How to Successfully Design a Drainage System for

Compliance with the New Urban Stormwater

Management Manual by D.I.D.

Workshop No. 3How to Design Detention/Sediment Basins and Culverts

for Compliance with the

“Urban Stormwater Management Manual for Malaysia” by D.I.D.

A 2-Day Hands-On Training Workshop* Organised By:

Dr. Quek & Associates

http://www.msmam.com

7th Workshop

26 – 27 June 2008

Venue: Universiti Teknologi Malaysia, Kuala Lumpur

* This is an BEM (Board of Engineers Malaysia) endorsed course. The BEM CPD (Continuing Professional Development) policy

requires all registered engineers to undertake a minimum of 50 hours of CPD per year. Attendance at this seminar attracts

valuable CPD hours towards your total. This workshop is accredited with 16 CPD hours by BEM.

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

TABLE OF CONTENTS

INTRODUCTION TO THE WORKSHOP .............................................................. 1

What Can You Gain from the Workshop? .................................................................... 1

Objectives of the Workshop and this Publication .......................................................... 3

Target Audience/Prerequisite .......................................................................................... 4

Content of the Workshop ................................................................................................. 4

Chief Course Instructor and Biodata.............................................................................. 4

Author, Publisher and Copyright.................................................................................... 5

Contact Details .................................................................................................................. 5

Request for Login Name and Password to MEMBERS ONLY area ........................... 6

Free eCourse ...................................................................................................................... 6

Training Certificate .......................................................................................................... 6

BEM/CPD Accreditation .................................................................................................. 6

Notations Used in this Publication................................................................................... 7

1

INTRODUCTION ........................................................................................ 8

1.1

General ................................................................................................................... 8

1.2

Design for Water Quantity and Quality Control ............................................... 8

1.3

Design for Quantity Control ................................................................................ 9

1.3.1

Major and Minor Systems ............................................................................... 9

1.3.2

Major and Minor Storms ............................................................................... 12

1.3.3

Major and Minor Systems Design Concepts ................................................ 12

1.3.4

Devices for Quantity Control ........................................................................ 13

1.3.4.1 Detention Storage.................................................................................. 13

1.3.4.2

Retention Storage .................................................................................. 14

1.4

Design for Quality Control ................................................................................. 15

1.4.1

Quality control criteria .................................................................................. 15

1.4.2

Differences between design for Quantity and Quality Control .................... 15

106746216 (2/16/16)

ii

Free software at http://www.msmam.com

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

1.4.3

Devices for Quality Control .......................................................................... 16

1.4.3.1 Post-Construction Stage ........................................................................ 16

1.4.3.2

During Construction Stage .................................................................... 17

1.5

Changes from the Planning and Design Procedure No. 1 ............................... 18

1.6

Relevant sections in MSMAM ........................................................................... 19

1.7

Summary Sheet ................................................................................................... 19

2.

DESIGN OF DETENTION BASIN ............................................................ 21

2.1

Review of Level Pool Routing Procedure ......................................................... 21

2.1.1

Storage Routing Method ............................................................................... 21

2.1.2

Worked Example 2.1- Level Pool Routing Through A Reservoir................ 25

2.1.3

Notes about the Spreadsheet Computation ................................................... 29

2.1.4

Changes from the Planning and Design Procedure No. 1 ............................. 30

2.1.5

Relevant Sections in MSMAM ...................................................................... 30

2.2

Detention Basin Routing..................................................................................... 31

2.2.1

Theory ........................................................................................................... 31

2.2.2

Worked Example 2.2 .................................................................................... 31

2.2.2.1 Problem................................................................................................. 31

Determine design storm criteria for the basin .................................... 32

2.2.2.3

Determine the permissible outflow from basin ................................... 32

2.2.2.4

Compute the basin inflow hydrograph ................................................ 34

2.2.2.5

Preliminary estimate of the required storage volume ......................... 35

2.2.2.6

Develop a basin grading plan .............................................................. 37

2.2.2.7

Compute the stage-storage relationship .............................................. 38

2.2.2.8

Sizing of the minor design storm primary outlet ................................ 38

2.2.2.9

Sizing of the major design storm primary outlet ................................. 39

2.2.2.10

Sizing of the secondary spillway outlet............................................... 40

2.2.3

2.2.4

2.2.2.2

2.3

Worked Example 2.3 .................................................................................... 51

Worked Example 2.4 .................................................................................... 51

Summary Sheet ................................................................................................... 52

Appendix 2A Computation of Design Storm ................................................................ 54

2.1

Design Rainfall .................................................................................................... 54

2.1.1

Computation of Design Rainfall ................................................................... 54

106746216 (2/16/16)

iii

Free software at http://www.msmam.com

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

Derivation of IDF Curves using MSMAM ........................................................... 54

Work Example 2.1- Derive IDF Curve for Ipoh ........................................................... 56

2.1.2.1 Derivation of IDF curves ...................................................................... 56

2 .......................................................................................................................... 57

2.1.2.2 How to Create the Spreadsheet ............................................................. 59

2.1.3.1

How to Use the Spreadsheet ................................................................. 59

Appendix 2B Rational Method ...................................................................................... 60

2.4

Design Discharge ................................................................................................. 60

2.4.1

Methods of computing peak discharges ........................................................ 60

2.4.1.1 Methods in MSMAM ............................................................................ 60

2.4.2

Rational Method of MSMAM ........................................................................ 62

2.4.2.1 Theory ................................................................................................... 62

2.4.2.2

Worked Example 2.3- Rational Method for a minor drainage system in

Ipoh

67

2.4.2.3

How to Create a Spreadsheet ................................................................ 70

3.

DESIGN OF SEDIMENT BASIN .............................................................. 71

3.1

Definition ............................................................................................................. 71

3.2

General Criteria for Installation of Sediment Basins ...................................... 71

3.3

Criteria for Sizing of Sediment Basins .............................................................. 72

3.4

Design of Dry Sediment Basins .......................................................................... 72

3.5

Design of Wet Sediment Basins ......................................................................... 73

3.6

Worked Example 3.1- Design of A Dry Sediment Basin ................................. 75

3.6.2.1 Settling Zone ......................................................................................... 76

3.6.2.2

Sediment Storage Zone ......................................................................... 77

3.6.2.3

Overall Basin Dimensions .................................................................... 78

3.7

Worked Example 3.2- Design of A Dry Sediment Basin (Ipoh) ..................... 81

3.8

Worked Example 3.3- Design of A Wet Sediment Basin ................................. 83

3.8.2.1 Settling Zone ......................................................................................... 84

3.8.2.2

Sediment Storage Zone ......................................................................... 85

106746216 (2/16/16)

iv

Free software at http://www.msmam.com

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

3.8.2.3

Overall Basin Dimensions .................................................................... 85

3.9

Worked Example 3.4- Design of A Wet Sediment Basin (Melaka) ................ 88

3.10

Worked Example 3.5- Design of A Dry Sediment Basin (Kuching) ............... 88

3.11

Worked Example 3.6- Design of A Wet Sediment Basin (Kuching) .............. 89

Appendix 3.1- Design of Silt Trap Using the Planning and Design Procedure No. 1Incorporating an Overflow Weir and Bypass Channel ............................................... 92

4.

