Solar Thermal Roofing For Year Round And

advertisement

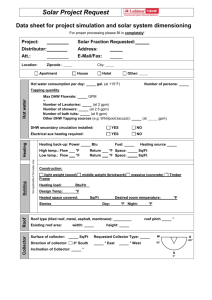

SOLAR THERMAL ROOFING FOR YEAR ROUND AND SEASONAL HEATING AT THE PENTAGON John P. Archibald American Solar, Inc. 8703 Chippendale Court Annandale, VA 22003-3807 ABSTRACT The Pentagon Reservation contains several buildings that support the operation of the main building and other agencies in the Washington, DC area. One of the buildings operates a loading dock for the receipt of materials. A nearby building supports an emergency generator to provide backup power in the event of a power outage. The paper will discuss the design and construction of two solar thermal tile retrofits at the Pentagon in Arlington, VA. The discussion covers air handling systems, thermal storage installation, hybrid heat recovery and the design and construction of the solar thermal tile retrofit for heating an emergency generator 1. HEATING NEEDS DOMINATE BUILDING AND INDUSTRIAL ENERGY USE Approximately 60% of all residential, commercial, and industrial energy use in the US is for heating buildings and industrial processes. See Fig. 1. This onsite use of energy is most often provided by conventional heating technology such as burning natural gas, fuel oil, or propane, or by electric resistance or heat pump heating equipment. The largest single energy use is for space heating, followed by water heating, then process heating. 1.1 Space Heating Building space heating for occupant comfort is essentially an air heating load, where the goal is to provide warm air next to the inhabitants. Solar air heating systems hold promise to satisfy the demand without conversion losses often associated with more conventional heating sources. Often these conversion losses involve the use of different heating media, such as water heating in boilers, as an intermediate process in hydronic based radiator or radiant floor heating systems. Where water based systems are used for space heating, the most visible conversion of energy is at the boiler or water heater. At this equipment, the fuel is often visibly burned and in many cases gas or electric meters may measure “energy” consumption. However, “energy consumption” measured at the burner is often twice the amount of energy required simply to heat air in the occupied spaces. Exhaust losses up the stack, line losses from the heated water pipes running through unconditioned spaces, duct losses from air escaping in the middle of the run, excessive heating of building envelopes from radiators or radiant floors, excessive stratification of heat between ceiling and floor in occupied spaces, and boiler or heater radiation losses at low firing rates can reduce heating system efficiency within the building to less than 50% when measuring the actual energy consumed. If electric heating energy is considered, a low 30%-40% power plant conversion efficiency must also be taken into account. If electric resistance heat is used, the true energy delivery for space heating may be on the order of 20% to 25% of the energy burned at the power plant. Space heating by heat pumps extracts heat from “sun warmed local air” to double or triple the productivity achieved by electric resistance heat. Even so, heat pumps only achieve about a 60% conversion efficiency compared to the energy consumed at the power plant. Poor off peak performance drops overall heat pump efficiency down to below 50% in many moderately cold climates. In comparison, solar heating technologies, both air and water heating, deliver between 10 and 30 times as much heat energy as they consume to run fans or pumps. If air heating is required, solar air heating technologies are often the most productive and least expensive energy conversion technologies compared to the energy consumed in the process. 1.2 Water heating If water heating is all that is required, usually solar water heating technologies are the most productive energy conversion method. Usually, the conversion from solar heated water-to-air or air-towater adds cost and reduces productivity. Conversion, via thermal storage, to coordinate supply with demand throughout the day, will also reduce efficiency and increase cost. Despite the technical capability of a particular solar technology at meeting an apparent demand, such as solar water heating for hydronic space heating, often a simpler solution, direct air heating, is a more productive and less costly approach. However, when solar air heating is installed for winter space heating, a small additional expense can fund the installation of solar air to water heating components for year round water heating. 1.3 Industrial Heating For industrial energy use, process heating and facility space heating consume nearly twice as much energy as all other industrial uses combined. The loads include an enormous variety of processes from; drying of lumber, textiles, and paper, to dehydrating air for pharmaceutical and candy production, to boiling water for canning foods and sterilizing production facilities. In many industrial applications, intermediate heating media are used to achieve a desired heating effect, e.g., water is boiled to steam to heat air to dry products. 