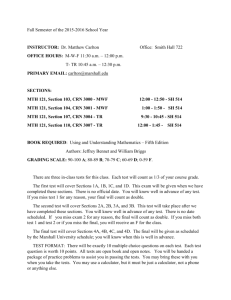

1506872

advertisement

1 THE CORROSION BEHAVIOR OF CHROMIUM 2 NITRIDE FILM ON AISI 4140 AND H13 STEELS 3 4 Running head: The corrosion behavior of CrN film 5 6 Pornwasa Wongpanya1*, Thipusa Wongpinij2, Pat Photongkam2, 7 Chonthicha Keawhan2, Sarayut Tunmee3 and Nirun Witit-Anun4 8 1 9 School of Metallurgical Engineering, Institute of Engineering, 10 Suranaree University of Technology, Nakhon-Ratchasima, 30000 Thailand 11 Tel. 0-4422-4486; Fax. 0-4422-4482; E-mail: pornwasa@sut.ac.th 2 12 Synchrotron Light Research Institute (Public Organization), 13 14 Nakhon-Ratchasima, 30000, Thailand 3 Department of Materials Science and Technology, Nagaoka University of Technology, 15 16 16031-1 Kamitomioka-machi 940-2188, Japan 4 Department of Physics, Faculty of Sciences, Burapha University, Chonburi 20131 17 Thailand 18 *Corresponding author, email: pornwasa@sut.ac.th 19 20 Abstract 21 The chromium nitride film (CrN) was prepared on steel substrates, 22 AISI 4140 and H13 with variation of substrate roughness, using reactive DC 23 magnetron sputtering technique at room temperature in controlled partial 24 pressures of Ar and N2 gas atmosphere. The films were polycrystalline 25 confirmed by X-ray diffraction analysis. The corrosion behavior was 26 investigated using an electrochemical technique in 3.5 wt% NaCl solution with 27 various pH values at room temperature. The results indicated that CrN coated 28 AISI H13 present better corrosion resistance than CrN coated AISI 4140 at 29 pH 2 and 7, but worse at pH 10. In addition, the rate of corrosion decreased 30 with a reduction of surface roughness. The chemical states of corrosion 31 product were clearly identified by spatially resolved secondary electron yield 32 X-ray absorption spectroscopy (XAS) with X-ray photoemission electron 33 microscopy (X-PEEM). It was found that formation of Cr2O3 is formed on non- 34 corroded CrN film and AISI H13 substrate, whereas Fe2O3 is formed on 35 corroded surface and AISI 4140 substrate. 36 37 38 Keywords: chromium nitride, corrosion behavior, electrochemical technique, X-ray photoemission electron microscopy, X-PEEM 39 40 Introduction 41 The metal-nitride films are extensively employed as a protection film for 42 surface improvement of engineering parts. They do not only represent high 43 hardness and high wear resistance, but they also protect the substrate from corrosion 44 in liquid environments (Darja et al., 2004; Zhou et al., 2003). Chromium nitride 45 (CrN) is inexpensive comparing to other nitrides, such as .TiN, TiAlN and TiAlSiN, 46 and its performance in terms of corrosion and wear resistance is generally applied 2 47 to many applications, e.g. auto mobile parts, cutting tools and molds. Many research 48 (Keawhan et al., 2012; Wongpanya et al., 2014) demonstrated that CrN coated 49 steels with difference of substrate roughness significantly improved their corrosion 50 resistance. They reported that the CrN coated steels exhibited better corrosion 51 resistance than the uncoated steels and the corrosion rate can be reduced by 52 decreasing roughness of steel substrate. In addition, the corrosion behavior of CrN 53 coated steels drastically changed with pH of solution in particular for the acid 54 solution (Christine and Alan, 2005). It is however, it still remains in question about 55 how type of steel substrate do affect to corrosion behavior of CrN film. In this paper, 56 it was focused on the evaluation of the corrosion resistance of CrN