DESIGN OF CULVERTS ....................................................................... 114

4.1

Inlet Control ...................................................................................................... 114

4.2

Outlet Control ................................................................................................... 114

4.2.1

Theory ......................................................................................................... 115

4.2.1.1 Velocity head (Hv) ...................................................................................... 115

4.2.1.2 Entrance loss (He) ....................................................................................... 115

4.2.1.3 Friction loss (Hf) ......................................................................................... 116

4.2.1.4 Total Energy Head (H)................................................................................ 116

4.2.1.5 Determining Headwater (HW) .................................................................... 117

4.3

Work Example 4.1 (Concrete Box Culvert) ................................................... 118

4.3.1

Case Study .................................................................................................. 118

4.3.2

Design for 50 years ARI ............................................................................. 118

4.3.3

Design for 100 years ARI ........................................................................... 120

4.3.4

Spreadsheet Computation ........................................................................... 122

4.4

Work Example 4.2 (Concrete Box Culvert) ................................................... 123

4.5

Work Example 4.3 (Concrete Pipe Culvert)................................................... 123

4.6

Work Example 4.4 (Rating Curve).................................................................. 124

4.7

Work Example 4.5 (Peak Discharges) ............................................................. 124

5.

REFERENCES: ..................................................................................... 126

106746216 (2/16/16)

v

Free software at http://www.msmam.com

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

How to Successfully Design a Drainage

System for Compliance with the New Urban

Stormwater Management Manual by D.I.D.

Workshop No. 3How to Design Detention & Sediment Basins and Culverts for

Compliance with the “Urban Stormwater Management

Manual for Malaysia” by D.I.D.

INTRODUCTION TO THE WORKSHOP

What Can You Gain from the Workshop?

As an engineer, do you have problem understanding all the requirements of the new

urban drainage design procedure gazetted by the Federal Government in 2001- the

“Urban Stormwater Management Manual for Malaysia” (“Manual Saliran Mesra

Alam Malaysia” or abbreviated as MSMAM) published by the Department of Irrigation

and Drainage (D.I.D.)?

If the answer is yes, then the following section contains some important information for

you.

Before 2001, engineers in Malaysia applied the “Planning and Design Procedure No. 1”

published by D.I.D. in 1975 for all their drainage design. This is a relatively simple

document to use- with only 242 pages covering ten chapters. But this has changed with

the implementation of MSMAM by the Government in 2001.

106746216 (2/16/16)

Free software

at http://www.msmam.com

1

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

It is a fact that the new Manual is much more thorough in its coverage of subject matters

compared to the old procedure. It contains 48 chapters spanning more than 1,100 pagesabout five times thicker compared to the “Planning and Design Procedure No. 1.”

The new MSMAM is an impressive document by any standards. Its content reflects the

latest advances in the field of stormwater quantity and quality management from around

the world, with many major changes in approaches and procedures. The preparation of

MSMAM was a task involving a large team of local and foreign experts, costing million

of Ringgits and took years to complete.

Not surprisingly, because of above, many engineers are still not familiar with the

requirements of MSMAM.

By attending the Workshop, you will learn:

1. How to solve drainage problems using the new “control-at-source” approach,

instead of the old approach of “rapid-disposal”,

2. What are the water quality issues you must considered- in addition to the drainage

issues when solving a drainage problem,

3. What are the new computer modelling techniques recommended, and

4. What are the major changes in design procedures and recommendations for

solving urban drainage and water quality issues.

The 2-Day Workshop will cover both the theoretical and practical aspects of urban

drainage design based on MSMAM. The theoretical aspect will give the students a broad

understanding of the principles behind various design procedures, while the practical

aspect will include many worked examples to ensure that the students can put theories

into practice.

106746216 (2/16/16)

Free software

at http://www.msmam.com

2

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

The Workshop will highlight the major differences between MSMAM and the Planning

and Design Procedure No. 1. It will also introduce participants to the tools, software and

resources available for application of the new design procedures.

Following are benefits of attending the Workshop:

1. You will be guided by a qualified lecturer with more than 20 years of industrial

experience in the fields of hydrology, hydraulic and water quality modelling, and

has extensive experience in applying the HEC-HMS and HEC-RAS Models.

2. You will benefit from the lecturer’s past involvement in the review process of

MSMAM and his experience in conducting courses on the “Workshop Series on

MSMAM.”

3. You will receive hands-on training using a PC with broadband internet connection

in a modern PC laboratory.

4. You will get a set of specially prepared course note which covers both theories

and step-by-step worked examples.

5. You will be taught the new requirements of MSMAM and the major changes from

the Planning and Design Procedure No. 1.

6. You can download many free computer programs for use with MSMAM. Note

these programs are extremely useful and can be used for your work, without

having to spend a lot of time rewriting them yourself.

7. You will get free lifetime access to the website http://www.msmam.com to

download new updated programs/software and course material.

8. You will be entitled to free lifetime technical support for material covered in the

course by email/phone and through the website. Email: webmaster@msmam.com

9. This workshop is endorsed by BEM for its Continuing Professional Development

(CPD) programme. You can gain valuable CPD hours by attending the workshop.

Objectives of the Workshop and this Publication

The objective of the workshop is to introduce the procedures for urban drainage design

for compliance with the “Urban Stormwater Management Manual for Malaysia.”

106746216 (2/16/16)

Free software

at http://www.msmam.com

3

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

The objectives of this publication are as follows:

To provide the workshop material for the 2-Day Workshop

To provide a resource material in urban drainage design for all participants of the

Workshop.

Target Audience/Prerequisite

The course is suitable for engineers/graduates in civil/environmental engineering. The

basic requirement is a degree in the above disciplines.

There is no prerequisite for Workshop No. 1 and 2. However, the prerequisite for

Workshop No. 3 is Workshop No. 1.

Content of the Workshop

Following are the major topics covered in this Workshop:

1. Design concept for quantity and quality control.

2. Design of detention basin.

3. Design of dry and wet sediment basins.

4. Design of culvert.

Chief Course Instructor and Biodata

The chief course instructor is Ir. Dr. Quek Keng Hong, who is a consulting engineer by

practice and the principal of Dr. Quek & Associates. He obtained his Civil Engineering,

Master of Engineering Science and Ph.D. degrees from the University of NSW, Australia.

He has over 20 years of post-graduate experience mainly in consultancy work. He

specialises in the field of water resources including hydrologic and hydraulic modelling

and environmental management.

Dr. Quek is a regular contributor of engineering journals, seminars and conferences, with

more than 30 publications to his credit. He has conducted regular workshops, seminars

and talks in his fields of expertise.

106746216 (2/16/16)

Free software

at http://www.msmam.com

4

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

Dr. Quek was the reviewer representing IEM in the review process of MSMAM

organised by D.I.D. He was the former Chairman of the Water Resources Technical

Division of IEM.

Dr. Quek has conducted a 4-day workshop entitled “Advanced Course On Urban

Drainage Design For Compliance With The New ‘Urban Stormwater Management

Manual For Malaysia’ By D.I.D.” jointly organised by the Water Resources Technical

Division and IEM Training Centre between 20 and 23 August, 2002.

Between 2002 and 2003, he has also conducted three 2-day workshops on MSMAM in

association with IEM training Centre in Petaling Jaya and Penang.

He was one of the presenters of the 2-day course entitled “Introduction to MSMAM”

conducted by the Water Resources Technical Division of IEM in conjunction with the

following State D.I.D’s in 2000 and 2001: Selangor, Wilayah Persekutuan, Pahang,

Trengganu, Melaka and Negeri Sembilan.

Over the years, Dr. Quek has also conducted numerous talks and seminars on MSMAM

at IEM HQ and other states.

Author, Publisher and Copyright

This Manual is prepared by Ir. Dr. Quek Keng Hong and published by Dr. Quek &

Associates.

The copyrights of all software referred to in this manual belong to their respective

owners. All rights reserved. No part of this manual may be reproduced, in any form or by

any means, without permission in writing from the publisher.