1.4 Diesel Generator Standby Heating One particular industrial heating application is the standby heating of emergency diesel generators. Diesel engines rely on the compression of air in the cylinders to reach the ignition temperature of the injected diesel fuel. In warm climates, the engines and the outside air will always be warm enough to allow the compression to achieve fuel ignition. However, in most US climate zones, cold outside air exists for enough hours of the year that ignition can not be guaranteed. In the colder climates, both the engine and the combustion air may need to be heated to guarantee year round cold starts. While air in the cylinders is what needs to be heated, a convenient approach to providing this heated air is to use an intermediate fluid, the cooling water that “jackets” the cylinders of the engine (jacket water). The most common approach is to install electric heaters in the jacket water circuit. These heaters are typically electric resistance type cartridge heaters. For large engines, (>1,500 KW) the fluid may be pumped through the engine. For small and mid sized engines, the heater is usually set up in a convection loop beside the engine. Heating of the jacket water in the cartridge heater causes it to rise up in the cylindrical cartridge and flow out through a pipe connected near the top of the engine. Within the engine, this warm water flows through the cylinder jackets to a pipe connected near the bottom of the engine, and then back to the bottom of the cartridge heater. Typically these heaters are set to maintain 130 degree F water temperature leaving the heater. Water returning from the engine is typically about 120 F. Even with the system properly installed, the engine is not evenly heated. Typically, the engine “block” will show increasing temperatures from bottom to top, with the bottom of the engine at ambient temperatures as low as O F in cold climates and the top of the engine at 80 to 90 F. Similarly, the engine temperature decreases rapidly with increasing horizontal separation from the heater supply and return lines. In general, the heaters seem to be sized at about 1 KW of heater capacity for each 100 KW of engine capacity. The heaters may only operate at their rated capacity during the coldest winter conditions. However, the electricity use during warm summer conditions can still be quite high, at several KW during 70 degree weather. Annual energy consumption for mid sized generators will be about 17,000 kilowatt hours per year in moderate climates. In some generator enclosures, additional heaters are also installed for fuel tanks and fuel lines, for space heating and battery heating. Where such heaters are installed in outdoor enclosures, annual heating loads can exceed 25,000 kWhr/yr. The heating elements may cost only a few hundred dollars to install, but cost thousands of dollars per year to run. While jacket water heating is almost universal, air heating can actually be less expensive and more productive. Air heating provides: both a heated engine and heated combustion air, more even heating of the engine, greater thermal storage in the mass of the engine and generator and enclosure to better respond to temperature changes, heating of the fuel and battery systems, and heating of the operating fluids such as oil in the sump which improves lubrication during startup. 2. SOLAR SPACE HEATING OF A LOADING DOCK One of the buildings at the Pentagon operates a loading dock for the receipt of materials, primarily during early morning through the afternoon. Trucks back to the two overhead roller doors to discharge materials. To the sides of the roller doors are air intake louvers which permit air flow through the loading dock as a supply air source to the industrial process within the building. Even with the loading dock doors closed, outside air can flow through the loading dock via the louvers. Despite the use of loading dock door seals, winter time operations are at close to outdoor ambient temperatures. Operators also complain that the exhaust from the overhead gas unit heaters is very localized at the center of each roller door, and is too hot when working off the back of a truck bed. The Pentagon Energy Office has contracted for the installation of solar thermal tile air heating system on the roof of the building (See Figs. 1 and 2). The solar heated air from this system will be delivered to the perimeters of the loading dock doors. Excess heated air at the top of the loading dock will be returned to the solar roof for re-heating and re-delivery to the dock doors. within the building. Hot air from the solar tile system heats the water in a coil in the air handler. The hot water is circulated to the storage tank during sunny weather. Hot water is drawn from the tank to the coil in the air handler when solar hot air heating is not available in the early morning or on cloudy days. A separate water to water heat exchanger has been designed into the system to circulate hot water to the tank from the industrial process. This hybrid system will increase the availability of stored heat in the tank even when solar heating is limited. Fig. 1 Solar Thermal Tile System To provide solar heat during the early morning hours, the solar air heating system incorporates water thermal storage. The water tank is heated via a hybrid system using solar heated air from the Fig. 3 Air handler The solar thermal roof is installed on a section of south facing roof adjacent to the loading dock. The roof consist of 100 square feet of Classic Slate solar tiles installed over corrugated metal absorbers. Air moving under the tiles is drawn into the building from a plenum at the east end of the roof section. Return air from the building is ducted along the top of the roof to a plenum at the west end. Supply and return air ducts penetrate the exterior wall of the loading dock above the roller doors. An air handler, inside the loading dock, incorporates 3 fans, water heating coils and backdraft dampers to control the air flow. Fig. 2 Solar thermal tile system installed solar tile system and waste heat from the industrial