Supplemental_Material

advertisement

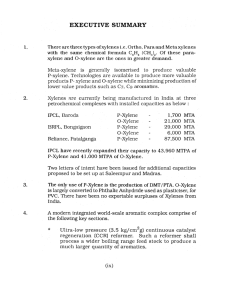

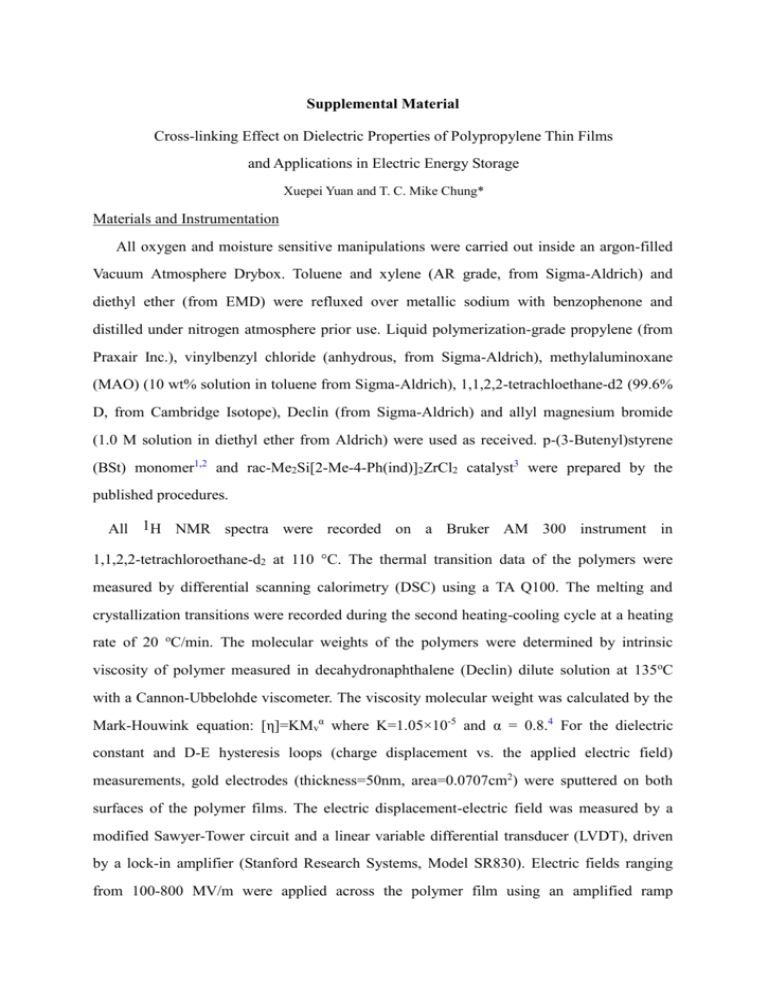

Supplemental Material Cross-linking Effect on Dielectric Properties of Polypropylene Thin Films and Applications in Electric Energy Storage Xuepei Yuan and T. C. Mike Chung* Materials and Instrumentation All oxygen and moisture sensitive manipulations were carried out inside an argon-filled Vacuum Atmosphere Drybox. Toluene and xylene (AR grade, from Sigma-Aldrich) and diethyl ether (from EMD) were refluxed over metallic sodium with benzophenone and distilled under nitrogen atmosphere prior use. Liquid polymerization-grade propylene (from Praxair Inc.), vinylbenzyl chloride (anhydrous, from Sigma-Aldrich), methylaluminoxane (MAO) (10 wt% solution in toluene from Sigma-Aldrich), 1,1,2,2-tetrachloethane-d2 (99.6% D, from Cambridge Isotope), Declin (from Sigma-Aldrich) and allyl magnesium bromide (1.0 M solution in diethyl ether from Aldrich) were used as received. p-(3-Butenyl)styrene (BSt) monomer1,2 and rac-Me2Si[2-Me-4-Ph(ind)]2ZrCl2 catalyst3 were prepared by the published procedures. All 1H NMR spectra were recorded on a Bruker AM 300 instrument in 1,1,2,2-tetrachloroethane-d2 at 110 °C. The thermal transition data of the polymers were measured by differential scanning calorimetry (DSC) using a TA Q100. The melting and crystallization transitions were recorded during the second heating-cooling cycle at a heating rate of 20 oC/min. The molecular weights of the polymers were determined by intrinsic viscosity of polymer measured in decahydronaphthalene (Declin) dilute solution at 135oC with a Cannon-Ubbelohde viscometer. The viscosity molecular weight was calculated by the Mark-Houwink equation: [η]=KMvα where K=1.05×10-5 and α = 0.8.4 For the dielectric constant and D-E hysteresis loops (charge displacement vs. the applied electric field) measurements, gold electrodes (thickness=50nm, area=0.0707cm2) were sputtered on both surfaces of the polymer films. The electric displacement-electric field was measured by a modified Sawyer-Tower circuit and a linear variable differential transducer (LVDT), driven by a lock-in amplifier (Stanford Research Systems, Model SR830). Electric fields ranging from 100-800 MV/m were applied across the polymer film using an amplified ramp waveform at 10Hz. The dielectric constant was measured by a HP multifrequency LCR meter, equipped with a temperature chamber. The breakdown strength measurement equipment consisting with the pinpoint electrode arm scanning over the sample surface was used. Typically 12 measurements were made per sample, performed in the insulating oil. The voltage was raised at a rate of 500 V/s until breakdown was detected. Synthesis of Long Chain Branched Isotactic Poly(propylene-co-BSt) Copolymers In a dry 300 mL Parr stainless steel autoclave equipped with a mechanical