Contact Details

Office: No. 11-1A, Jalan Bandar 10, Pusat Bandar Puchong, 47100 Puchong, Selangor

Darul Ehsan, Malaysia. Phone: (603) 5882 2085 Facsimile: (603) 5882 1603.

106746216 (2/16/16)

Free software

at http://www.msmam.com

5

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

To contact the author send email to: webmaster@msmam.com. For free software and

information on upcoming courses, visit the course website at:

http://www.msmam.com. All software and worked examples in this manual are available

for download from the above site.

Request for Login Name and Password to MEMBERS ONLY area

You must have your own login name and password (i.e., membership) to access the

MEMBERS ONLY area of http://www.msmam.com to download the FULL versions of

the spreadsheet software and worked examples.

To request for your membership, you must send an email to membership@msmam.com

giving full details of your name, email address, dates of attendance, company address and

contact phone numbers for verification purpose.

Note the membership is given only to participants of the workshop. Sharing of your login

name and password with others may result in withdrawal of your membership without

notice.

Free eCourse

You can subscribe to the Free eCourse at http://www.msmam.com. You can also invite

your friends and colleagues to do the same. The eCourse contains useful reference

material, sent to you at 2-day intervals in a number of installments.

Training Certificate

All participants who successfully completed the Workshop will receive a Training

Certificate.

BEM/CPD Accreditation

This is an BEM (Board of Engineers Malaysia) endorsed course. The BEM CPD

(Continuing Professional Development) policy requires all registered engineers to

106746216 (2/16/16)

Free software

at http://www.msmam.com

6

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

undertake a minimum of 50 hours of CPD per year. Attendance at this seminar attracts

valuable CPD hours towards your total.

Dr. Quek & Associates is an Accredited Training Provider for the BEM CPD

programme. You will gain 16 CPD hr by attending any one of Workshop 1, 2 or 3 i.e., 1

CPD hour for every hour of attendance.

You may keep a copy of the receipt and certificate as proof of attendance required by

BEM. Please note, however, that you must attend the workshop daily and sign the

attendance sheet each day before you will receive your certificate. Payment alone cannot

be accepted as proof of your attendance.

Notations Used in this Publication

In this publication, there are numerous references to figures, tables and appendices in

MSMAM and other publications. These are underlined in order to differentiate them from

the same references used in this publication. The convention adopted is as follows:

If the reference is not underlined e.g., Table 4.1, it refers to a table in this publication.

If the reference is underlined e.g., Table 4.1, it refers to a table in MSMAM.

If the table is taken from a publication other than MSMAM, then the source is stated after

the table reference e.g., Table 1 of HP11.

The above apply to tables, figures, appendices and etc.

106746216 (2/16/16)

Free software

at http://www.msmam.com

7

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

1 INTRODUCTION

1.1

General

Workshop 3 covers the following:

Design concept for quantity and quality control.

Design of detention basin

Design of dry and wet sediment basin

Design of culvert

It is strongly recommended that participant attend Workshop No. 1 before

attending Workshop No. 3 as the fundamentals of design storm computation, timearea method and reservoir routing are covered in the former.

1.2

Design for Water Quantity and Quality Control

Topics to be covered are divided into two broad areas as follows:

Design for Quantity Control, and

Design for Quality Control.

Design for Quantity Control covers the following topics:

1. Major and Minor Systems

2. Major and Minor Storms

3. Major and Minor Systems Design concepts

4. Devices for Quantity Control

Design for Quality Control covers the following topics:

1. Quality control criteria

106746216 (2/16/16)