process The air handler for the system includes three equally sized inline fans and 4 backdraft dampers. The fans are rated at 100 CFM at 1” static pressure. They are designed to move 1 to 2 CFM per square foot of solar tile roof. Each fan consumes only about 80 watts of power. In comparison, the system delivers about 2,900 watts (10,000 BTU/hr) of peak heating thermal energy. The supply fan draws air from the solar roof, and Fig. 4 Solar heating emergency generators exhausts across the water heating coils. The return fan sends the coil exhaust air back to the solar tile system for re-heating. Water is constantly pumped through the coils to store solar heat in two 265 gallon water tanks. In the early morning, the tanks deliver heat to the coils. By mid-morning, the solar roof supply fan is delivering heat to the coils for storage in the tanks. The door fan draws air from the return plenum, downstream of the water coils, to feed the warm air ducts around the loading dock doors. When the supply and return fans are not running, the door fan draws air from the room, across the hot water coils. If the door fan calls for heat while the solar supply and return fan are running, the door fan will draw air from both the solar supply fan and the room, across the hot water coils. The use of spring loaded backdraft dampers balances pressures across the fans and coils ensures air flow from the intended source with minimal controls. The system has been designed with a larger tank capacity than required for thermal storage from the solar roof. The design has incorporated the larger capacity to accommodate a second available source of heat from an industrial process within the building. Issues of funding for the second heating source have delayed the installation of the heat recovery system. In the meantime, the system is operated at reduced volume to ensure adequate temperatures are maintained in the thermal storage tanks. The water heating system is designed to take water from the colder tank bottom and feed it to the pump and the coils for solar heating of the water. However, when the loading dock door fan is started, to deliver heat to the loading dock, the water flow to the coils needs to be reversed to deliver warm water from the top of the “hot” tank. This is accomplished by two solenoid actuated valves and a piping loop to the top of the hot tank. The two solenoid actuated valves are wired in series with the loading dock door fan. Whenever the door fan is activated, the source of water from the tanks is reversed and hot water flows to the coils. 3. SOLAR HEATING OF AN EMERGENCY GENERATOR Reliable electrical power is essential to ensure safe operation of the industrial equipment inside the building. As a result, an emergency generator is installed in an outdoor enclosure adjacent to a small storage building. The shed roof of the storage building faces south at a slope of 4 in 12. The generator is located about 4 feet from the north side of the building. The Pentagon Energy Office contracted for the installation of an emergency generator solar heating system. The system incorporates 100 square feet of Classic Slate Solar Tiles installed on 6 foot wide by 17 foot tall section of the shed roof. The solar tile system is the weather tight roof of the building. Supply and return ducts from the roof are enclosed in a vertical trunk on the north side of the building down to a fan enclosure near the generator. Solar heated air is drawn from the solar roof down to the fan enclosure on the north side of the building. The fan enclosure consists of two fans rated at 150 cfm at .75 inch water static pressure for the supply and 79 cfm at .5 inch water for the return. Total combined wattage is about 200 watts. The solar heated air is blown about 3 feet across to the generator enclosure, in a trunk above ground. The solar heated air is discharged directly under the diesel engine. Warm air from the upper part of the generator enclosure is drawn back to the roof by a return fan. The return fan takes this air to the bottom of the roof and discharges it into a plenum on the lower half of the west side. From the plenum, air moves across the bottom half of the collector to a plenum on the east side, then up through the plenum to the top half of the roof. The air then moves across the top half of the roof before being drawn into the supply duct and fan. This serpentine approach was required to ensure that the air move across more than 10 feet of collector surface to achieve a proper temperature rise. 4. STRUCTURAL INTEGRATION WITH THE BUILDINGS Both solar roofs are attached to the main structural walls of the building and rest on top of the existing standing seam metal roofs. In the case of the storage building, the structural members that tie the roof to the walls, actually penetrate the existing roof to attach to the walls. The weather tight solar tile roof completely covers the old existing roof from ridge to eaves so the structural openings are of no consequence to the weather integrity of the building. Both of the solar roofs installed at the Pentagon, use the side of the roof as supply and return plenums. The generator roof has over 34 feet of side (17’ east and 17’ west). The industrial building has only 10 feet of side (5’ east and 5’ west by 20’ long) One disadvantage of the supply and return plenums at the side is that the side edge leakage can have a greater impact on delivered temperature than with supply suction at the center of the tile field. However, very simple sealing of the tiles at the roof edge greatly reduces the leakage. Sealing is accomplished by caulking with a small volume