coating on AISI 57 4140 and H13 steels. The corrosion resistance of the CrN coated and uncoated steels 58 in 3.5 wt% NaCl solution were tested by an electrochemical method. Since some 59 engineering parts were used in liquid environments, they were used in contact with 60 both acid and alkaline solutions. Therefore, corrosion was tested in solution at pH 61 2, 7 and 10 that is more realistic approaches toward solving the problem of metal 62 corrosion. After electrochemical testing, the corroded surfaces of CrN coated and 63 uncoated steels were investigated by scanning electron microscopy (SEM). And, 64 X-ray photoemission electron microscopy (X-PEEM) has been used to evaluate the 65 corrosion products on the corroded surface of CrN coated steels. 66 67 Materials and Methods 68 Sample preparation 3 69 Firstly, AISI 4140 and H13 steels were prepared with dimensions of 70 10x10x2 mm3. The chemical compositions investigated by atomic emission 71 spectroscopy were shown in Table 1. They were heated for 30 minutes at 850oC 72 (AISI 4140) and 1025oC (AISI H13); subsequently they were oil–quenched and 73 tempered. The sample were polished with SiC paper at various grit numbers, e.g. 74 180, 600 and 1200 for preparing difference of substrate roughness. The 75 microstructures of these steels were studied by light optical microscopy. They were 76 ground, polished and etched for the metallographic microstructure evaluations. An 77 etchant solution used to reveal microstructure was prepared from a 2% nital solution 78 composes of 2 ml nitric acid and 98 ml ethyl alcohol. The microstructure of AISI 79 4140 steel were found to consist a mixture of ferrite and pearlite, whereas the 80 microstructure of AISI H13 steel were compose of ferrite and carbide in the 81 normalizing condition as shown in Figure 1 a) and b). After heat treatment, the 82 microstructure of AISI 4140 and H13 steels had been changed to be martensite and 83 retained austenite as shown in Figure 1 c) and d). Before CrN coating, the substrate 84 samples were rinsed by distilled water, acetone and were air-dried. The DC 85 magnetron sputtering process was employed to deposit CrN film on these samples 86 with deposition conditions as shown in Table 2. List of samples for corrosion 87 evaluation dependent on steel types and surface roughness was shown in Table 3. 88 89 Corrosion Testing 90 The corrosion behavior of uncoated and CrN coated samples was evaluated 91 by electrochemical technique in accordance with ASTM standard G44-99 (ASTM 4 92 G44-99, 2005). Experiments were performed using a potentiostat analyzer. An 93 electrochemical cell contains three electrode cells including samples as a working 94 electrode, graphite as counter electrode and silver/silver chloride (Ag/AgCl with 95 3.0 M KCl) as a reference electrode. The samples were polarized to potential 96 between -900 mV and +200 mV at a scan rate of 1.0 mV/s in 3.5 wt% NaCl solution 97 with pH value of 2, 7 and 10 at room temperature. The pH of solution was adjusted 98 by addition of hydrochloric acid (HCl) and sodium hydroxide (NaOH). The 99 polarization curves were used to study the corrosion behavior of samples. They 100 were carried out in order to obtain important corrosion parameters, e.g. corrosion 101 potential (Ecorr) and corrosion current density (Icorr). The corrosion rate (CR) was 102 calculated from the polarization curve according to Faraday’s law and was 103 evaluated by the Tafel extrapolation technique. 