Free software

at http://www.msmam.com

8

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

2. Differences between design for Quantity and Quality Control

3. Devices for Quality Control

1.3

Design for Quantity Control

1.3.1 Major and Minor Systems

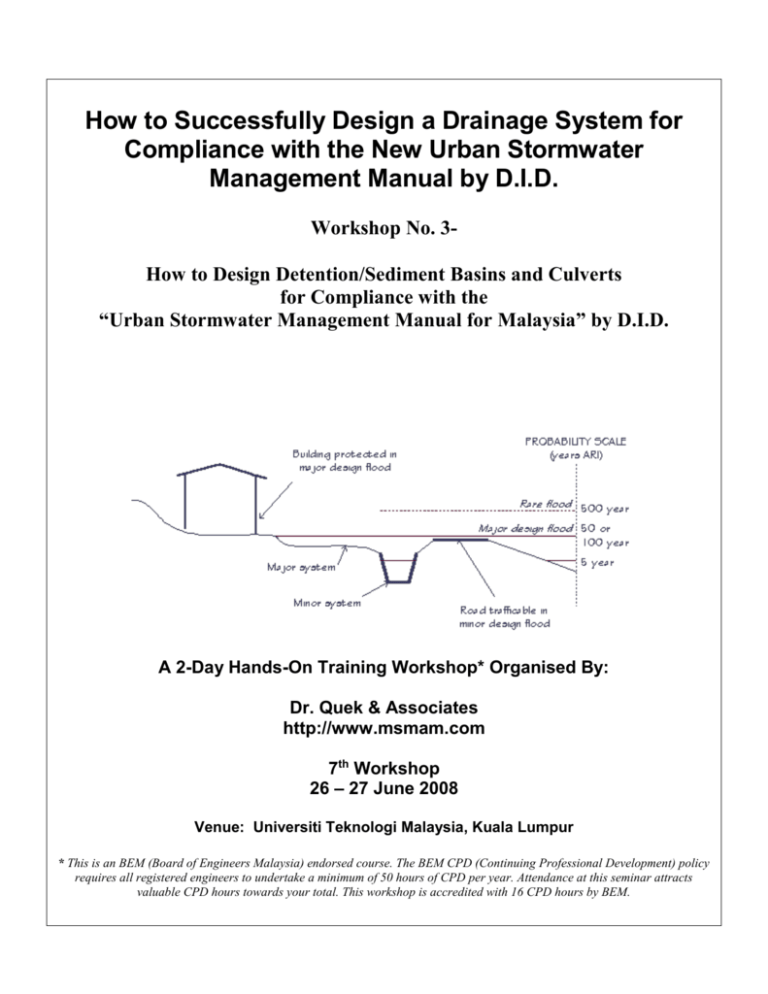

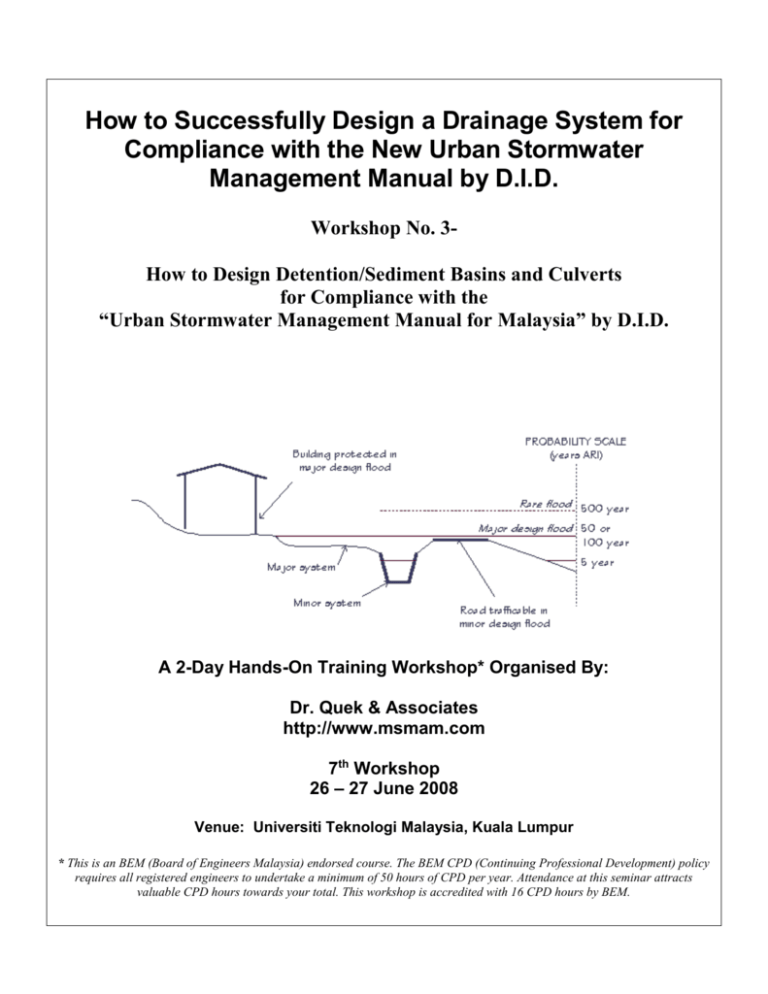

Design concepts for the major and minor systems are illustrated diagrammatically

in Figure 1.1.

The basic concepts of major and minor systems are discussed below:

Minor system is designed to convey runoff from a minor storm, which occurs

relatively frequently, and would result in inconvenience and nuisance flooding.

Examples: kerbs, gutters, inlets, open drains and pipes.

Major system is designed to convey runoff from a major storm, which comprises

the many planned and unplanned drainage routes that convey runoff to waterways

and rivers. It is designed to protect the community from the consequences of large

and rare events which could cause severe flood damage, injury and loss of life.

Differences between the design objectives of Major and Minor System are

summarised in Table 1.1.

106746216 (2/16/16)

Free software

at http://www.msmam.com

9

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

FIGURE 1.1 MAJOR AND MINOR SYSTEM DESIGN CONCEPTS (DID, 2000)

106746216 (2/16/16)

10

Free software at http://www.msmam.com

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

The choice of design standards for both major and minor storms should be made

by economic analysis, considering the tangible and intangible costs and benefits

of different levels of protection.

AN ILLUSTRATION OF DESIGN FOR QUANTITY CONTROL

Design for Quantity Control

Rare major

storm, severe

damage and

loss of life

Frequent minor

storm, nuisance

flooding

Major System

(Major drains or planned

drainage routes)

Minor System

(Kerbs, gutters, inlets,

open drains and pipes)

TABLE 1.1 MAJOR AND MINOR SYSTEM DESIGN OBJECTIVES (DID, 2000)

MAJOR SYSTEM

MINOR SYSTEM

Reduced injury and loss of life

Improved aesthetics

Reduced disruption to normal business

Reduction in minor traffic accidents

activities

Reduced damage to infrastructure services Reduced health hazards (mosquitoes, flies)

Reduced emergency services costs

Reduced personal inconvenience

Reduced flood damage

Reduced roadway maintenance

Reduced loss of production

Reduced clean-up costs

Increased feeling of security

Increased land values

Improved aesthetics and recreational

opportunities

106746216 (2/16/16)

Free software

at http://www.msmam.com

11

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

1.3.2 Major and Minor Storms

Major and minor storms- Table 4.1 shows the design storm ARIs for urban

stormwater systems.

It can be seen that the ARI for minor system ranges from 1, 2, 5 to 10 years

depending on the types of development. The ARI for major system, however,

ranges up to 100 years for all types of development.

1.3.3 Major and Minor Systems Design Concepts

There are major differences in approach on the design for minor and major

systems. These are presented in Figure 1.2 and discussed as follows:

Community facilities are major drainage structures for larger areas which

combine different landuse areas. Quantity design based on hydrograph approach

using larger storms of up to 100 years ARI.

On-site facilities are minor drainage structures provided for individual housing

and industrial sites. Quantity design for ARI of 2 and 10 years.

106746216 (2/16/16)

Free software

at http://www.msmam.com

12

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

FIGURE 1.2 GENERAL DESIGN CONCEPT FOR MAJOR AND MINOR

SYSTEMS (DID, 2000)

1.3.4 Devices for Quantity Control

The main devices for stormwater quantity control are as follows:

Detention Storage- either Onsite Detention (OSD), Community Detention or

Regional Detention (Chapters 19 and 20 of MSMAM).

Retention Storage- either Onsite Retention, Community Retention or Regional

Retention (Chapters 21 and 22 of MSMAM).

1.3.4.1 Detention Storage

The basic concept of providing detention storage is to limit the peak outflow rate

for a specific range of flood frequencies to that which existed before

development.

106746216 (2/16/16)

Free software

at http://www.msmam.com

13

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

The primary function of detention facilities is to reduce peak discharge by the

temporary storage and gradual release of stormwater runoff by way of an outlet

control structure.

Examples of Onsite Detention include: car park, surface and underground tanks,

rooftop and landscaped area. See Figure 18.2.

Community and Regional Detention facilities are larger facilities than OSD which

are provided in public areas outside private properties. These are commonly

formed by the construction of an embankment across a stream and/or the

excavation of a basin storage area.

Two main types: dry and wet basins.

Examples of dry basins include public parks and playing fields.

Examples of wet basins include: ponds and lakes.

1.3.4.2 Retention Storage

True retention facilities reduce runoff volume and peak discharge by the

temporary storage of stormwater runoff, which is subsequently released via

evaporation and infiltration only.

Examples of Onsite and Community Retention include: infiltration trench,

soakaway pit, porous pavement and infiltration basin. See Figure 18.2.

Examples of Regional Retention include: basin method, Ditch and Furrow

Method, flooding method, irrigation method and recharge well method (refer

Chapter 18).

106746216 (2/16/16)

Free software

at http://www.msmam.com

14

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

1.4

Design for Quality Control

1.4.1 Quality control criteria

Criteria for sizing for sediment retention (Chapter 4):

3 month ARI for construction project taking < 2 years

6 month ARI for construction project taking > 2 years

1.4.2 Differences between design for Quantity and Quality Control

Table 1.2 summarises the major differences between design for quantity and

quality control. It is important to understand the differences in approach.

Quality control mainly concerns control of sediment, as many pollutants are

attached to sediment particles.

TABLE 1.2 GENERAL HYDROLOGIC DESIGN CONSIDERATIONS

(DID, 2000)

Quantity

Quality

Runoff peak

Runoff volume

Landuse % imperviousness

Landuse activities

Management of infrequent storms

Management of frequent storms

Multi storm ARI design approach

Single storm ARI design approach

(major/minor)

Detention/retention may not perform in

Ponds may not be efficient in infrequent

repeated/multiple storms

storms

Event and continuous (retention only)

modeling

106746216 (2/16/16)

Annual average load modelling

Free software

at http://www.msmam.com

15

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

AN ILLUSTRATION OF DIFFERENCES BETWEEN

QUANTITY AND QUALITY CONTROL

Differences Between Quantity and

Quality Control

Runoff Peak, Infrequent

Storm, Major/Minor

ARI, Event Modelling

Runoff Volume, Frequent

Storms, Single ARI,

Annual Average Load

Modelling

Quantity Control

Quality Control

1.4.3 Devices for Quality Control

1.4.3.1 Post-Construction Stage

Following are the main runoff quality control devices at the post-construction

stage:

Filtration- Examples: Biofiltration swales and vegetated filter strip. Main

processes include: sedimentation, filtration, infiltration, soil adsorption and

biological uptake by plants.

Infiltration- Examples: Infiltration trench, infiltration basin and porous

pavement.