of high temperature sealant in the triangular openings below the tiles and above the drip edge. Shortly after completion of the exterior portions of the solar tile systems, the Washington DC area experienced the 5 th largest snowstorm ever recorded. Approximately 18” of snow fell over a 2 day storm. Snow accumulated on both roofs. Within 36 hours, the snow slid off of the storage building solar roof. The system operated on automatic control again on the first partly sunny day following the storm. On the industrial building, the snow also accumulated on the 50 foot slope of the standing seam metal roof above the solar tile system. Over the next several days snow banked up above the solar tile roof and very gradually slid up and over the solar tile roof section. Melting snow continued to flow under the solar tile system on the existing metal roof. After a week, there was no damage to any of the structure, tiles, or trim. Final connection of the mechanical systems in the building were still in progress when all snow had melted. 6. MONITORING PERFORMANCE The Emergency Generator system was monitored from 1/27/03 to 2/18/03. A current meter was placed on the 115Volt AC line at the circuit breaker feeding the combined electric cartridge heater and the battery charger. A temperature data logger was installed to monitor the return water temperature to the cartridge heater and the outside temperature. A current meter was also installed to monitor the operating hours of the supply and return fans. In the case of the industrial building, the solar tile roof floats over the existing standing seam roof, with no penetration of the weather tight envelope. In this case, rainwater and snow melt flow under the solar tile roof. During this period, the weather in Washington remained unseasonably cold and outdoor temperature varied between 50F and 25F. The power draw on the heater cycled between full on and full off. Peak current was 13.8 amps. Average hourly current for the heater varied between 8.5 amps and 12.5 amps. Only during the weekly 30 minute generator tests did the current draw drop below this range as the engine achieved normal operating temperatures. The electric current rises and falls in opposition to the changes in the ambient temperature. 5. INITIAL OPERATIONS Previous solar roofs have taken supply air from the center of the tile field and introduced outside air at the sides to the tile field. The return water temperature to the electric cartridge heater remained between 92 and 80 degrees F with occasional excursions up to 109 F during the engine tests. The return water Temp top of radiator 120 100 80 60 40 20 Temp return to heater Heater current Ambient Temp 16 14 12 10 8 6 4 2 0 257 209 193 177 161 145 129 113 97 81 65 49 33 17 1 241 Daylight 0 225 Temp Deg F & Lumens/sq ft 140 Current (amps @ 115VAC) Pentagon EDG monitoring hours start 1/27/03 14:00 Fig. 5 Monitored emergency generator temperature varied as the ambient temperature varied. In contrast, the temperature of the water hose at the top of the radiator varied in opposition to the ambient temperature changes. This occurred because the colder ambient temperature increased heater average power, which increased the temperature of the water at the top of the jacket water circuit, which is the top of the radiator. In February, the solar tile system for the emergency generator begins automatic operation of the fans, on a clear sunny day at about 10 AM. It continues to run until about 6PM, providing 8 hours of collection with a differential thermostat setting of 16 degrees between the roof temperature and the sensor strapped on the top of the radiator hose. Mid day temperatures of the air discharged from the duct below the diesel engine were about 40 degrees F above the ambient temperature at the generator. These temperatures were achieved before any edge sealing of the solar tiles and with no insulation of the fans or supply and return ducts in the fan enclosures. Both are planned after testing of the roof discharge temperatures during warmer weather. 7. CONCLUSIONS Diesel electric heater energy use is proven to vary with outside ambient temperature. Solar air heating of the enclosures can raise the temperature within the enclosure and directly adjacent to the diesel engine. The solar thermal tile air heating systems are currently delivering solar heated air to emergency generators. The solar thermal tile system has been demonstrated to provide a weather tight “solar roof” over a storage building and provide solar heated air to an adjacent emergency generator. Solar thermal roofing technology has been designed and installed to provide space heating for a loading dock. Thermal storage via air to water heat exchange and water storage have been installed. A hybrid thermal storage system using heat recovery from industrial process has been designed into the installed system. 8. REFERENCES 1. American Solar analysis of US Department of Energy, Energy Information Administration data from Residential Energy Consumption Survey, Commercial Building Energy Consumption Survey and Manufacturing Consumption of Energy. 2. Archibald, J.P., 1999, Building Integrated Solar Thermal Roofing, Solar 99 Conference Proceedings of the ASES Annual Conference 3. Archibald, J.P., 2001, Design And Construction Of Solar Thermal Tile Systems For Stand-By Heating Of Emergency Diesel Generators, Forum 2001Proceedings of the ASES Annual Conference ACKNOWLEDGMENT The author would like to acknowledge the support of the Pentagon Energy Office and Defense Protective Service during the construction and initial operation of these solar thermal tile systems.