104 105 Structural and Surface Characterizations 106 The crystallographic phase structure of CrN films before corrosion testing 107 was studied by the X-ray Diffraction. After the testing corroded surface was 108 characterized by scanning electron microscope (SEM) and X-ray photoemission 109 electron microscopy (X-PEEM) 110 111 Results and Discussions 112 The Crystallographic Structure of CrN film 113 Figure 2 shows the X-ray diffraction pattern of CrN film deposited on AISI 114 4140 and H13 steels. The XRD analysis reveals the films deposited on both 5 115 substrates were polycrystalline with four diffraction peaks of CrN (111), (200), 116 (220) and (311) planes at 2θ angles of 37.38º, 43.50º, 63.20º and 76.20º, 117 respectively. The dominant orientation of CrN film in this study is the (111) plane. 118 The strong orientation in the (111) plane is also reported by Ruden et al. (2013). 119 Corrosion Behavior 120 A Comparative study of corrosion resistance of uncoated and CrN coated samples 121 Figure 3 shows examples of polarization curves of AISI 4140-180, AISI 122 H13-180, CrN/4140-180, CrN/4140-1200, CrN/H13-180 and CrN/H13-1200 123 samples tested in 3.5 wt% NaCl solutions at pH 2, 7 and 10. In Table 4, the corrosion 124 parameters of each sample was evaluated from the polarization curves and based 125 on Tafel equation (Uhlig, 1971). It is obvious the CrN film highly impacts on 126 corrosion properties of the AISI 4140 and H13 steels in particular the corrosion 127 potential (Ecorr) and corrosion current density (Icorr). From a comparison of the 128 corrosion potential (Ecorr) of the CrN coated samples and uncoated samples, it is 129 found that the CrN coated samples have higher corrosion potential (Ecorr) than the 130 uncoated samples. In addition, it is found that CrN coated samples show lower 131 corrosion current density (Icorr) than the uncoated samples (Cunha et al., 1999). 132 Thus, a corrosion rate (CR) of CrN coated samples is lower than that of uncoated 133 samples for all substrates and pH solutions as shown in Figure 4. This implies that 134 the corrosion resistance is better since the CrN coated on the surface of substrate 135 (Liu et al., 1995; Walter et al., 2011). Those results indicate CrN coated samples 136 have better corrosion resistance than that of the uncoated samples. Corrosion 137 resistance of CrN coated samples is attributed to the presence of chromium (Cr) and 6 138 nitrogen (N) atoms within CrN film. After CrN film reacted with the corrosive 139 solution, the chromium atoms were oxidized to chromium oxide. It is well known 140 that the chromium oxide is a stable oxide film and it is able to inhibit corrosion 141 (Lippitz and Hubert, 2005; Ibrahim et al., 2002; William Gripset et al., 2006). For 142 nitrogen atom, the nitrogen atoms in the CrN film are dissolved into the solution in 143 the form of nitrogen anions (N-) during corrosion, and then they repel chloride 144 anions (Cl-) away from the surface of sample. Moreover, nitrogen anions (N-) 145 combines with hydrogen ion (H+) in the solution to form the ammonium (NH4+) as 146 shown in Equation (1), which results in increase pH of solution. As a result, 147 corrosion attack from the solutions decreases. (Chyou and Shih, 1991; Grabke, 148 1996). 