106746216 (2/16/16)

Free software

at http://www.msmam.com

16

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

Gross Pollutant Trap- Remove coarse sediment (and other pollutants e.g.,

nutrients and metals attached to sediment), litter and debris. Examples:

booms, in-pit devices, trash rack and litter control devices, sediment traps,

SBTR (Sediment Basin and Trash Rack) traps, proprietary devices. Do not

provide flow attenuation.

Constructed Ponds and Wetlands- function both for water quality control and

flood control. Only remove fine sediment. Not suitable for coarse sediment.

Provide temporary flood storage to reduce downstream flow peaks. Improve

water quality by sedimentation and biological processes.

1.4.3.2 During Construction Stage

During the construction stage, the main runoff quality control methods are as

follows:

Erosion and Sediment Control Measures- These are Best Management

Practices (BMP). Examples:site planning considerations, vegetative

stabilization, physical stabilization, diversion of runoff, flow velocity

reduction, sediment trapping and filtering.

Erosion and Sediment Control Plans- Preparation of a ESCP before start of

project detailing types of erosion control measures.

106746216 (2/16/16)

Free software

at http://www.msmam.com

17

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

AN ILLUSTRATION OF DESIGN FOR QUALITY CONTROL

Design for Quality Control

3 mth ARI for construction project < 2 yrs

6 mth ARI for construction project > 2 yrs

During Construction Stage

(BMP, ESCP)

1.5

Post Construction Stage

(Filtration, infiltration,

GPT, SBTR, Ponds and

Wetlands)

Changes from the Planning and Design Procedure No. 1

Following are the major changes from P&DP No. 1:

1. Change from “rapid disposal” to “Control-at-source.”

2. Method of computing design rainfall

3. Design ARI for major and minor systems

4. Computation of peak discharge- empirical and rainfall-runoff model (time-area,

RORB, HEC-HMS, etc)

5. Water quality consideration

6. Use of hydraulic model HEC-RAS

7. More detention, retention and water quality control devices.

106746216 (2/16/16)

Free software

at http://www.msmam.com

18

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

1.6

Relevant sections in MSMAM

Following are the relevant sections of the MSMAM manual referred to in this

Section:

Chapter 4- design criteria

Chapter 11- Hydrologic design concepts

Chapters 19 and 20- Detention Storage

Chapters 21 and 22- Retention Storage

1.7

Summary Sheet

1. The major changes in MSMAM include:

A shift from the old approach of conveyance-based, “rapid-disposal”

approach to the new “control-at-source” approach,

Greater emphasis on water quality management- in addition to water

quantity management,

Greater emphasis on the use of computational models including computer

software,

Changes in design procedures for various drainage components, and

More thorough coverage of subject matters.

2. Topics covered are divided into two broad areas as follows:

Design for Quantity Control, and

Design for Quality Control.

3. Design for Quantity Control covers the following topics:

Major and Minor Systems

Major and Minor Storms

Major and Minor Systems Design concepts

Devices for Quantity Control

4. Design for Quality Control covers the following topics:

106746216 (2/16/16)

Free software

at http://www.msmam.com

19

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

Quality control criteria

Differences between design for Quantity and Quality Control

Devices for Quality Control

5. Major differences in approach on the design of detention storage for minor

and major systems:

Onsite Stormwater Detention Facilities (OSD)- minor drainage structures

for individual housing and industrial sites, designed for minor storm, can

use rational methods.

Community or Regional Detention- major drainage structures for larger

areas which combine different landuse areas, designed for both major and

minor storms, located in public lands, hydrograph methods required.

.

106746216 (2/16/16)

Free software

at http://www.msmam.com

20

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

2.

DESIGN OF DETENTION BASIN

2.1 Review of Level Pool Routing Procedure

2.1.1 Storage Routing Method

The sizing of detention basins can be done using a reservoir routing method such

as the Level-Pool Routing Procedure, which computes storage routing by solving

the continuity equation and the storage function.

The continuity equation or the equation of conservation of mass simply expresses

the condition that the rate of inflow less the rate of outflow at any instance in time

is equal to the rate of change in storage in the basin as follows:

I Q

S

t

(2.1)

where

I

is the instantaneous inflow rate of discharge to the basin (m3/s)

Q

is the instantaneous outflow rate of discharge from the basin (m3/s)

S

is the volume of temporary storage in the basin (m3)

The above equation may be expressed in finite difference form as follows:

I

j

I j 1

2

Q

j

Q j 1

2

S j 1 S j

t

(2.2)

where

j, j+1 are time steps j and j+1, respectively.

t

is the time interval defining the finite difference approximation of

the continuity equation.

The above equation can be rearranged such that all known variables are placed on

the left side of the equation and all unknown variables on the right as follows:

106746216 (2/16/16)

Free software

at http://www.msmam.com

21

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

AN ILLUSTRATION OF RESERVOIR ROUTING

Inflow Hydrograph

Hydrograph Method

Initial

Conditions

Si & Qi

Continuity Equation

Storage Function Q=f(S)

S

t

I Q

Rating curve: Q=f(H)

Storage curve: H=f(S)

Outflow Hydrograph

Qp

Qp

t

t

Qp

t

106746216 (2/16/16)

Free software

at http://www.msmam.com

22

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

AN ILLUSTRATION OF APPLICATION OF DESIGN STORM +

HYDROGRAPH METHOD + RESERVOIR ROUTING METHODS

Design Storm

Calculate IDF data

I

t

Hydrograph Method

Time Area Method or

Runoff Routing Method

Reservoir Routing

Level Pool Routing

Through Detention Storage

Detention Basin

Calculate Water Level

(Workshop 2)

Use HEC-RAS model to

calculate water level in drain

EOpen Drain

Qp

t

106746216 (2/16/16)

Free software

at http://www.msmam.com

23

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

I

j

2Sj

2 S j 1

I j 1

Q j

Q j 1

t

t

(2.3)

It is evident from the above equation that a second equation is necessary to solve

the two unknown variables of Qj+1 and Sj+1. This second equation is referred to as

the storage function, which expresses the relationship between the storage in the

basin and the discharge from the basin in the form of Q = f(S).

The storage function represents the combined effect of:

1. The discharge characteristics or the “rating curve” as represented by Q=f(H)

2. The topography of the site i.e., the geometric properties as represented by the

storage curve or H versus S data of the storage facility, expressed as H= f(S).

By combining Q=f(H) and H= f(S), the storage-discharge relationship for the

basin or the storage function can be derived as Q = f(S).

The discharge characteristics for a basin with spillway outlet can be represented

by the following spillway discharge equation:

Q s cL( H H s ) 3 / 2

(2.4)

where

Qs

is the spillway discharge in m3/s.

c

is the weir coefficient for the spillway (ranging from 1.45 m0.5/s for a

broad crested weir to 2.15 m0.5/s for an ogee crested weir)

L

is the effective length of the spillway (m)

H

is the water level (m)

Hs

is the spillway crest elevation (m)

106746216 (2/16/16)

Free software

at http://www.msmam.com

24

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

A level pool routing can be carried out using either one of the following

approaches:

a spreadsheet like MS Excel (see Work Example 2.1)

a simple computer program (Fortran Program: resrot1z.zip- a bonus

program given to participants of the Workshop)

2.1.2 Worked Example 2.1- Level Pool Routing Through A Reservoir

This is a worked example using a spreadsheet to perform level pool routing

through a reservoir.

Following are the data required for the solution of Equation 2.3:

1. Time step.

2. Stage-Storage relationship- usually derived from topographic maps.

3. Stage-Discharge relationship- can be based on formula such as Equation 2.4

for spillway or other appropriate formula.