stirring, 50mL of toluene, 10 mL MAO solution and a specific amount of BSt were mixed. The autoclave was charged with 20 psi of argon gas, and then charged with 1 psi hydrogen (30-40 mL). About 100 mL of liquid propylene was transferred from Kenco Liquid Level Gauge into the autoclave, heated to 30o C to show the pressure of 180 psi. 1 umol of rac-Me2Si[2-Me-4-Ph(ind)]2ZrCl2 catalyst diluted in 3 mL of toluene was then injected under argon pressure of 220 psi. The reaction mixture was stirred and maintained at 30o C and 220 psi for 3 minutes. The reaction was terminated by the addiction of methanol, and the resulting LCB PP-BSt copolymer product was washed with acidic methanol, rinsed with methanol and acetone for five times, and dried under vacuum at 40o C. Figure S1 shows 1H NMR spectrum of LCB PP-BSt copolymer containing 3.65 mol% of the incorporated BSt units. The pendant styrene functionality is observed by three vinyl protons with chemical shifts at 6.8, 5.7, and 5.2 ppm and aromatic protons with two chemical shifts at 7.3 and 7.15 ppm. On the other hand, the LCB branch points are identified by the aromatic protons with a chemical shift at 7.1 ppm. Figure S1. 1H NMR spectrum and peak assignments of a LCB PP-BSt copolymer. Film Preparation and Thermal Cross-linking Reaction The LCB PP-BSt copolymer was redissolved into xylene at an elevated temperature, and the heated polymer solution was directly cased into films (thickness 10-15 um) at 100o C. The resulting films were heated in a vacuum oven at 220o C for 2h and then annealing at 120o C for overnight. The result x-PP films were subjected to vigorous solvent extraction by immersing the x-PP films into the boiling xylene for 5h before picking up the films from the solution. The same solvent extraction procedures were repeated 3 times, using fresh xylene in each solvent extraction step. This was to ensure removal of the soluble polymer fraction before drying the film and determining the gel content by the percentage of the remaining film weight. DSC Curves Figure S2. Comparison of DSC curves during the second (a) heating and (b) cooling cycles for PP, x-PP-1, x-PP-2, and x-PP-3 thin film dielectrics. D-E Hysteresis Loops A DC electric field was applied across each PP film with an initial amplitude of 100 MV/m, which was then increased 100 MV/m intervals until reaching 500 MV/m. Figure S3. D-E hysteresis loops for (a) PP, (b) x-PP-1, (c) x-PP-2, and (d) x-PP-3 dielectrics. Reference (1) Langston J.A.; Colby R.H.; Chung T.C.; Shimizu F.; Suzuki T.; Aoki M. Macromolecules 2007, 40, 2712. (2) Lin W.T..; Shao Z..; Dong J.Y.; Chung T.C. Macromolecules 2009, 42, 3750. (3) Spaleck W.; Kuber F.; Winter A.; Rohrman J.; Bachmann B.; Antberg M.; Dolle V.; Paulus E.F. Organometallics 1994, 13, 954. (4) Brandrup, J.; Immergut, E.H. Polymer Handbook; 3rd Ed.; Wiley-Interscience Publication: New York, 1989.