149 N ( s) 4H (aq) 3e NH4 (aq) (1) 150 151 Effect of steel types on corrosion behavior 152 Figure 4 shows corrosion rate of uncoated and CrN coated samples 153 dependent on steel types. It is obvious that the AISI H13 and CrN/H13 samples 154 show lower corrosion rate than the AISI 4140 and CrN/4140 samples, respectively, 155 at pH 2 and 7. This might be due to chemical compositions of substrate as shown 156 in Table 1. The AISI H13 steel (5.40%Cr) has chromium content higher than that 157 of the AISI 4140 steel (0.81%Cr). This means that chromium oxide was developed 158 on the surface of the AISI H13 easier than that of the AISI 4140. As a result, the 7 159 AISI H13 and CrN/H13 samples have better corrosion resistance than the AISI 160 4140 and CrN/4140 samples, respectively. 161 In contrast, the uncoated AISI 4140 shows lower corrosion rate than the 162 uncoated AISI H13 at pH 10 as shown in Figure 4. The solution at pH 10 was 163 adjusted by addition of sodium hydroxide (NaOH) that results in higher amount of 164 OH- and Na+ as shown in Equation (2). The iron (Fe) in the AISI 4140 substrate are 165 dissolved to be Fe2+ and the Fe2+ further combines with hydroxide ions (OH-) to 166 form iron (II) hydroxide (Fe(OH)2) as shown in Equation (3). 167 NaOH ( s) Na (aq) OH (aq) (2) 168 2Fe( s) O2 ( g ) 2H2O(l ) 2Fe2 (aq) 4OH (aq) 2Fe(OH )2 ( s) (3) 169 170 According to Pourbaix diagram of iron (Beverskog, B. and Puigdomenech, 171 I., 1996), at pH 10 and potential between -0.6 V and 0.0 V, Fe are dissolved to be 172 Fe(OH)2, Fe3O4 and Fe2O3. This can confirm that at pH 10, the Fe(OH)2 is easily 173 initiated on AISI 4140 steel. It is believed that the Fe(OH)2 can prevent corrosion 174 but it is unstable film. And, it can be oxidized to be an iron oxide (Fe2O3). While, 175 the AISI H13 steel has chromium oxide, it thus inhibits the diffusion of OH-into 176 substrate. As a result, Fe(OH)2 is difficultly formed. With all above information, it 177 can be concluded that the uncoated AISI 4140 steel has high corrosion resistance 178 than the uncoated AISI H13 steel at pH 10. However, formation of oxide has to be 8 179 further evaluated by X-ray photoemission electron microscopy (X-PEEM) 180 combined with X-ray absorption spectroscopy (XAS). 181 Effect of substrate roughness on corrosion behavior 182 It clearly demonstrates that substrate roughness of substrate effects on their 183 corrosion rate as shown in Figure 4. The samples prepared under the rougher surface 184 roughness (XX-180 and XX-600) have higher corrosion rate (CR) than the samples 185 prepared under the finer surface (XX-1200) for all pH solutions. This is due to the 186 fact that the rough surface leads to more defects in CrN film and also results in 187 lower complete coverage of the samples by the coating. Figure 5 shows examples 188 of image surface scanned by SEM of CrN/4140-180, CrN/4140-600 and CrN/4140- 189 1200 before corrosion test, it shows that the CrN/4140-180 sample has more defects 190 than the CrN/4140-600 and CrN/4140-1200 samples, respectively. 191 Effect of pH of solution on corrosion behavior 192 It is obvious that the corrosion rate decreases as the pH of solution increases 193 as shown in Figure 4. The highest corrosion rate is observed at pH 2 because of 194 addition of hydrochloric acid (HCl). The Cl- ions are adsorbed at the surface of CrN 195 coated and uncoated samples, then they penetrate and attack the samples especially 196 at the defects of CrN film such as porosity (Hui et al., 2003; Mazhar et al., 2001). 197 In addition, high concentration of hydrogen (H+) ion in solution at pH 2 promotes 198 hydrogen evolution causing higher corrosion rate (Keawhan et al., 2012). 