4. The inflow hydrograph.

5. Initial values of storage and discharge.

Excel Filename: DrQuekLevelPoolRouting1a.zip.

Equation 2.3 can be solved using the spreadsheet below as follows:

2 S j 1

Q j 1 which is

t

1. At time j+1, compute the RHS of Equation 2.3 ie,

equal to the LHS of the equation or the sum of I j I j 1 and

2Sj

t Q j which are all known. (Col. 4+Col. 5= Col. 6)- See purple cells.

2. Prepare a table of Stage-Discharge-Storage data as referred to above and

2S

Q . (See Col. 9, 10, 11, 12.)- See light blue cells.

compute

t

106746216 (2/16/16)

Free software

at http://www.msmam.com

25

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

2 S j 1

Q j 1 compute the value of Qj+1 and

t

3. For a particular value of

water level (which is the sum of stage and the basin elevation at zero stage) by

interpolating the table in (2). (Interpolate Col. 6, 7 & 8 from Col. 12, 10 & 9.)

2 S j 1

4. Compute the value of

Q j 1 which is equal to

t

2 S j 1

Q j 1 minus 2 x Qj+1. (Col. 5= Col. 6 - 2 x Col. 7)- see green

t

cells.

5. The above process is repeated for each subsequent time steps until the outflow

becomes zero.

TABLE 2.1 LEVEL POOL ROUTING USING SPREADSHEET

1

2

3

4

t

T (min) I

Ij+I(j+1)

(min)

J

12

0 0.0000

j+1

13 0.4375 0.4375

j+2

14 0.875 1.3125

j+3

15 1.3125 2.1875

j+4

16 1.75 3.0625

j+5

17 2.1875 3.9375

j+6

18 2.625 4.8125

j+7

19 3.0625 5.6875

j+8

20

3.5 6.5625

j+9

21 4.14 7.6400

j+10

22 4.78 8.9200

j+11

23 5.42 10.2000

j+12

24 6.06 11.4800

j+13

25

6.7 12.7600

j+14

26 7.34 14.0400

j+15

27 7.98 15.3200

j+16

28 8.62 16.6000

j+17

29 9.26 17.8800

j+18

30

9.9 19.1600

j+19

31 10.45 20.3500

j+20

32

11 21.4500

j+21

33 11.55 22.5500

j+22

34 12.1 23.6500

106746216 (2/16/16)

5

6

7

8

9

10

11

12

(2Sj/dt) (2S(j+1)/dt) Q(j+1)

WL(mRL)=H H (m)

Q (m3/s) S (m3)

(2S/dt)+Q

-Qj

+Q(j+1)

+Datum

0

0

0

99.5

0.00

0.00

0

0.000

0.2335

0.4375

0.102

99.55

0.025

0.051

4.500

0.201

0.832

1.546

0.357

99.675

0.050

0.102

9.000

0.402

1.8115

3.0195

0.604

99.775

0.075

0.153

13.500

0.603

3.102

4.874

0.886

99.85

0.100

0.204

18.000

0.804

4.5155

7.0395

1.262

99.95

0.125

0.255

22.500

1.005

6.186

9.328

1.571

100.025

0.150

0.306

27.000

1.206

8.0055

11.8735

1.934

100.1

0.175

0.357

31.500

1.407

9.974

14.568

2.297

100.175

0.200

0.408

36.000

1.608

12.294

17.614

2.66

100.25

0.225

0.459

40.500

1.809

15.41

21.214

2.902

100.3

0.25

0.51

45

2.010

19.08

25.61

3.265

100.375

0.275

0.604

59.500

2.587

23.062

30.56

3.749

100.475

0.300

0.698

74.000

3.165

27.888

35.822

3.967

100.525

0.325

0.792

88.500

3.742

33.412

41.928

4.258

100.6

0.350

0.886

103.000

4.319

39.828

48.732

4.452

100.65

0.375

0.980

117.500

4.897

46.942

56.428

4.743

100.725

0.400

1.074

132.000

5.474

54.948

64.822

4.937

100.775

0.425

1.168

146.500

6.051

63.846

74.108

5.131

100.825

0.450

1.262

161.000

6.629

73.352

84.196

5.422

100.9

0.475

1.356

175.500

7.206

83.57

94.802

5.616

100.95

0.50

1.45

190

7.783

94.5

106.12

5.81

101

0.525

1.571

215.400

8.751

106.15

118.15

6

101.05

0.550

1.692

240.800

9.719

Free software

at http://www.msmam.com

26

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

j+23

j+24

j+25

j+26

j+27

j+28

j+29

j+30

j+31

j+32

j+33

j+34

j+35

j+36

j+37

j+38

j+39

j+40

j+41

j+42

j+43

j+44

j+45

j+46

j+47

j+48

j+49

j+50

j+51

j+52

j+53

j+54

j+55

j+56

j+57

j+58

j+59

j+60

j+61

j+62

j+63

j+64

j+65

j+66

j+67

j+68

j+69

j+70

j+71

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

12.65

13.2

13.75

14.3

14.85

15.4

14.62

13.84

13.06

12.28

11.5

10.72

9.94

9.16

8.38

7.6

7.16

6.72

6.28

5.84

5.4

4.96

4.52

4.08

3.64

3.2

2.98

2.76

2.54

2.32

2.1

1.88

1.66

1.44

1.22

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

24.7500

25.8500

26.9500

28.0500

29.1500

30.2500

30.0200

28.4600

26.9000

25.3400

23.7800

22.2200

20.6600

19.1000

17.5400

15.9800

14.7600

13.8800

13.0000

12.1200

11.2400

10.3600

9.4800

8.6000

7.7200

6.8400

6.1800

5.7400

5.3000

4.8600

4.4200

3.9800

3.5400

3.1000

2.6600

2.2200

1.9000

1.7000

1.5000

1.3000

1.1000

0.9000

0.7000

0.5000

0.3000

0.1000

106746216 (2/16/16)

