Residential Construction – Local Emphasis Program

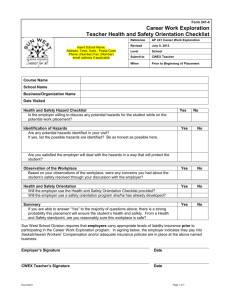

advertisement

DIVISION MEMORANDUM MIOSHA Construction Safety and Health Division Michigan Occupational Safety and Health Administration Department of Licensing and Regulatory Affairs (LARA) DOCUMENT IDENTIFIER: DATE: CSHD-MEMO-COM-14-1R1 May 13, 2014 SUBJECT: Residential Construction – Local Emphasis Program I. Purpose: II. Scope: III. References: IV. Distribution: V. VI. Cancellations: History: VII. VIII. Expires: Contact: IX. Originator: This memorandum establishes enforcement policies and provides instruction to ensure compliance with serious safety hazards associated with residential construction. This memorandum applies to safety staff in the MIOSHA Construction Safety and Health Division (CSHD). A. Division Instruction, CSHD-COM-09-1, Construction Inspection Targeting, as amended. B. MIOSHA Field Operations Manual (FOM), as amended. MIOSHA Staff; OSHA Lansing Area Office; General; S-drive Accessible; MIOSHA Weekly; and Internet Accessible. All previous versions of this memorandum. History of previous versions include: CSHD-MEMO-COM-14-1, May 6, 2014 May 15, 2015 Patricia Meyer, Director, Construction Safety and Health Division /Patricia Meyer/ Patricia Meyer, Director Construction Safety and Health Division Significant Changes: Corrected Optional Information Code and removed the reference to Focused Inspections Division Instruction. Background: Fatalities in the residential construction industry accounted for 37% of the overall construction fatalities in Michigan over the last five years (2008-2013) – most due to falls. Increasing enforcement activities and training outreach in the residential construction industry is one of the strategies in the MIOSHA Strategic Plan for reducing injuries and fatalities. This Local Emphasis Program (LEP) contains instructions for conducting safety inspections of singleand multi-family construction projects where workers are exposed to serious safety hazards that are likely to cause death or serious injuries. MIOSHA will continue to use its current targeting system as described in Division Instruction CSHD-COM-09-1, Construction Inspection Targeting, as amended. This LEP applies to programmed safety inspections only. The LEP will be in effect for a period of one year, from May 15, 2014 through May 15, 2015. MIOSHA anticipates inspecting over 500 residential jobsites over the duration of the LEP. The number of employers, affected employees, and serious violations, will be tracked and compiled. Enforcement Activities: The home building sector consists mainly of small employers with ten (10) or less employees, having limited resources and/or access to training opportunities. The CSHD-MEMO-COM-14-1R1 May 13, 2014 Residential Construction – Local Emphasis Program purpose of this LEP is to focus inspections on the MIOSHA Residential Top 5 serious safety hazard categories: Falls, Scaffolds, Ladders, Personal Protective Equipment /Tool Guarding, and Electrical. (Appendix A). Serious violations that are not one of the MIOSHA Residential Top 5 will also be addressed during inspections; however the main focus will be on the MIOSHA Residential Top 5. Staff will distribute a MIOSHA Residential Inspection Checklist (Appendix B) to each employer during the inspection in order to assist them in identifying common hazards that are associated with residential construction. Other tools and resources will be distributed as appropriate. Documentation and Coding Requirements: An OSHA-1 will be completed only for employers having alleged serious violation(s). However, when none of the employers at the jobsite are receiving an alleged serious violation(s), an OSHA-1 will still be completed for the primary (N1) employer. If the general contractor (GC) is receiving an alleged serious violation, they will be considered the N1 employer. If the GC did not receive a violation or there is no GC at the jobsite, one of the subcontractors will be designated as the N1 employer. A Residential Inspection Narrative (Appendix C) will be completed and included in the N1 employer’s case file only. The narrative will document all of the following for each employer at the jobsite: (1) company name, (2) company address, (3) number of employees at the jobsite for this employer, and (4) verification that a copy of the Residential Inspection Checklist was given to this employer. LEP inspections are considered a partial programmed inspection. The S 8 Optional Information Code and “Single or Multi” will be used for tracking purposes in Box 42 on the OSHA 1 during this LEP. The total number of employees/workers on the jobsite will also be documented on the N1 contractor’s OSHA 1 only. See example below for LEP coding: N1 Employer = S 8 LEP-SINGLE-12* (*total # of employees on jobsite) Non N1 Employers = S 8 LEP-SINGLE Health inspections and all other unprogrammed safety investigations/inspections, (i.e., complaints, accidents, referrals) will continue to use the S13 Optional Information Code. Citation Policy: All serious violations will be grouped into one citation per MIOSHA Residential Top 5 category in accordance with Chapter VI. II. C. 2 of the Field Operations Manual. Additional Resources: Information, fact sheets, and other tools can be found on the MIOSHA website at www.michigan.gov/miosharesidential. 