199 At pH 7 and 10, hydroxide ions (OH-) in solution can react to iron in the 200 substrate to form unstable hydroxide film which can against corrosion 9 201 (Beverskogand Puigdomenech, 1996). The passive region of CrN coated samples 202 is clearly observed in polarization curves as shown in Figure 3 b) and 3 c). This is 203 due to the fact that CrN film reacts with OH- in the solution at pH 7 and 10; 204 subsequently chromium hydroxide (Cr(OH)2) is produced. And this chromium 205 hydroxide enhances corrosion resistance. As a result, all of CrN coated samples 206 show corrosion resistance at pH 7 and 10 better than at pH 2. 207 Surface Microstructure Analysis 208 Since surface of uncoated and CrN coated samples are attacked and 209 destroyed by aggressive solution; corrosion products have been generated. The 210 certain corrosion products, especially oxide formation, were analyzed with 211 scanning electron microscope (SEM) and X-ray photoemission electron 212 microscopy (X-PEEM) in order to evaluate which element or compound is 213 responsible for corrosion resistance. In this study, the samples tested in solution at 214 pH 2 were selected to evaluate because such samples show the highest corrosion 215 rate. Figure 6 shows secondary electron images of uncoated (AISI 4140 and H13) 216 and CrN coated (CrN/4140 and CrN/H13) samples after corrosion test at pH 2. The 217 uncoated samples show more degradation than the CrN coated samples. In addition, 218 it is found that the CrN/4140 sample shows more crack surface of film than the 219 CrN/H13 sample. As a result, the corrosion products on surface of the AISI 4140 220 and CrN/4140 samples are higher than those of the AISI H13 and CrN/H13 samples, 221 respectively. 10 222 To identify the compound which is responsible for corrosion resistance of 223 CrN coated samples, the CrN/H13 and CrN/4140 samples immersed in solution at 224 pH 2 were selected to be investigated by spatially resolved X-ray absorption 225 spectroscopy using X-PEEM. The X-PEEM technique can visualize corrosion 226 surface and the image intensities were relevant to X-ray absorption coefficient. 227 These help to characterize the surface by the shapes and sizes of the corroded area. 228 Figure 7 shows X-PEEM images and XAS spectra of CrN/H13 sample, having two 229 areas, e.g., area 1 as an intact CrN film (Cr- and N-enrichment) and area 2 as a CrN 230 film removed which is deep down to the AISI H13 substrate (Fe-enrichment). The 231 Four elements, e.g., Cr, N, Fe and O were investigated at the photon energy of 560 232 - 600 eV, 390 - 420 eV 700 - 730 eV and 515 – 550 eV for Cr L3,2-edge, N K-edge, 233 Fe L3,2-edge and O K-edge, respectively (Guiot et al., 1999; Frazer et al., 2003; 234 Hocking et al., 2006; Wasinger et al., 2003; Esaka et al., 1997; Schedel-Niedrig et 235 al., 1998). These four elements were evaluated since Cr and N are main components 236 of CrN film while Fe is a main component of AISI H13 substrate and O is a main 237 component of oxide generated as a result of corrosion reaction. It is obvious that 238 the CrN film (area 1) showed high intensity of Cr L3,2-edge and N K-edge, while 239 the low intensity of O K-edge and Fe L3,2-edge were detected. At the CrN film 240 removed (area 2), it showed high intensity of Fe L3,2-edge, Cr L3,2-edge and O K- 241 edge, while the low intensity of N K-edge were detected. These implied it would be 242 Cr oxided for both areas. The oxidation of Cr to be chromium oxide (Cr2O3) is a 243 vital key for corrosion protection of CrN film (Cunha et al., 1999; Schedel-Niedrig 244 et al., 1998). The XAS spectrum of Fe L3,2-edge was detected at area 2; this reveals 11 245 the oxidation of Fe to be rust (Fe2O3) (Hocking et al., 2006). Fe(OH)2, is unstable 246 do it cannot be detected. It confirms that it was transformed to Fe2O3. 