118.52

131.61

145.42

159.95

175.466

191.854

207.784

222.04

234.508

245.302

254.422

261.872

267.762

272.092

274.752

275.852

275.732

274.732

272.962

270.312

266.782

262.372

257.192

251.132

244.306

236.714

228.576

220.112

211.322

202.206

192.764

182.996

172.902

162.482

151.812

141.082

130.412

119.732

109.232

98.722

88.396

78.258

68.502

58.934

49.554

40.556

130.9

144.37

158.56

173.47

189.1

205.716

221.874

236.244

248.94

259.848

269.082

276.642

282.532

286.862

289.632

290.732

290.612

289.612

287.732

285.082

281.552

277.142

271.852

265.792

258.852

251.146

242.894

234.316

225.412

216.182

206.626

196.744

186.536

176.002

165.142

154.032

142.982

132.112

121.232

110.532

99.822

89.296

78.958

69.002

59.234

49.654

6.19

6.38

6.57

6.76

6.817

6.931

7.045

7.102

7.216

7.273

7.33

7.385

7.385

7.385

7.44

7.44

7.44

7.44

7.385

7.385

7.385

7.385

7.33

7.33

7.273

7.216

7.159

7.102

7.045

6.988

6.931

6.874

6.817

6.76

6.665

6.475

6.285

6.19

6

5.905

5.713

5.519

5.228

5.034

4.84

4.549

101.1

101.15

101.2

101.25

101.275

101.325

101.375

101.4

101.45

101.475

101.5

101.525

101.525

101.525

101.55

101.55

101.55

101.55

101.525

101.525

101.525

101.525

101.5

101.5

101.475

101.45

101.425

101.4

101.375

101.35

101.325

101.3

101.275

101.25

101.225

101.175

101.125

101.1

101.05

101.025

100.975

100.925

100.85

100.8

100.75

100.675

0.575

0.600

0.625

0.650

0.675

0.700

0.725

0.75

0.775

0.800

0.825

0.850

0.875

0.900

0.925

0.950

0.975

1.00

1.025

1.050

1.075

1.100

1.125

1.150

1.175

1.200

1.225

1.25

1.275

1.300

1.325

1.350

1.375

1.400

1.425

1.450

1.475

1.50

1.525

1.550

1.575

1.600

1.625

1.650

1.675

1.700

1.725

1.75

1.775

Free software

at http://www.msmam.com

27

1.813

1.934

2.055

2.176

2.297

2.418

2.539

2.66

2.781

2.902

3.023

3.144

3.265

3.386

3.507

3.628

3.749

3.87

3.967

4.064

4.161

4.258

4.355

4.452

4.549

4.646

4.743

4.84

4.937

5.034

5.131

5.228

5.325

5.422

5.519

5.616

5.713

5.81

5.905

6.000

6.095

6.190

6.285

6.380

6.475

6.570

6.665

6.76

6.817

266.200

291.600

317.000

342.400

367.800

393.200

418.600

444

482.900

521.800

560.700

599.600

638.500

677.400

716.300

755.200

794.100

833

905.900

978.800

1051.700

1124.600

1197.500

1270.400

1343.300

1416.200

1489.100

1562

1694.500

1827.000

1959.500

2092.000

2224.500

2357.000

2489.500

2622.000

2754.500

2887

3091.000

3295.000

3499.000

3703.000

3907.000

4111.000

4315.000

4519.000

4723.000

4927

5206.500

10.686

11.654

12.622

13.589

14.557

15.525

16.492

17.460

18.878

20.295

21.713

23.131

24.548

25.966

27.384

28.801

30.219

31.637

34.164

36.691

39.218

41.745

44.272

46.799

49.326

51.853

54.380

56.907

61.420

65.934

70.448

74.961

79.475

83.989

88.502

93.016

97.530

102.043

108.938

115.833

122.728

129.623

136.518

143.413

150.308

157.203

164.098

170.993

180.367

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

j+72

j+73

j+74

j+75

j+76

j+77

j+78

j+79

j+80

j+81

j+82

j+83

84

85

86

87

88

89

90

91

92

93

94

95

106746216 (2/16/16)

1.800

1.825

1.850

1.875

1.900

1.925

1.950

1.975

2.00

2.025

2.050

2.075

2.100

2.125

2.150

2.175

2.200

2.225

2.25

2.275

2.300

2.325

2.350

2.375

2.400

2.425

2.450

2.475

2.50

2.525

2.550

2.575

2.600

2.625

2.650

2.675

2.700

2.725

2.75

2.775

2.800

2.825

2.850

2.875

2.900

2.925

2.950

2.975

3.00

Free software

at http://www.msmam.com

28

6.874

6.931

6.988

7.045

7.102

7.159

7.216

7.273

7.33

7.385

7.440

7.495

7.550

7.605

7.660

7.715

7.770

7.825

7.88

7.932

7.984

8.036

8.088

8.140

8.192

8.244

8.296

8.348

8.40

8.451

8.502

8.553

8.604

8.655

8.706

8.757

8.808

8.859

8.91

8.958

9.006

9.054

9.102

9.150

9.198

9.246

9.294

9.342

9.39

5486.000

5765.500

6045.000

6324.500

6604.000

6883.500

7163.000

7442.500

7722

8069.900

8417.800

8765.700

9113.600

9461.500

9809.400

10157.300

10505.200

10853.100

11201

11594.900

11988.800

12382.700

12776.600

13170.500

13564.400

13958.300

14352.200

14746.100

15140

15558.400

15976.800

16395.200

16813.600

17232.000

17650.400

18068.800

18487.200

18905.600

19324

19757.900

20191.800

20625.700

21059.600

21493.500

21927.400

22361.300

22795.200

23229.100

23663

189.741

199.114

208.488

217.862

227.235

236.609

245.983

255.356

264.730

276.382

288.033

299.685

311.337

322.988

334.640

346.292

357.943

369.595

381.247

394.429

407.611

420.793

433.975

447.157

460.339

473.521

486.703

499.885

513.067

527.064

541.062

555.060

569.057

583.055

597.053

611.050

625.048

639.046

653.043

667.555

682.066

696.577

711.089

725.600

740.111

754.623

769.134

783.645

798.157

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

3.025

3.050

3.075

3.100

3.125

3.150

3.175

3.200

3.225

3.25

3.275

3.300

3.325

3.350

3.375

3.400

3.425

3.450

3.475

3.50

9.437

9.484

9.531

9.578

9.625

9.672

9.719

9.766

9.813

9.86

9.906

9.952

9.998

10.044

10.090

10.136

10.182

10.228

10.274

10.32

24116.500

24570.000

25023.500

25477.000

25930.500

26384.000

26837.500

27291.000

27744.500

28198

28699.500

29201.000

29702.500

30204.000

30705.500

31207.000

31708.500

32210.000

32711.500

33213

2.1.3 Notes about the Spreadsheet Computation

The initial time j is taken as 12 min in the computation.

The inflow hydrograph is computed using either Time-Area Method or the

Runoff-Routing Model.

Water level WL (m RL) is equal to Water Depth (m) + datum (RL).

The function VLOOKUP() automatically takes the lower value in the

iteration. But this is not a problem as the result is still within the required

order of accuracy.

The outflow hydrograph has the highest peak discharge of 7.44 m3/s at 101.55

m RL.

The highest peak discharge is compared to and found to be less than the predevelopment peak.

The highest water level of 101.55 m RL is found to be lower than the top of

the reservoir, thus will not cause overtopping of the reservoir.

Refer to the downloaded spreadsheet for details.

106746216 (2/16/16)

Free software

at http://www.msmam.com

29

813.320

828.484

843.648

858.811

873.975

889.139

904.302

919.466

934.630

949.793

966.556

983.319

1000.081

1016.844

1033.607

1050.369

1067.132

1083.895

1100.657

1117.420

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

Two worksheets are included: SHORTHSQ (with a shorter H-S-Q table) and

LONGHSQ (with a longer H-S-Q table). Notice both give identical answer.

So a short H-S-Q is good enough in this case.

2.1.4 Changes from the Planning and Design Procedure No. 1

Based on the Modified Rational Method to compute the inflow hydrograph.

The cumulative inflow and the outflow hydrographs are plotted and the largest

differential storage is taken as the required storage of the detention basin. The

ARI is 100 years.

2.1.5 Relevant Sections in MSMAM

Refer Appendix 20.B of MSMAM.

106746216 (2/16/16)

Free software

at http://www.msmam.com

30

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

2.2 Detention Basin Routing

2.2.1 Theory

This section provides guidelines for the design of the community/regional based

stormwater detention facilities. Some of the requirements for the design of a dry

detention basin are as follows:

The primary outlets for detention basins shall be designed to reduce the

post-development peak flows to below the pre-development peak flows

for both the minor and major system design storm ARI.

The sizing of a detention basin requires the following data:

o Inflow hydrograph

o Stage-storage curve

o Stage-discharge curve

2.2.2 Worked Example 2.2

2.2.2.1 Problem

Design a dry detention basin for a catchment as follows:

Location= Ipoh

Flow will be directed to the basin via a grassed floodway along the

alignment of an existing stream.

A low flow pipe system with a capacity of 2.1 m3/s will bypass the basin

and combine with the basin outflow in the downstream floodway.

