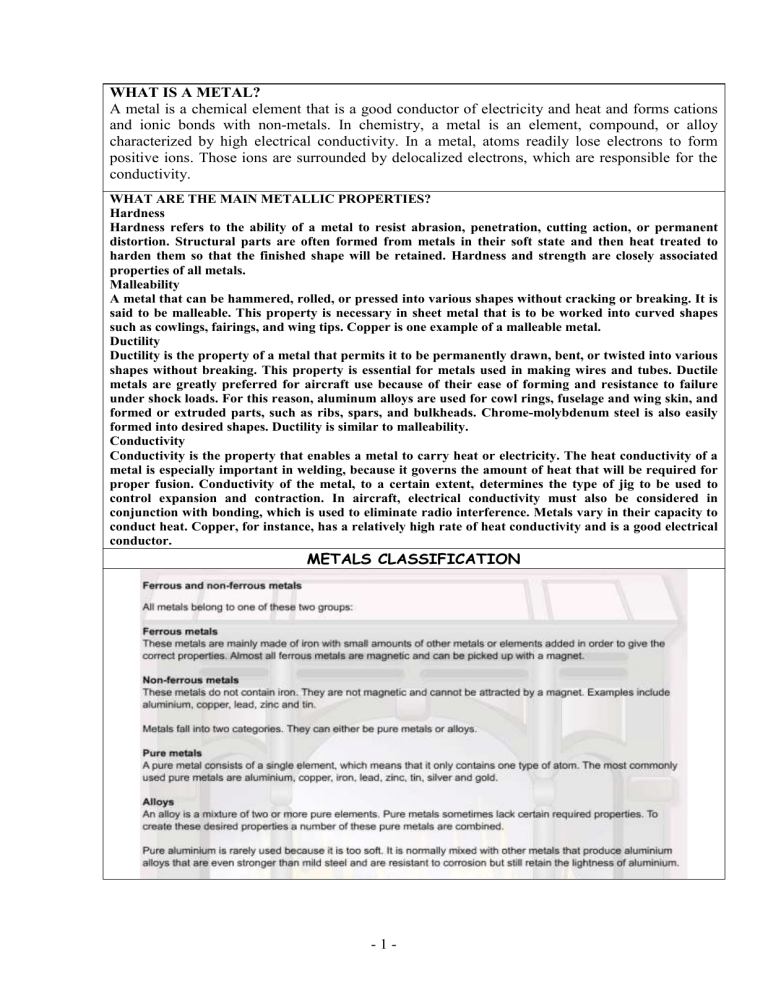

metals classification

advertisement

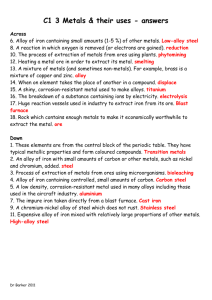

WHAT IS A METAL? A metal is a chemical element that is a good conductor of electricity and heat and forms cations and ionic bonds with non-metals. In chemistry, a metal is an element, compound, or alloy characterized by high electrical conductivity. In a metal, atoms readily lose electrons to form positive ions. Those ions are surrounded by delocalized electrons, which are responsible for the conductivity. WHAT ARE THE MAIN METALLIC PROPERTIES? Hardness Hardness refers to the ability of a metal to resist abrasion, penetration, cutting action, or permanent distortion. Structural parts are often formed from metals in their soft state and then heat treated to harden them so that the finished shape will be retained. Hardness and strength are closely associated properties of all metals. Malleability A metal that can be hammered, rolled, or pressed into various shapes without cracking or breaking. It is said to be malleable. This property is necessary in sheet metal that is to be worked into curved shapes such as cowlings, fairings, and wing tips. Copper is one example of a malleable metal. Ductility Ductility is the property of a metal that permits it to be permanently drawn, bent, or twisted into various shapes without breaking. This property is essential for metals used in making wires and tubes. Ductile metals are greatly preferred for aircraft use because of their ease of forming and resistance to failure under shock loads. For this reason, aluminum alloys are used for cowl rings, fuselage and wing skin, and formed or extruded parts, such as ribs, spars, and bulkheads. Chrome-molybdenum steel is also easily formed into desired shapes. Ductility is similar to malleability. Conductivity Conductivity is the property that enables a metal to carry heat or electricity. The heat conductivity of a metal is especially important in welding, because it governs the amount of heat that will be required for proper fusion. Conductivity of the metal, to a certain extent, determines the type of jig to be used to control expansion and contraction. In aircraft, electrical conductivity must also be considered in conjunction with bonding, which is used to eliminate radio interference. Metals vary in their capacity to conduct heat. Copper, for instance, has a relatively high rate of heat conductivity and is a good electrical conductor. METALS CLASSIFICATION -1- IRON PRODUCTION The modern production of iron involves heating iron ore with coke and limestone in a blast furnace, where temperatures range from 392°F (200°C) at the top of the furnace to 3,632°F (2,000°C) at the bottom. Some blast furnaces are as tall as 15story buildings and can produce 2,400 tons of iron per day. Inside a blast furnace, a number of chemical reactions occur. One of these is the reaction between coke (nearly pure carbon) with oxygen to form carbon monoxide. This carbon monoxide then reacts with iron ore to form pure iron and carbon dioxide. Limestone is added to the reaction mixture to remove impurities in the iron ore. The product of this reaction, known as slag, consists primarily of calcium silicate. The iron formed at the bottom of a blast furnace exists in a molten form known as pig iron. The slag is also molten but less dense than the iron. Efforts to use pig iron for commercial and industrial applications were not very successful. The material is brittle. There are several methods to convert pig iron into stronger forms of iron like cast iron and wrought iron. More importantly, when additional elements, such as manganese and chromium, are added to the converter, a new product—stainless steel—is formed. Vocabulary: Raw material: materia prima Range: rango Iron ore: mineral de hierro coke: coque, tipo de carbón. limestone: piedra caliza blast furnace: horno vertical top: upper part of something bottom: is the opposite of top. occur: happen nearly: casi slag: escoria pig iron: molten iron, fundición de hierro. brittle: property of a material to break easily. manganese: manganese chromium: cromo steel: acero tough/toughness: (tenacidad) mechanical property. A tough material can resist hitting. -2- FERROUS METALS NAME ALLOY OF IRON AND…. Mild steel Up to 0,6% of Carbon Tough (tenaz) (C) It rusts easily. Up to 1,6% C Tough (tenaz = (acero templado) Carbon steel (acero al carbono) PROPERTIES USES Common in workshops. Cutting tools resistente a los golpes) Stainless steel Nickel and chromium Cast iron Up to 6% of C Resistant to rust. Home, Tough. knives Strong but brittle Engines (fundición) (quebradizo) NON FERROUS METALS NAME COLOUR ALUMINIUM Whitish grey COPPER (cobre) Redish brown SILVER (plata) Whitish grey LEAD (plomo) Bluish grey TIN (estaño) Bluish grey NON FERROUS ALLOYS NAME ALLOY OF … BRASS (latón) Copper+Zinc BRONZE (bronce) Copper+Tin PROPERTIES USES Light, soft, ductile, malleable, easy to work corrosion resistant, ductile, malleable Ductil, malleable, resists corrosion Heavy, ductile, malleable. Soft, it does not rust PROPERTIES USES Hard, easy to machine. Soft, resists corrosion, easy to polish. -3- buildings, TOOLS USED TO WORK WITH METALS: TO MEASURE AND DRAW: TO CUT: TO HOLD: TO HOLE: TO FILE: TO JOIN: TO FINISH: A: B: C: D: E: F: G: H: I: J: K: L: -4-