247 To study the effect of substrate steels on corrosion of CrN film, X-PEEM 248 images and XAS spectra of CrN/4140 and CrN/H13 samples after tested at pH 2 249 were comparatively evaluated. The area 2, where is the CrN film was removed due 250 to the corrosion reaction, of two samples were analyzed in particular for the Cr and 251 Fe as shown in Figure 8. It is obvious that both samples show the spectra of Fe L3,2- 252 edge, but the CrN/H13 sample shows lower intensity of Fe L3,2-edge than the 253 CrN/4140 sample. In addition, only the CrN/H13 sample shows the spectra of Cr 254 L3,2-edge. This can be used to confirm that Cr2O3 developed at surface of AISI H13 255 substrate. Therefore, the CrN/H13 sample has better corrosion resistance than the 256 CrN/4140 sample. Moreover, it is found that the corroded area of CrN/4140 sample 257 is deeper than that of CrN/H13 sample as shown in Figure 8 a). 258 Conclusions 259 The corrosion behavior of CrN films deposited on AISI 4140 and H13 substrate 260 was studied. The preferential orientation of CrN film is in the (111) plane. For the 261 corrosion behavior, the CrN coated samples exhibited better corrosion resistance 262 than the uncoated samples for all pHs. In addition, it is found that the CrN coated 263 AISI H13 shows better corrosion resistance than the CrN coated AISI 4140 for pH 264 2 and 7. At pH 10, the CrN coated AISI 4140 are better corrosion resistance than 265 the CrN coated AISI H13. In addition, the samples prepared under the rougher 266 surface roughness have higher corrosion rate than the samples prepared under the 267 finer surface. X-PEEM images and XAS measurements have proven to be great 12 268 techniques to evaluate corroded surface and to identify the chemical state of 269 corrosion products. XAS spectra suggests Cr2O3 on CrN film and AISI H13 270 substrate, and it showed Fe2O3 on corroded surface and AISI 4140 substrate. 271 272 Acknowledgements 273 The authors gratefully acknowledge the financial support of this work by Office of 274 the National Research Council of Thailand (NRCT), Suranaree University of 275 Technology with the Contract No. 61/2553 and Synchrotron Light Research 276 Institute of Thailand under contract No.2552/05. The authors wish to thank 277 scientists of BL3.2Ub at SLRI for their support during the experiments. 278 279 References 280 ASTM. (2005). Standard practice for exposure of metals and alloys by alternate 281 immersion in neutral 3.5% sodium chloride solution. ASTM: G44-99. 282 ASTM International, West Conshohocken, PA, USA. 283 284 Beverskog, B., and Puigdomenech, I. (1996). Revised pourbaix diagrams for iron at 25oC-300oC. Corros. Sci., 38(12):2,121-2,135. 285 Trepanier, C., and Pelton,A.R. (2005). Effect of temperature and pH on the 286 corrosion resistance of nitinol. Proceeding of ASM Materials &Processes 287 for MedicalDivices Conference 2004; August 25-27, 2004; Saint Paul, 288 Minnesota, USA, p. 392-397. 289 290 Chyou, S. D., and Shih, H. C. (1991). The effect of nitrogen on the corrosion of plasma-nitrided 4140 steel. Corrosion, 47(1):31-34. 13 291 Cunha, L., Andritschky, M., Rebouta, L.,and Pischow, K. (1999). Corrosion of CrN 292 TiAlN coatings in chloride-containing atmosphere. Surf. Coat. Technol. 293 116-119:1,152-1,160. 