2 Appendix A “MIOSHA RESIDENTIAL TOP 5 HAZARD CATEGORIES” 1. FALL PROTECTION – Serious hazards associated with Part 45, Fall Protection. For example: 2. SCAFFOLDS – Serious hazards associated with Part 12, Scaffolds and Scaffold Platforms. For example: 3. Extension ladder is not extended 3’ above the roof or other surface Extension ladder is not tied off (using ladder to access the roof) Standing on the top step or cap of a step ladder Damaged/broken ladders Not providing a ladder for access to heights greater than 19” PERSONAL PROTECTIVE EQUIPMENT & TOOL GUARDING – Serious head, eye, and tool guarding hazards associated with Part 6, Personal Protective Equipment and Part 19, Tools. For example: 5. No guardrails (10’or greater in height) Single or damaged scaffold planks/platforms No personal fall arrest system (ladder jack scaffolds) Scaffold is not designed with a 4 times safety factor Rough terrain forklift work platform (not tied off, platform not secured) LADDERS – Serious hazards associated with Part 11, Fixed and Portable Ladders. For example: 4. No guardrails (6’or greater in height) No personal fall arrest systems (6’or greater in height) No fall protection plan (must prove infeasibility or greater hazard) Wall/window/floor openings not guarded or covered No hard hats (falling objects, swinging lumber, moving equipment) No safety glasses (flying debris, grinding/cutting) Hard hats and safety glasses (pneumatic nail guns) No guards on saws ELECTRICAL – Serious hazards associated with Part 17, Electrical Installations. For example: No ground fault current interrupter (GFCI) Damaged electrical cords/tools Exposure to energized electrical equipment and power lines Appendix B MIOSHA RESIDENTIAL INSPECTION CHECKLIST Site Location: Project Name: Site Foreman: Date of Inspection: Work Activity: FALL PROTECTION Yes No N/A Yes No N/A Yes No N/A Yes No N/A Is fall protection in place or used when working at heights of 6' or more? (i.e., Guardrails, Midrails, Safety Nets, Personal Fall Arrest System) *A Personal Fall Arrest System is composed of a safety harness, lanyard, and appropriate anchor point. Is a written Fall Protection Plan in use? Is it site-specific? Does it document why it is infeasible or creates a greater hazard to use conventional fall protection? Are employees trained how to recognize fall hazards; install fall protection, (i.e., guardrails); and properly use a Personal Fall Arrest System? Is this training documented? Are holes and other openings, such as stairway openings, properly covered? (i.e., covers are securely fastened, support 2x the intended load, marked "hole" or "cover") SCAFFOLDING Are guardrails in place on scaffold platforms at heights of 10' or more? Are baseplates and adequate mudsills in place? Is the scaffold designed by a competent person to meet the design requirements for supporting 4 times the maximum intended load? Has the scaffold been inspected for defective and missing components? (i.e., damaged planking, bent bracing, not fully planked) Does the Rough Terrain Fork Lift Truck Scaffold meet the design requirements? (i.e., toeboard, guardrail, anchorage point to attach lanyard, platform secured to the forks) Is a Personal Fall Arrest System being used while working on a Ladder Jack Scaffold? LADDERS Do extension ladders extend 3' above the landing area? Are they tied off or secured? Are all ladders Type 1 or Type 1A? (Type II or Type III ladders are not allowed.) Are ladders set up on solid footing and free of trip hazards at the base and top? Are step ladders fully opened with the spreaders locked? Are ladders in good condition with no defects/damage? (i.e., broken rungs or split side rails) Are ladders, ramps or steps provided at elevation changes of 19" or more? TOOLS Are guards in place on table saws, portable electric saws, grinders, compressors, etc.? Are damaged tools tagged or removed from service? PLEASE SEE OTHER SIDE ELECTRICAL Yes No N/A Yes No N/A Yes No N/A Yes No N/A Are all electrical tools protected by a functioning GFCI receptacle, GFCI circuit or GFCI adapter? Are extension cords and trailing cords in good condition and free from damage, wear, missing ground prongs, etc.? Are energized electrical parts protected from accidental contact? (i.e., electrical panel covers are in place, receptacles are secured in approved junction box, temporary wiring is secured at ceiling level, ends of wires are capped or taped) Are power lines clearances being maintained at a minimum of 10' from tools and equipment? PPE Are hard hats worn where risk of being struck by falling/flying objects or from contacting an object? Are safety glasses worn during cutting/sawing/nailing or other operations having a risk of flying particles or objects? *Both a hard hat AND safety glasses are required when operating a nail gun or when working in the vicinity of a nail gun. Is footwear adequate for site conditions and work activities? (i.e., safety boots) SITE CONDITIONS Is there safe access and egress for employees to access the site and structure? Are ground conditions adequate to support equipment? (i.e., cranes and aerial lifts) Is the excavation around the foundation properly sloped or shored to prevent collapse? Is housekeeping being maintained for the site? Are toilets and drinking water available for employees? ADMINISTRATIVE Has an Accident Prevention Program been developed, maintained, and coordinated with employees? Is it available at the work site? Is there an employee trained in basic first aid and a first aid kit available at the work site? Are emergency procedures in place in the event of an incident? Disclaimer: This list is meant to be used as a tool to assist employers with the inspection of their worksites to identify potential hazards that may be present. This checklist will not identify all hazards or items present at your worksite and additional inspection checklists, tools, or aids will be necessary to properly inspect your site. Remember that it is an employer’s obligation to provide to their employees employment and a place of employment that is free from recognized hazards which can cause death or serious physical harm. Appendix C MIOSHA RESIDENTIAL INSPECTION NARRATIVE N1 Employer: Safety Officer: Worksite Address: Inspection # Opening Conference Date: Optional Reporting # Total # of workers on jobsite City/State: Zip Code: List each employer that was on the jobsite during the inspection, their address, # of employees, and then check the last box to verify a Residential Checklist was given to this employer. A Residential Inspection Narrative is to be completed for each jobsite. Include only in the N1 employer’s case file. Employer Name 1) 2) 3) 4) 5) 6) 7) 8) 9) 10) Employer Address # of Employees Checklist Distributed