Excel filename: DrQuekDetention1a.xls

The worksheets in the above file are are summarised as follows:

106746216 (2/16/16)

Free software

at http://www.msmam.com

31

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

No.

Worksheet Name

Purpose

1

2

ShortDuration

IDF

3

100yr15min, 100yr30min, 100yr60min

4

50yr15min, 50yr30min, 50yr60min

5

5yr15min, 5yr30min, 5yr60min

6

5yr30minPreDev, 50yr30minPreDev

7

Compute

8

culvert1

9

culvert2, culvert2a, culvert2b

10

Spillway

11

rout5yr30min, rout50yr30min,

rout100yr30min

For computing 15 min short duration storm

Compute IDF data for input to time-area

method

Time-area method for 100 year 15, 30 and 60

min duration storm for post development

case.

Time-area method for 50 year 15, 30 and 60

min duration storm for post development

case.

Time-area method for 5 year 15, 30 and 60

min duration storm for post development

case.

Time-area method for 5 and 50 year 30 min

duration storm for pre-development case.

Summary of all time-area method results and

determination of net inflow to basin after

subtracting low flow.

Culvert sizing and computation of stagedischarge curve for Q5 minor flow

Culvert sizing and computation of stagedischarge curve for Q50 major flow

Spillway sizing and computation of stagedischarge curve for Q100 major flow

Level-pool routing procedure for 5, 50 and

100 year basin inflow of 30 min duration

2.2.2.2 Determine design storm criteria for the basin

The aim is to reduce the post-development peak flows for the minor and major

system ARI to less than or equal to the pre-development peaks.

The major and minor system design storms are 5 year and 50 years ARI,

respectively in accordance with Table 4.1.

The design storm for the secondary outlet spillway is 100 year ARI.

2.2.2.3 Determine the permissible outflow from basin

The time of concentration for the catchment is 30 minutes.

106746216 (2/16/16)

Free software

at http://www.msmam.com

32

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

Permissible basin outflow= Pre Development Peak- Bypass flow.

As shown in Table 2.3, the permissible basin outflows are:

4 m3/s for 5 year flow

6.25 m3/s for 50 year flow

TABLE 2.2 PRE AND POST DEVELOPMENT TOTAL FLOW HYDROGRAPH

M3/S

Time

(min)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

Pre

Development

Pre

Pre

Dev

Dev

5 yr

50 yr

30

30

min

min

0.00

0.00

0.00

0.12

0.36

0.58

0.78

1.33

1.44

2.77

4.12

6.17

6.14

8.35

4.79

6.33

2.96

3.90

1.78

2.35

0.77

1.01

0.15

0.19

0.00

0.00

106746216 (2/16/16)

Post Development

Post

Dev

5 yr

15

min

0.00

0.55

1.42

2.53

6.74

11.01

8.86

3.55

0.57

0.00

0.00

0.00

0.00

Post

Dev

5 yr

30

min

0.00

0.33

0.89

2.15

4.86

8.84

10.87

8.00

4.94

2.97

1.28

0.25

0.00

Post Development

Post

Dev

5 yr

60

min

0.00

0.06

0.27

0.86

1.81

4.30

7.03

8.42

9.49

8.02

5.69

3.94

2.93

2.11

1.57

1.04

0.45

0.09

0.00

Post

Dev

50 yr

15

min

0.00

0.75

1.90

3.40

9.08

14.72

11.79

4.70

0.76

0.00

0.00

0.00

0.00

Post

Dev

50 yr

30

min

0.00

0.46

1.19

2.88

6.54

11.76

14.35

10.54

6.50

3.91

1.69

0.32

0.00

Post Development

Post

Dev

50 yr

60

min

0.00

0.10

0.37

1.17

2.50

5.73

9.24

11.02

12.43

10.49

7.45

5.16

3.84

2.77

2.05

1.37

0.58

0.12

0.00

Post

Dev

100 yr

15

min

0.00

0.83

2.09

3.75

10.01

16.18

12.95

5.16

0.84

0.00

0.00

0.00

0.00

Free software

at http://www.msmam.com

33

Post

Dev

100 yr

30

min

0.00

0.50

1.30

3.16

7.20

12.89

15.70

11.53

7.11

4.28

1.84

0.35

0.00

Post

Dev

100 yr

60

min

0.00

0.11

0.41

1.29

2.78

6.29

10.10

12.04

13.57

11.46

8.13

5.63

4.19

3.02

2.24

1.49

0.64

0.13

0.00

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

TABLE 2.3 BASIN INFLOW HYDROGRAPHS

M3/S

Time

(min)

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

Pre

Development

subtract low

flow

5 yr

50 yr

30

30

min

min

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.67

2.02

4.07

4.04

6.25

2.69

4.23

0.86

1.80

0.00

0.25

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

Post Development

Post Development

Post Development

subtract low flow

subtract low flow

subtract low flow

5 yr

15

min

0.00

0.00

0.00

0.43

4.64

8.91

6.76

1.45

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

5 yr

30

min

0.00

0.00

0.00

0.05

2.76

6.74

8.77

5.90

2.84

0.87

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

5 yr

60

min

0.00

0.00

0.00

0.00

0.00

2.20

4.93

6.32

7.39

5.92

3.59

1.84

0.83

0.01

0.00

0.00

0.00

0.00

0.00

50 yr

15

min

0.00

0.00

0.00

1.30

6.98

12.62

9.69

2.60

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

50 yr

30

min

0.00

0.00

0.00

0.78

4.44

9.66

12.25

8.44

4.40

1.81

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

50 yr

60

min

0.00

0.00

0.00

0.00

0.40

3.63

7.14

8.92

10.33

8.39

5.35

3.06

1.74

0.67

0.00

0.00

0.00

0.00

0.00

100 yr

15

min

0.00

0.00

0.00

1.65

7.91

14.08

10.85

3.06

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

100 yr

30

min

0.00

0.00

0.00

1.06

5.10

10.79

13.60

9.43

5.01

2.18

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

100 yr

60

min

0.00

0.00

0.00

0.00

0.68

4.19

8.00

9.94

11.47

9.36

6.03

3.53

2.09

0.92

0.14

0.00

0.00

0.00

0.00

2.2.2.4 Compute the basin inflow hydrograph

The basin inflow hydrographs were computed using the Time-Area method for

the following events:

Post Development- 100 year ARI storm, Duration=15, 30 and 60 minutes.

Post Development- 50 year ARI storm, Duration=15, 30 and 60 minutes.

Post Development- 5 year ARI storm, Duration=15, 30 and 60 minutes.

Pre Development- 50 year ARI storm, Duration=15, 30 and 60 minutes.

Pre Development- 5 year ARI storm, Duration=15, 30 and 60 minutes.

The basin inflow hydrographs are summarised as shown in Table 2.3. These are

obtained as follows:

106746216 (2/16/16)

Free software

at http://www.msmam.com

34

WORKSHOP NO. 3- DETENTION / SEDIMENT BASIN & CULVERT DESIGN

_______________________________________________________________________

Flows in Table 2.3= Flows in Table 2.2 - Bypass flow.

2.2.2.5 Preliminary estimate of the required storage volume

A preliminary estimate of the required basin volume can be made using the

following equation (Equation 20.13) for the major design storm ARI.

Vs 1.291 Vi (1

Qo 0.753 t i 0.411

)

( )

Qi

tp

(2.5)

where

V

V

s

= estimated storage volume (m3)

i

= inflow hydrograph runoff volume (m3)

Q

i

= inflow hydrograph peak flow rate (m3/s)

Q

o

= allowable peak outflow rate (m3/s)

t

t

i