294 Darja, K.M., Peter, P., Miha, C., and Marijan, M. (2004). The corrosion behavior 295 of Cr-(C,N) PVD hard coatings deposited on various substrates. 296 Electrochim. Acta., 49(9-10):1,527-1,533. 297 Esaka, F., Furuya, K., Shimada, H., Imamura, M., Matsubayashi, N., Sat, T., 298 Nishijima, A., Kikuchi, T., Kawana, A.,and Ichimura, H. (1997). XAS 299 study on the intermediate species formed during the surface oxidation of 300 CrN films. J. Phys IV., C2-1,149-C2-1,150. 301 Frazer, B.H., Gilbert, B., Songderegger, B.R., and Stasio, G.D. (2003). The probing 302 depth of total electron yield in the sub-k eV range: TEY-XAS and X- 303 PEEM. Surf. Sci., 537(1-3): 161-167. 304 305 Grabke, H. J. (1996). The role of nitrogen in the corrosion of iron and steels. ISIJ Int., 36(7): 777-786. 306 Guiot, E., Wu, Z.Y., Gota, S., and Gautier-Soyer, M. (1999). Polarized O K edge 307 spectra of Fe2O3 (0001) nanometric films: A full multiple scattering 308 interpretation. J. Elec. Spec., 101-103:371-375. 309 Hocking, R.K., Wasinger, E.C., Groot, F.M.F., Hodgson, K.O., Hedman, B.,and 310 Solomon, E.I. (2006). Fe L-Edge XAS studies of K4[Fe(CN)6] and 311 K3[Fe(CN)6]: A direct probe of back-bonding. J. Am. Chem. Soc., 312 128(32):10,442-10,451. 14 313 Hui, P.F., Cheng, H.H., Jung, K.L., and Yih, H.S. (2003). Effects of PVD sputtered 314 coating on the corrosion resistance of AISI 304 stainless steel. Mater. Sci. 315 Eng., 347(1-2):123-129. 316 Ibrahim, M.A.M., Korablov, S.F., and Yoshimura, M. (2002). Corrosion of 317 stainless steel coated with TiN, (TiAl)N and CrN in aqueous 318 environments. Corros. Sci., 44(4):815-828. 319 Keawhan, C., Wongpanya, P., Witit-Anun, N.,and Songsiriritthigul, P. (2012). 320 Corrosion behavior of AISI 4140 steel surface coated by physical vapor 321 deposition. J. Met. Mater. Min., 22:69-76. 322 323 Lippitz, A., and Hubert, Th. (2005). XPS investigations of chromium nitride thin films. Surf. Coat. Technol., 200(1-4): 250-253. 324 Liu, C., Leyland, A., Lyon, S.,and Matthews, A. (1995). An a.c impedance study 325 on PVD-coated mild steel with different surface roughness. Surf. Coat. 326 Technol., 76-77:623-631. 327 Mazhar, A.A., Arad, S.T., and Noor, E.A. (2001). The role of chloride ions and pH 328 in the corrosion and pitting of Al-Si alloys. J. Appl. Electrochem., 329 31(10):1,131-1,140. 330 Ruden, A., Restrepo-Parra, E., Paladines, A.U., and Sequeda, F. (2013). Corrosion 331 resistance of CrN thin films produced by dc magnetron sputtering. Appl. 332 Surf. Sci., 270:150-156. 333 Schedel-Niedrig, T. (1998). X-Ray absorption spectroscopy: sensitive 334 characterization of (model-) catalysts with the electron yield technique. 335 Fresen. J. Anal. Chem., 361:680-682. 15 336 337 338 339 Uhlig, H. H. (1971). Corrosion and corrosion control. 2nd ed. John Wiley & Sons Inc., NY, 37-59p. Walter, R.,and Bobby Kannan, M. (2011). Influence of surface roughness on the corrosion behavior of magnesium alloy. Mater. Des. 32(4):2,350-2,354. 340 Wasinger, E.C., Groot, F.M.F., Hedman, B., Hodgson, K.O., and Solomon, E.I. 341 (2003). L-edge X-ray absorption spectroscopy of non-heme iron sites: 342 experimental determination of differential orbital covalency. J. Am. Chem. 343 Soc., 125(42): 12,894-12,906. 344 William Grips,V. K., Barshilia, Harish C., EzhilSelvi, V., Kalavati, andRajam, K.S. 345 (2006). Electrochemical behavior of single layer CrN, TiN, TiAlN 346 caotings and nanolayered TiAlN/CrN multilayer coatings prepared by 347 reactive direct current magnetron sputtering. Thin Solid Films., 514(1-2): 348 204-211. 349 Wongpanya, P., Tunmee, S., Euaruksakul, C., Songsiriritthigul, P.,and Witit-Anun, 350 N. (2014). Corrosion behavior and mechanical properties of CrN film. 351 Adv. Mate. Res., 853:155-163. 352 Zhou, Q.G., Bai, X.D., Chen, X.W., Peng, D.Q., Ling, Y.H.,and Wang, D.R. 353 (2003). Corrosion resistance of duplex and gradient CrNx coated H13 354 Steel. Appl. Surf. Sci., 211(1-11):293-299. 355 16 356 357 Table 1. Chemical composition of AISI 4140 and H13 steels (in wt.%) determined by atomic emission spectroscopy Grade C Cr Si Mn Mo V Fe AISI 4140 0.47 0.81 0.26 0.78 0.19 - Bal. AISI H13 0.42 5.40 0.48 0.35 1.12 0.81 Bal. 358 17 359 360 Table 2. The deposition conditions of CrN coating (Keawhan et al., 2012; Wongpanya et al., 2014) Ar flow rate (sccm) 6 N2 flow rate (sccm) 9 Base pressure (mbar) 5.0 x 10-5 Working pressure (mbar) 3.5 x 10-3 Ar pressure (mbar) 3.3 x 10-3 N2 pressure (mbar) 5.7 x 10-4 Current (A) 800 Voltage (V) -456 Deposition time (min) 45 Target-to-substrate spacing (cm) 15 Coating thickness (nm) 914 361 362 18 363 Table 3. List of samples for corrosion test Substrate AISI 4140 AISI H13 SiC paper Uncoated samples CrN coated samples No. 180 AISI 4140 - 180 CrN/4140-180 No. 600 AISI 4140 - 600 CrN/4140-600 No. 1200 AISI 4140 - 1200 CrN/4140-1200 No. 180 AISI H13-180 CrN/H13-180 No. 600 AISI H13-600 CrN/H13-600 No. 1200 AISI H13-1200 CrN/H13-1200 364 19 365 Table 4. Corrosion parameters obtained from the polarization curves of uncoated and 366 CrN coated samples pH Samples AISI 4140 pH2 AISI H13 CrN/4140 CrN/H13 AISI 4140 pH7 AISI H13 CrN/4140 CrN/H13 AISI 4140 pH10 AISI H13 CrN/4140 CrN/H13 SiC paper Ecorr (mV) -571 -595 -559 -514 -578 -473 -538 -520 -518 -509 -500 -499 -535 -535 -598 -478 -527 -534 -485 -442 -400 -361 -407 -291 -582 -595 -559 -450 -352 -482 -465 -421 -419 -442 -389 -386 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 No.180 No.600 No.1200 367 20 Icorr (µA/cm2) 175.00 67.00 52.00 120.00 55.00 42.92 75.00 20.00 12.50 26.00 18.07 7.24 32.00 21.00 12.00 18.17 7.55 4.36 16.00 8.50 6.50 7.00 6.18 1.33 18.00 12.50 7.00 35.06 15.25 16.05 9.00 4.50 2.20 14.00 6.50 3.70 CR (mm/year) 1.9356 0.7786 0.6043 1.3946 0.6392 0.4992 0.9382 0.2502 0.1563 0.3252 0.2240 0.0897 0.3719 0.2440 0.1394 0.2113 0.0878 0.0507 0.2001 0.1063 0.0813 0.0875 0.0766 0.0165 0.2091 0.1564 0.0813 0.4078 0.1773 0.1867 0.1126 0.0563 0.0275 0.1751 0.0813 0.0460 368 369 370 Figure 1. Microstructures of the substrate samples; a) AISI 4140, b) AISI H13, c) AISI4140 after heat treatment and d) AISI H13 after heat treatment 371 21 372 373 Figure 2. X-ray diffraction pattern of CrN film on AISI 4140 and H13 steels 22 374 375 376 Figure 3. The polarization curves of samples in 3.5 wt% NaCl solution at a) pH 2, b) pH 7 and c) pH 10 23 \ 377 378 Figure 4. Comparative corrosion rate of the uncoated and CrN coated samples 379 24 380 381 382 Figure 5. Secondary electron images of surface of CrN/4140-180, CrN/4140-600 and CrN/4140-1200 samples before corrosion test. 383 384 25 385 386 Figure 6. Secondary electron images of uncoated (AISI 4140-180 and AISI H13-180) 387 and CrN coated (CrN/4140-180 and CrN/H13-180) samples after corrosion 388 test in 3.5 wt% NaCl solution 389 26 390 391 Figure 7. X-PEEM images and XAS spectra of the CrN/H13-180 sample after corrosion test in 3.5 wt.% NaCl solution at pH 2 27 392 393 Figure 8. Comparative X-PEEM images and XAS spectra of the CrN/4140-180 and 394 CrN/H13-180 samples after corrosion test in 3.5 wt.% NaCl solution at pH 2 28